Author: Malcolm Frazer

The latest trend in hopped up beer is a style called Brut IPA, which as its names suggests, is brewed to be as dry as possible and carbonated to the point of sparkling. Given the attenuation limits of most ale yeasts, brewers of this novel style have come to rely on unique methods to increase fermentability, one of which involves using enzymes.

A fairly popular option for brewers of Brut IPA is Amylo 300, an amyloglucosidase enzyme that, according to BSG, “can hydrolyse sequentially both exo alpha 1,4 and alpha 1,6 glycosidic linkages and can therefore be used to degrade starch polymers and maltose to glucose, for the production of high alcohol and low carbohydrate beers.” In essence, use of this product will make a normal wort highly fermentable, upping the attenuation to levels that couldn’t be accomplished without they enzyme.

When it comes to using such enzyme, there’s some debate as to whether it should added during the mash to assist the natural enzymes in the conversion process, or to the beer during fermentation. As a lover of both dry and hoppy, I’ve been itching to try my hand and brewing a Brut IPA and figured I’d test it out for myself!

| PURPOSE |

To evaluate the differences between a Brut IPA produced with Amylo 300 enzyme adding during the mash and the same beer with enzyme added to the beer at yeast pitch.

| METHODS |

The recipe for this Brut IPA was designed to be dry and supremely hop forward.

BRÜt IPA

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 6 gal | 60 min | 74.9 IBUs | 3.9 SRM | 1.053 | 1.008 | 5.9 % |

| Actuals | 1.053 | 1.007 | 6.0 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pilsner (2 Row) Ger | 12 lbs | 92.31 |

| Vienna Malt | 1 lbs | 7.69 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Galaxy | 28 g | 60 min | First Wort | Pellet | 14 |

| Galaxy | 56 g | 30 min | Aroma | Pellet | 14 |

| Nelson Sauvin | 28 g | 5 days | Dry Hop | Pellet | 12 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| San Diego Super Yeast (WLP090) | White Labs | 80% | 65°F - 68°F |

Notes

| Water Profile: Ca 204 | Mg 18 | Na 33 | SO4 351 | Cl 175 |

Download

| Download this recipe's BeerXML file |

Having recently relocated to Atlanta from Pittsburgh and yet to unpack my brewing gear, I was fortunate to be invited by Schoolhouse Beer And Brewing to use their Grainfather systems for this xBmt. After collecting the brewing liquor, we began heating it up.

Each volume of brewing water received the same amount of minerals to achieve my desired profile.

We then proceeded to weigh out and mill two identical sets of grain.

