Author: Matt Del Fiacco

Brewers commonly boil wort for between 60 and 90 minutes depending on the base malt used, though some opt for even longer boils to encourage Maillard reactions that are believed to add depth of malt character and a darker color in the final beer. Those craving the full, rich, caramel flavors found in styles like Barleywine or Scottish-style ale have been known to boil wort for 2 hours or longer. In fact, on a recent trip to the famous Traquair House Brewery in Scotland, I learned most traditional Scottish breweries boil wort for about two hours in large copper kettles, which is contrary to the popular belief they boil down their wort over a much longer period of time.

I’m passionate about Scottish-style ale and brew them fairly often, so learning that the quintessential deep flavors they’re known for are achieved with but a mere 2 hour boil was pretty surprising, especially given the typically simple grainbills. It’s possible the use of copper kettles plays a role, as their high conductivity may lead to a stronger Maillard reaction. However, considering the non-significant results of prior xBmts on boil length, I became interested in the impact an extended boil has on beer and put it to the test!

| PURPOSE |

To evaluate the differences between a 60 minute boil and 180 minute boil in otherwise similar beers.

| METHODS |

For this xbmt, I went with a somewhat paler version of a Scottish Heavy recipe I’ve been tweaking for quite some time.

Òrain

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5 gal | 60 min | 16.3 IBUs | 5.7 SRM | 1.040 | 1.011 | 3.8 % |

| Actuals | 1.04 | 1.012 | 3.7 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Golden Promise (Simpsons) | 7.187 lbs | 96.64 |

| Crystal, Medium (Simpsons) | 4 oz | 3.36 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| East Kent Goldings (EKG) | 22 g | 60 min | Boil | Pellet | 5 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Tartan (A31) | Imperial Yeast | 73% | 65°F - 70°F |

Notes

| Water Profile: Ca 50 | Mg 5 | Na 5 | SO4 44 | Cl 70 |

Download

| Download this recipe's BeerXML file |

I got starter of Imperial Organic A31 Tartan yeast going almost a few day ahead of time.

I started my brew day by collecting the full volume of brewing liquor for both batches, making sure to account for boil off rate so both batches would end up with the same OG. After adjusting each to my desired profile, I turned on the heat.

While the water was heating, I weighed out and milled the grains for each batch.

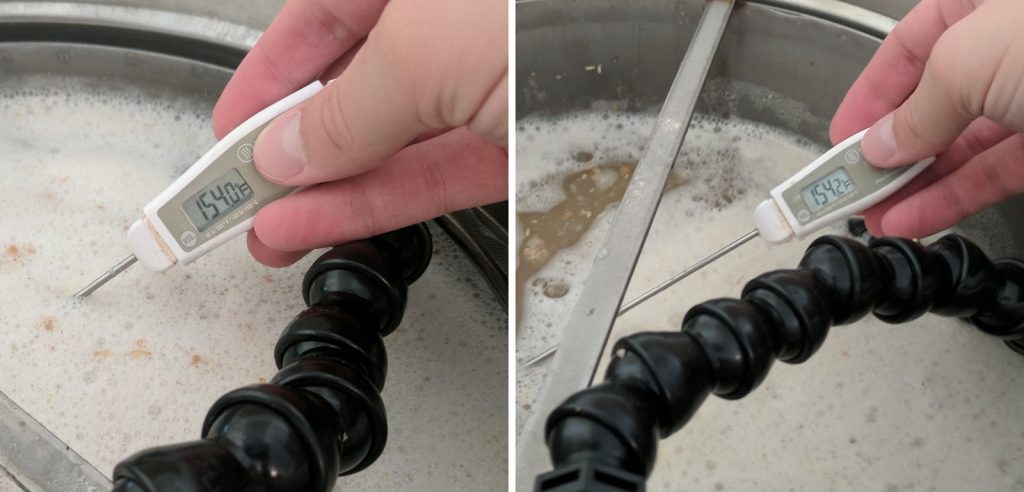

Once strike temperature was reached, I incorporated the grains and gently stirred before making sure both hit my intended mash temperature.

