Author: Matt Del Fiacco

Cooler fermentation temperatures are generally believed to result in cleaner beer that displays less yeast derived characteristics, allowing other ingredients to play a more central role. The clean and crisp flavor profile of most lager styles is accepted as being largely a function of cool fermentation temperature, as it’s said to suppress the development of esters and phenols often found in ales.

We’ve explored the impact of fermentation temperature quite extensively, more than any other single variable, and the results of those xBmts have been pretty fascinating. While we’ve tended to focus mostly on traditional lager strains, we have completed a few xBmts using ale yeasts, though each one was aimed at exploring the impact of warmer fermentation temperatures. With so many xBmts calling into question lager fermentation dogma, I became curious about how ale yeast would fair when fermented cooler than recommended.

I’ve heard reports from a number of brewers that the popular “Chico” strain has a tendency to throw off peach-like esters when fermented too cool. For the person who doesn’t have a temperature controlled space to ferment in and wants to produce a clean American-style ale during the cooler months, this can pose an issue, as such characteristics may not be desired. Of course, that’s only if it actually makes a difference, which is what I aimed to find out in this xBmt!

| PURPOSE |

To examine the differences between two beers fermented with a popular clean ale yeast at either 68°F/19°C or 50°F/10°C.

| METHODS |

In order to make sure nothing interfered with the variable being tested, I went with a simple American Blonde Ale recipe for this xBmt.

Out In The Elements

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 29.7 IBUs | 4.2 SRM | 1.050 | 1.012 | 5.1 % |

| Actuals | 1.05 | 1.012 | 5.0 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pale Malt, Maris Otter | 9.25 lbs | 90.24 |

| Vienna Malt (Weyermann) | 1 lbs | 9.76 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Pekko | 7 g | 30 min | Boil | Pellet | 15 |

| Pekko | 11 g | 15 min | Boil | Pellet | 15 |

| Pekko | 25 g | 5 min | Boil | Pellet | 15 |

| Pekko | 25 g | 3 days | Dry Hop | Pellet | 15 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Flagship (A07) | Imperial Yeast | 75% | 60°F - 72°F |

Notes

| Water Profile: Ca 80 | Mg 2 | Na 10 | SO4 125 | Cl 62 |

Download

| Download this recipe's BeerXML file |

Given the vast difference in fermentation temperature, pitch rate was a factor when designing this xBmt. After consulting with the crew, and considering the results of prior pitch rate xBmts, it was determined both batches would be pitch at a hybrid rate of approximately 1 million cells per mL per °P. A few days before brewing, I made a starter of Imperial Yeast A07 Flagship, which the manufacturer recommends fermenting at 60°F/16°C or warmer.

On brew day, I gathered my RO water, adjusted it to my desired profile, and set the controllers to heat it to strike temperature.

While the water was heating, I weighed out and milled the grains.

Once strike temperature was reached, I added the grains, stirring gently to incorporate, then turned the recirculation pump on before checking to ensure each batch hit my target mash temperature.

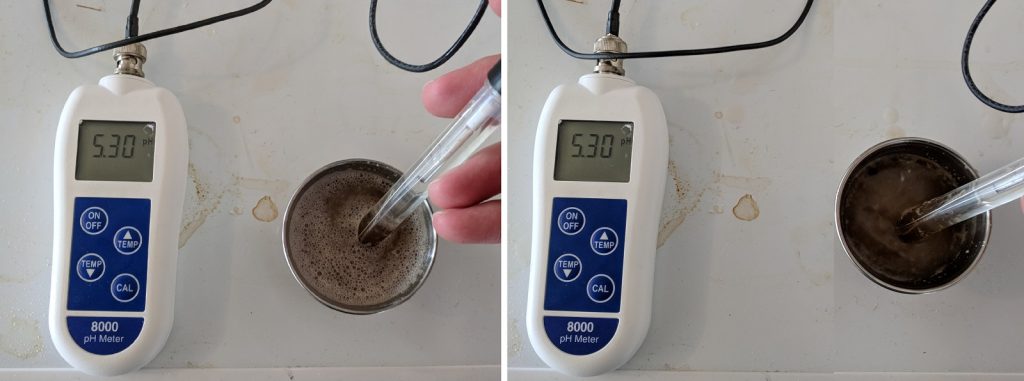

I took pH readings 15 minutes into each mash that confirmed both hit my expected 5.3 pH.

After each 60 minute mash rest, I removed the grains and let them drip into the kettle while the wort was being heated.

While waiting for the wort to reac a boil, I measured out the kettle hop additions for each batch.

The worts were boiled for 60 minutes with hops added per the recipe.

When the boils were complete, I quickly chilled them with my CFC, filling each fermentor with an identical amount of wort.

