Author: Matt Del Fiacco

Shock. Disbelief. Head scratching. All adequate descriptions of how I felt about prior xBmts showing participants were unable to distinguish lagers fermented warm from the same beers fermented cool with both WLP800 Pilsner Lager and Saflager W-34/70 yeasts. Conventional wisdom, which I admittedly accepted without question, has it that lagers require cooler fermentation temperatures in order to restrain ester development such that the resultant beer is clean and crisp, yet the results from the aforementioned xBmts suggest any differences caused by rather disparate fermentation temperatures weren’t large enough for tasters to reliably tell them apart.

Indeed, a follow-up xBmt designed to test the extremes by comparing beers fermented with Saflager W-34/70 at either 60˚F/16˚C or 82˚F/28˚C did return significant results, but only by a small margin, and surprisingly, a majority of tasters who got the triangle test correct preferred the warm fermented sample. After xBmt results suggested participants could reliably distinguish a beer fermented with WLP001 California Ale yeast from the same beer fermented with Safale US-05, I wondered if results from the aforementioned fermentation temperature xBmts using Saflager W-34/70 might be specific to that particular strain and not necessarily other versions said to be from the same source. Loaded with skepticism, I designed an xBmt to test out the impact fermentation temperature has on one of my favorite yeasts, Wyeast 2124 Bohemian Lager.

| PURPOSE |

To evaluate the differences between a lager fermented cool (48˚F/9˚C) and the same lager fermented warm (72˚F/22˚C) with Wyeast 2124 Bohemian Lager yeast.

| METHODS |

I wanted to use a recipe I’d brewed many times before and knew well for this xBmt, so I went with a house staple.

Na Zdravi Czech Premium Pale Lager

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 33.2 IBUs | 3.9 SRM | 1.047 | 1.011 | 4.7 % |

| Actuals | 1.047 | 1.013 | 4.5 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pilsner (Weyermann) | 8.75 lbs | 92.72 |

| Carafoam (Weyermann) | 4 oz | 2.65 |

| Carahell (Weyermann) | 4 oz | 2.65 |

| Melanoidin (Weyermann) | 3 oz | 1.99 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Saaz | 25 g | 60 min | Boil | Pellet | 4 |

| Saaz | 31 g | 30 min | Boil | Pellet | 4 |

| Saaz | 62 g | 15 min | Boil | Pellet | 4 |

| Saaz | 62 g | 0 min | Boil | Pellet | 4 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Bohemian Lager (2124) | Wyeast Labs | 71% | 48°F - 58°F |

Notes

| Water Profile: Yellow Balanced in Bru’n Water Spreadsheet |

Download

| Download this recipe's BeerXML file |

A few days before brewing, I made a single starter of a Wyeast 2124 Bohemian Lager yeast that I stepped up to ensure enough cells for two 5 gallon batches. At the start of my brew day, I set both eBIAB systems to heat the mash water, which I’d adjusted to my desired profile.

While the water was heating, I weighed out and milled the grains for each batch

When strike temperature was reached, I dropped the grain baskets into either kettle, stirring to fully incorporate, then checked to see if I hit my target mash temperature.

I typically employ a Hochkurz step mash for this beer, so I did raise the temperature to 160˚F/71˚C thirty minutes into the mash.

