Author: Marshall Schott

If only one style of beer were responsible for the craft beer boom, a beer so deliciously unique that it captured the palates of the otherwise uninterested, India Pale Ale would have to be it. An oft cited tale is that George Hodgson created the hoppy and relatively high alcohol IPA in order to survive the trip From England to India, though as Mitch Steele points out in his definitive guide on the style, the historical evidence seems to suggest India was actually receiving standard pale beer. In fact, what we think of as IPA today appears to be the product of myriad iterations by numerous brewers over the last couple centuries, no doubt spurred by the entry of beers from other English breweries into the Indian market, namely Allsopp’s from Burton-on-Trent, a region known for its high sulfate water.

The history of IPA is fascinating and I heartily recommend Mitch’s book for anyone who enjoys digging into style origins, but a history lesson this is not. Suffice to say, the baton has been passed by the brewers of yore to those of today as evidenced by various sub-types of this style that come in all colors and, nowadays, levels of opacity. But before all these adjectives came to be, there was the not-so-humble American IPA, which the BJCP describes as follows:

A decidedly hoppy and bitter, moderately strong American pale ale, showcasing modern American or New World hop varieties. The balance is hop forward, with a clean fermentation profile, dryish finish, and clean, supporting malt allowing a creative range of hop character to shine through.

Inspired by the likes of Sierra Nevada, Firestone-Walker, and Stone Brewery, homebrewers the world over began crafting their own versions of IPA using techniques picked up from the pros. Having produced many delicious batches myself using conventional methods over the years, I was curious to see what would happen by taking a shorter and shoddier approach to brewing an IPA!

| BREWING THE BEER |

It’d been awhile since I had a standard, clear American IPA on tap, so I went with a tried-and-true recipe I’ve done well in competitions with, Lil Slack IPA, making some modifications due to the hops I had on hand.

Short & Shoddy American IPA

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 20 min | 52.3 IBUs | 8.6 SRM | 1.062 | 1.017 | 6.0 % |

| Actuals | 1.062 | 1.014 | 6.3 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pale Ale Malt (Muntons) | 12 lbs | 81.36 |

| Munich Malt (Muntons) | 2 lbs | 13.56 |

| Honey Malt (Gambrinus) | 12 oz | 5.08 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Galaxy | 19 g | 20 min | First Wort | Pellet | 18.1 |

| Citra | 30 g | 5 min | Boil | Pellet | 13.8 |

| Galaxy | 30 g | 5 min | Boil | Pellet | 18.1 |

| Simcoe | 30 g | 5 min | Boil | Pellet | 13.1 |

| Citra | 30 g | 3 days | Dry Hop | Pellet | 13.8 |

| Galaxy | 30 g | 3 days | Dry Hop | Pellet | 18.1 |

| Simcoe | 30 g | 3 days | Dry Hop | Pellet | 13.1 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Pub (A09) | Imperial Yeast | 72% | 64°F - 70°F |

Notes

| Water Profile: palm full of gypsum, 1/3 palm full of calcium chloride |

Download

| Download this recipe's BeerXML file |

The night before brewing, I collected the water for this full volume BIAB batch, forgoing the use of the filter I usually use. Chlorine levels are generally pretty low in my tap water and my city doesn’t use chloramines.

While the water was flowing, I poured a good pile of gypsum in my measuring palm then added what appeared to be about 25% that amount of calcium chloride.

Once the water was collected and the minerals added, I dropped my heat stick into the kettle and set the timer to turn on a couple hours before I planned to brew the next day.

Next, I measured out and milled the grains.

I got to brewing the following morning around 8:25 AM, after dropping my kids off at school, joined by a couple curious friends. Jersey mashed in by dropping the bag of grains into the pre-heated strike water then giving it a gentle stir.

I didn’t pay attention to the strike temperature recommendations in BeerSmith, instead relying on my own experience brewing hundreds of batches. I usually mash this beer at 150°F/66°C and came in a tad warmer than that, which still isn’t bad seeing as I was shooting from the hip.

After a brief 20 minute mash rest, the grains were removed from the kettle and allowed to drip while the wort began heating.

It took about 20 minutes for the wort to reach a boil on this cool morning, and when it did, I immediately tossed in my immersion chiller to sanitize then my buddy CJ helped out by adding the kettle hop additions.

