Author: Brian Hall

Typically, the only time beer is deliberately frozen is for the purposes of distillation when making styles like Eisbock. However, with the widespread use of chest freezers and bypass thermostats as fermentation chambers and keezers, it’s not too uncommon to hear of a homebrewer who has frozen a carboy or keg full of beer, usually a result of accidentally leaving the temperature probe hanging outside the freezer.

While the dangers of freezing in a glass or pressurized container are fairly obvious, especially if said vessel is nearly full, there’s also quite a bit of concern about the effect freezing has on the perceptible characteristics of the beer. Does something occur during the conversion from a liquid to a solid then back to a liquid that noticeably impacts beer aroma, flavor, or mouthfeel?

On numerous occasions, I’ve forgotten about commercial beers I set outside during cold Anchorage winters for quick chilling, returning to discover undrinkable beer-cicles. My anecdotal experience is that, once thawed, the beers tasted just fine, no different than previous tastings. Curious if I was missing something, and inspired by the numerous stories of frozen beer gone bad, I decided to put it to the test!

| PURPOSE |

To evaluate the differences between a pale lager that was frozen for 5 days then thawed and the same beer that remained in a liquid state.

| METHODS |

Hoping to accentuate any impact freezing might have on beer, I chose to brew a simple pale lager for this xBmt.

Tundra

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 18.9 IBUs | 3.9 SRM | 1.045 | 1.011 | 4.4 % |

| Actuals | 1.045 | 1.008 | 4.9 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

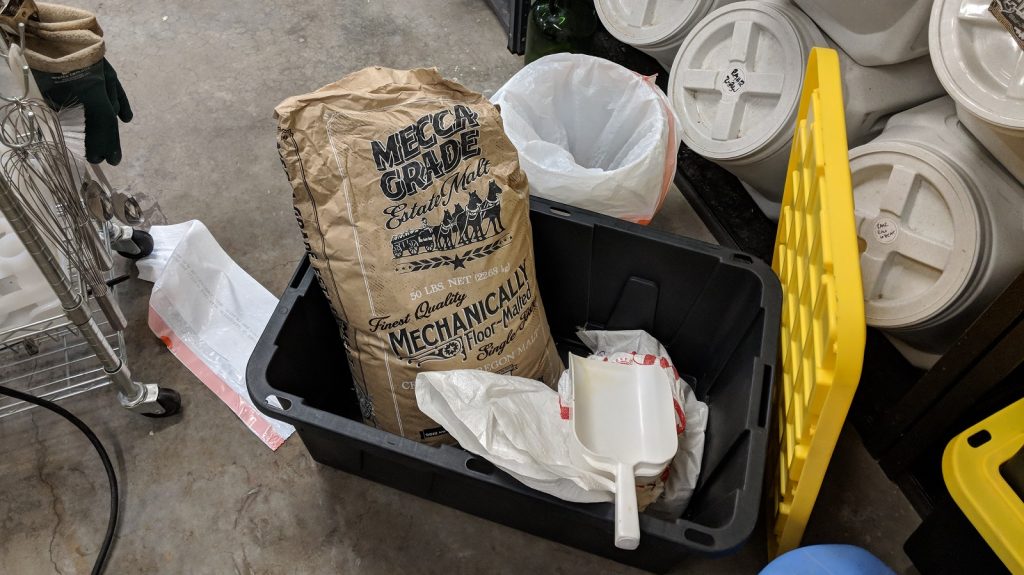

| Pelton Pilsner Style Malt (Mecca Grade) | 9 lbs | 90 |

| Vanora Vienna-style Malt (Mecca Grade) | 1 lbs | 10 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Tettnang | 22 g | 60 min | Boil | Pellet | 4.5 |

| Tettnang | 22 g | 15 min | Boil | Pellet | 4.5 |

Notes

| Water Profile: Ca 50 | Mg 7 | Na 5 | SO4 75 | Cl 60 |

Download

| Download this recipe's BeerXML file |

I stirred up a couple starters of Imperial Yeast L17 Harvest a day ahead of time.

