Author: Marshall Schott

Back in March 2016, we published an xBmt comparing a beer where hops were added to the boiling wort either loose or in a bag that surprisingly yielded a significant result. In that xBmt, I intentionally added the dry hops to both batches loose, as the purpose was to evaluate the impact bagging kettle hop additions has on beer. Undoubtedly spurred by the the fact the variable did appear to make a difference, we received a ton of suggestions to perform an xBmt on the effect bagging dry hops has on beer. Okie dokie!

I couldn’t find much in the way of professional literature on bagging dry hops, likely due to the fact it isn’t really a practice commonly used by professional brewers. As such, I resorted to informally surveying homebrewers who do bag their dry hops and discovered a few primary reasons they do so, the most common of which had to do with ease of racking beer out of the primary fermentor. Of those I surveyed who endorsed this as being why they bag their dry hops, many reported not having the ability to cold crash, which made some sense to me– hops are more likely to remain in solution if the beer stays warm, which could increase the risk of a clogged racking cane or hops making it to the keg/bottling bucket. Another perfectly logical reason for bagging dry hops came from those who harvest yeast after primary fermentation and leaving as much other gunk out, including hop debris. Finally, the third and most simple reason these brewers cited for bagging their dry hops: its what they’ve always done.

I’ve been adding dry hops loose to beer for the past 5 years or so, though there was a time I bagged them, my reasoning mostly inline with the last one mentioned above. It wasn’t until I considered the fact most clear commercial beer was dry hopped sans bag that I made the switch, a decision that was validated by the fact I perceived my beers to be of at least equal quality as before. Motivated by the findings of the aforementioned xBmt, the time had come to test it out for myself!

| PURPOSE |

To evaluate the differences between a beer dry hopped loose and the same beer where the dry hops were bagged.

| METHODS |

The recipe for this xBmt was designed to be simple enough to allow any differences caused by the variable to shine through.

Gimme That Sack Pale Ale

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 33.9 IBUs | 5.1 SRM | 1.051 | 1.012 | 5.2 % |

| Actuals | 1.051 | 1.008 | 5.6 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pale Malt (2 Row), Rahr | 8.375 lbs | 72.04 |

| Pale Malt, Maris Otter | 1.625 lbs | 13.98 |

| Vienna Malt | 1.125 lbs | 9.68 |

| Victory Malt | 8 oz | 4.3 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Azacca | 6 g | 30 min | First Wort | Pellet | 13.7 |

| Azacca | 14 g | 15 min | Boil | Pellet | 13.7 |

| Azacca | 60 g | 1 min | Boil | Pellet | 13.7 |

| Azacca | 90 g | 3 days | Dry Hop | Pellet | 13.7 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

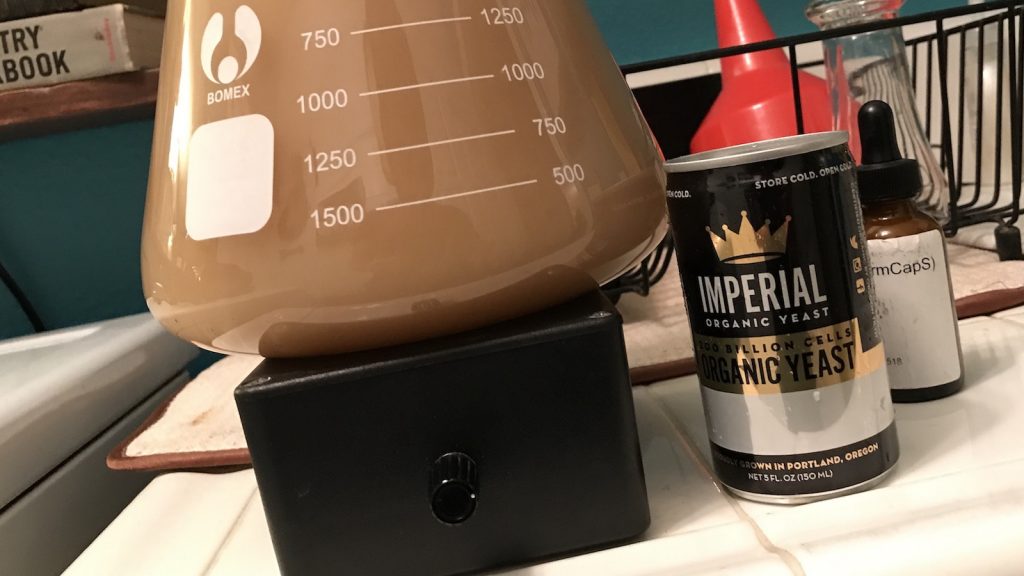

| Flagship (A07) | Imperial Organic | 75% | 60°F - 72°F |

Notes

| Water Profile: Yellow Bitter in Bru’n Water Spreadsheet |

Download

| Download this recipe's BeerXML file |

I made a large starter of Imperial Organic A07 Flagship yeast a couple days before brewing, about half of which was slated to be harvested for later use and the rest would be evenly split between batches.