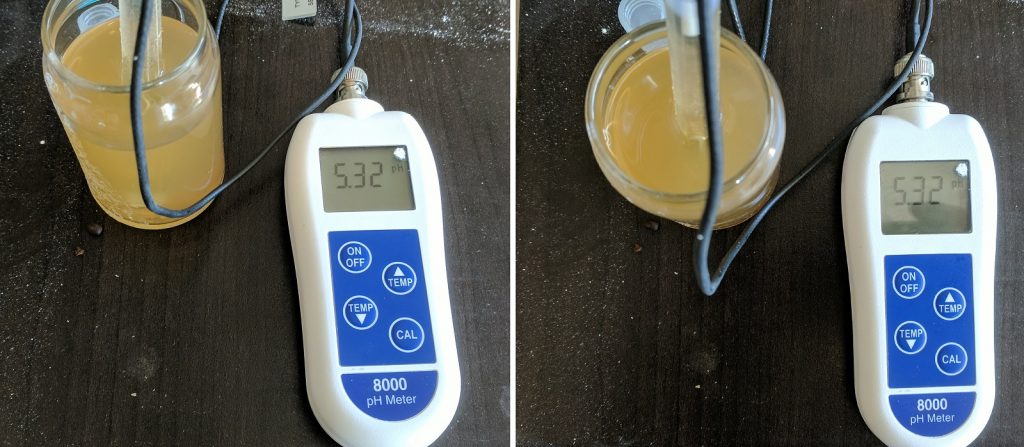

I took pH readings 15 minutes into each mash and found both were right where I wanted them to be.

Once each mash was finished, I lifted the grains and let them drain until the proper volume was reached. I added the bittering hops to the 60 minute boil wort as soon as it reached a boil.

I added the bittering charge to the 180 minute boil batch after 2 hours of boiling, at which point the 60 minute boil batch was chilled and in the fermenter. At the completion of the boil, I chilled the wort using my CFC and racked it directly to a fermentation keg.

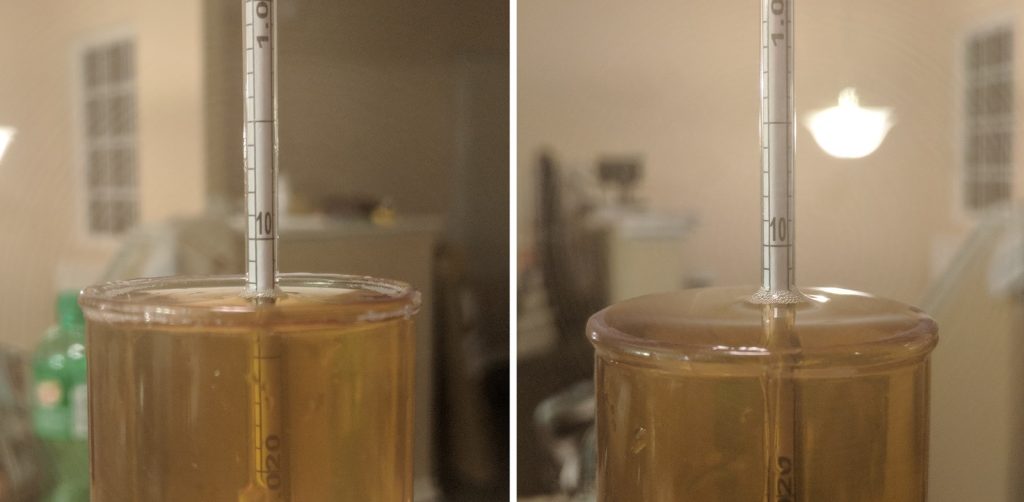

Hydrometer measurements revealed both worts hit my 1.040 OG target.