Following the brief 20 minute boil, I quickly chilled the wort to 72°F/22°C, which was about 6°F/3°C warmer than the temperature of my groundwater at the time.

Without allowing any time for the trub to settle, I transferred 5.5 gallons/21 liters of wort to my sanitized Brew Bucket.

A refractometer reading at this time showed the wort had reached a very respectable 15.1 °P, or 1.062 OG.

I moved the wort filled fermentor to my fermentation chamber and pitched a can of Imperial Yeast A09 Pub directly into it while it was still warm. It was 10:30 AM for a total brew day length of 2 hours and 5 minutes, another 8 minutes if you count the time it took to clean my Brew Bag and kettle.

The weather had been pretty cool and I was concerned the temperature in my chamber might be too cool for this English yeast, but I decided not to use any form of heating; while likely unnecessary, the controller was set to cool at 74°F/23°C, just above the temperature of the starting wort. I put the airlock in place and walked away.

Despite pitching less than the recommended number of yeast cells due to forgoing a starter, I noticed activity just 12 hours later. A check of the temperature strip the following morning showed the beer was hovering right around 67°F/19°C, indicating it cooled a bit before fermentation kicked off while exothermic heat had maintained a pretty solid temperature for this strain.

At 4 days into fermentation, I added the hefty dry hop charge, which I left in the beer for 2 more days before returning to take a hydrometer measurement showing FG per BeerSmith had been reached.

I planned to take another FG reading the following night and keg if it was unchanged, but then I realized I could make this beer even shoddier by letting it sit on the large dry hop charge for another week, which some believe can lead to grassy flavors. After 8 more days, 14 total since brewing, I kegged the beer, opting to skip my typical cold crash and gelatin fining process.

The filled keg was placed in my cool keezer, the headspace was purged with CO2 a few times, and it was left to chill for about 16 hours before I attached high pressure gas to burst carbonate. After 22 hours at 35 psi, I reduced the gas to serving pressure and let it condition another 4 days before sampling. The first few pints had quite a bit of hop particulate floating around, likely due to skipping the cold crash, but after another couple days, it was pouring quite nice.

| METHOD |

Participants, all blind to the brewing methods used, were served samples of the beer in standard clear taster glasses then asked to focus on its appearance, aroma, flavor, and mouthfeel. Each participant completed a brief survey in a relatively quiet setting after being instructed not to interact with others while evaluating the beer.

| RESULTS |

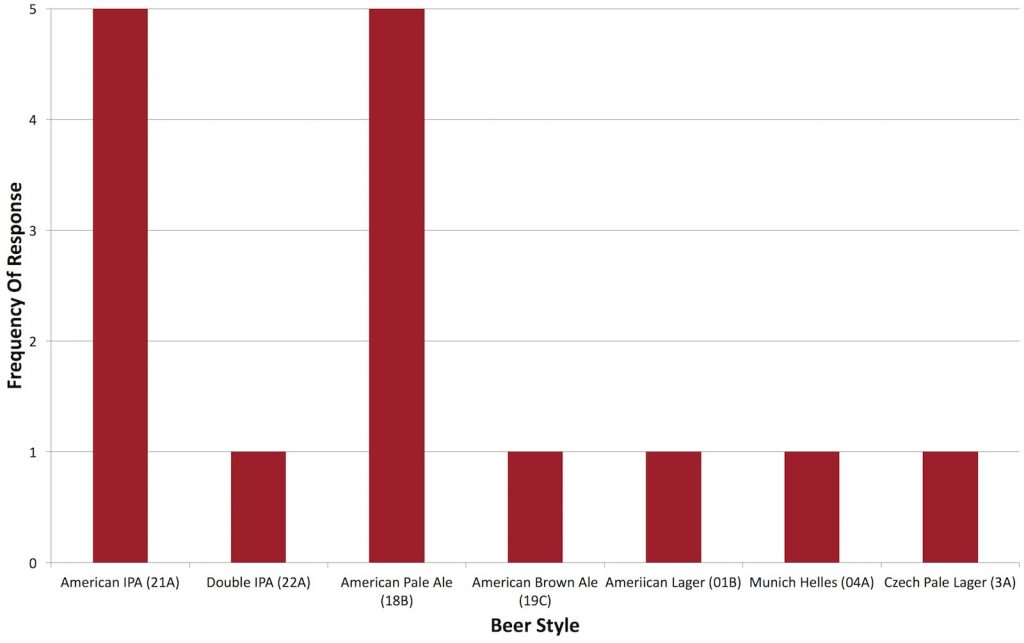

A total of 15 people of various levels of experience participated in this Short & Shoddy evaluation. Participants were first asked to write-in the style they believed the beer to be based on their perception.