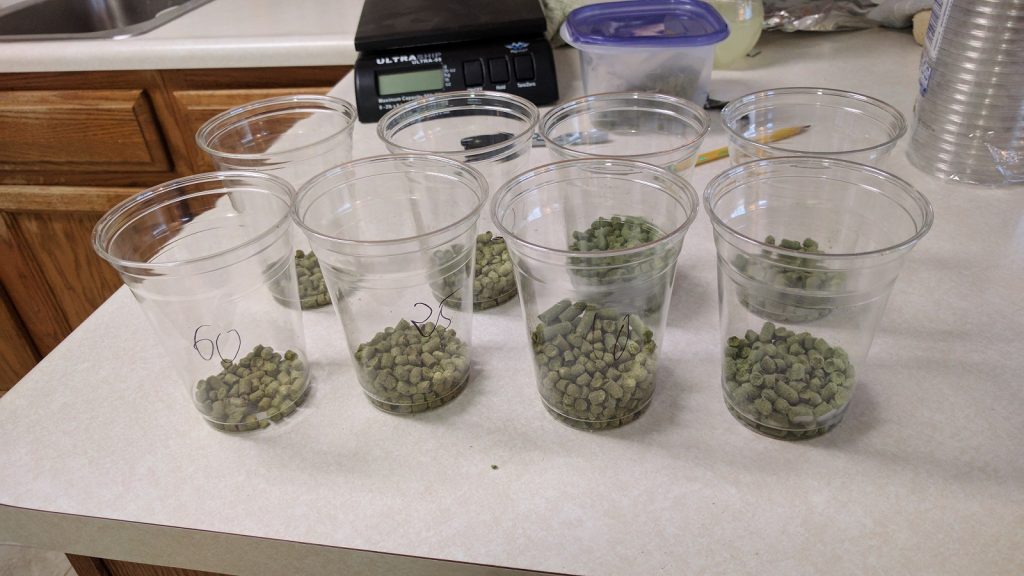

After another 10 minutes, I bumped the temperature up again for a mash out before removing the grain baskets and letting them drain while the wort was heating to a boil. During the wait, I weighed out my hop additions.

Hops were added as stated in the recipe, each addition followed by the familiar smell of boiling hops– never gets old!

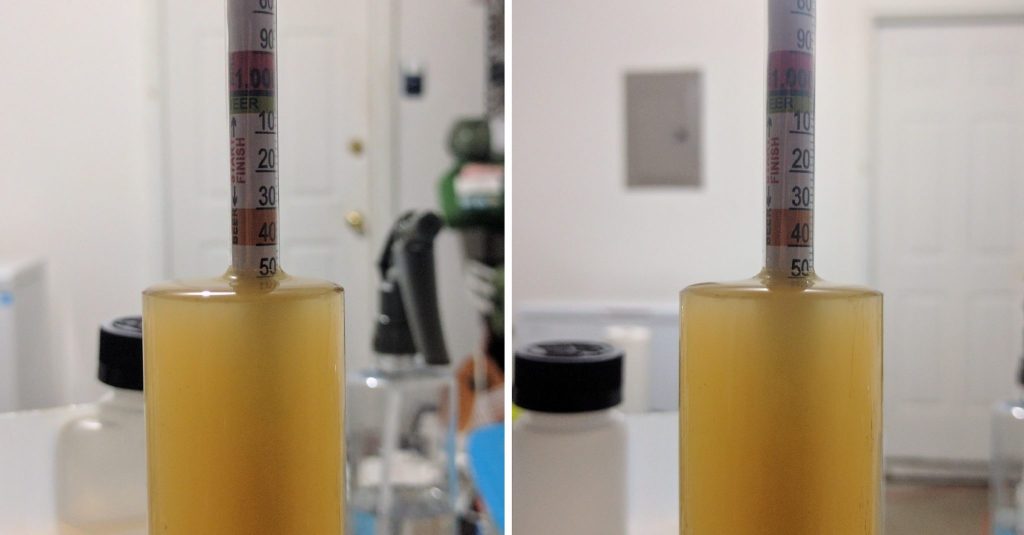

When the 90 minute boils were complete, I chilled each wort with a stainless immersion chiller to 80°F/27°C then ran equal amounts from each batch into separate fermentation kegs, which were placed in separate chambers to finish cooling. Hydrometer measurements confirmed both batches achieved the same OG.

With both beers stabilized at their respective fermentation temperatures of 48˚F/9˚C and 72˚F/22˚C 6 hours later, I decanted the yeast starter then evenly split the remaining yeast between the batches. The cool ferment beer was left alone for 7 days before I gently ramped the temperature to 72˚F/22˚C for a diacetyl rest while the warm ferment batch was controlled to 72˚F/22˚C throughout fermentation.