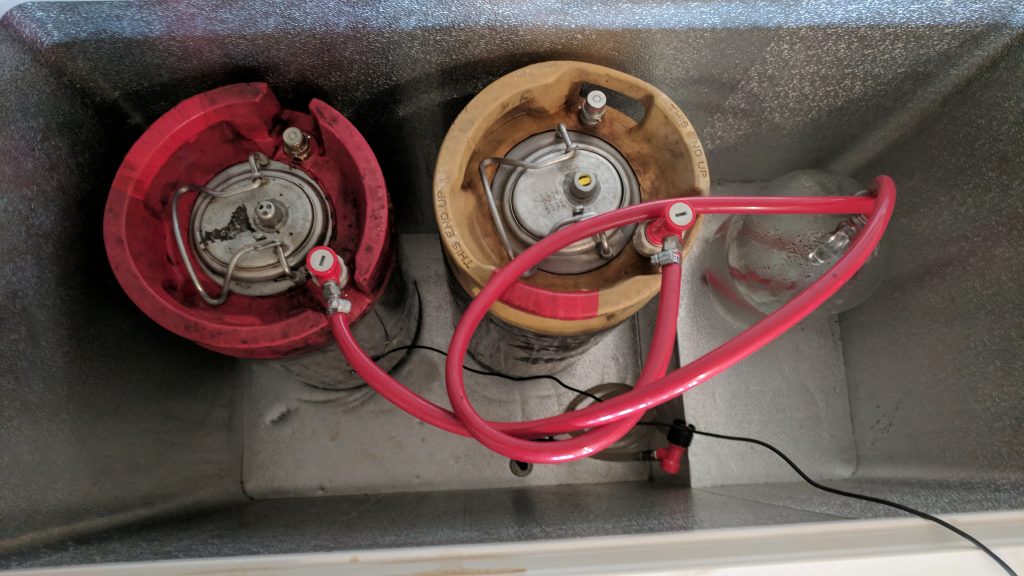

The worts were placed next to each other in the same temperature controlled chamber where they were left alone for a couple hours. Once both were sitting at my target fermentation temperature of 66°F/19°C, I split the yeast starter equally between then attached blowoff tubes.

Fermentation dwindled a week post-pitch and I let the beers sit a few more days to allow for clean-up of any off-flavors. Hydrometer measurements after 10 days showed both were sitting at the same 1.011 FG.

I cold crashed the beers and pressure transferred them to serving kegs before hitting them with a quick round of burst carbonation.

Following 2 weeks of conditioning in my kegerator, the beers were ready to serve to participants.

| RESULTS |

A panel of 22 people with varying degrees of experience participated in this xBmt. Each taster, blind to the variable being investigated, was served 2 samples of the 60 minute boil beer and 1 sample of the 180 minute boil beer in different colored opaque cups then instructed to select the unique sample. At this sample size, a total of 12 (p<0.05) correct selections would have been required to achieve statistical significance, while only 10 tasters (p=0.16) chose the different beer, indicating tasters were not able to reliably distinguish a Scottish Golden Ale made with a standard 60 minute boil from one made with an extended 180 minute boil.

My Impressions: In three blind triangle tests, I was able to select the odd-beer out twice, but I have to admit that I was largely guessing. I think that the 180-minute boil beer was slightly more crisp, but I honestly had an incredibly hard time telling these beers apart. They were identical, to my palate, in terms of of appearance, aroma, and flavor.

| DISCUSSION |

Brewers often discuss extending the boil length as a way to encourage Maillard reactions thereby imparting a deeper malt character and darker color to the finished beer. It made sense to me wort being in contact with heat longer could produce this effect and I admittedly expected the 180 minute boil beer to be perceptibly different than the 60 minute boil beer. Of course, this wasn’t the case, participants in this xBmt were unable to reliably distinguish one beer from the other, and my own biased performance was no better than theirs.

It would appear that when controlling for evaporation losses, length of the boil has minimal if any impact on overall beer character. It’s entirely likely that, given the same starting volume of liquor, a beer produced with a 180 minute boil would look and taste different than one boiled for only 60 minutes. However, the results of this xBmt along with those of prior xBmts on this variable seem to suggest any such differences would more than likely be a function of wort condensing due to evaporation loss than caramelization or Maillard reactions from a longer boil. While I’ll continue boiling as usual, this experience has inspired me to continue exploring the impact of boil length, particularly under unique conditions such as when a copper kettle or a more powerful heat source is used.

If you have thoughts about this xBmt, please feel free to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support Us page for details on how you can very easily do so. Thanks!

36 thoughts on “exBEERiment | Boil Length: 60 Minutes Vs. 180 Minutes In A Scottish Heavy”

What about a weird form of “kettle decoction” during the boil? Imagine taking, say, 10% of the kettle volume and boiling it separately – and aggressively – in a large frying pan or wok, reducing by at least a half, even down to an almost sauce-like richness? Then split the main kettle volume when done – and add the “kettle decoction” to one half. Ferment two batches and compare…

Surely? if there is anything to the Maillard process, this will make a noticeable difference?

Crazy – or ???

I do exactly this to achieve traditional decoction flavors in my pils with a fraction of time and effort. 25 min into mash i pull 1.2 gallons of wort and pressure boil for 30 minutes (250F @15psi) while i bump the rest of the mash to 158 F.

