Author: Jake Huolihan

The German term lager is both a verb and a noun, referring not only to the process of storing beer in a cool environment over time for conditioning, but the beer produced using this very process. Lagering is believed to have originated in Bavaria in the early nineteenth century when brewers began storing beer in cool caves during the warm summer months, a practice that, in combination with the use of bottom-fermenting yeasts, led to crystal clear, crisp, and deliciously clean beer.

Despite advancements in brewing knowledge and technology, many modern brewers espouse the benefits of employing a traditional lager step, believing it necessary to produce the delicate flavors and high drinkability characteristic of styles like Helles, Pilsner, and Märzen. From this perspective, lagers are a labor of love requiring a good degree of patience with the payoff being a wonderful drinking experience.

Alternatively, some brewers of today fall in to the “freshness is best” camp when it comes to lagers, contending that long lagering periods serve only to age the beer and remove certain desirable characteristics. As a lover of lager who also happens to be rather impatient, I’ve tended toward the less time consuming approach in my own brewing. Curious to learn what I might be missing, I decided to put it to the test!

| PURPOSE |

To evaluate the differences between a Festbier that underwent an extended lagering period and one that did not.

| METHODS |

I went with a modified version of Bill Eye’s Märzen recipe for this xBmt, subbing out Caramunich for Pilsner malt in order to bring it more stylistically inline with a Festbier.

Üold

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 22.4 IBUs | 6.9 SRM | 1.055 | 1.014 | 5.4 % |

| Actuals | 1.055 | 1.018 | 4.9 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Weyermann Vienna | 7.5 lbs | 61.22 |

| Munich II (Weyermann) | 3.75 lbs | 30.61 |

| Odyssey Pilsner | 1 lbs | 8.16 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Hallertau Magnum | 8 g | 60 min | Boil | Pellet | 11.5 |

| Perle | 15 g | 30 min | Boil | Pellet | 8 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Harvest (L17) | Imperial Yeast | 72% | 50°F - 60°F |

Notes

| Water Profile: Ca 49 | Mg 0 | Na 8 | SO4 38 | Cl 61 |

Download

| Download this recipe's BeerXML file |

In order to appropriately test the impact of extended lagering time, I had to make two batches of the same recipe at different times, the non-lagered batch being brewed 11 weeks after the lagered batch. While we typical make a strong effort to keep things as controlled as possible, this gap in brewing time required me to make some concessions. To ensure the beers were as identical as possible, I collected the grain and hops at the same time then stored half as ideally as possible, the grains unmilled in an airtight container while the hops were vacuum sealed and kept in a freezer.

The yeast used for each batch was the same approximate age at time of pitch, which some might argue created a vector of difference due to different initial propagation dates; however, given Imperial Yeast’s excellent quality assurance, this was determined to be less risky than pitching lower viability yeast from the same lot into the beer brewed later.

The brew days for each batch were as identical as I could make them and began with the collection of RO water that I adjusted to my desired profile before turning on the electric element.

While the water was heating up, I milled the previously collected grain.

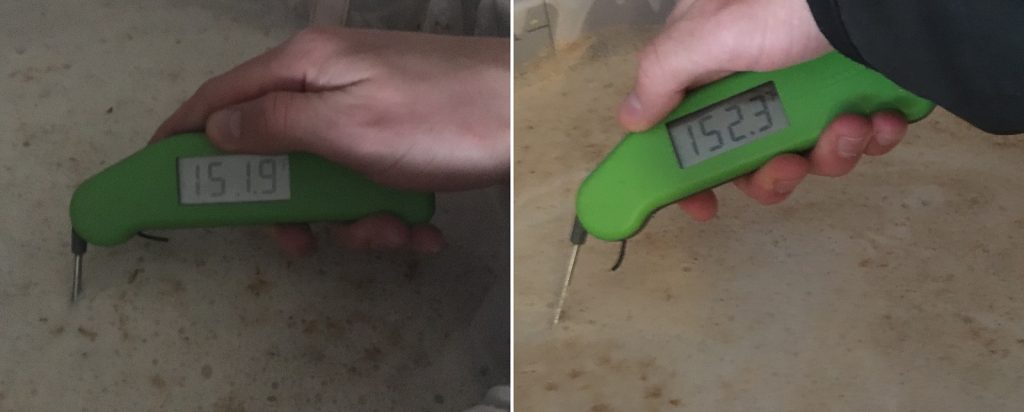

Once the water was adequately heated, I added the grains and stirred to incorporate before checking the mash temperature.