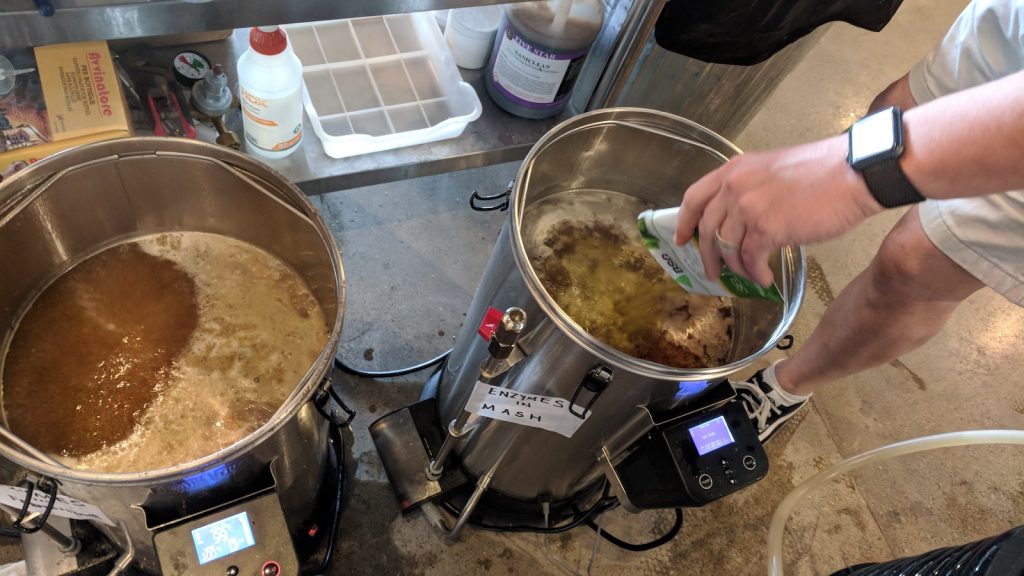

Each batch was doughed in at 122˚F/50˚C then ramped to 148˚F/64˚C for a 40 minute rest. It was at dough in that we added a dose of Amylo 300 to one batch.

The mashes were left to rest for 60 minutes.

At the end of each mash rest, we sparged.

While waiting for the wort to boil, we gathered all of the hops needed for these beers.

The worts were boiled for 60 minutes with hops added at the times stated in the recipe.

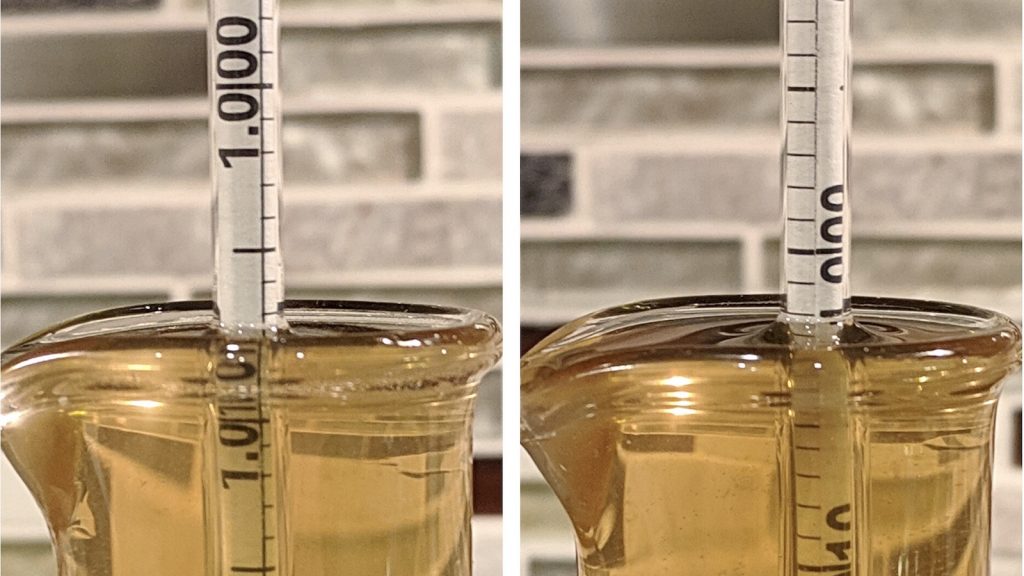

Following the boil, the worts were chilled and equal volumes were transferred to identical glass carboys. Hydrometer measurements at this point revealed no difference in OG between the worts.