Supposedly Samuel Smith does this on some beers (I think Old Brewery Bitter)

Given that the temperatures needed to drive most maillard are well above boiling, this is not a surprising result.

Is there a listing of experiments indicating whether the outcome was significant or non-significant?

In a sense, yes. You can go to the xbmts page and sort by p-value. Anything under .05 is significant, it’s about 1/3 of xbmts.

Much obliged.

Next round is on me.

Pay attention because many “non-significant difference” lead us to a very significant result, as shown in experiments like “boil length 30min vs 60min”. This experiment was “non-significant” in differences between participants perception, suggesting a short boil as a feasible technique to brew.

I consider beermaking my hobby, and I love doing it, so I never cut corners to save time. I typically step mash, and it often takes over two hours. I always boil for 90 minutes. At this altitude, the water boils at 202 to 203F, so a 60 minute boil may not be enough…

Really interesting perspective! If you enjoy your beer and your process, that’s what matters. Like you said, it’s a hobby, enjoying your time and product is vital.

My water boils at 204 most days… I do 60 min boils with very good results. Wonder if there’s any possibility of a High Altitude vs Low Altitude exBEERment?

I wonder if _when_ you start heating the wort and the concentration of the sugar at first flame is more important. Just playing a guessing game here, but what if in a big brewery they turn on the heat (steam jacket? maybe direct fire?) as soon as there is enough wort from the lauter to cover the bottom of the kettle. This high gravity wort _could_ experience more temperature driven reactions as the rest of the wort is slowly sparged in over an hour or whatever it takes to get the sugar out of the grain.

That’s a possibility I’d love to explore more! I want to talk with more direct-fire breweries.

How did you get the same gravity in the 3 hour boiled beer? Did you add water back after the boil to get to the same volume as the 1 hour beer, or did you start with more wort at the beginning of the boil?

Option two, the volume of the 3-hour boil was initially greater than the 1 hour boil, and had been adjusted accordingly to account for the volume difference (pH mainly)

Some strong Scottish styles – such as Wee Heavy – recommend kettle caramelization – where you drain first gallon or so of first runnings and boil it vigorously to concentrate sugars, for maybe 15-20min, before adding the rest of the wort. I think this technique gives a very prominent butterscotch/toffee type flavor, but it may work best on high gravity wort (first runnings from my wee heavy is well over 1.100). I think the effect is weaker if you add all wort at once, and especially when using a relatively low gravity wort (1.040 or below).

So this is interesting to me, because the Traquair House brewery (and this is supported by the Noonan book Scotch Ales) actually doesn’t recommend boiling down. The “kettle caramelization” boil-down technique was (I believe) a homebrew method to try to account for the fact that direct-fire, copper kettles may caramelize the wort more than a stainless steel vessel.

It’s something I really want to try, because I think it would have an effect for sure, and it would be a really interesting “homebrew adaptation” to traditional methods (since copper kettles are so damn expensive).

“It’s possible the use of copper kettles plays a role, as their high conductivity may lead to a stronger Maillard reaction.”

It isn’t just heat conductivity, copper catalayzes maillard reactions allowing them to occur at lower temperatures. I think you may have hand waved this part of the experiment off too quickly.

That’s super interesting! Do you have any sources you can share? I’d love to read up on it.

Definitely didn’t mean to “hand-wave” the variable off at all, buying a copper kettle for this xbmt just wasn’t feasible. I keep my eye out at auctions and estate sales for an affordable one though. It’s definitely an xbmt I plan to repeat with different variables (boil vessel, boil intensity, etc), but I don’t think the lack of a copper kettle invalidates the context here. In fact, if anything, I think it points to the fact that maybe it IS the copper that causes a difference, if there is one.

But as always, single data point, single style, single system, all that jazz.

You don’t need a copper kettle. Just take your old copper immersion chiller and put it in the boil for the full time.

That’s definitely an idea, but I don’t think it would solve the problem. What we would be aiming for is the higher heat transfer of the metal, so it would need to be in direct contact with the fire on one side and the wort on the other. Its caramelization effectively. A wort chiller might add some micronutrients, but the heat would disperse just as evenly because of all the liquid.

Or cut some pieces of copper pipe and boil them in.

As a catalyst, the copper doesn’t need to be the part transferring the great, just in contact with the hot wort, if in fact it had an effect. The higher heat transfer would be a separate effect.