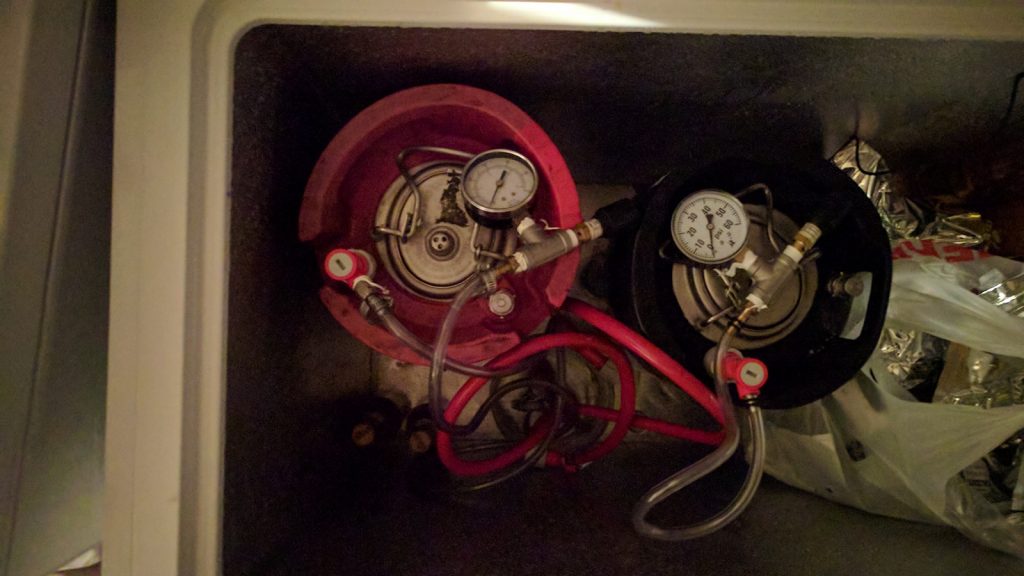

Both beers were spunded for natural carbonation over the final 3 days of fermentation, after which they were cold crashed to 36˚F/2˚C and left to lager for 1 week.

After transferring the beers to serving kegs, I degassed samples from each and took hydrometer measurements showing both hit a similar FG.

Once adequately carbonated, the beers were put in my keezer with the gas set to serving pressure for a few days before they were ready to serve to participants.

| RESULTS |

A total of 20 people of varying levels of experience participated in this xBmt. Each participant was served 1 sample of the cool ferment beer and 2 samples of the warm ferment beer then asked to identify the sample that was unique. While 11 tasters (p<0.05) would have had to correctly identify the unique sample in order to reach statistical significance, only 8 (p=0.34) picked the odd-beer-out, indicating participants in this xBmt were not able to reliably distinguish a lager fermented at 48˚F/9˚C from the same lager fermented at 72˚F/22˚C using Wyeast 2124 Bohemian Lager yeast.

For fun, I figured I’d share the preference data of the 8 tasters who got the triangle test correct, even though it means nothing. In all, 3 people said they preferred the cool ferment lager, 4 liked the warm ferment beer more, and 1 person noted having no preference despite noticing a difference.

My Impressions: I attempted 4 triangle tests with these beers and selected the unique sample only twice. While my palate can certainly be called into question, I honestly could not tell the beers apart, despite my confidence going into these tests that I’d be able to easily distinguish a difference. I fully expected the cool ferment beer to be more crisp than the warm ferment batch based on what I believed to be true about lager fermentation, but that wasn’t the case at all. The warm ferment batch, which was fermented far warmer than I’d ever intentionally ferment anything other than maybe a Saison, was equally as clean, crisp, and flavorful as its cool ferment counterpart, which was surprising as hell.

| DISCUSSION |

We’ve been taught that fermentation temperature is one of the most important factors when it comes to making good beer, particularly lager styles, which purportedly require cool temperatures to keep undesirable esters and other off-flavors at bay. I can’t really say how I’d feel about the results of this xBmt showing tasters were unable to reliably distinguish a lager fermented cool from one fermented warm if someone else had performed it, but after sampling these beers myself both side-by-side and in semi-blind triangles, I find myself questioning my preconceived convictions. The beers tasted exactly the same to me despite being fermented 24°F/13°C apart from each other, and having brewed the, I knew what to look for.