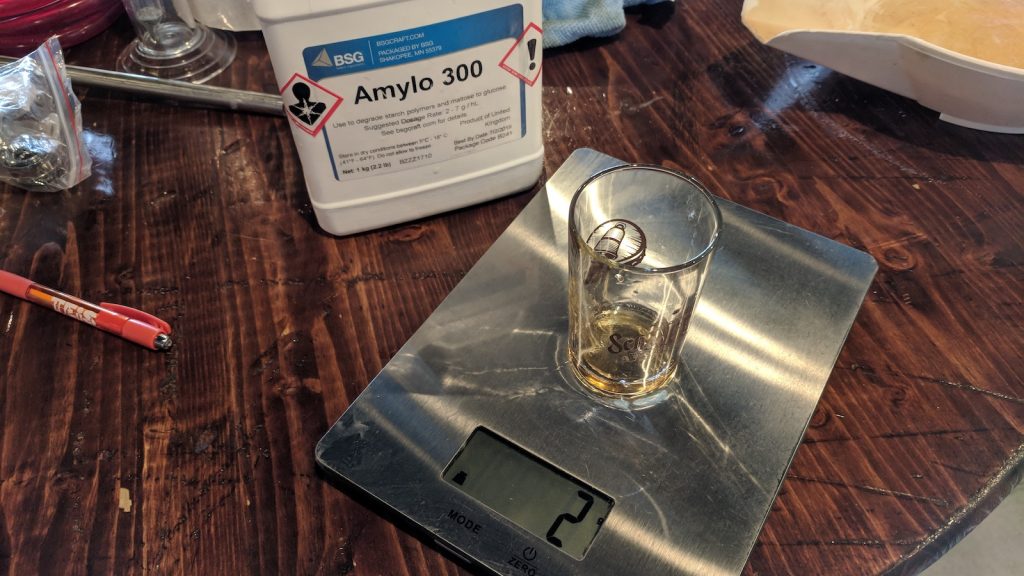

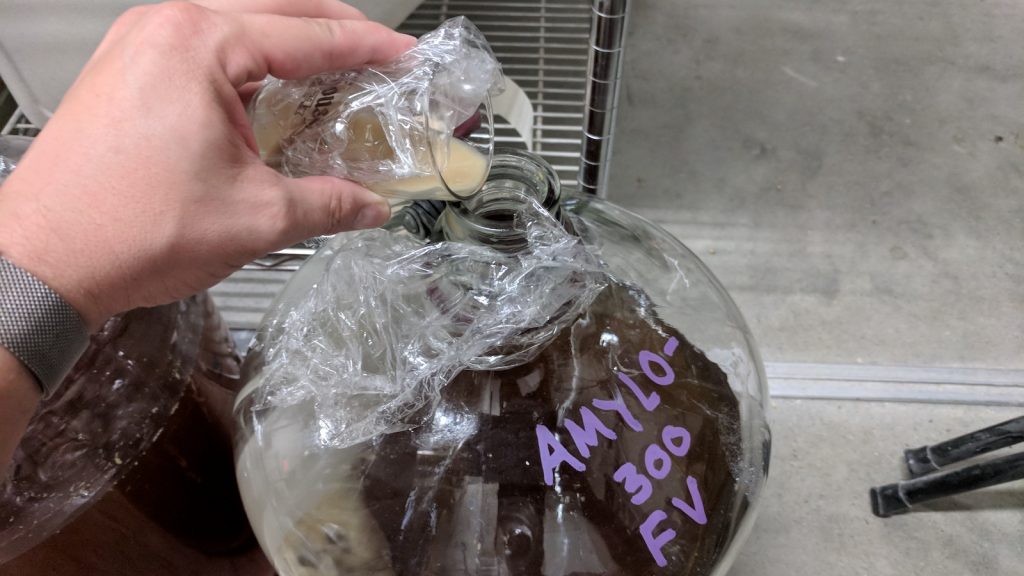

Each wort was pitched with a vial of WLP090 San Diego Super Yeast, after which the same amount of Amylo 300 that was used in the mash of one batch was added to the wort of the other batch.