My first order of business the following morning was collecting the strike water for both batch, which I used my sous vide machine to heat.

As the water was warming up, I weighed out and milled the grain.

Due to kettle size limitations, I’m unable to brew 10 gallon full volume batches in a single vessel, so I performed 2 identical mashes at the same temperature.

Once the mash rests were complete, I removed the grain bags and allowed them to drip until the same volume was collected from each.

At this point, I combined the worts into a single kettle then proceeded with the boil, hops being added at the times stated in the recipe.

Following the 60 minute boil, I quickly chilled the wort before splitting it equally between sanitized Brew Buckets.

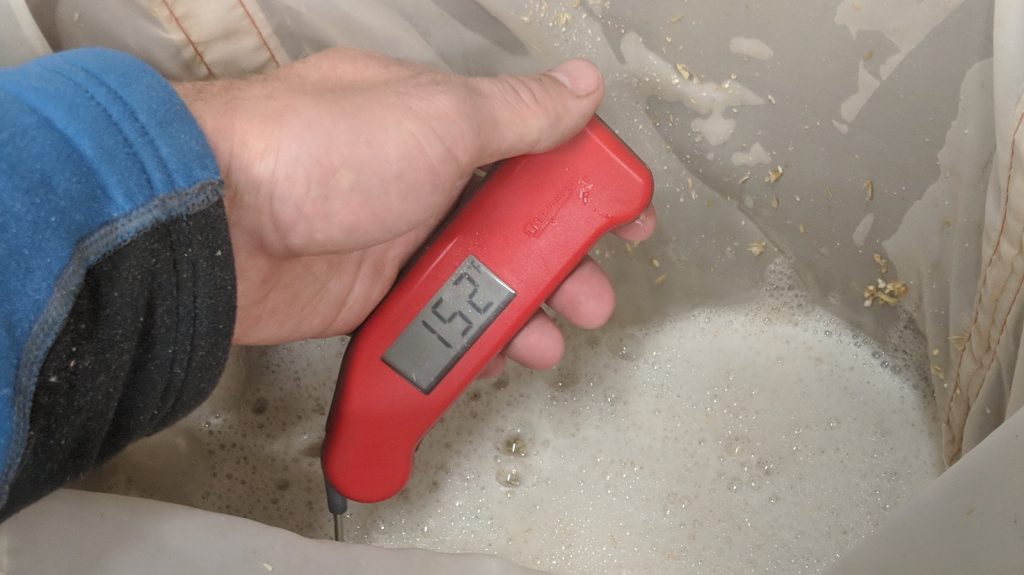

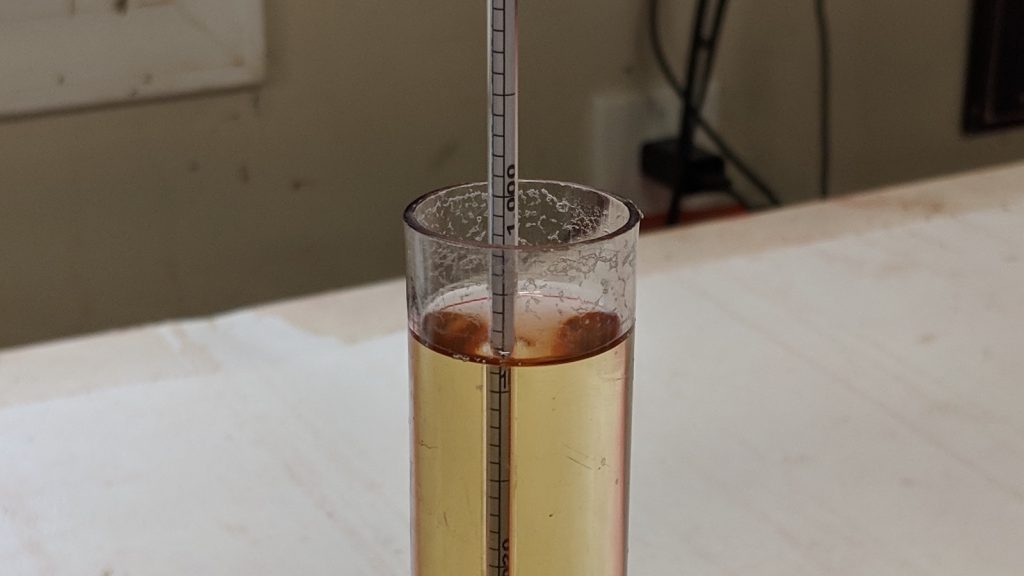

A hydrometer measurement showed the wort was sitting at my 1.045 OG target.

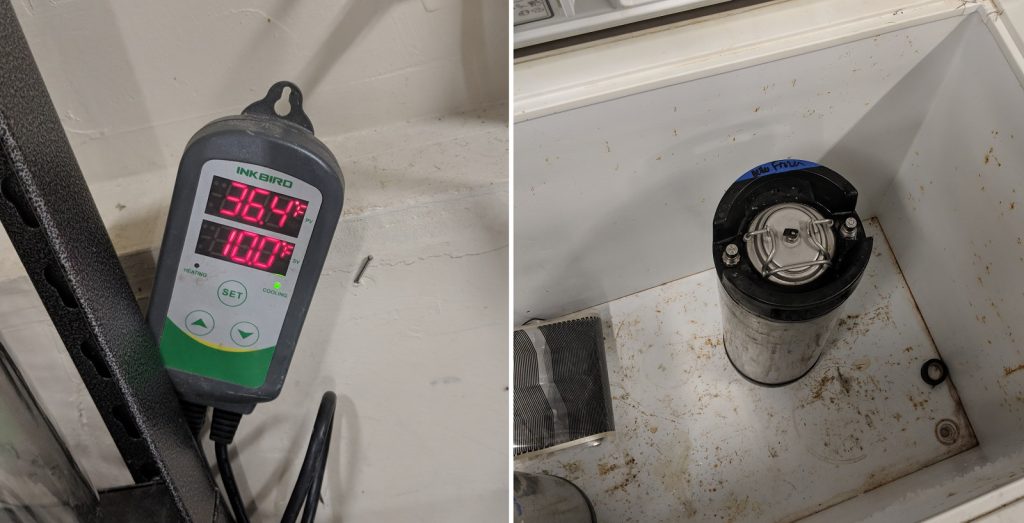

I pitched a yeast starter into each batch and allowed the beers to ferment at 52°F/11°C for a few days before gently warming it up over the course of 2 weeks. After a couple days at 68°F/20°C, fermentation activity had halted so I took hydrometer measurements confirming the same FG had been reached in both.

I swapped out the airlocks with BrüLoonLocks filled with CO2 and cold crashed the beers for a couple days. I then racked 4.25 gallons from each batch to separate CO2 purged kegs, making sure to leave room for the expansion that occurs when liquid freezes.

Both beers were fined with gelatin and left at the same temperature for a week before I placed one keg in my cool keezer and the other in my fermentation chamber controlled to 10°F/-12°C.

The beer froze. I left it alone for 5 days before moving it to a room temperature environment for thawing. The following day, with the beer fully melted and still very cold, I placed it next to its non-frozen counterpart in my keezer. Both were burst carbonated and allowed to condition for a week before they were ready to serve to participants.

| RESULTS |

A total of 22 people of varying levels of experience participated in this xBmt. Each participant was served 2 samples of the frozen beer and 1 sample of the beer that was not frozen then asked to identify the sample that was unique. At this sample size, 12 tasters (p<0.05) would have had to correctly identify the unique sample in order to reach statistical significance; however, only 9 tasters (p=0.29) made the correct selection, indicating participants in this xBmt were unable to reliably distinguish a pale lager that was frozen for 5 days then thawed from one that remained in a liquid state.