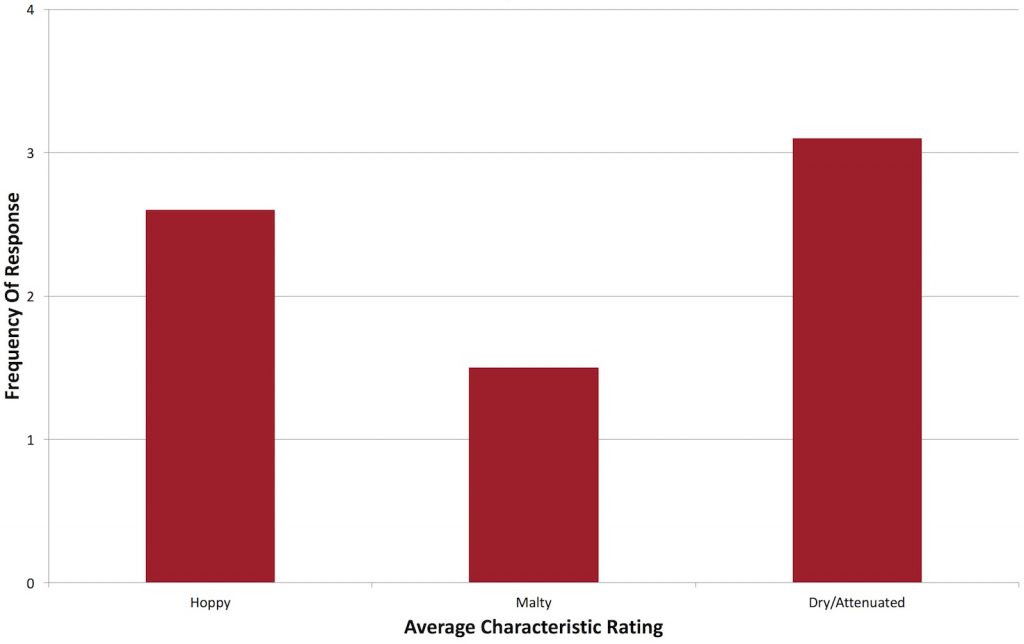

Tasters were then instructed to rate how hoppy, malty, and dry they perceived the beer to be on a 0-5 scale where a rating of 0 indicated “not at all” and 5 indicated “extremely;” these ratings were then averaged.

