Matt has been homebrewing since 2011 and enjoys nothing more than waiting out the central Illinois winters with big, wood-aged beers. He is passionate about making wood-aging more accessible and exciting for homebrewers, and while his brewing tends to focus on high gravity styles, there is a soft spot in his heart for Czech lagers. Running on a “lagers forever” platform, Matt has served as the president of the Association of Bloomington-Normal brewers. Currently, Matt spends his club time bouncing around northern and central Illinois performing triangle tests and talking about brewing.

Matt has been homebrewing since 2011 and enjoys nothing more than waiting out the central Illinois winters with big, wood-aged beers. He is passionate about making wood-aging more accessible and exciting for homebrewers, and while his brewing tends to focus on high gravity styles, there is a soft spot in his heart for Czech lagers. Running on a “lagers forever” platform, Matt has served as the president of the Association of Bloomington-Normal brewers. Currently, Matt spends his club time bouncing around northern and central Illinois performing triangle tests and talking about brewing.

| ABOUT MATT |

How did you get into brewing?

My college roommate and I were really into J.R.R. Tolkien and we had tossed around the idea of making our own mead. Nothing really came of that, but the thought of making my own alcohol was something that stuck with me. After several months, I saw a Mr. Beer kit on sale and decided it would be fun to at least give it a shot. The rest really cascaded out of control from there.

What was your first batch and how did it turn out?

I made my very first batch using a “Mexican Cerveza” Mr. Beer kit that came with a can of pre-hopped extract with a packet of dry yeast taped to the lid. It made one gallon of beer. I thought it turned out really well. It was light, fairly bland, and accessible. Not an incredible beer, but it got me hooked on the hobby. To be totally honest, I’ve made worse beers since that first one.

How did you get involved with Brülosophy?

I was a moderator of the Homebrewing subreddit, which is an awesome community that I still really care about. That’s where I was introduced to Brülosophy and eventually developed a relationship with Marshall. I’m a writer who blogged at To Brew a Beer and also wrote articles for other brewing outlets. Loving what Brülosophy was up to (as well as the people behind it), I couldn’t pass up the opportunity when Marshall brought up the idea of me joining the crew. In addition to motivating me to learn more about brewing, being a contributor would give me the opportunity to visit more homebrew clubs and meet more homebrewers, which is great since the community is easily the most important part of this hobby for me.

What xBmt has surprised you the most?

Probably The Decoction Effect where Malcolm compared a beer brewed using a single infusion to one made with a triple decoction. Czech Pilsner is one of my favorite styles and are famously triple decocted. A lot of people with pretty solid credentials are adamant that decoctions make a huge difference in the final product, so I was really surprised when those results came back non-significant, more than any other xBmt. I would have thought temperature rests would have made a difference, let alone the fact that some of that grain got boiled three times. I’m not ready to totally ditch the idea of decoction, but man, that one surprised the hell out of me.

Have the xBmts influenced your current brewing perspectives?

I don’t think there is any way they couldn’t have. As a result of the xBmts, I’m less likely to recommend specific practices to new brewers as being “required,” things like yeast starters, fermentation temperature control, etc. I still do those things, of course, and I think there is a fair degree of insurance in a lot of our traditional practices, but I love to see more accessibility and approachability for new brewers, in terms of both process and community. I like to see people comfortable with approaching the conversation.

What are your 3 favorite styles of beer?

Imperial Stout

While I enjoy having a couple pints of lighter beer styles per drinking session, my natural drinking inclination is to nurse a beer. Big, bold Imperial Stouts are at the top of my list of favorite styles. I love the range of interpretation, the layers of flavor, and the overall experience of an Imperial Stout.

Czech Pilsner

No story or history, I just straight up love this style! You could call Pilsner Urquell my gateway lager, but really I just love this style because I love it. Light, refreshing, and full of delicious Saaz hop character.

Scottish Heavy

Scottish beers have a special place in my heart from both my time abroad and my own brewing research. The history of both the style as well as the people who brew them is captivating. I love the full flavor with a bit of sweetness I get from Scottish Heavy, and it also happens to be a rare style of beer my wife enjoys, so sharing that together is something I really value.

What are your favorite ingredients?

Malt: Pale Ale malt

Without a doubt, Pale Ale malt is my go to base malt. I brew a lot of ale and tend to prefer malty styles, so having something that can impart rich flavors all on its own while also supporting specialty malts is key to me. That said, I love trying new varieties and blends too.

Hops: Czech Saaz

I don’t usually go out of my way for hoppy styles, but it’s hard to resist the floral character from a big dose of Czech Saaz. It’s a defining ingredient of one of my favorite styles and it blends incredibly well with other hops. The defined but subtle notes from the hop make it perfect.