Each mash was left to rest for 60 minutes, during which I stirred every 15 minutes.

I collected the kettle hop addition during the mash rest.

When the mash was complete, I collected the sweet wort in my kettle and brought it to a boil.

Both worts were boiled for 60 minutes, after which they were quickly chilled to slightly warmer than my groundwater temperature.

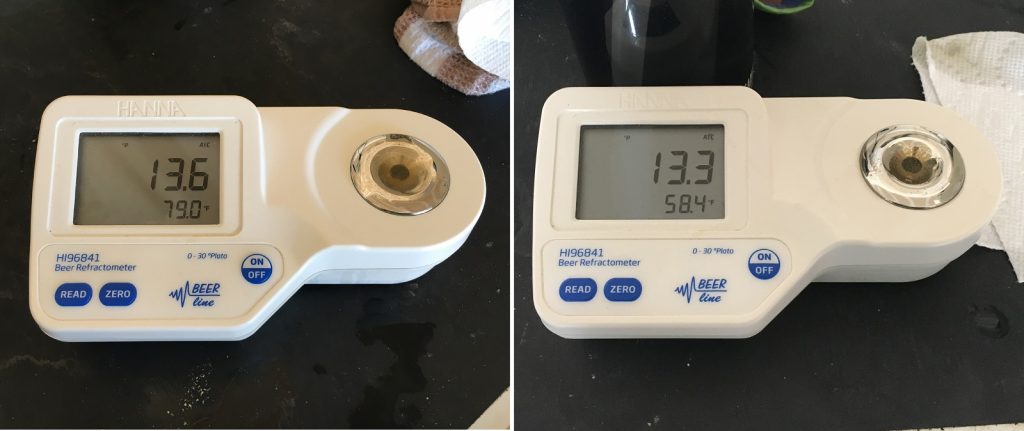

Refractometer readings revealed both worts achieved a similar OG despite being brewed 11 weeks apart.

The worts were transferred to identical Brew Buckets and hooked up to my glycol chiller and left to finish cooling to my desired fermentation temperature of 50°F/10°C. I made vitality starters using about 500 mL of remnant wort from each batch, into which I pitched 2 pouches of Imperial Yeast L17 Harvest.

I noticed diminished signs of fermentation activity in both beers 10 days after pitching and gently raised the temperature to 58°F/14°C for a diacetyl rest. Hydrometer measurements taken from each batch at 13 days post-pitch showed they ended up at the same FG.

Both batches were then chilled back down to 50°F/10°C where they sat for a day before being chilled further to 45°F/7°C. After 2 more days, the beers were racked to sanitized and CO2 purged kegs.