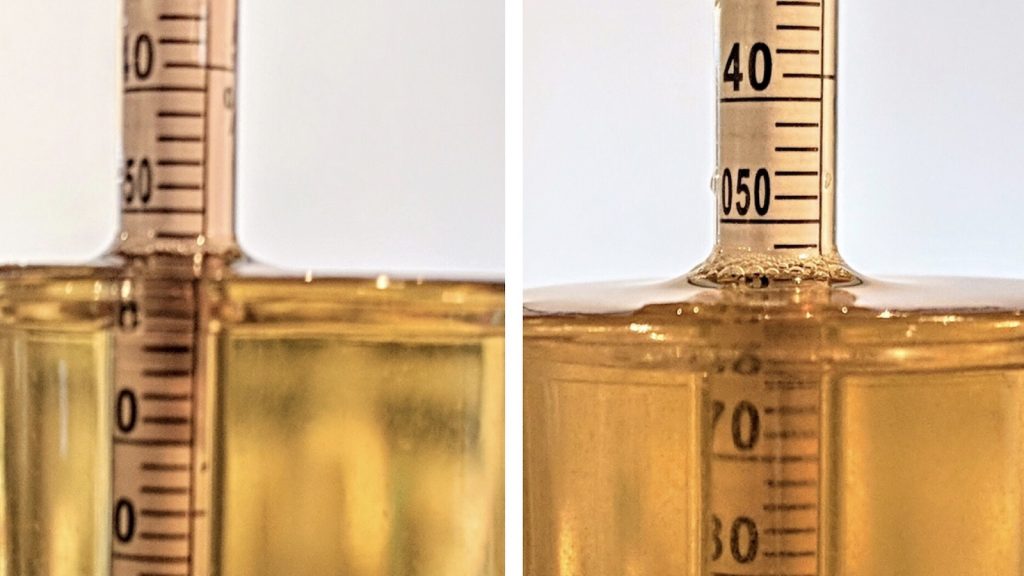

After oxygenating the worts, they were placed next to each other in a fermentation chamber controlled to 66˚F/19˚C. After a week of active fermentation, the temperature was raised to 70˚F/21˚C to encourage complete attenuation. I left the beers alone for another week before adding the dry hop charge, which mingled with the beers for another 3 days. Hydrometer measurements taken at this point showed the beers had indeed attenuated differently, the one that had the enzyme added to the fermentor finishing a bit lower.

The beers were fined with gelatin, cold crashed overnight, then kegged. After a week of cold conditioning on gas, they were ready to serve to participants. Interestingly, the beer that had the enzyme added in the mash was slightly hazier than the beer where the enzyme was added to the fermentor.

| RESULTS |

A total of 24 people of varying levels of experience participated in this xBmt. Each participant was served 2 samples of the beer made with Amylo 300 added to the mash and 1 sample of the beer made with Amylo 300 added to the fermentor in different colored opaque cups then asked to identify the unique sample. While 14 tasters (p<0.05) would have had to identify the unique sample in order to reach statistical significance, 18 (p=0.00004) made the accurate selection, indicating participants in this xBmt could reliably distinguish a Brut IPA made with enzyme added to the mash from one made with enzyme added to the fermentor.

The 18 participants who made the accurate selection on the triangle test were instructed to complete a brief preference survey comparing only the beers that were different. A total of 7 tasters reported preferring the beer where the enzyme was added to the mash, 8 liked the beer made with enzyme added to the fermentor more, 2 people had no preference despite noticing a difference, and 1 person reported perceiving no difference.

My Impressions: Out of the 3 semi-blind triangle tests I attempted, I correctly selected the unique sample every time, with confidence. To me, the beer made with enzyme added to the mash smelled and tasted maltier, almost as if the Vienna malt came through more intensely. I perceived the beer made with enzyme in the fermentor to be less sweet and lacking in the bread crust character I noticed in the other version. My preference was handily for the one with the enzyme added to the fermentor, as I appreciated the dryness I perceived from that batch.

| DISCUSSION |

A key feature of Brut IPA is dryness, which many brewers of this style accomplish by adding enzyme somewhere during the process, the most common points being the mash or the fermentor. Countering contentions that it doesn’t matter when the enzyme is introduced, tasters in this xBmt were able to reliably distinguish a Brut IPA made with Amylo 300 added during the mash from one where the enzyme was added at yeast pitch.

I’ve sampled a number of commerical Brut IPA and they’ve run the gamut from austere to intensely flavored, low in bitterness to abrasively bitter, and crystal clear to slightly hazy. Moreover, I’ve found some to posses a level of sweetness despite the high level of attenuation, providing a pleasurable balance of malt and hops. Based on the results from this xBmt, it seems plausible some of these characteristics could be driven by the point at which enzyme is added during the brewing process, which provides yet another lever of control for brewers making this style.

