Author: Malcolm Frazer

As far as innovative homebrewing equipment goes, Ss Brewtech has been on the cutting edge for years, providing high quality stainless steel kettles, mash tuns, and fermentation vessels that are within most homebrewers’ reach. As manufacturers of professional brewing equipment as well, Ss Brewtech has struck a nice middle-ground with their higher end quasi-pro equipment, an area they really seem to shine.

Over the last few years, I’ve had the pleasure of using the Brewmaster Edition Chronical, an impressively tricked-out conical fermentor that’s essentially a small version of what a professional might use. As great as the unit is, its size puts a hamper on the ability to control fermentation temperature– it just doesn’t fit in typical refrigerator and chest freezer chambers. Being concerned with consistency and predictability, particularly when brewing exBEERiment beers, precise temperature control is important to me. I initially rigged up a convoluted system that pumped ice water through the coil in my Chronical, which worked quite well for ales, though it became unwieldy when fermenting 2 beers at the same time. It was also difficult to effectively ferment lagers at traditionally cool temperatures and cold crash.

After chatting with the folks from Ss Brewtech about chilling options, they offered to send me their new (at the time) Ss Glycol Chiller to use in exchange for an honest review. They explained it could be used to independently control the temperature for up to 4 fermenting beers at the same time and that it was powerful enough to effectively cold crash without any other form of chilling. Having previously used a glycol chiller that I’d built myself and ultimately ended up getting rid of, I was curious to see how this much nicer version would compare.

The product reviewed for this article was provided by the manufacturer in exchange for an honest review; no other compensation was provided. The opinions expressed in the article are solely those of the author and a concerted effort was made to approach the review from an unbiased perspective.

A simple explanation of how the Ss Glycol Chiller works– it has a self-contained refrigeration unit that keeps glycol stored in a reservoir at a consistent 28°F/-2°C. When the temperature of the beer gets too warm as measured by a controller, a pump turns on and sends cold glycol through the coils submersed in the beer in the fermentor. Once the beer drops back down to below the set-point, the pump turns off.

Assembly

Unfortunately, the delivery company had their way with my package and it arrived with some necessary parts broken. As expected, Ss Brewtech was quick to remedy the issue, and once the replacement parts arrived, I proceeded with what little assembly was required.

It’s not necessarily a tiny unit, but for what it does, I feel it has a reasonable footprint at 20″ W x 20″ D x 15″ H (51 cm x 51 cm x 38 cm), which integrates nicely into my homebrewery.

Usage & Build Quality

Based on my experience with the BME Chronicals, it’s obvious Ss Brewtech cares about quality, and they certainly proved as much with the Ss Glycol Chiller. With so many parts, I’ll provide a more detailed overview of the various components and connections of the chiller in this section.

The chiller relies on a 1/3 horsepower Tecumseh compressor to provide 2300 BTU per hour cooling capacity, which maintains an ample supply of consistently cold glycol.

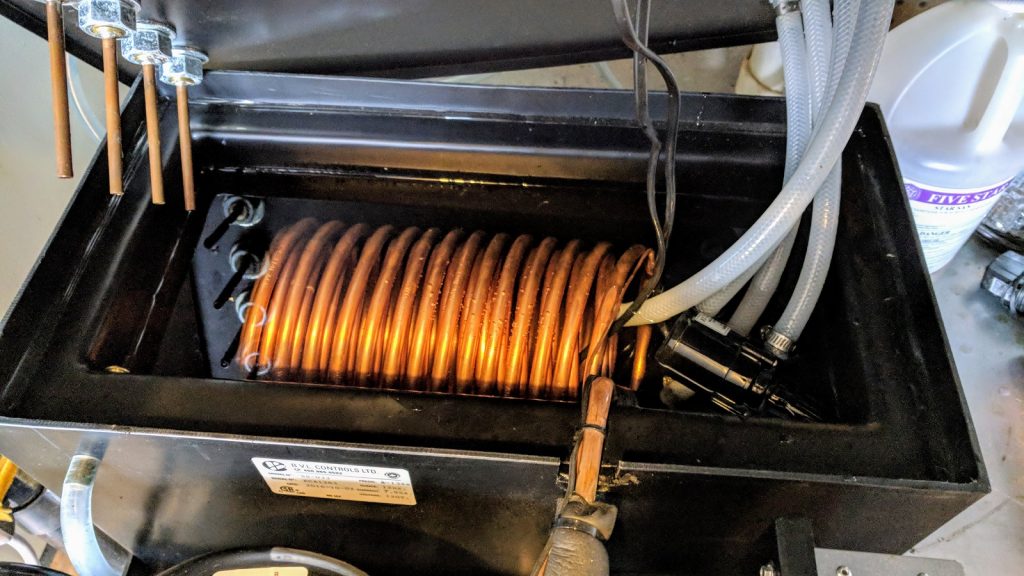

A solution of 1/3 propylene glycol and 2/3 water is placed in the 3 gallon reservoir and kept cold by a copper refrigerant line. Small pumps submersed in the glycol get independently activated when the temperature sensor in the particular beer they’re controlling indicates it’s warmer than desired.