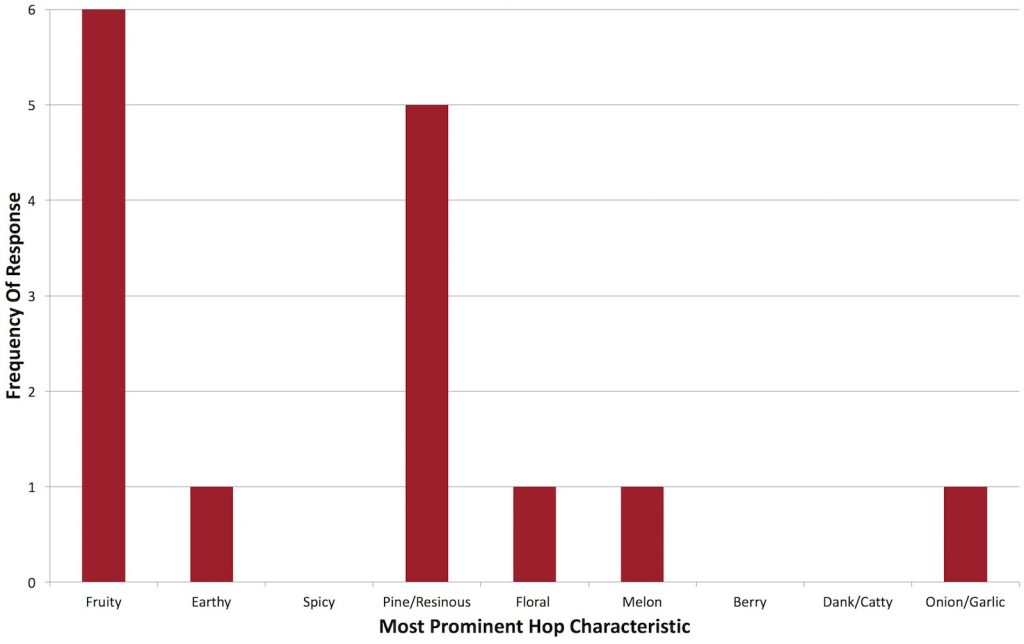

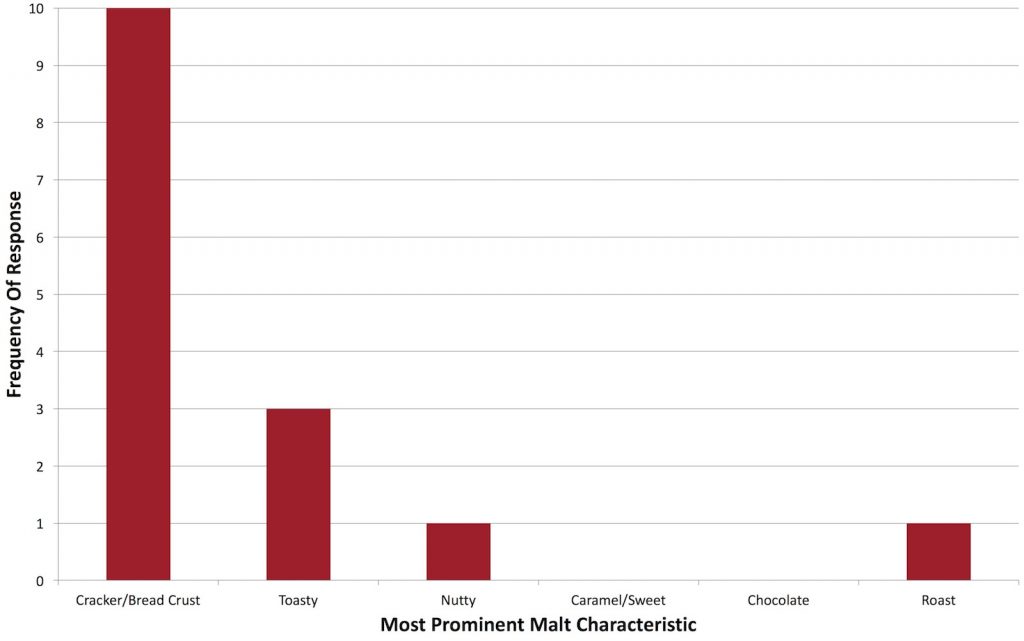

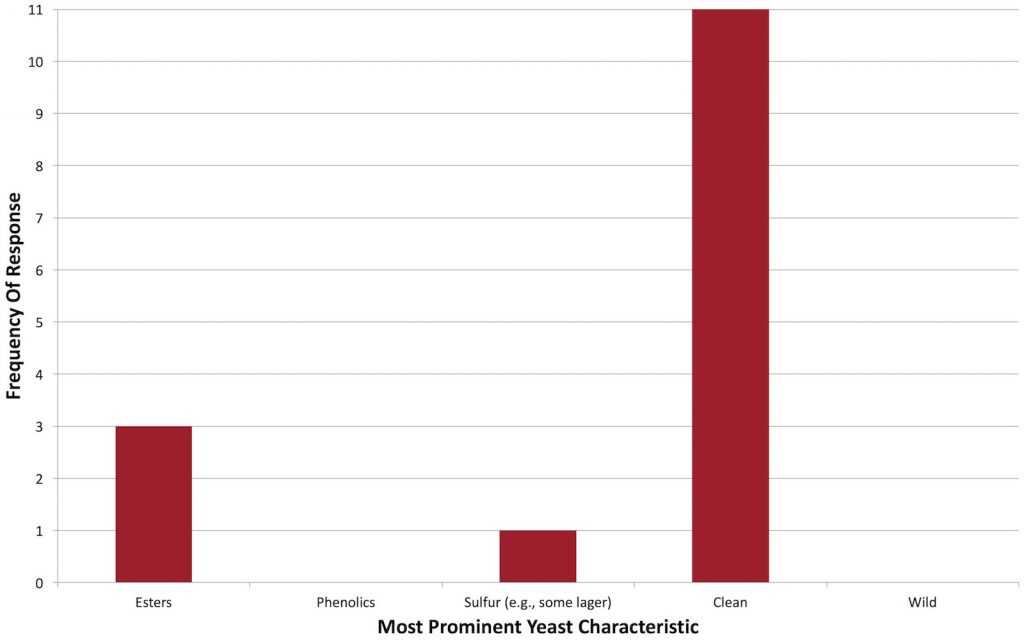

Tasters were provided a list of common hop, malt, and yeast characteristics then instructed to select from each the one they perceived as being strongest in the beer.

