A brewer of nearly 2 decades, Malcolm currently resides with his patient wife, 2 lovely daughters, and adorable son in Atlanta, GA. He loathes the status quo and relishes dispelling dogma, both of which drive his love for experimentation with both food and adult beverages. In addition to photography and randomly breaking into song, Malcolm enjoys cooking, pickling, and brewing up interesting concoctions using wild yeasts, bacteria, and other fun ingredients. He’s a proud veteran of the US Navy Submarine Fleet and is very active in local homebrewing communities.

A brewer of nearly 2 decades, Malcolm currently resides with his patient wife, 2 lovely daughters, and adorable son in Atlanta, GA. He loathes the status quo and relishes dispelling dogma, both of which drive his love for experimentation with both food and adult beverages. In addition to photography and randomly breaking into song, Malcolm enjoys cooking, pickling, and brewing up interesting concoctions using wild yeasts, bacteria, and other fun ingredients. He’s a proud veteran of the US Navy Submarine Fleet and is very active in local homebrewing communities.

| ABOUT MALCOLM |

How did you get into brewing?

Sometime in the summer of 1998, a few of my roommates were gathered around a pot on the lower level patio of our two story apartment. About 6 of us were renting the upper and lower section of this complex, I stumbled out onto the upper balcony, hungover from a night of debauchery, and get a whiff of this cereal syrupy aroma. I ask them what the fawk they were cooking, cuz it sure wasn’t chili or a fish boil. “Joe” explained that he used to brew with his dad and they found the kit at a hardware store. I was invited to join due to my professed love of beer and food.

What was your first batch and how did it turn out?

It was liquid sadness. If you could bottle disappointment that was it. I am pretty sure the can of “syrup” or extract had hieroglyphics on it. The hops were mostly powder and grey-ish, and the yeast was caked into a mass that resembled the seasoning from Top Ramen noodles. At the time, I was just going along for the ride. After tasting the packaged abomination, I was determined to make a good beer. I went to a library, found a few books, then bought the ones I felt were the best. I read and re-read them several times while underway and on station aboard the USS Neverports (SSN-365).

How did you get involved with Brülosophy?

The technical side of brewing has always intrigued me, but I was curious as to what combination of these figurative control levers mattered. Sure, I loved taking the deep dive into enzymology or sulfate-to-chloride ratios, but I was always bothered by the question as to weather or not it mattered, and by that I mean at what point it was perceivable. So, I ran experiments. Then while web searching data collection methodology back in late 2014, I came across Brülosophy. I connected with Marshall, we chatted off-and-on for a bit, and eventually there was talk of me joining the crew. While I was flattered and had some interest, I was busy with other stuff and initially turned the offer down. We continued to banter online and argue in a playful manner until Marshall more or less said I had to join. Damn Jedi’s. Today I consider Marshall a brother. We argue, fight, give each other shite. We love each other. Wouldn’t have it any other way.

What xBmt has surprised you the most?

Many do, to be blunt. I question everything we do, as is my nature. I am just like the many of the readers in that I try to rationalize our counter-intuitive results. If I had to pick the most surprising, they would be fermentation temperature deltas and decoction. I have performed a lager ferment at warm temp and made a reasonable facsimile of a lager. Never would have thought it possible. And as to the decoction xBmt– WTF?! I know the painstaking effort I put into those beers, and for that to come back with a non-significant finding, I was shocked. I wanted to immediately do a retrial. One is coming…

Have the xBmts influenced your current brewing perspectives?

Some. I worry less. But I still worry a bunch. It’s my nature and it’s how I brew and cook. I like for my beer and food to turn out a certain way. I guess if there is no fuss, I feel as if I didn’t put my all into it. However, now I know that while I may still desire for a brew to proceed along with the precision of a Japanese train (only 20 seconds early!), I know the cars aren’t coming off the tracks due to a few minor errors along the way. Now I am fairly laissez-faire with many aspects and focus more on a few details. On the hot side it is water chem and recipe, and on the cold side it’s yeast health, transferring/ packaging.

What are your 3 favorite styles of beer?

I honestly don’t know! Seriously, I’m an occasion and mood based drinker. As a rule, I tend to drink lower ABV beers. I enjoy lighter lagers at parties, picnics, sport events. I love experimental wild ales and Lambic inspired ales, especially when sharing them with other brewers of such styles. They inspire a great passion– the journey to find them and create them is half the fun. Sharing them with other appreciators is extremely rewarding.

I try NEIPA all the time but only finish them when the brewer manages to not make them turbid or without a harsh hop bite. I love the best versions of the style, they are among my favorite, but I hate the other 98%.