Very interested to see if kettle composition or btu’s epuldhave sn impact. As always interesting read

Could the design of the copper kettle affect Maillard/carmelization? My apple butter (and beer, soon) copper kettle has a rounded bottom, as does the kettle at Traquair House (according to brewery tour web page). Glass laboratory kettles I have used were all rounded, and set down into a rounded heating mantle which enveloped 50% of the kettle. Commercial brewing kettles seem to mostly have domed tops, as well. I am not an engineer, but it seems to me these factors would impact heat distribution/concentration.

Did the guys at the Scottish brewery you visited have any evidence about the benefits of a copper kettle? Had they tried stainless and noticed a difference in the final product?

Traquair House is an old brewery, and very proud of their heritage (as they should be). I didn’t get a chance to ask questions about the copper kettle correctly, but did get a chance about the “boil down”, which they are asked about often and are adamant is not a standard practice in Scottish brewing.

How was the beer? The recipe looks very authentic, though maybe bit low on bitterness.

I really enjoy it, and you’re correct that traditionally this bitterness would be a tad low. I’ve actually found the beer to be a bit more bitter than we assume, in Scotland at least. I also think the caramel malt would be a bit non standard, and there would be some roast malt for color.

But I loved it.

180 minute boil? My ADHD kicks in around 90 minutes. What about using a pressure cooker on your first runnings? I currently use “cara-” grains to get the caramelization I need.

Also, since we are discussing copper, the Augustiner brewery located in Austria uses an open air wort chilling process. Imagine dumping your hot wort on the floor then squeegeeing it into small opening to drip down a copper cooling ladder. I freaked when I first saw this then I remembered this: https://www.ncbi.nlm.nih.gov/pmc/articles/PMC3067274/

Caramelization of fructose happens at 110°C, but there is nearly no fructose in wort. Glucose caramelization happens at 160°C and that is not gonna happen a lot in wort.

I would propose the following experiment, however.

Take a simple malt like pilsner. Make two beers woth only difference being malt bill, one with 95% pils and 5% crystal/caramel 60-100 and another with 100% pils. Take 5% of the second beer wort and boil it separately in a pot or pan until the water is gone and you can actually have caramelization. Then add it to the rest of the wort and boil.

This way you can see two things. First if there is a difference in making your own caramelized wort or adding caramel malt (better than boiling longer or buying copper pots and whatnot, also useful for making SMaSH and if you dont have caramel malts at hand) and second, pinpoint flavours tat ocurr with caramelization of beer wort.

Those are my two cents at least

So, given the experiment was to try and enhance maltiness of the beer – what was the conclusion in this respect? Not to boil longer, but did you find any better / more successful ways to increase that flavour?

John Palmer and Jamil Zainasheff had a talk about the “kettle carmelization” perception, granted it was only a hypothetical discussion, on the Brew Strong podcast and they concluded that the attributes associated with “kettle carmelization” are attributed to the concentration of the wort by evaporation. They discounted the contribution of Maillard reactions on the basis that they start to occur at 280 – 330 F, where as the boiling point of water is 220 F so the temperature of the wort never reaches the lowest temperature required to induce Maillard reactions. They also pointed to the fact that most Maillard reactions take place in environments more deplete of water versus the abundance of water present in wort.

Something else about Maillard reactions which most discussions tend to forget: acidity inhibits Maillard reactions, and wort has a pH of around 5.2.

I wonder if there are some examples where mineral content comes into play here. For an extended boil you have 4 options:

1. Dilute the mash with source/adjusted water, preserving the mash pH/chemistry, but the increased volume leaves more mineral content in the final product.

2. Dilute the mash with RO, changing the mash pH/chemistry but preserving the final mineral content.

3. Dilute pre-boil with RO preserving mash chemistry but potentially changing boil chemistry.

4. Dilute post-boil with RO preserving boil chemistry and final mineral content.

5. Dilute pre or post boil with source water, preserving mash chemistry but increasing final minerals.

Perhaps in a style starting with a heavier malt forward mineral profile, the extended boil could make more of a difference.

More salt – more malt

I know it’s an old post but had a question. I understand experimentally controlling for hop contact time, but an argument would be that perhaps the long boil with the bittering hops in is the key. You could control for IBU by adjusting the hopping rate in the recipe maybe. Of course this assumes the real question here is “is the Scottish method different?”.. if it’s “what is the isolated true effect of boil time” then this experiment answers that question really well .. love your stuff!