Yeast: Imperial Yeast A31 Tartan

Purportedly source from McEwan’s Brewery in Edinburgh, Scotland, this is my favorite currently available yeast. It has an incredibly wide fermentation temperature tolerance and fits in a wide variety of styles. It’s noted as being more or less expressive depending on factors like pitch rate and fermentation temperature, but I’ve found it to be a clean yeast that leaves behind some body and sweet malt character without being cloying. Imperial A31 is the closest thing I have to a house ale yeast.

What’s your desert island beer?

It might not be so enjoyable in the heat of a desert island, but my favorite beer is Ten Fidy, an imperial stout from Oskar Blues. It’s not the best Imperial Stout I’ve ever had (Dosvidanya from Destihl holds that title for me), but it’s a beer I’m always thrilled is around. Ten Fidy is a heavy, balanced Imperial Stout that leans into its roast with a sharp bitter chocolate note. And it’s accessible at my local liquor stores throughout the year, which is a huge plus. Oskar Blues also has a barrel-aged version of Ten Fidy that’s fantastic!

What music do you listen to while brewing?

I start my brew days pretty early te leave time on the weekends to spend with family and friends, so I’m usually not in the mood for anything fast paced. My favorite band is The Classic Crime, though lately I’ve been really in to Nahko and Medicine for the People and Vocal Few. If it’s a later brew day though, I’ll usually be listening to something like Motion City Soundtrack, Fall Out Boy, or Rise Against. No shame.

I’m also an avid fan of audiobooks and podcasts. I’m currently listening to the Chronicles of the Unhewn Throne series, which I enjoy in the same way I imagine my wife enjoys Gossip Girl. For podcasts, I swap between a few depending on my mood, but often find myself listening to Lore, Hardcore History, or Criminal.

What else do you enjoy doing besides brewing?

Outside of brewing, I spend most of my time reading or playing video games. I’m really involved in my day-to-day work as a user experience specialist, which means a lot of research and synthesis. I’m a huge fantasy and sci-fi buff, so along with every other fantasy fan in the world, I’m currently waiting on the last Gentlemen Bastards and Kingkiller Chronicles books to be released. My video game tastes are really similar– I’m currently playing through a heavily modded version of The Elder Scrolls III: Morrowind.

My less nerdy hobbies include making hot sauce, cooking, and spending time with my wife and dog.

If you could go back, what brewing advice would you give yourself?

Simplify your shit! When I was a new brewer, I’d meet people with 5 pumps and 3-tier systems, all with inline oxygen and the like. It was overwhelming, but I also had aspirations for something similar. Now, I find myself looking for ways to cut additional moving parts out of my system.

| BREWING GEAR & PROCESS |

After my first Mr. Beer kit batch, I jumped to brewing all grain using a Coleman cooler and a Brew Bag fabric filter coupled with a propane burner and kettle for the boil. This worked great for several years and I was really happy with the quality of my beer. I eventually moved to a single vessel BIAB system that used a new burner, a pump for recirculation, and a Brew Bag fabric filter with false bottom. My current system is a BräuSupply Unibräu all-in-one electric brewing system that relies on two 1600 watt heating elements for heating liquor and wort.

Similar to BIAB, the Unibräu uses a stainless steel basket in place of a bag for lautering. The simplicity and consistency of this systems is very appealing to me, I can’t see myself transitioning away from it and have no qualms recommending it to others!

Pre-Brew Preparation

After designing a recipe in BeerSmith, I shift my focus to water. The tap water in my town changes throughout the year and isn’t really ideal for brewing as is. I plan to spend some time identifying the different profiles throughout the year via Ward Labs reports and a TDS meter, but for now I buy all of my RO water from the store and adjust with minerals. I determined the water chemistry adjustments to make using the Bru’n Water Spreadsheet then weigh out my mineral additions using a precision scale.

With the adjusted water heating in the kettle, I prepare the grains for the mash. I don’t have a ton of space in my townhouse, so I typically keep only 2 base malts on hand, Pale Ale and Pilsner, which are stored in Vittles Vaults.

I use an UltraShip Digital Shipping scale to weigh out my grains.

When the water is close to strike temperature, I mill my grain with a Cereal Killer mill directly into the Unibräu’s stainless steel filter basket.

I make a starter in some form or another for nearly every brew day. For beers that are around or over 1.080 OG, I’ll make a starter a few days beforehand to bump up the cell count. Once the starter is done fermenting, I crash, decant, then make a vitality starter on brew day. For smaller beers, I usually make vitality starters from a single pack of Imperial Yeast.