Hop Characteristics

Malt Characteristics

Yeast Characteristics

Next, participants were asked to indicate whether or not they detected any off-flavors in the beer; those who did were provided a list of common off-flavors and instructed to select the one they perceived as being strongest. Out of the 15 participants, not a single one felt the beer possessed any off-flavors.

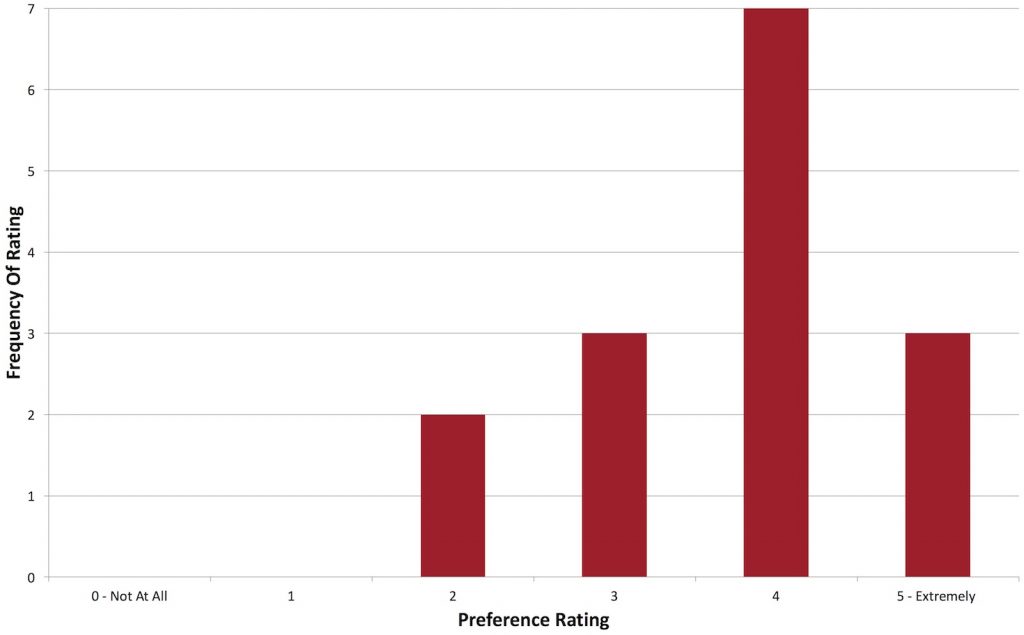

Tasters were then asked to rate how much they enjoyed the beer on a 0-5 scale where 0 indicated they hated it and 5 indicated they loved it.