This being my first go at making a Brut IPA, I’m not ready to dogmatically accept that enzyme should or shouldn’t be added at a specific point in the process. However, the fact the one made with enzyme added at yeast pitch finished 0.005 SG points lower leaves me inclined to rely on this approach, or perhaps even adding enzymes at both points, if my goal is dryness.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

62 thoughts on “exBEERiment | Impact Adding Enzyme To The Mash vs. To The Beer Has On A Brut IPA”

When brewing brut IPA, it is presented as if adding extra amylase enzymes makes the beer OG very low. However, I obtain the same results as you by using a yeast like Mangrove Jack’s M27/M29 saison yeast.

Saison yeasts are usually not very neutral in flavour. Maybe you get the OG down as far as you would by using enzymes, however you create somethin pretty different taste-wise. In my opinion the hops should be the dominant factor, not the yeast/phenols.

The idea here is to accomplish exactly that, but in the absence of yeast-derived esters that a saison strain would provide.

Bingo

More or less on topic question : how did you manage to run 2 Grainfathers side-by-side at the same time? In terms of running the app I mean. Obviously on 2 separate devices but how did you manage for one device to be strictly paired with one GF and the other with the other one?

Side : how did this recipe tasted? Worth brewing another time? I’m desperately looking for a good Brut IPA recipe, one that would be very hop-forward.

Cheers guys and keep up the good work!

In one beer, the enzyme was given 60 minutes to react. In the other, it was given a at least a week (168 hours, and probably longer considering I can’t tell that anything was done to denature the enzyme). So, you aren’t really asking the question “Does it matter at what stage I add the enzyme?” you are asking “Does an enzymatic reaction approach greater completion if given more time?”

In one beer, the enzyme was given 60 minutes to react.

I know this.

In the other, it was given a at least a week (168 hours, and probably longer

Right.

…considering I can’t tell that anything was done to denature the enzyme).

Right. That was part of the experiment, being that brewers – professional and amateur – were adding AMG at different points. We have tested other variables that “seemed obvious” and came back with counter-intuitive results.

One of the things I wondered was if the AMG, while in the typical mash pH range, and at the higher-temperature, might work quickly enough to reach the limit of its effect on the wort.

So, you aren’t really asking the question “Does it matter at what stage I add the enzyme?” you are asking “Does an enzymatic reaction approach greater completion if given more time?”

Kinda both, right? You mash regimen may impact the fermentability as well, along with the enzyme.

Two years late here, hope you can still read this. Clearly the enzyme added to mash didn’t have enough time to convert as per FG readings. I wonder if giving just an additional half hour would do the trick, considering faster kinetics at higher temperature (mash T).

As always, love your blog!

To continue this logic:

Since we aren’t denaturing the enzyme, does it continue to work, and will those last 2 or more points convert over time and be fermented potentially creating bottle bombs?

AMG added during mash will be denatured during boil

If the enzyme is added during fermentation, it stays active and should convert everything. At that point it’s up to the yeast to do the rest. This can cause bottle bombs, diacetyl, and other off flavors if fermentation is not allowed to finish completely. The enzyme is in the finish product you drink as well.

The other risk is yeast contamination. Commercial brewers who add the enzyme to the ferm will not be able to reuse the yeast unless their okay with the enzyme being in the next beer. This is part of the reason some brewers add their enzyme to the mash.

Agree on the yeast harvesting issue.

Yes, kinda. One of the reasons people add the enzyme during the mash is so that they know it’s dead. Adding it to the fermenter means that it will continue activity until it’s finished converting starches and complex sugars to simple ones. Brewer’s who are bottle conditioning should be aware of this and its potential to extend fermentations and ensure that the beer is stable before bottling (kegging isn’t as much of an issue). But, it’s also possible that some other factor is limiting the attenuation and that the beer is stable for those reasons, such as alcohol intolerance (although this is probably not an issue here. I would also guess that amyloglucanase enzymes also have a limit, and that it is possible that there are certain things that can raise the gravity that the enzyme + yeast combo still can’t ferment. Finally 1.000 does not actually equal zero sugar as alcohol skews the density, when I made a brut IPA it actually finished negative plato and below what my hydrometer could measure (below 0.996). Anyway, Brut IPA’s are super fun, but be careful if bottle conditioning!