When viewed together with other surprising fermentation xBmt results, these findings suggest to me brewers who love lager styles may not have to avoid making them due to fermentation temperature limitations. As we say often, a single xBmt result does not a principle make, and while 3 non-significant fermentation temperature xBmts using traditional lager strains certainly isn’t conclusive, it’s enough to get me to open my eyes to the idea that maybe the processes we’ve adopted from historical methods isn’t necessarily required. Regardless, I’ll likely continue to ferment most of my lagers cool for the most part, but if I desire a quick turnaround Pilsner or Märzen, I won’t hesitate to ferment it like an ale.

If you have any thoughts about this xBmt, please share them in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support Us page for details on how you can very easily do so. Thanks!

30 thoughts on “exBEERiment | Fermentation Temperature: Wyeast 2124 Bohemian Lager Yeast In A Czech Premium Pale Lager”

I wonder if (in historical terms) low fermentation temperatures with lager yeasts is/was in function of reusing yeast? Maybe lager yeast fermented high causes different results when repitched in consecutive warm fermentations?

While reading I wondered the same… Is there a possibility the yeast could have had a propensity to become less stable at higher temos and the traditional cool temp is to make it less likely to have genetic mutations over generations? But maybe not who knows?

Or maybe the cool temp was adopted into regiments to help keep competing bacteria and infectious yeasts at bay and lager yeast just evolved to work better at the low temps?

Anyways another interesting xbmt result!

I wonder if any of the known beer history writers could shed light upon historic documentation or treatises which specify that lager yeast used at higher temperatures tastes different?

It is certain that Altbier, which is fermented with a top fermenting yeast a low (10°C) temperature does taste clean. But is that a function of the yeast or the fermentation? Difficult to test, because there are not many top-fermenting yeast strains which work in a reasonable time at this temperature, except alt strains.

I have read up somewhat on statistics, and from what I understand it seems that the p-test should normally be followed up by other experiments. Maybe you could start doing the same xBmt with other lager types, like bock, dunkel and schwarzbier. And to be complete, I think you should also the same test with the same kinds of beer, but for other lager strains that you haven’t used yet.

Interesting. Another interesting xBmt will be to test for variating temperatures. In the book, Yeast : The Practical Guide to Beer Fermentation, White and Zainasheff claims that stable temperature is important for yeast performance.

Interesting that the beers were hard to tell the difference. Do you add Co2 when you initially rack the wort into the keg? Also if you used the spunding valve to carbonate naturally, why did you force carb at the end? I just built some spunding valves and I am trying to learn more about how they operate. Thanks for doing these exBEERiments!

Force carbonation wasn’t mentioned. The beer was put in a keezer and set to serving pressure for a few days.

There might be a historical explanation for the theory that lagers need low temperatures to produce clean-tasting beers. Traditionally, lagers were fermented and cellared at temperatures that selected for cold-tolerant strains of S. pastorianus and excluded more expressive, contaminating wild yeasts or bacteria. This ensured consistency of the beer, a fairly neutral ester profile, and provided a low-tech way of controlling yeast hygiene before brewers had access to labs.

I suspect the connection between low temp and clean-tasting lager has been misunderstood and evolved into a bogus theory about low temps producing “cleaner” beer, which higher temps encourage “more expressive esters”. I reckon the brulosophy exbts are exploding these myths.

I won’t be changing my process anytime soon either, but these experiments do convince me that most discussions about ester creation are WAY oversimplified. Like most things fermentation-related, esterification is a complex biochemical process heavily influenced by the presence of precursors, temperature, yeast strain, yeast health, trub levels, and likely several other important things that I’ve forgotten to mention (see articles below by people smarter than I am).

While these articles mention some of the same tropes we’ve been discussing, I like the focus on flavor thresholds. My guess is, if you did chemical analysis of Matt’s beers, there would probably be a difference in the presence of esters. However, it appears to be below the flavor threshold, so unless the esters would cause other problems then why would we care?

http://scottjanish.com/esters-and-fusel-alcohols/

https://www.gastrograph.com/blogs/gastronexus/ester-production-in-fermentation.html

Taking all of this information together, one could easily infer that underpitching yeast in relatively poor health would produce lots of esters (and probably more at higher temps and vice versa).