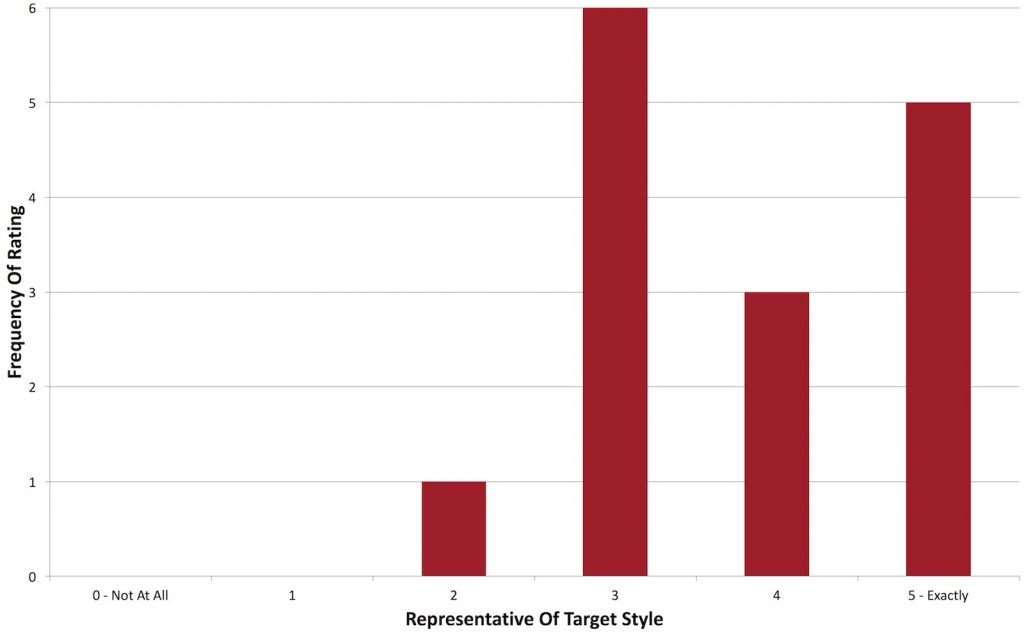

Finally, the beer style was revealed to participants and they were asked to rate how representative it was on a 0-5 scale where 0 meant “not at all” and 5 meant “extremely.”

My Impressions: I hadn’t had a standard, clear American IPA on tap in a long time, so I was really excited for this beer, and it largely lived up to expectations. I chose to ferment it with Imperial Yeast A09 Pub, purportedly Fullers strain, because that’s what I’ve heard Firestone Walker uses for Union Jack, which I love. I definitely got a strong tropical fruit aroma from this beer with notes of citrus and stone fruit in the background, characteristics that might be easily mistaken for esters, which I wasn’t personally picking up. The low-medium body helped to balance the touch of Honey malt with the hop flavor, which I perceived as being fruit-forward with a noticeable piney note, reminiscent of an IPA I might have ordered 3 years ago. Exactly what I was going for!

| CONCLUSION |

There are a number of issues one might expect to be present in an American IPA mashed for 20 minutes with unfiltered tap water, boiled for 20 minutes, pitched warm with a lower than recommended cell count of a notably characteristic English yeast strain, and left on dry hops for over a week. The fact not a single participant noted creamed corn, grassy, medicinal, or any other off-flavors is pretty surprising, providing even more compelling evidence certain conventional brewing methods may not necessarily be required to produce tasty beer.

The 2 hours I spent making this IPA was no less enjoyable than my longer brew days, in fact I liked having a couple more hours to take care of other responsibilities. Having successfully brewed a number of nice beers using Short & Shoddy methods, I find myself questioning more and more the veracity of the methods developed decades ago when it comes to modern brewing. This has nothing to do with a lack of respect for those giants upon whose shoulders we stand, rather I’m of the opinion ignoring modern advancements in brewing science and technology halts the great work started by those who came before us.

I absolutely and unashamedly plan to brew more beers of various styles using Short & Shoddy methods, it’s such an easy way to make a delicious batch of beer in about the same time it takes to brew up an extract batch. It’s true that nobody noted any off-flavors in this IPA, but filtering tap water is too easy not to do and gives me some security. While my tastes have evolved a bit and I’d likely leave out the Munich malt in future batches, this Short & Shoddy American IPA was pretty damn great, not only meeting my expectations, but surpassing them.

If you have thoughts about this Short & Shoddy brew, please feel free to share in the comments section below!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support Us page for details on how you can very easily do so. Thanks!

33 thoughts on “Short & Shoddy | American IPA”

More than a quarter of the participants thought the beer was something other than an IPA or Pale? Wow.

Yeah, man, blind evaluation is more difficult than many think!

I wouldn’t really consider it meaningful, how many folks in your peer group, of non brewers can readily identify a beer or wine to style with a blind tasting,

I’m not sure I’d consider terribly meaningful regardless of whose peer group was involved. It’s interesting wresting though. Remember that study where sommeliers were unable to determine a red wine from a white wine when they were blindfolded? Blind evaluation ain’t as easy as people think!

Reminds me of a simple american style pils I did for a company picnic last summer. About 1.040, 15 IBU, maybe 1/4 or 1/2 oz Saaz late hopping. Very mild. One of the patrons, a lover of dark beers and craft beers, took a drink and exclaimed, “ahh, a good hoppy ale, I love it” or something like that. I held my tongue, but I noticed others disagreeing with their expressions. I didn’t tell him what the beer was, and served in opaque cups.