What was the dosage rate for this enzyme?

Also, I have some unbranded “amylase enzyme” I’ve successfully used for stuck fermentation. Is there a difference between one amylase and another?

Dosage per the manufacturer is 2-7g/ HL (26.4 gal). I believe we ended up at 2 grams, for 6 gallons, which is on the high end.

26.4 gal /6 gal = 4.4.

7g/ 4.4 would have suggested 1.6 g. We rounded up for ease of measurement.

I do know that after reading the data sheets and instructions for various manufacturers they seem to list different pH and temperature Optima. They also list different temperatures for denatureing. So I wonder if different manufacturers may perform differently as well.

What temp was your Mash? Doesn’t the Amylo enzyme begin to denature at around 143F?

Good question. Was left out somehow. Being updated now.

We started at 122F (50C) and ramped slowly (about 30 min to 148F (64C) for a 40 min rest.

Enzyme added at 122F (50C) as recirc started.

Ok-So it definitely had time to do its thing. Thanks for the update.

At our brewery we find that a rest at 144 for 60 minutes nets us a FG of 1.002 or lower, and we get to denature the wort in the boil to avoid any packaging issues that could happen.

One of the concerns I’ve seen is harvesting yeast and bringing any remaining enzyme into the next batch. That is the reason why I see some professionals use the enzyme only in the mash.

FYI, per BSG –

Amylo™ 300 works optimally well in brew house mash at temperature of 55-62C~ (131-144F) and pH ranges of 5.4 – 5.6. Amylo™ 300 is active up to 65C (149F).

Try saving some wort from the mash, then add back to the fermenter. Then your beer will be reinheitsgebot compliant. My cousin who’s a chemist for the food industry told me that AMG is just a generic term for alpha/beta amylase. Yes, it continues to work despite being outside of its optimal temperature, slowly in lower fermenting temperature.

Reinheitsgebot compliant? Fun to play within the (arbitrary) boundaries, for the sake of a challenge, but otherwise not a goal of mine.

α-amylase, β-amylase, and amylo-glucosidase are three separate enzymes, but they do have overlap. I think in the food industry they do use them for different purposes but also interchangeably if the goal is just to make starch into sugar.

AMG enzyme hydrolyses α-1,4 AND branching α-1,6 linkages. With a pH optima of 4.0-5.0 and temp of 65F (as per above depending on manufacturer).

α-amylase. Acts at random locations along the starch chain at the α-1,4 linkages, and therefore α breaks down long-chain carbohydrates yielding maltotriose and maltose – from amylose, or maltose, glucose and “limit dextrin” from amylopectin. It does not necessarily yield a highly fermentable wort.

With a pH optimal of 6.7-7.0 Temp ~145-162F. T optimal 68C (154F).

β-amylase – works from the non-reducing end, β-amylase catalyzes the hydrolysis of the second α-1,4 glycosidic bond, cleaving off two glucose units (maltose) at a time. So, it tends to leave a more fermentable wort than α-amylase alone. Though in beer sort they seldom as alone. pH optimal of 4.0-5.0. Temp ~131-149F. T optimal 65C (149 F).

How about limit dextrinase? They are rarely mentioned but they do catalyze the hydrolysis alpha 1,6.

Have you considered that un-boiled wort is full of lactobacillus, enterobacter, and the like? Not the best thing to add back to a fermenting beer.

Most of them die at >140 deg F. I won’t worry too much about that.

” However, the fact the one made with enzyme added at yeast pitch finished 0.005 SG points lower leaves me inclined to rely on this approach, or perhaps even adding enzymes at both points, if my goal is dryness.”