A simple to use controller is used to regulate the temperature of the glycol solution that can be controlled to whatever temperature the user desires.

The reservoir cover has 4 plastic output ports on the right side, each one connected to a separate pump by tubing on the underside, as well as 4 brass ports on the left side that receives the used and thus warmer glycol solution, completing the closed loop.

I’m not sure why Ss went with plastic on one side and metal on the other, as outfitting the entire thing with metal barbs would improve durability. In fact, one of the broken pieces when I received the unit was a plastic barb, though I haven’t had any issues since repairing it.

A length of tubing extends from the out port to the chilling coil input on the fermentation vessel then more tubing is used to connect the chilling coil output to the return port on the chiller.

With everything connected, all that’s left to do is set one’s desired temperature on the controller regulating the beer, which for me is the Ss Brewtech FTSs, and the Ss Glycol Chiller will handle the rest.

Performance

Using the Ss Glycol Chiller in conjunction with the SS Brewtech FTSs, my fermenting beers consistently stay within 1°F/0.5°C of my desired temperature, regardless of whether I’m making a warm fermented ale or cool fermented lager. When the beer temperature gets too warm and the sensor triggers the glycol pump, it takes all of 1-2 minutes to chill it back down to where it needs to be.

In addition to maintaining fermentation temperature, there are some other things I use this unit for, such as chilling wort to pitching temperature. In the summer when my groundwater is warm, I’ll use the chiller to finish what my immersion chiller couldn’t. On many occasions, I’ve racked 90°F/32°C wort from my kettle to my fermentation vessel then used the glycol to chill it to 68°F/20°C in as little as 5 minutes. For lagers, another 5-10 minutes is all that’s necessary to bring the temperature down to 50°F/10°C. It’s pretty incredible. Actually, with the confidence I’ve gained in the system, I sometimes pitch when the wort is still warm, set my desired fermentation temperature, and walk away. Dangerous, I know. I am dangerous.

Of course, the glycol chiller also works great for post-fermentation lagering and cold crashing, reducing the beer from fermentation temperatures as warm as 68°F/20°C to 32°F/0°C in as little as 15 minutes, a far cry from the 2+ hours it takes in chest freezer chambers. And beers can be held at lager temperatures for as long as the brewer wishes prior to packaging, meaning it’s clear and all-but-carbonated when it comes time to package.

Ss Glycol Chiller Hacks

I like to be able to move my fermentation vessels around for cleaning and such, which was a bit of a hassle since the tubing to and from the glycol chiller was attached with hose clamps. My cheap yet effective solution to this was to install plastic quick disconnects between all tubing connecting the chiller to the fermentation vessel.

One option some people opt to do is wrap all of the tubing running between the chiller and fermentation vessel with foam insulation to reduce warming when the pump is running. This is particularly helpful when the chilling unit is farther away from the fermentor and requires longer supply lines, though with my current setup, I haven’t had to insulate and the chiller works great.

The insulation also helps keep the condensation formed during chilling from dripping off the tubes and forming puddles, which can lead to corrosion. It’s for this reason that I will be adding insulation soon.

| THE VERDICT |

My experience with the Ss Glycol Chiller over the last year has been nothing short of fantastic. In addition to its ease of use, reasonable footprint, sleek look, it reliably maintains fermentation temperature better than any other method I’ve used in my 20 years of homebrewing. While chest freezers and refrigerators work well for single batches, one of the most appealing things about the Ss Glycol Chiller is that it allows for fermentation of up to 4 batches at the same time at completely different temperatures– I can be make a Hefeweizen next to a Kölsch!

As with anything, there are certainly some drawbacks to this unit, the most obvious of which is cost. At $1,099.00, the Ss Glycol Chiller isn’t intended for the new brewer trying to figure out if the hobby is for them– this is a serious piece of equipment for serious brewers interested in upping their fermentation game. Another downside to this unit is that it is specifically designed to work seamlessly with Ss Brewtech FTSs compatible fermentation vessels, and while there are ways to retrofit it to work with other fermentors, the process can be a hassle and reduces much of the convenience. My last complaint is minor and has to due with the plastic glycol out ports, which are more susceptible to breaking than the brass input ports. I doubt I’ll end up ever breaking one, as I keep my chiller safely stored, but metal for all of the nozzles seems an easy way to reduce the risk such issues.