Getting back to the psychological vs. the physical– do I love UK Pub Ales because I think I am supposed to, being of English heritage and having worked at English pubs? Or do I actually like them because they are delicious and nutritious? The world may never know. A well brewed, cellar temp, brilliantly clear Pub Ale of modest strength, poured with a bit of off white foam atop a copper hued liquid, with it’s malty hints of biscuit, toffee, and bread crust, coupled with an artful dose of earthy tea-like hoppy goodness… one of life’s true delights, in my humble opinion.

What are your favorite ingredients?

Malt: Simpsons Golden Promise

It’s a Scottish analog to the English Maris Otter. “Malcolm Frazer” is a Scottish name, though I was born in SE London. I was in the nuclear field, just like Homer Simpson. Match made in heaven. Oh, and it’s yummy. I enjoy the slightly more sweet biscuit character it provides compared to American Pale 2-row, yet it’s not quite as intense as Maris Otter, to my perception.

Hops: All over the map

Depends on the beer I am making, really. I just do not care for beers to be over onion-y or overly reliant on one note– too much tropical or pine or anything lacks nuance and bores me.

Yeast: And so it is with yeast as it is with hops

I like to blend Saison yeasts before adding a menagerie of microbes if making a “Farmhouse/ Saisony/ Wild Ale Thingy.” For UK Ales and NEIPA, I like Imperial A01 House, purportedly the Whitbread Dry strain. For lagers, I mostly use WLP838 Southern German Lager or WY2308 Munich, but I’ve also had good luck with Saflager W-34/70. For Belgian beers, I love Wyeast 3522 Ardennes. And for cheat-code easy sour beer brewing, I just pitch Wyeast 3763 Roeselare Ale Blend.

What’s your desert island beer?

Pilsner Urquell Unfiltered. Served from a side pour. Hladinka. In a glass mug. Next question.

What music do you listen to while brewing?

I mix it up depending on mood, very much akin to how the style of beer I drink is often influenced by external factors. If it’s early in the morning, I may have nothing playing or just listen to a podcast. If the kids are at school, then maybe it’s Polynesian or Island Reggae, which brings me back to Hawaii. I listen to a lot of older hip-hop, funk, rap, and random rock mashups, as they bring me to my high school and early Navy days. Stuff like Tribe Called Quest, Funky Homosapien, Pharcyde, Gangstar, Digable Planets, Public Enemy, Rage Against the Machine, NIN, Marilyn Manson, Chili Peppers, STP. Or even some old UK Punk or Skate Punk, like The Business. I am all over the place.

What else do you enjoy doing besides brewing?

Being a dad. Being a husband. Cooking. Baking. Fermenting everything. Photography.

If you could go back, what brewing advice would you give yourself?

Despite the risk of coming off as a cop-out, I wouldn’t change a thing. After 20 years, and various stages of learning and growth, I like where I am and how I got here. Sure, there was some inefficiency of time and money spent along the way, but all those experiences have given perspective to call upon if asked to help others or even myself.

| BREWING GEAR & PROCESS |

I’ve gone through so many brewing setups over the last 20 years, it is both amazing and sad. I’ve spent a ton of money making 3-tier systems, horizontal systems, semi-automated systems, all just to get back to a simple 2-tier batch sparge cooler setup with a BIAB bag as my filter method. With my recent move from Pittsburgh, PA to the Atlanta area, it’s likely I’ll make even more adaptations to my setup. We shall see.

Pre-Brew Preparation

With as long as I’ve been brewing, I usually have at least one version under my belt of whatever it is I’m planning to make. As such, I usually start by looking at past notes to see what I did or didn’t care for the last time I brewed the particular style. I sometimes compare my current version of a recipe to something similar in a brewing magazine or from a winning NHC beer– kind of a hive mind collection method that I then distill down. I build my recipes using BeerSmith, which I switched to after years of using BeerTools.

Then I consider water. I use a BrewLab by Lamotte to test my water a few times per year, comparing it to a Ward Labs test every year or to check for accuracy.

I use the Bru’n Water Spreadsheet to determine mineral and acid additions, sometimes starting with a blend of municipal and RO water. I typically collect my water and make any adjustments the night before brewing.