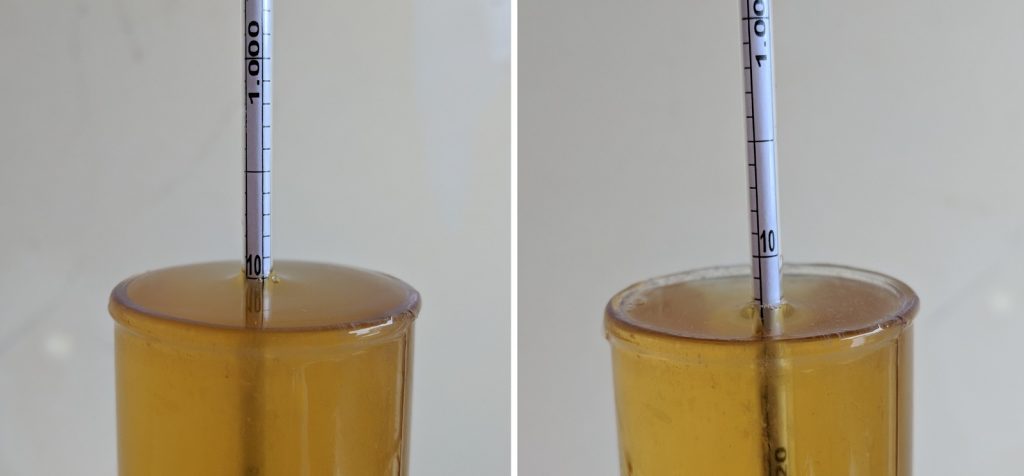

The filled fementors were placed in separate fermentation chambers where they were left to finish chilling to their respective fermentation temperatures. Hydrometer measurements at this point showed both worts achieved the same expected OG.

It took a few hours for both worts to stabilize at their set fermentation temperatures, after which I them with similar doses of pure oxygen then split the yeast equally between each wort. Insulated temperature probes were attached to the sides of each fermentor and the controllers were set to maintain the beers at either 68°F/19°C or 50°F/10°C.

Within a few hours, the warm ferment beer was bubbling away while the cool ferment batch was showing no signs of activity. Thankfully, my worries were quelled when I found the cool ferment beer actively fermenting the following morning. Out of curiosity, I took hydrometer measurements 7 days into fermentation, as activity in the warm ferment batch had dropped off. At 1.011 SG, the warm ferment beer was nearly done, though the 1.016 SG of the cool ferment beer indicated it still had a ways to go. With both beers showing no signs of fermentation after 8 more days, I took another set of hydrometer measurements showing a slight difference in FG.

I proceeded with transferring the beers into CO2 purged kegs.

The filled kegs were placed in my cool keezer and burst carbonated overnight. After a week of lagering, both beers were carbonated and ready to serve!

| RESULTS |

A total of 20 people of varying levels of experience participated in this xBmt. Each participant was served 1 sample of the beer fermented at ale temperature and 2 samples beer fermented at lager temperature in different colored opaque cups then asked to identify the unique sample. At this sample size, 11 tasters (p<0.05) would have had to identify the unique sample in order to reach statistical significance, which is exactly how many were able to do so (p=0.038), indicating participants in this xBmt could reliably distinguish a Blonde Ale fermented at 68°F/20°C with Imperial Yeast A07 Flagship, said to be sourced from Sierra Nevada, from one fermented at 50°F/10°C.

The 11 participants who made the accurate selection on the triangle test were instructed to complete a brief preference survey comparing only the beers that were different. A total of 6 tasters reported preferring the beer fermented warm, 3 said they liked the beer fermented cool more, and 2 tasters reported having no preference despite perceiving a difference.

My Impressions: Out of the 5 semi-blind triangle tests I attempted myself, I selected the odd-beer-out a mere 2 times, which is pretty much inline with random guessing. This despite knowing the variable and feeling confident I’d be able to tell them apart when tasting hydrometer samples. Ultimately, the finished beers tasted the same to me, both were very clean with a bready malt character and a great tea-like herbal quality that was balanced nicely by subtle spicy note from the hops.

| DISCUSSION |

Traditional lager yeast seems to have developed a reputation for being rather fickle, quick to throw off undesirable, or at the very least, stylistically incompatible esters if fermented even slightly warmer than recommended. While there are some who swear that tiny changes in fermentation temperature when using ale yeasts has an appreciable impact, I think it’s fair to say most brewers view S. Cerevisiae as being at least somewhat more robust than its lager yeast counterpart.

Looking at all of the fermentation temperature xBmts together, it appears the opposite might actually be true. We’ve demonstrated numerous times that beers fermented cool with certain lager strains are indistinguishable from warm fermented versions, while similar xBmts with ale yeasts have come back significant. And the fact participants in the present xBmt were capable of telling apart a Blonde Ale fermented at 50°F/10°C from one fermented at 68°F/20°C supports this notion.