Brewing

I typical get started the night before brewing by measuring out the total volume of RO water I need and adding it to the kettles. I use the Unibräu v2 that utilizes two 1600W stainless steel elements, so I also check to ensure all of my plugs and extension cords are good to go. It makes for a much easier brew day in the morning when I can just wake up, plug things in, and do other work while the water is heating to strike temperature.

When the strike water is to the right temperature, I mash in by lowering the grain baskets into the kettle. I then gently stir the mash with a large whisk until no dough balls are present. Once mashed in, I turn on the recirculation pump to ensure consistent temperature throughout the duration of the mash. On the inlet valve at the top of my kettle is attached a length of Loc-Line, which affords me some control over the flow of the wort.

At this point, I check the temperature of the mash with my Thermapen Mk4 thermometer to make sure everything is going as planned.

During the mash rest, I weigh out my hop additions.

I usually mash for 60 minutes, less for Short & Shoddy batches, sometimes more for bigger beers or when I’m step mashing. When mash rest is finished, I raise the grain basket out of the kettle then place it on the Unibräu’s built-in catch and let the wort continue draining into the kettle.

At this point, I beginning heating the wort by setting the controller to boil mode and adding the additional element to the wort. It takes about 20 minutes for the wort to reach a boil, which is when I usually add the bittering hop addition.

When the boil is finished and I’ve cut the heat, I pump the wort through an exCHILLerator MAXX counterflow chiller directly into a sanitized fermentor.

For the most part, I use corny kegs to ferment in, which means I’m usually brewing 4.5 gallon batches. Once filled with chilled wort, I place the fermentation keg in my temperature controlled chamber and attach a blowoff assembly to the gas post.

If my groundwater isn’t cool enough to chill the wort to my desired pitching temperature, I’ll leave it in the chamber until it drops. For beers of about 1.080 OG or higher, I dose the wort with pure oxygen prior to pitching yeast, a step I generally skip for smaller beers.

With the yeast pitched, I close up the fermentation chamber and clean my brewery.

Packaging

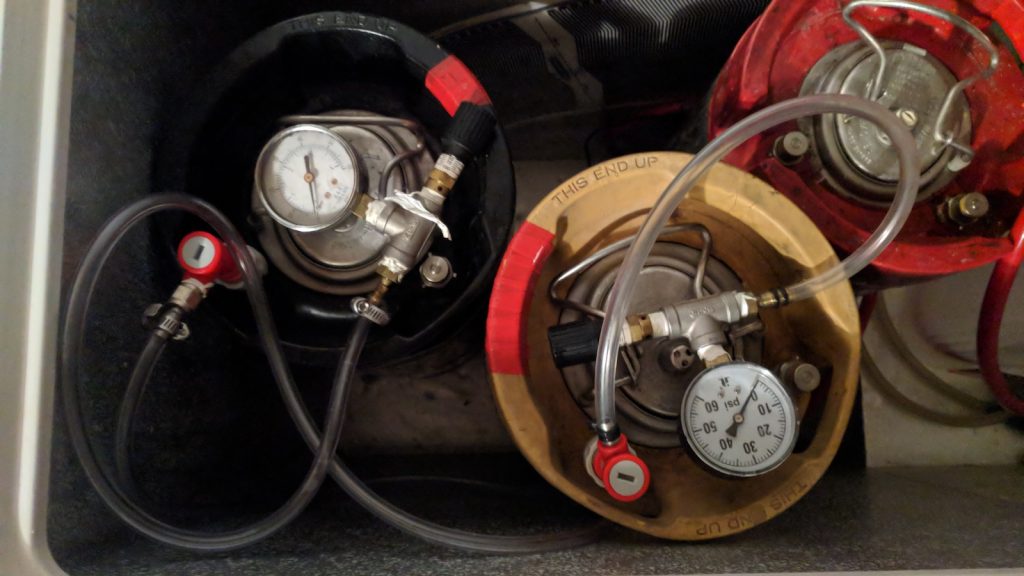

Depending on my timeline and the style of beer, I’ll choose 1 of 2 packaging methods. My preferred method is spunding, which involves racking beer that isn’t completely done fermenting to a clean serving keg.

I then attach a spunding valve and allow the yeast to finish their job under about 10 psi, which carbonates the beer at the same time.

Alternatively, I force carbonate. When the beer is done fermenting, I remove the gas disconnect and cold crash for a few days, often fining with gelatin. After a couple days, I transfer the cold beer to a serving keg that was purged with CO2 via pushing sanitizer out with gas. The filled keg is then placed in my kegerator 30 psi of CO2 for a brief period of burst carbonation, after which I reduced to serving pressure and let it condition until it’s ready to serve.