I’d love to see how these short and shotty brews do in competitions with actual judges, rather than the type of people that this this beer was a munich helles? Just food for thought. I’m sure they would do well, would just love to see the results.

That’s sorta what The Brü Club is about!

I’d love to see a competition where the judges weren’t told what they were judging and had to categorize the beer! I suspect there would be some unusual decisions. Jokes aside, from memory brulosophy found that the ability to detect the variable doesn’t correlate with experience.

This is absolutely awesome and makes me feel WAY more comfortable about the fact that sometimes I do things like only boil for 30 minutes instead of the usual 60 or even 90 minutes that I’ve read some brewers insist on.

Done that thing – didn’t like that the results – but there again I can identify brews by taste – though mostly i just brew to MY taste ! Am a bit of a super taster – ad not bad at creating recipies for food curries and sauces as well as beers to emulate stuff i have tasted without knowing what it is ..

You hit your predicted OG of 1.062? That’s a departure from your previous SaS batches, no?

I adjusted my efficiency based on prior batches and nailed it!

What was your efficiency?

But…what about DMS? And, what’s with the subjective, human, testers? I bet robots in a lab could pick up the DMS!

Possibly… or maybe not?

https://brulosophy.com/2015/10/08/update-lab-data-on-pils-malt-boil-length-exbeeriment/

I actually forgot about that experiment. So your lab guy is biased, too! Dammit Marshall, stop disproving the old wive’s tales! Some of us find comfort in them! And, what will become of brewing forum discussions if you take away most of the ammunition for the arguments? You really need to think about this. /sarc

Good experiment, as usual.

Have you found a way to make bad beer yet? So far you seem to be proving it isn’t possible. I wonder if ingredients have improved so much that less process control is required. Did you even aerate this batch? I’m about to switch back to stovetop extract brewing just to get an understanding of what is really required to make good beer.

Oh yeah:

https://brulosophy.com/2014/12/04/seeking-the-source-exbeeriment-results/

I’ve also not enjoyed a few hoppy beers, especially NEIPA, I’ve made that ended up taking on that purple/gray color after a few weeks in the keg.

I’ve had the purple thing over the past year too!! Any ideas why that happens?

Ideas, yes, but so not certain. We’re thinking it has to do with an interaction between manganese and oxygen.

Interesting…I think oxygen plays a role, too. Where do you think you’re getting manganese from?

Bottle this batch and see what happens.. (it’ll suck). I think the vast majority of the time when homebrewed IPAs suck, its because it was bottled/bottle conditioned/not kegged. There’s a serious flavor thing that happens, it was like night and day when I started kegging.

Bottled vs kegged IPA sounds like a good experiment.

Would be great.

In the next IPA/APA/Blonde/Cream, I will give it a try by sure.

Moreover, I’m waiting for a review about the stopper suck airlock product.

Great work Marshall! I will be doing this in the future! I’m always looking for shortcuts with kids and work life’s too short to spent so much time making beer when we could spend it “Drinking Beer”! I love the addition of the Hanna digital refractometer. I have a Milwaukee Instruments one btw. I’m going to try and do a short and shoddy NEIPA someday soon! Hey no need for cold crash or fining with it anyway. No muss no fuss. Cheers from Sydney Mate.

I’m surprised that you did no oxygenation.

For one, I don’t ever oxygenate and it hasn’t been an issue in hundreds of batches. We’ve also done some xBmts showing it doesn’t make an appreciable difference. But mostly, that would be very Short & Shoddy!

🙂

I never oxygenate either. I never have issues with fermentation starting. I use the Speidel fermenters and there is so much headspace (lots of air) there is no need to.

When I ussd carboys, I never had problems either.

Always great stuff Marshall – thanks so much. Do you account for the additional volume or lack of with the shorter boil at all? I’m struggling with getting volumes right in Beersmith these days for some reason and a shorter boil must (?) lead to a greater volume?

Thanks as always – genius..

Gav

Hey Gavin! When I change the boil time in BeerSmith, it automatically reduces the volume of liquor suggested for a 60 minute boil based on my boil off rate and other equipment settings. So yeah, I do adjust for it, but just by changing the boil time.

Thanks for the response Marshall – I was not aware this option was there but I’ll check it out. More BeerSmith education – its a great tool.

Gavin – Marshall did a few videos on using BeerSmith – very helpful and worth checking out.

https://www.youtube.com/watch?v=QmW7pwQP5mQ