Overall, the Ss Glycol Chiller has met all of my cooling system demands– it’s reliable, requires little in the way of maintenance, and it works exactly as it’s supposed to. Yeah, it’s expensive, but I consider valuable the fact it allows me to independently control 4 fermentors at the same time, something no freezer or refrigerator chamber can do. It’s also small enough to fit on the bottom of my brew cart, freeing up the space taken up by other larger chambers. For the hardcore brewer who shares my obsession with precision and consistency, especially those already using Ss Brewtech fermentation vessels, the Ss Glycol Chiller is sure to be hit!

The Ss Brewtech Glycol Chiller can be purchased direct from the manufacturer.

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

35 thoughts on “Product Review | Ss Brewtech Glycol Chiller”

Nice review. It seems expensive, but if you are a really dedicated homebrewer with aspirations, this solution sounds great. It’s really great hiw efficient it is and how great it does in chilling to apropriate temperature.

On a side note: have you done an experiment where you would “investigate” the effects of too much yeast/hops in suspension in the final beer? The so called yeast/hop bite? I recently brewed a 4.6% Session IPA and although very good, it seems to differ whether I pour the sediment in the glass or leave it.

Nice review – i have one question though – can it raise the temp of the fermenting beer? I brew in my garage and ferment in a converted inkbird controlled fridge that has a tube heater in it. In the winter even the tube heater struggles to get the temp up to typical ale temps…

The FTSS has a cone shaped heating pad that slips in between the neoprene jacket and the fermenter. It’s controlled by the controller on the front of the conical (the blue number display in several pictures.

The FTSS kits have a heating option (small pad that sticks to the bottom of your vessel) so itll do that job.

Since it is not selled outside USA, i’m building a diy version of this glicol chiller to me. reading this article makes me feel i’m on the right path for my homebrewing needs. You can see pictures of my glycol chiller at @solariumpub on instagram. Thanks!

I’m curious how this is going for you?

Jake was so intrigued by Malcolm’s review, he ended up buying a Ss glycol chiller himself. They both regularly brag about it to the rest of the crew…

Love it. No complaints. Sure, it isn’t cheap, but that is a decision you make going in. I think it’s worth it.

Thanks for the review.

How is the noise level when the compressor is running and how frequently does it kick on when fermenting?

The noise level is similar to a couple loud computer fans or maybe a little louder than a chest freezer, but if the door to your brew area is closed it isn’t quite noticeable. If you keep the correct glycol/water ratio then the temperature in the reservoir will be more stable and the system will turn on less frequently (though the pump will be running whenever your fermenter needs to drop its temperature). I can’t say for certain how frequently it turns on, sorry.

Rob’s comment seems to align* with my experience.

The noise factor is not an issue for me because it resides in my garage, and if I’m in my garage, I usually have music on.

How often it cycles and the power consumption will depend on a number of factors – the ambient temperature, the number of fermentors*, what temp they are being held to, what point of fermentation they are in, whether or not the glycol lines and FVs are insulated and so on.

*edited for grammar

One thing I’ve struggled with is what if my garage gets too cool overnight and we need to warm the fermenting beer slightly? A two stage inkbird and seedling mat does that and a $1000 piece of equipment won’t. Is the solution to just keep your chronicals in a warmer place?

SS Brewtech also makes a heat-wrap for their conical fermenters that can be plugged into that temp control unit. It’s pretty much the same concept as an Inkbird controller with a seed mad, but just a little more purpose made for their equipment.

FTSs comes with a heating mat as well.

The FTSs 2 provides both heating and cooling.

The cooling is obviously via the above reviewed Ss Brewtech Gycol Chiller, and the heat can be provided via a cut to fit heating pad.

“further away from the fermentor “Further” indicates non-physical distance. “We were further apart on what to brew.” “Farther” indicates physical distant as in “far”. Yes, I am the Grammar Nazi :>) but I read your posts and just got my shipment of Brülosophy yeast. Keep up the great work!

Good catch, I will change it. Marshall will love this because he has a love for grammar-ing as well.

No matter how much he may claim NOT to be a grammar nazi, nothing could be further from the truth.

I recently took the plunge on the SS Glycol chiller and feel this review accurately (and fairly) covers the experience. My note here is for the incremental upgrade brewer: I didn’t get the BME a little over a year ago so when it came time to hook everything up I spent nearly as much on the unit buying compatible lids and coils.

Silicone is also another investment which might be overlooked: several pro-brewers and home brewers note that standard food grade plastic tubing gets brittle and breaks at or below freezing temps. I’m happy with my investment, but there’s probably another $500 in tubing and quick disconnects depending on the length of one’s runs.