Serving

I have a small kegerator that fits 2 corny kegs, though only has a single product tower with a Perlick 630SS faucet. As such, I tend to reserve the faucet for personal beers and use picnic taps to serve xBmt beers, to keep things consistent.

When taking beer out of the house for data collection or family gatherings, I use 1 liter swing top bottles that I fill with a Blichmann beer gun, which allows me to purge the vessels with CO2 prior to filling.

Cleaning & Sanitation

I probably go a little overboard with cleaning in my brewery, but my system has a lot of moving parts that I like to know are well taken care of. Immediately after brewing, I rinse the kettle out with water then fill it with Powdered Brewery Wash (PBW) before kicking the heating elements on and letting the solution recirculate. After 15 minutes or so of recirculation, I rinse the kettle before filling it again with fresh water that I bring to a boil to run through my exCHILLerator CFC.

I boil all of my tubing, rubber, and anything else that can withstand the heat. Everything else gets rinsed, cleaned with PBW, and rinsed again. I completely disassemble my fermentation kegs for a good cleaning after every batch, while my serving kegs get such treatment every 3 or so batches.

I use Star San for my day-to-day sanitizer and always keep a 5 gallon solution on hand as well as a spray bottle for spot sanitizing.

Contact Matt via email at matt@beerconnoisseur.local and feel free to leave any questions in the comments section below! A regularly updated version of Matt’s process and gear can be found on his contributor page.

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support Us page for details on how you can very easily do so. Thanks!

11 thoughts on “Brülosophy Contributor Spotlight: Matt Del Fiacco”

Great read on your process, Matt! One question: How long does it usually take you from start to finish on brew day?

I am a BIAB brewer who is thinking of making the leap to electric, but with so many moving parts, it seems like just more to clean and assemble/disassemble.

The convenience of electric though is what draws me to it. As a husband and a father of 3, I also start in the wee hours of the morning. Being able to time your water and wake up to it ready to go would be super awesome.

Hey Bryan, thanks!

Jut as an alternative, you should check out the Hot Rod heating element. You could use that and a controller to heat your water and have it ready to go in the morning, without necessarily making the full jump to electric.

So, one of the downsides is that there are a lot of moving parts. Which isn’t a problem in and of itself, but it definitely adds to my cleaning time. If I don’t include cleaning time, I can finish a brew day in three hours if I’m runnning both elements on the kettle. An hour mash, an hour boil, and an hour for ramp times + chilling + rest, etc.

Including cleaning, we’re looking at closer to four or five hours depending on how much I do at a given time. I clean the kettles immediately on brew day, but some other stuff (mostly organization) falls to the side.

Thanks for the reply!

That was kind of what I was thinking once cleaning was factored into play. An extra hour isn’t terrible with all of those moving parts, but I’ve got things down to a similar scale in terms of time (roughly 3 hours from start to finish with maybe another 15 minutes after for cleaning up, but I always clean things and store them as I move throughout the brew day which saves me some time).

I know I’ve seen the Hot Rod heating element on here before, and thanks for bringing that up. Will definitely look into that, as the time it could save would be totally worth it!

This reads a little oddly:

Do you mean involves racking beer that still is not completely done fermenting?

Great catch David, thanks! That is what I meant.

You may go overboard with cleaning in your brewery, but you sure don’t go overboard with cleaning that kegerator! Good lord man, grab a cloth.

Ha you’re telling me! I mentioned in another comment, the brewing system and everything involved in the actual beer production are cleaned meticulously on brew day. Other stuff, like organization and counter tops? Happens less often. Needs to happen more.

Good luck with your wait on that Kingkiller Chronicle book! Have you gotten into The Stormlight Archive at all? Brandon Sanderson is nothing if not prolific.

Also – thanks for the introduction… I really like all of your contributions to the site!

Preach.

I haven’t! I actually own the first two as audio books. I just bought the first Robin Hob book, The Assassin’s Apprentice. Interesting so far. But I’m planning on starting that series soon.

I instantly got hooked onto Sanderson and he has a huge back catalog – most of which takes place in the same universe. Pretty great stuff. I’ll have to check out The Assassin’s Apprentice after I finish the 1248 page third installment of The Stormlight Archive. It’s a tome!

I love your point about simplicity. I’m actually in the process of building a small batch BIAB system out of a 6 gallon pot and one pump (similar to yours). I plan on 3 gal batches so I can brew more often and try more things. I would love to go full electric but don’t want to spend the money on the controller. I will use gas heat for now but was thinking about using an induction cooktop to do controlled step mashes and infusion mashes. Any thoughts or experience with induction cooktops?