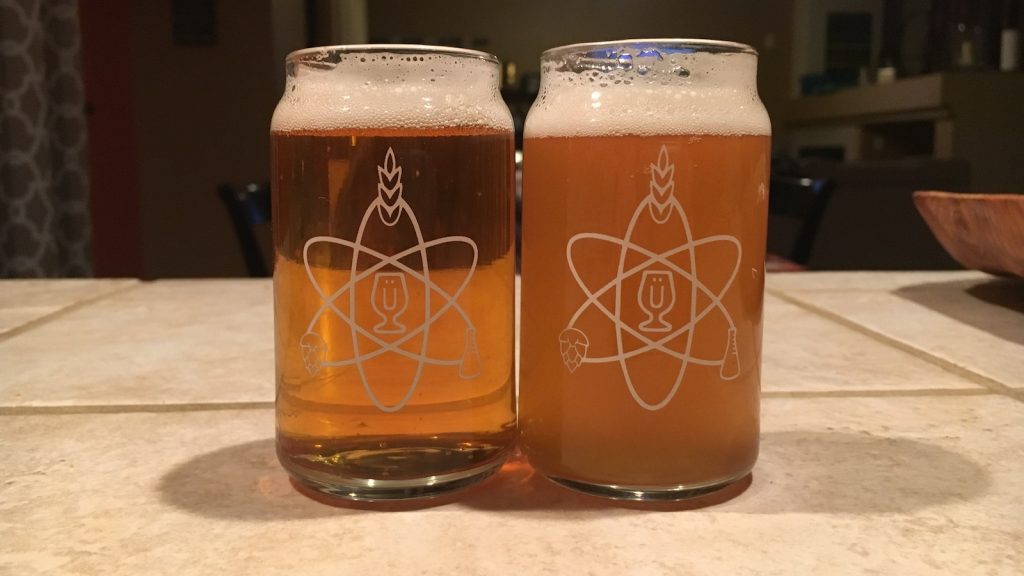

While both kegs were placed in my 38°F/3°C keezer, the lagered batch sat in the cool environment for 8 weeks before the non-lagered version was placed next to it. I let the beers condition for 3 more weeks before collecting data. Intentionally skipping the gelatin fining step, the difference in clarity was rather stark.

| RESULTS |

A total of 22 people of varying levels of experience participated in this xBmt. Each participant was served 1 sample of the lagered beer and 2 samples of the non-lagered beer in different colored opaque cups then asked to identify the unique sample. While 12 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, only 8 (p=0.46) did, indicating participants in this xBmt were unable to reliably distinguish a beer that was lagered 11 weeks longer than the same beer that was held cold for only 3 weeks prior to serving.

While we don’t usually share preference data on xBmts that fail to achieve significance, I thought some might be interested to know that of the 8 participants who were correct on the triangle test, the lagered and non-lagered batches both won the preference of 3 people, while the other 2 claimed no preference.

My Impressions: Out of the 5 semi-blind triangle tests I attempted, I only guessed the odd-beer-out 3 times. To be honest, knowing what I knew about the variable and given the difference in appearance, I was surprised with how difficult it was to distinguish these beers. The only difference I thought I noticed was in the aroma, the lager batch just seemed less aromatic, but they tasted identical. And this was not a bad thing, as this Festbier may have been one of the best lagers I’ve made to date and ended up taking 3rd place in a local Märzen/Festbier competition host by The Brew Hut.

Marshall and his family happened to be in Denver during the time I was collecting data for this xBmt, so I brought some of these beers along for him to try. Similar to my experience, he was unable to identify the unique sample with confidence out of various triangle test attempts.

| DISCUSSION |

Lagering is an age-old practice that was presumably born out of necessity and has come to be viewed by many as essential to producing clean, crisp lager beer. Despite caves no longer being the cooling mechanism of choice for modern brewers, the idea that extended cold storage somehow serves to refine beer character has held strong, which makes the fact tasters in this xBmt were unable to reliably tell apart a lagered Festbier from one that wasn’t lagered so interesting.

The one obvious difference between the beers in this xBmt was the appearance, the lagered version predictably finishing much clearer than the one that wasn’t lagered. What’s striking about this is that the particulate suspended in the non-lagered batch didn’t create a perceptible difference, which aligns with findings from past xBmts. As a follow-up to this xBmt, I’d be interested to repeat it using gelatin to fine the non-lagered beer.

When considering explanations for these results, a couple main things come to mind. It’s well known that cool temperatures delay certain chemical reactions known to negatively impact beer, while reducing exposure to oxygen exposure can prolong shelf-life. Both of the beers in this xBmt were not only treated in a manner to limit cold-side oxidation, but kept cool after packaging, which may have slowed the aging process. Of course, that does little to explain the lack of “green/young” flavor in the non-lagered beer.

As impatient as I am, I was fully prepared to accept that the lagered beer was decidedly better than the non-lagered beer and commit to changing my hasty ways. However, based on both my experience as well as the blind data, I feel more confident skipping the extended cold aging step and turning my lager beers around sooner. Confident, but not entirely convinced. I definitely look forward to exploring this variable more in the future.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

21 thoughts on “exBEERiment | Impact Lagering Has On A Festbier”

I just give my lagers time to clear and then serve, depending on inventory. I get the exact same results as was written here. Longer the beer, clearer the beer. Tastes the same to me.

So just to clarify (even though it didn’t make a difference) did you brew them 11 weeks apart or 8? In the first part of the article it says you brewed 11 weeks apart but later it says you lagered for 8 weeks though all other parts of the process seem the same (keeping both cold conditioning for 3 weeks).

is this a pretty authentic Festbier recipe? i’ve never had one. this one looks delish. it looks a lot maltier than i imagined them.

I guess you can interpret this in two ways. One is that lagering doesn’t need to be done as it only serves to clear up the beer. The other is that lager doesn’t need to be served fresh as ageing doesn’t noticeably affect flavour.