Does it come with the ability to do four fermenters? Or are more accessories needed?

It will supply sufficient cooling for four fermenting vessels (FVs) of 5, 7, 14 gal, (1/2 BBL) size, or 3 1BBL FVs. You need either an FTSs, or to provide your own temperature controller and pump (which the controller would trigger upon reaching setpoint), for each FV.

Thanks. Seems identical to the Penguin 1/2hp glycol chiller but $200 more expensive.

https://www.penguinchillers.com/product/12-hp-glycol-chiller/

The Ss Brewtech has a 3 gal reservoir vs the Penguin’s 2 gal.

Otherwise that looks like a fine product as well but I have no experience with it.

The Penguin does have a 1/2 HP compressor compared to the 1/3 HP of the SS. What it lacks in reservoir capacity, it makes up for in BTU.

I’ve been eyeballing both of these chillers for a while. Eventually I’ll pull the trigger on one.

Thanks for the review.

It appears their 1/2 hp unit has a 2,650 BTU/hr heat removal, so it would be interesting to see if the reduced reservoir capacity is made up by the increased heat removal capability.

I suppose I could do the math based on the thermal capacity of 33% glycol solution at 28 degrees Fahrenheit, maybe later if I get bored.

Great review! I’ve been on the fence about adding this and some chronicals to my brewery. My biggest concern is having the wort in the middle of the coil in the fermenter freezing when using glycol. Did you experience any of that during testing?

Not that I have been aware of. Some people have had an issue with not being able to get below 40F, and the matter has been addressed via Ss Brewtech’s FAQ link on the Chiller page.

In essence, they believe that if you’re moving from a much warmer temperature, i.e., an ale fermentation of 68 F, and then just crank it down to ~ 35 F, having 28 F glycol move through the coil may cause localized icing, thus insulation, reduction of cooling ability.

I had not experience that, perhaps because I typically moved the beer temperature down in steps.

I have a 14 gallon Chronical and a 7 gallon Brewbucket, both with the temperature control systems. I researched the topic of glycol quite a bit and ended up buying mine from, Penguin Chillers. https://www.penguinchillers.com/product/12-hp-glycol-chiller/

This was the glycol chiller that SS Brewtech used to recommend before it sold its own unit. It has more horsepower and is $899. I also bought the US Plastic’s quick connect adapters.

I love this system. You can’t go wrong buying SS Brewtech equipment. I love their tanks and accessories, but I thought I would pass along this tip if a few hundred dollars matters to others as much as me.

I absolutely love Ss Brewtech and the equipment that they sell: I use their Chronical, brew kettle, and insulated MLT: all are some of the best brewing investments that I’ve made so far. I loved the idea of this chiller when it came out….but the price point was just a bit too high for me. About a year ago I decided to make my own chiller using a window A/C unit, which cost roughly $200. It has completely changed my beers (making a huge difference with my lagers in particular). I have a YouTube video showing the chiller I made, if anyone is interested: https://youtube.com/watch?v=zxdydeDxyf4

Hey Malcolm – It looks like you may have addressed this in an earlier post but I just wanted to confirm. I have two Ss buckets but also have a Spike conical and an Anvil bucket fermenter. The latter two companies offer similar cooling systems with a jacket, controller, pump, etc. Would/do these other systems work with the Ss glycol chiller as well? Both have smaller pumps included in their setups

Thanks in advance and Cheers

Mike

Yop. It’s just a matter of getting the right fittings. Any system that can be powered on or off via a temp probe and pumps glycol should work.

Is it loud? Want to know how suitable this is to have in the living room as I have a flat.

Pardon for the late reply. When they chiller compressor turns on it can be a bit noisy.

For cleaning after each fermentation, I’ve been completely disassembling my 7 gallon Chronicals. The only part I hate is pulling the tubing from the glycol chiller off of the coil. I use the plastic quick disconnects but that doesn’t address this problem of course. I tried soft silicone tubing (which does pull off easier) but it kinked badly off of the barb fitting of the coil. There’s probably some super simple solution for this someone is using. Anyone?

I use these (~ $20) from https://www.freshwatersystems.com and they work great for quick disconnects:

– DPCD22006 Valved In-Line Hose Barb Coupling Insert 3/8 ID Barb

– DPCD17006 Valved In-Line Hose Barb Panel Mount Coupling Body 3/8 ID Barb

Too bad SS has apparently discontinued the 1/3 HP model, now gotta go with the 3/8 HP (only have 3 FTSS’s to cool so a bit overkill).

Thanks for rsponding.