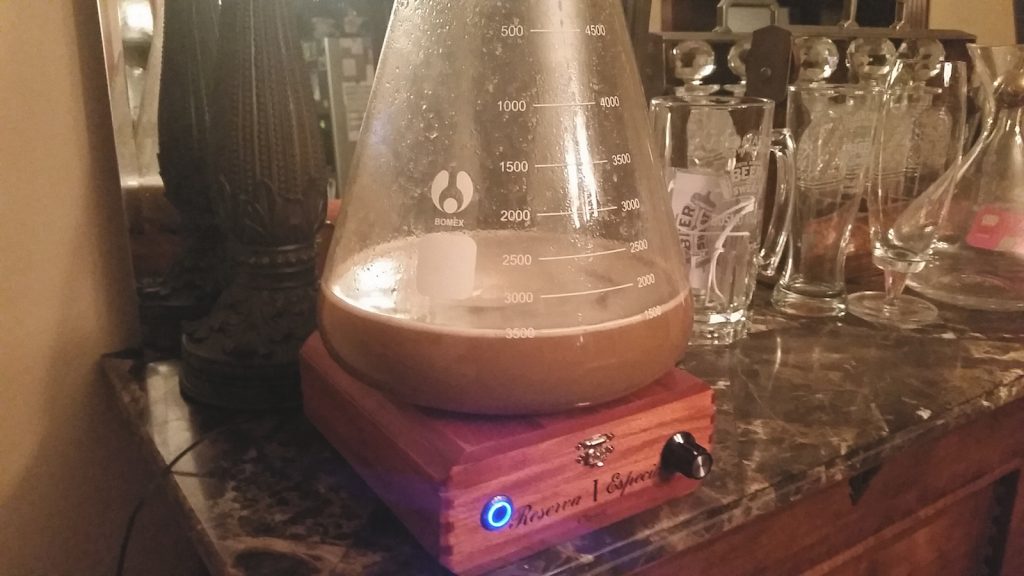

With water collected and a printout of my recipe on my brew table, I place my bucket heater heat stick in the brewing liquor and set a timer so that it turns on a few hours before brew time. When I make starters, I throw them together a day or 2 before brewing so that they have enough time to fully propagate.

While I occasionally weigh out my grains ahead of time using a small scale, I always wait until right before mashing in to mill them with my Monster Mill MM3.

Brewing

There’s really nothing special about the way I brew. I currently use a converted Coleman Xtreme cooler as a MLT with a Brew Bag fabric filter for lautering. I start by heating the strike water with a bucket heater heat stick and once it’s at strike temperature, I transfer it to my MLT with a large plastic pitcher before mashing mash in.

I use a giant commercial kitchen whisk to fully incorporate the grains, it works so much better than a paddle, in my experience. For those batches where I try to mitigate hot-side oxidation, I pump the strike water over to the grain. Regardless, once the mash is fully mixed in, I use a ThermaPen thermometer to check the temperature.

About 15 minutes into the the mash, I steal a sample to measure the pH.

While the enzymes are doing their thing, I measure out the hops and any other kettle addition. I also set up my BrewTimer app, and make sure the times and additions are correct for this brew. I have a few profiles saved.

I generally rely on the batch sparge method and initially heat the full volume of water before mashing in, then heat the remaining volume with my heat stick or burner to 170°F/77°C for the sparge. Once the mash rest is complete, I collect the sweet wort in my Spike Brewing V3 kettle and immediately start heating it with my propane burner.

I usually make a small first wort hop addition to reduce the chances of a boilover. While the first running are warming up, I add the sparge water to the MLT, stir a few times, then drain the rest of the wort into my kettle. For batches where I’m reducing hot-side oxidation, I usually use the no sparge method and slowly drain the wort into a covered vessel.

When the wort reaches a boil, I start my timer and begin making the planned hop additions. It’s at this point I try to do some cleaning, namely tossing the spent grain then giving my MLT and fabric filter a good rinse. I also prepare by fermentation vessels to receive the wort.

I abandoned the use of my plate chiller long ago in favor of a JaDeD Brewing Hydra immersion chiller, which I add to the boiling wort with about 15 minutes left to go. Once my timer indicates the boil is over, I quickly chill the wort to slightly warmer than groundwater temperature.

When the wort is adequately chilled, I pump it over to my 7 gallon Ss Brewtech Chronical fermentor.

As the wort is filling the fermentation vessel, assuming it doesn’t require further cooling, I add the yeast then dose with pure oxygen. The filled fermentors are then wheeled over to my stainless steel table where I connect it to my Ss Brewtech glycol chiller and set the controller to maintain my chosen fermentation temperature.

I usually check on things a few hours after pitching to make sure everything is performing as expected. When signs of fermentation are complete, I use the glycol chiller to cold crash in the fermentor and often fine with gelatin once the beer is cool enough.

Packaging

Nearly all of my beers are kegged, and I fairly recently began transferring from the fermentor when the beer is about 1 °P from expected FG to reduce the risk of oxidation. This isn’t always the case, as I’m only able to do it if I’m around toward the end of fermentation. I use CO2 to push the beer into a fully purged keg that has a spunding valve attached. My keg purging process involves first filling the keg with Star San solution along with some metabisulfite, which gets displaced with CO2 from a tank.