With that in mind, I wonder if the lack of significance in these experiments can be explained by the combination of a few factors that keep most esters below the flavor threshold:

1) Pitching a sufficient quantity of healthy yeast

2) Relative consistency of temperature (understand the stable vs. variable xBMT differs, see #1)

3) Homebrew scale’s lack “large volume” concerns that occur in pro brewing (the scale at which a lot of the research is done)

Based on these experiments and the one from Scott Janish, it’s clear to me that you can make great beer within a much wider temperature range than previously thought (if you achieve a high-quality fermentation with sufficient quantities of healthy yeast).

How to make the best beer … well we’ll never all agree on that, will we?

Thank you so much for these temperature experiments. It confirms, in my head at least, that I’m doing just fine with fermenting my beers at room temperature in my guest room shower. I’ve not had any off flavors so far, at least not that anyone has detected. I’m going to keep doing what I’m doing and not worry about purchasing a fermentation chamber. 70-72 degrees seems to be working just fine for me.

Fascinating! Curious as to the yeast pitch amount used? Since fermenting at 72 wouldn’t this call for a significantly less amount of yeast than if fermenting at 48? Was that factored or did you just make a typical huge lager starter and divide in half?

Thanks! Great exbt!

I think we, as home brewers, need to always remember that our hobby is growing and improving. I can’t believe I am an old timer in this hobby, but at 27 years of brewing I guess I am. Many of the well known practices and convictions of the past were developed for a reason. Many of those reasons no longer exist. In service to our hobby and to the brewing industry, manufacturers and yeast labs are always trying to improve their products. Malt is now fully modified, we used to have to do step mashing. That is part of the reason partial mash was so popular…you didn’t have to step mash. Hops have exploded. I remember when Centennial was the new crazy cool hop. We called it super Cascade. Yeast has also improved dramatically, and perhaps more than any other facet of home brewing. I can remember when we had 6 and only 6 choices for yeast, now we have hundreds. The yeast labs have worked incredibly hard to develop and select yeasts that perform under harsh conditions. And to develop lager yeast that will ferment just fine at ale temperatures. The main reason is obvious, think about the money the commercial brewers will save if they can ferment at 65 rather than at 48. But the yeast labs are also people who love the same craft we love. If they can make a buck and do something that helps us all improve our beer, they will do it every time. I can tell you from past experience, this experiment would have generated a statistically significant finding 20 years ago. I also suspect it would generate a significant finding with some of the other lager yeasts. But with the Weihenstephan strain we gain the full benefit of the research and development (careful selection and breeding) of the yeast laboratories. They have literally bred the off flavors out of the yeast up to temperatures of about 74 F (23 C). I no longer ferment lager yeast cold. Haven’t for years. 1 chamber set to ale temps. Beer comes out great every time. But I also use the Weihenstephan strain for all of my lagers.

Great work, keep it up.

I think you have a very good point. Yeast and molecular biology have developed, but routines, practises and traditions have not.

Thanks for the experiment 🙂

A few comments / questions:

+1 on John’s spunding question – if you force carb, then you started spunding too late, right? What were the CO2 volumes after spunding in each beer.

– What was the gravity of the 48F beer when the diacetyl rest started? Was the beer almost done by the time the diacetyl rest started?

– There are many lager fermentation profiles in the traditional and new German literature, but the “traditional profile” chosen is not a well known lager fermentation profile, so one cannot rule out that the effect of finishing fermentation at that high temperature made the 48F beer less lager like.

Cheers,

“There are many lager fermentation profiles in the traditional and new German literature, but the “traditional profile” chosen is not a well known lager fermentation profile, so one cannot rule out that the effect of finishing fermentation at that high temperature made the 48F beer less lager like.”

Yes that’s a valid point. There’s still a huge difference in temp profile of the two batches but the experiment would have been even more persuasive if the diacetyl rest was at a lower temp too.

This is super, super interesting. Thanks for doing the work and documenting it so well!

Hard to tell exactly from the pictures, but are you reading the bottom of the meniscus? Looks higher than 1.047 to me.