In conversations with tasters following completion of the survey, those who were correct frequently cited the aroma as being the giveaway, though their descriptions were opposite of what one might expect. The beer fermented cool was generally noted as being less clean than the warm fermented beer, in which a number of tasters perceived bready and floral notes in.

While the results weren’t terribly surprising to me, I found it very interesting that the ale yeast performed so well at such a cool temperature, as I’d always believed it would struggle in such conditions. Despite the fact I was unable to distinguish the beers in this xBmt when participants could, I have no plans to start fermenting my ales at lager temperatures, though if I didn’t have the controls I do, I’d certainly worry a little less about my beer if it dropped colder than planned during fermentation.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

19 thoughts on “exBEERiment | Fermentation Temperature: Imperial Yeast A07 Flagship A Blonde Ale”

Maybe I’m missing something, but how can you ferment wort at 50° when the recommended temp range only goes down to 60°? Ideally, the yeast would drop out before fermentation was finished.

The Chico strain is very tolerant of low temperatures and doesn’t drop out, but other ale yeasts, especially English ones, might stall and give up.

In theory, you’re correct. If you take a look at the article the cool fermented beer did end up having a slightly higher finishing gravity than the warm fermented beer. So it may have dropped out towards the tail end of fermentation, but at least in this batch the flagship yeast was able to ferment fairly well!

I’ve found manufacturer recommendations to be completely weird. The recommendation for WLP530 is between 66 and 72, but Westvleteren ferments with that yeast into the low 80s. I’ve done the same with a dubbel and it tasted great. I think the yeast companies must gauge their temperature recommendations in some way that isn’t analogous to real brewing conditions.

Was there any peach flavour in the cool-ferment beer? I’m wondering if that flaw is imaginary, like “grassy” flavours from hops.

Grassy hop flavor is not imaginary. It’s often subdued by other hop flavor, but in some highly hopped beer you’ll taste it.

I personally didn’t really notice any peach flavors, but seems like there are a lot of anecdotal reports of perceiving it. The expectation could for sure influence that perception, but I’m not ready to rule it out based on this one xbmt.

I can confirm I got a very distinct peach ester out of US-05 at 58’F

My last batch with us-05 was VERY peachy, undrinkable really. I probably under pitched and fermented cool though. I haven’t used that strain since.

I did a split batch brew with US 05 and Wyeast 1056 fermented at 65 degrees. The 05 had a very noticeable peach flavor and the 1056 did not have that flavor. 80% of my non brewing family members selected the 05 beer as being different in my informal triangle tests. I could easy taste the difference.

I was a total skeptic about the peach in 05 but after the test I’ve stopped using it.

I had similar results this past fall fermenting with US-05 at cooler basement temps ( ~58F – 60F ) … way too many peach / banana flavors for my liking, and they never seemed to clean up or mellow out.

Now that it’s a little warmer I’m giving it another shot, and hope to bottle that batch today. Oddly enough I don’t recall any major off flavors or other problems from fermenting at 70F or above, as I did constantly last summer.

Similar experience using US 05 vs Wyeast German Ale….

Nottingham ale yeast ferments very clean at 60°F

Id suspect that the cold fermented beer would have a higher amount a diacytyl if a diacytyl rest was not performed as it often is when fermenting at lager yeast temps. Did you do a diacytyl rest with the cold fermentation batch? If not, this may have led a difference in the perception of taste in the 2 beers

I would be very curious to see this repeated with a variety of ale yeast strains. Is it possible the lagering process, which has to do with creating an environment preferable to specific strains, is outdated? Is our yeast selection process good enough that we no longer need to discourage certain bacteria from participating? As the discussion describes, lager yeast strains seem to be unaffected by *temperature* at large, whereas ale yeasts seem to react to it, or die out at low temps in my experience.

I also have had peach at low temps (63) with 05, confirmed by my homebrew club. But the current batch also fermented cool (61) with 05 has no peach. Two differences: the current batch started warmer, and had a higher pitch rate, 11g in 3gal. If I have to ferment cool, I’ll pitch more yeast.

Opinions on the beer itself? I’ve been looking a recipe the uses solely Pekko hops, and wel…

After this experiment and the previous WLP 800 experiment with little difference between 50F v. 66F fermentation temps, I wonder if we should start upping the lager fermentation temperature a bit, say to about 56-60F, rather than the traditional 49-50F? Less lag time, more robust/healthier yeast, perhaps less sulfur? Maybe the cold fermentation historically was more out of necessity than intentional. I must add that my lager starters are at room temperature and they always get to full kreusen in less than 12 hours. I can’t say that for my 51F fermenting batches. Thoughts?

I like your blog, but it’s turning into one gigantic product placement advertisement. I get that you get free stuff for reviews, but don’t make it so obvious.