My Impressions: With the exception of the fairly easily noticeable difference in appearance, I was unable to tell these beers apart, which was confirmed by various incorrect triangle tests. Even side-by-side and biased by awareness of the variable, these beers were the same to my nose and mouth. The beer was decent, not necessarily as crisp as I’d hoped for, but definitely tasty enough to consume amply.

|DISCUSSION |

Frozen beer is an issue that seems to be happening more often as the hobby of homebrewing grows, in fact John Palmer waxes poetic about his own experience with an icy Vienna Lager in How To Brew. Despite the myriad horror stories found in online forums, the results from this xBmt showing tasters were unable to reliably tell apart a pale lager that was frozen suggests such conditions had little impact on aroma, flavor, and mouthfeel.

While these findings may ease the minds of homebrewers prone to making minor mistakes, there is one issue that deserves consideration. Without proper conditions, freezing temperatures will impair yeast, rendering a good portion unable to metabolize sugar. For those who keg and force carbonate, this is a moot point, but brewers who bottle condition should consider adding some fresh yeast to ensure their beer carbonates.

The difference in clarity between the beers in this xBmt, slight as it may have been, was rather curious to me. Assuming it was chill haze, it seems plausible that it would have cleared up to at least the same level as the beer that wasn’t frozen once it warmed up, but that didn’t seem to be the case. Perhaps something about freezing creates a more permanent haze that, while noticeable with the eyes, doesn’t impact other perceptible qualities.

I’ve never personally had a batch of beer I made freeze on me, but the results of this xBmt have confirmed my experience with frozen commercial beers, namely that it doesn’t seem to have a negative impact on quality. I won’t be intentionally freezing beers because of this xBmt, though in the event I do so unwittingly, I won’t fret as much as I might have before.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

26 thoughts on “exBEERiment | Impact Freezing Beer Has On Munich Helles”

Reading this experiment made me think … Wonder if you can do this with hoppy beers you can’t drink immediately. Since hoppy beers as we know lose that hop punch as time goes on why not freeze it for a few weeks and then thaw when ready to drink ?? Sounds reasonable right ? Wonder if the freezing would impact the hop quality ?

Sounds logical, things do tend to keep better when frozen. Next experiment: NEIPA after 2 months, where one batch has been stored in the freezer and the other in the fridge?

There you go. Good idea.

That’s a good idea!

I obviously only have anecdotal experience here, but in my experiences with accidentally leaving my temperature probe outside my keezer I have found that there is a very noticeable effect on hoppy beers even though, like this experiment, I’ve noticed little to no effect on beers that are not hop forward.

No idea, but I’m not sure the application? Just to have NEIPA to defrost and drink?

Say you want to brew a large batch when you can, but want to store and drink in smaller volumes? Or maybe you want to enter the beer into a competition a few month away?

Or maybe you want to brew 30 gallons in one sitting but wont be able to drink it all until later.

My experience with frozen beer is that yes, it is indistinguishable during consumption. The effects of freezing have always been apparent though, on the back end of the consumption process.

Anyone else?

Brulosophy for the win…again, well done guys.

How long does it take your Anova sous vide machine to get your water to strike temp? My guess is a looong time.

I had an older model Anova sous vide that would take under 3 hours to heat 8 gal of strike water in a 10 gallon cooler. (1150 watts I think, which worked out math-wise)

This is great that you can set it and forget it and have perfect temp strike water.

I never needed 8 gallons so I would drain some off before adding the grain.

I did that about 6 times but the last one killed it. It apparently ingested too much steam, condensed on the inside and and blew out some of the electronics. Anova has no option to repair. So… be very careful how it is setup so it is not ingesting any steam. (“any” because it is going to be there a long time)

I bought some of the walmart $13 ones to replace it. We’ll see how long they last.