Or just mash at a lower with the enzyme. The 148F mash temp is at the very upper range of tolerability for Amylo 300 (149F). Optimal temp range for Amylo 300 is listed as 131-144F.

Well, the enzyme was added at 122F. Then ramped to 148F over 30 min. Then held at 148 F for 40 min.

As stated above, BSG states –

Amylo™ 300 works optimally well in brew house mash at temperature of 55-62C~ (131-144F) and pH ranges of 5.4 – 5.6. Amylo™ 300 is active up to 65C (149F).

But, if a brewery desired to only add it in the mash, to help ensure it is denatured, then I’d mess around with dosage rates, temps, and times, until I achieved my goals. I like simplicity and speed. Enzyme into FV for me!

Yeah, and really it’s a matter of contact time. In the mashed version you got just over an hour, while in the fermenter you got over 2 weeks. Only question I have is one of stability–having active enzyme in a “finished” beer may or may not be a problem.

Check out Good Beer Hunting podcast EP-161 with Kim Sturdavant. He mentions brewers having diacetyl type off flavors when adding the enzyme to the fermenter (purportedly due to poor yeast health and/or packaging too early due to longer than usual fermentation activity). Another article about Kim mentioned adding the enzyme at the tail end of fermentation after harvesting yeast.

Thanks, Chad. Good I do to share.

Very informative! Kim from social brewery, the creator of the brut ipa, recently brewed one in Juguetes Perdidos, an award wining argentinian brewery, and he added the enzyme in fermentation. I recall watching an interview of him saying he was trying his bruts with the enzyme in the másh instead of fermentation so I asume he chose the latter.

Thanks for the post!

Great info. Thanks for sharing!

How was the bitterness? The little bit of research I have done typically shows that the IBU’s are around 25 with an OG of 1.050ish.

It was fine to my tastes but perhaps a tad high for this new class of drinker that likes dessert beer – ie back sweetened kettlesours, pastry stouts, and -2 IBU NEIPAs. Lol.

🙂 Thanks!

It makes sense actually, not even based upon time of reaction. When you boil, new, sweet compounds are formed through caramelization that will never be acted upon by the mash AMG as it is now destroyed by the heat whereas the fermenter AMG can break those new compounds down to use as yeast fuel.

Interesting that this provided a significant result when some other FG differences haven’t (just from my own hazy recollection). Wonder if that’s a taste contributed by the enzyme, something about taste being able to pick out the super-low gravity more than it can tell between .02 and .01… just musing.

I had similar initial thoughts. When speaking internally my first inclination would be that 1.25 plato or .005 gravity points would not be a big enough mouth feel difference. I similarly wondered if the difference becomes greater as you get closer to 0.

Check out Good Beer Huntomg podcast EP-161 with Kim. He mentioned brewers noting diacetyl like off flavors when adding the enzyme during primary fermentation. He mentions this may be due to packing too quickly or poor yeast conditions from abnormal/ longer than fermentation conditions. In another article he mentioned adding the enzyme after removing the yeast.

Kim Sturdavant suggested add the enzyme to the kettle while lautering, then hold off on heating the kettle until all wort is in and has 30 minutes of contact with the enzyme at around 145 degrees or lower.

Wow, super timely! I have a Brut IPA fermenting right now.

The recipe I based mine on used two different enzymes. One was a ‘high temperature’ enzyme which went into the mash. The other was a ‘low temperature’ enzyme which went into the fermenter, after vigorous primary fermentation had mostly dropped off.

I can’t remember the names, but the one you used sounds like my ‘low temperature’ enzyme. I think the ‘high temperature’ one was alpha amylase?

I’m giving it an extra week at 18 degrees before I raise the temp for a few days and dry hop, then crash cool and bottle.

General consensus seems to state that using Galaxy as an early bittering addition produces harshness. Did you find this to be true? Would the fact you used it as a FWH addition counter this as well perhaps?