I think things are different for brewers who rely on natural carbonation – it definitely takes longer for the beer to taste right. But good to know that this step can be skipped if you force carbonate and fine.

“I guess you can interpret this in two ways. One is that lagering doesn’t need to be done as it only serves to clear up the beer. The other is that lager doesn’t need to be served fresh as ageing doesn’t noticeably affect flavour.”

I would say that “ageing at COLD TEMPS doesn’t noticeably affect flavour.” Both beers were the same age.

This is wrong, the beers were 11 weeks apart in age, not the same age

Eh. Nevermind. I with draw this comment 😛

I primarily brew lagers. I have found that pitch rate, mash temp, and fermentation temp affects the taste more than the time length of lagering. I have won awards with beers that have lagered in as little as 2-3 weeks. I am not surprised at the results here, I have found that the beers loose some of the malty notes that are prominent in the first couple weeks. This is one of my favorite styles, love the smell of the mash.

Have you tried fermenting lagers warm? Like in the 65-68 degree range?

Nice experiment, although I think you might notice a bigger difference if you did a longer lagering – I believe six months or more is common or at least traditional for this style. I haven’t done the experiment myself so for all I know, the results might be the same, but it’d be interesting to see.

I’m guessing you did not use your Clear Beer floating dip tubes on the non lager batch?

Stop messing around, boys. Don’t just repeat this one with gelatin, go full short & shoddy with gelatin (& without the 3 week rest post packaging – who’s got time for that?!) vs traditional methods (including lagering).

Would also be interesting to see the differences on a recipe that had a bit of late hopping.

Keep up the good work!

Awesome exbeeriment! These results excite me! Really glad you skipped gelatin fining – really cool to see the clarity difference.

I wouldn’t say this is testing the impact of lagering or not, though. Instead, it’s really testing the impact of length of lagering period (3 weeks vs 11 weeks). Plenty of commercial and homebrewers lager for only 3-4 weeks, then package/serve.

Thanks for the experiment. My main reason for writing is to suggest a column for °LOV.

Simply because as more craft maltsters enter the game their branded names carry less significance, i.e. pelton or even weyermann II, which I assume is around 7° (but am too lazy to actually check). It’s only fair since you include AA%. Certainly not a necessity if it is all based on some prescribed format, just saying…

Now more about me because that generally is the theme to the comment section, ahem, I don’t properly lager my beers because I don’t have a dedicated ferm chamber. I cold condition all my beers for 4-7 days using a cooler, ice, and refreezable cold packs. The only difference is I burst carb ales and let lagers condition in keg for 10 days to 2 weeks at serving pressure. That seems to be adequate time to clarify. I’m happy to know I may not be missing much in the way of off flavor remediation. At least that is all I care to take away from this. Cheers.

Also, nice vanity shot of the Trek.

Time to step the cycling game up bruh…

I will only ever own vintage bikes. That’s my commuter, it’s been going strong since 1989 and rides better than any non high end bike I’ve ridden.

Also downtube shifters ftw

Interesting results. Diminished malt flavors were mentioned in the comments. I’ve started to add DME at 2/3 bottling strength to my lagers when I keg them. Seems to help.

1988 Raleigh Technium MB. Best bike I ever had for cobblestone streets. Gave it away in 2012. I miss that bike.

Both beers were aged/conditioned for the same time, although they weren’t lagered for the same time. I wonder if you skipped the lager step and used gelatin, if that would impact the taste, since the particulates simply wouldn’t have been in suspension as long.

I withdraw my comment. That’s what I get for skipping to the bottom. Amazing results and experiments! I’m really grateful for what you do here, as a budding brewer. I REALLY want to make a Helles but was turned off by the supposed two month turnaround time. Now I know I don’t have to wait that long!! 👏🏼😁🙌🏼

Given the substantial energy consumption required to keep the keep at those low temperatures for 11 weeks, I find this xbmt very helpful and informative. Much better than trying to skim half an hour off your brewday and such.

There have so many things as I have learned more about brewing where people say you should do something a certain way to brew a good beer, usually involving an incredible amount of time and more effort. When in reality nobody can even tell the difference between doing it the long and time consuming way and the quick way.

Curious do you have a recipe for the other Marzen in the Beer Hut competition, specifically the winner? 🙂