It didn’t take too long, turned on, ran errands with the kids, came back and it was at temp! So somewhere in less than 5 hours it worked.

I’m glad there is no difference because I intentionally freeze (0C) my beer when I cold crash.

I have had a beer get too cold and freeze or partially freeze and change in the process, though it’s not just the actual freezing per say that does it… I think what happenes sometimes is that as the half or mostly empty keg dropping in temp (say the kegorator or keezer is just slightly colder than 32°F) you go about your normal routine and have some pints over a few days…. Anyways as the keg slowly freezes the beer tour pouring starts to change just a bit and by the time it is totally noticable and mostly frozen you check it and the ice inside is discovered … Upon thawing the left over beer has basically gone through an esibock process and is thinner and more watery as the slower to freeze alcohol was drained away in the pints that got poured before the freezing is discovered… Thats what happened for me at least… Cheers thanks for the great exbeeriments eh!

I have accidentally frozen my keggerator twice. Beer was fine after. Additionally, my yeast cultures, in pint jars in the same freeze, were recoverable in a starter and worked fine in follow on brews.

What about frozen already carbonated beer? That always seems to happen more than freezing uncarbonated beer.

Side note: Seems like a lot of pictures are missing?

This beer was already carbonated.

No pics missing, was just a single batch that got split at kegging so less double shots.

I had two kegs freeze solid during a cold snap in December here in MN a couple years ago. One was a Belgian IPA and a Porter. They were in my keg fridge out in the garage. At first I thought it was just frozen in the draft lines only to lift the kegs and see they were solid. Each keg was about 1/2 to 3/4 full. I figured the beers were shot and was more concerned about my kegs, lines, taps, etc. I brought them into the basement to thaw out and moved the fridge inside as well. Once they were back to liquid state I hooked them back up and was pleasantly surprised the beers tasted fine! The carbonation hadn’t changed much either. I entered the Porter into a large comp in January and took first in it’s category. I won’t be freezing my kegs on purpose again either but feel better knowing that if it does happen everything should be fine.

Yeah, there’s really no reason for the carbonation to change. The CO2 will go out of solution as the water crystallizes, but will have nowhere to go (provided the seals are good). When the ice melts the CO2 simply go back into solution.

Why would it go out of solution as water crystallizes? Wouldn’t solubility increase as it got colder?

A crystal lattice (e.g. ice) tends to exclude impurities, that’s why you can cold-distill beer or cider – flavours, sugars and alcohol are forced out of the water and concentrated as the water freezes. The same goes for the CO2 (or rather the carbonic acid while in solution). Sure some of it will remain dissolved in the alcohol slutiotion remaining and the solubility would increase in thet, but not enough I’d wager.

Ugh, good article but please don’t say distill (as you did in the first paragraph). Despite what federal bureaucrats separated from reality might think, freezing to make eisbock and the like is freeze concentration, not distilling. Distillation requires vaporization of the liquid, the gas from which is then condensed into a distillate. Yeah, yeah, this is a technicality, but it still irks me.

At first glance, I wondered who the heck would bother testing freezing and thawing beer!? Oh yeah, Brian Hall would. Of course. 😉

I have done some experimenting with freezing and removing the ice for several reasons and have noticed some interesting discoveries.

Some beers after freezing and removing the ice will take on this horrible brown color for a week or two then it drops clear. If the beer is too bitter from over boil hopping and I don’t have anything to mix it with I will ice bock it and it will reduce the bitterness. Also if I brew a beer which is to light in abv or mouthfeel I will ice bock it and the end result is good with a higher abv and a bigger mouth fee.. This method doesn’t work well with beers which have a lot of non fermenting sugars because they tend to build up sweetenss.

Oh and it takes much longer to freeze carbonated beer vs uncarbonated and of course the end result is uncarbonated beer.