Done 3 batches so far. First and second batches with amyloglucosidase in the mash only (1 hour at 142 degrees), with an increased amount of enzyme in the second batch. Both finished at 1.005 and 1.004 respectively. For my third batch the enzyme was added during the mash and during fermentation. This batch finished at 1.002. The addition during fermentation was added post peak krausen (approximately day 3) along with yeast nutrient.

Though a zero or below FG does not define a good Brut IPA as the 3 I’ve brewed have been on par with professionally brewed bruts I’ve tasted, I’ll probably be adding during mash and fermentation in the future to push for a lower FG.

Great. Thanks for sharing your results.

Did you use powder or liquid amylase? If powder, did you just sprinkle into fermenter or dilute it in some type of solution?

Liquid. See the article. There is a pic of it being weighed out and then another of it being added to the FV (carboy).

Where did the recipe go? I saw it when this article was first published.

Having some issues with the BeerXML plugin, actively working on it now. Standby!

I realise this wasn’t the purpose but I was wondering how you rated your final beer and what you would tweek next time if you were brewing for pleasure. I’m thinking of brewing this recipe myself and was wondering.

How much of the enzyme was added (weight or volume)? Was the mash rest @64oC 40 min or 60 min? How did the beers taste, especially the drier one? How was the bitterness level?

Thought I’d add another comment. I brewed this beer recently and kept to the recipe with the exception of the bittering hops. It looked way too bitter in BeerSmith so I reduced the early hop addition and brought it forward to 30 mins. I added the enzyme to the mash and it ended up at 1.000FG. The biggest issue I had with the beer was pouring it. I aimed for a carbonation level of 3 but with my keg setup this required 20 PSI. This with a 4mm beer line (ID) and 3.8m long. I’ve tried lowering the temp and this improved things but it’s still foaming heaps. What beer I do get is great,

I have some Amylase Enzyme powder. What is the best method for diluting it into the fermenter?

Just sprinkle it in, rack beer onto it? Apologizes if you mentioned this in the above, I didn’t see it and haven’t really seen any details on other forums, just simply add during fermentation…

I used liquid. you can see it in the article. There is a pic of it being weighed out, and then another of it being poured in the FV batch.

I guess I didn’t answer the powder question – but that is just as well since I have not used it. Friends told me they added to mash malt prior to mashing in. For FV use I guess I’d take a few oz of wort during transfer, and add the powder to it, then add the slurry to the rest of the wort in the FV. Add yeast and hope for the best.

I’m trying my hand at a Brut IPA this week. Was planning on adding Ultraferm during cool down and pull the chiller at 140 and allow the pump to recirculate for several minutes prior to transferring to the carboy. Cheers!

Good luck!

Thanks and happy with the results. OG=1.053 FG=1.002 with Safale5. Single boil hop of Nelson Sauvin then a dry hop with same that never floated! LOL.

What were your thoughts on using that water profile? High SO4 to accentuate the hop character?

I recently added BSG’s powdered amyloglucosidase (labeled as “Glucoamylase Enzyme 1 oz”) directly to the fermenter, AFTER primary fermentation started to die down, for a couple batches. In both cases — a 1.059 (WLP644) and 1.035 (US-05) — it restarted fermentation and took them close to 0.998. They were no-boil batches, so the body/mouthfeel did not suffer excessively. It was exactly what I was hoping for!

( more details on reddit’s Keto_Brewing )

Is the Hopping schedule shown in the recipe section correct? Overall numbers show 74 IBU but Brewfather puts 1oz at 60 and 2oz at 30 at almost 150 IBU. Am I seeing this right?

Hi

Given that they both beers were liked almost equally by the tasters, and that a higher conversion would be possible by adjusting the wort temperatures and time.. it would make sense to go this route, the only reason being that amg is not deactivated in the fermenter, no even if pastuerized..and left to conditioning will continue converting sugars, possibly leading to over fermentation, sourness or other effects. It is shut off in the boil however.. so if there is no marked advantage.. using it for wort preparation seems to be the best choice.