Neat. Out of curiosity, how much faster did the warm-fermented beer reach terminal gravity?

I would be interested to understand the fermentation vessel details a bit more. In the keg? Could be that pressure was a factor in the insignificant results?

Because you guys don’t have enough trolls, I’ll step in with your new motto:

“Brulosophy: Temperature control and pitch rate doesn’t affect low gravity beers.”

Great experiments… I now ferment my Pils reasonably cold still but seldom Lager for more than a week (an extended cold crash really) and notice no issues. I used to ferment in the wardrobe and I did notice that they were less clean and crisp. Unfortunately I can’t eliminate water as I only used to filter (basic one stage filter) but not treat the water. Since moving to Germany I control ferm temps and filter and treat the water for much better beers.

What I wonder though is whether fluctuating ambient temps might cause some issues. In these experiments even though its warm its constant rather than moving throughout the day. I may even test this myself soon… But perhaps could be something to Experiment on. Given the low thermal mass at homebrew level in theory if fluctuating temps does cause issues it would be more obvious….

This XBMT (layered on the other lager temp results) inspired me to try a lager without powered temp control (my ferm. chamber has recently become a kegerator… yayy kegs! boo, loss of space). I recently brewed a festbier with WLP 833 around 64. I was a bit worried about it ($$$) but I’m happy to report that with: 1. a big, vital pitch of decanted starter, and 2. good oxegenation (pure oxy), I can find no evidence that the higher temp affected this beer negatively at all. Thanks for the motivation/education regarding this issue (I’d echo counterbrew’s assessment that our techniques and ingredients are of such higher quality now, we likely are continuing cautionary methods that are no longer necessary).

This is really fascinating. How many times have we had this drummed into our head that fermentation temperature is absolutely, positively, one of the most important factors to control? While it may still be important, perhaps it’s the range of temperatures that could be loosened up to still produce the same quality and flavor profile.

1.047 OG, looks a little higher to me

I’m under the impression that Lager yeast that has been grown during high temperatures will then be prone to produce off-flavors in future generations.

I brewed a Zoiglbier that accidentally went through its first evening at 80 degrees, and then, due to further chiller problems, spent the next day at 68 degrees. It had pretty much reached FG by then. The beer ended up tasting fine, not fantastic, after diacetyl rest and proper lagering- but that yeast wasn’t harvested and used again for fear that future generations would taste bad.

I’d like to see an xbeeriment where yeast from a hot-lager fermentation is collected and re-pitched into two more lagers, one cold and one warm again, to see what, if any, off flavors are produced.

Interesting! I recently harvested some room temperature fermented Bohemian Lager “beer” off of a fifteen year old yeast sample that was stored at RT. The beer was surprisingly amazing, better than before. As I still have some samples this would be a great exbeerment!

“A few days before brewing, I made a single starter of a Wyeast 2124 Bohemian Lager yeast that I stepped up to ensure enough cells for two 5 gallon batches….With both beers stabilized at their respective fermentation temperatures of 48˚F/9˚C and 72˚F/22˚C 6 hours later, I decanted the yeast starter then evenly split the remaining yeast between the batches.” Do you mean you pitched a lager sized starter into the ale temperature batch? Doesn’t that mean you pitched double the number of cells needed at ale temperature? Over-pitching might explain why the warm fermented batch didn’t taste much different than the cool fermented batch.

>Doesn’t that mean you pitched double the number of cells needed at ale temperature?

Yep, it does mean that! And that’s entirely possible, but conventional wisdom would tell us that the warm-fermented batch would still throw off a noticeable amount more esters than the cool-fermented batch, which is more so what this xbmt was about. It would be a cool xbmt to test out a traditional lagering process to an ale process, so couple the pitching rate variable, ferm temp variable, and time. Time would be a rough part though, considering we try to make out batches on the same day.

Thank you for doing these experiments. You are doing the brewing community a huge service!

Putting my brew bucket in the 50 degree basement is still pretty easy even so. It’s great to know it’s probably more about the yeast though!

Have you found that a starter with this yeast doesn’t look to be super active and smells like a sulphur bomb? Asking for a friend. I’m the friend. Just wondering if that’s normal