When carbonating beer that was packaged prior to reaching FG, I pressurize the keg with 2-5 psi of CO2 and leave the spunding valve attached. For beers that have no extract left, I burst carbonate by hitting the keg with 30 psi of CO2 and let it sit in my 38°F/3°C freezer for 24 hours before reducing to serving pressure. The beers are usually ready to drink at this point, but they seem to pour nicer after a few more days of cold conditioning.

Serving

I currently serve my beer from cobra taps from kegs sitting in a temperature controlled chest freezer. It’s not ideal, but sadly my keezer gave up the ghost just prior to my move to Atlanta. I bought it in 2004 and it served me well many years beyond what was expected. A new keezer is in the planning stages.

Cleaning & Sanitation

I primarily use PBW to clean my tubing and cold-side gear, allowing it to soak for a bit before rinsing and letting it air dry. If I’m out of PBW, I don’t have any issues using OxiClean Free instead, seems to work about as well with a little more foaming. For sanitizing, I’m all about the Star San. One thing I’ve found works really well on my stainless gear are “magic erasers” cleaning pads, super durable and effective.

Contact Malcolm via email at malcolm@beerconnoisseur.local and feel free to leave any questions in the comments section below! A regularly updated version of Malcolm’s process and gear can be found on his contributor page.

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support Us page for details on how you can very easily do so. Thanks!

16 thoughts on “Brülosophy Contributor Spotlight: Malcolm Frazer”

Hey Malcolm, welcome to Atlanta! I’ve got 2 questions:

– Got a favorite pub ale recipe you can point to?

– Have you found an Atlanta source for Imperial Yeast? None of the homebrew shops I know about carry it.

Thanks. Love ATL so far.

I can share a recipe or two later when I get back home.

For Imperial, ask Schoolhouse Brewing in Marietta, Tom, the owner, is a great guy.

Magic eraser for SS. Duh,never thought of that! Thanks Malcolm.

Right on, man

Maybe you misunderstood Malcolm. He loathes Status Quo (the rock band). 😀

😘😄

Do you have condensation challenges on your fermentors? I run the same glycol unit with a 7G SS Unitank, and certain times of year I can’t seem to keep them dry, jacket or not.

Hey Blair,

I did not have much condensation issues while in the fairly moderate whether in Western, PA. There was some on the glycol lines but that was mitigated via insulation.

We shall see what Atlanta weather has in store for me, though I do intend to move the fermenters to the below grade basement.

Seriously one of the best profiles I have ever read. Malcolm, thank you so much for inspiring the homebrew community as well as myself! I love your attention to detail within the brewing process and how you are seemingly forever open minded to improve your craft. Cheers from California!

Wow, very kind Jacob. We love to hear from the readers, or even better – interacting with you – whether it be online, at HBC, or chance meeting out and about.

Stay groovy.

~Malcolm

Malcom, love your articles and contributions, always informative and your writing style is entertaining.

I’ve seen you mention your submarine service a couple times, just curious if you were a nuke, and if so which flavor.

Kind words, Newky.

I was an RO. And a ships diver. I can send ya some short shorts pics. Haha.

Nice, I was an RO (skimmer type) too, have since crossed to the “dark side”.

And while I do appreciate the offer of a dive shorts pic, I’ll pass.

I love what you guys are doing here and have turned several friends onto the website and podcast as well, keep it up man!

Cheers, mate.

Hi Malcom. I was told that you would know about the conversion of window A/C units for coolers for kegged Beer. I have 3 that I would like to use. Is it worth the effort of should I just put them in the alley.

I have made them to varying degrees of success. Best advice I’d gives is to watch a few youtube vids, or look up the instructables or DIY pages, which is exactly what I did.

Be very careful while handling the refrigerant coils, follow glycol instructions and give yourself a buffer to avoid an accidental freeze (error on the side of caution and use MORE glycol rather than less) – 1/3 glycol to water is fine for most types – so one gallon glycol and 2 gallons of distilled – for 3 gallons total (or more depending on the size of the cooler with will house the coils and you glycol mix).

Pros- You can make a very large reservoir (large cooler). Large AC units can have good BTU ratings but the small ones are less efficient than a built for purpose chiller. You have them all ready – so inexpensive.

Cons- You have to build them. They can look great if you put the effort in but usually they look shitey and take up more room. They do not seem to react as quickly, that will depend on the A/C unit and it’s ratings – usually not an issue depending heat load and ambient. If you are not careful with the coils they can break.

https://www.youtube.com/watch?v=HBrrVwvuAQE