The afternoon before my brew day, I started the long process of collecting my RO water.

Once that was going, I weighed out and milled the grains.

The next morning began with me heating the full volume of brewing liquor to strike temperature then Tim mashing in.

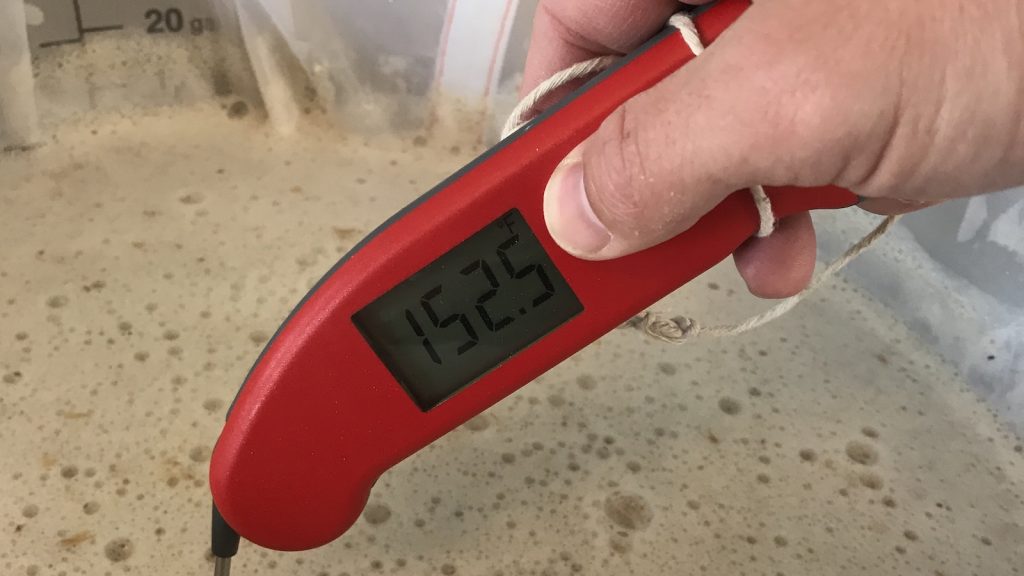

With the grain fully incorporated into the water, I confirmed I’d hit my target mash temperature.

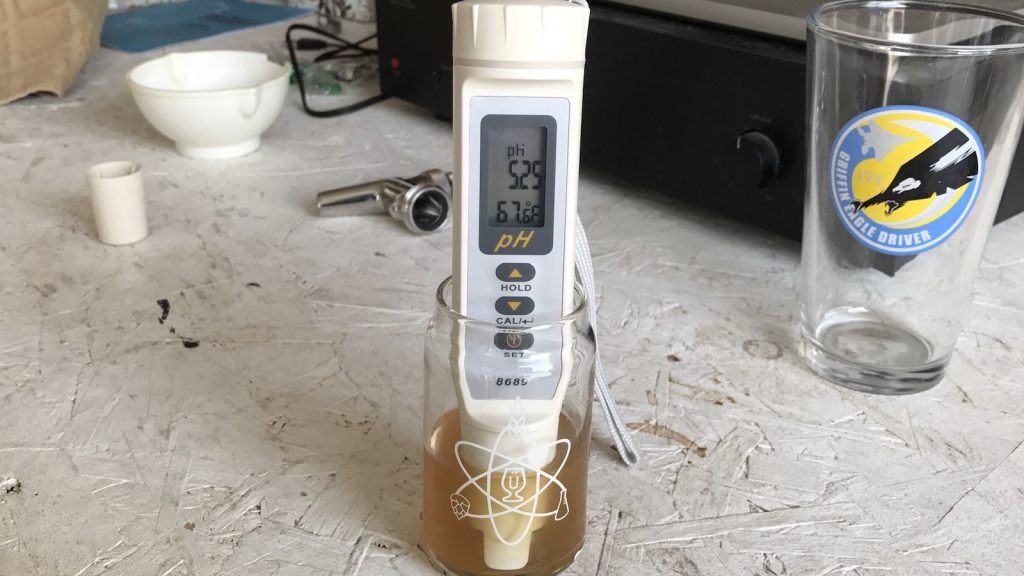

A measurement 15 minutes later showed I’d also nailed my desired mash pH.

I weighed out the kettle hop additions during the 60 minute mash rest.

When the mash was complete, I collected the sweet wort.

The wort was transferred to my kettle and boiled for an hour with hops added per the recipe.

At the end of the 60 minute boil, I quickly chilled the wort to slightly warmer than my groundwater temperature.

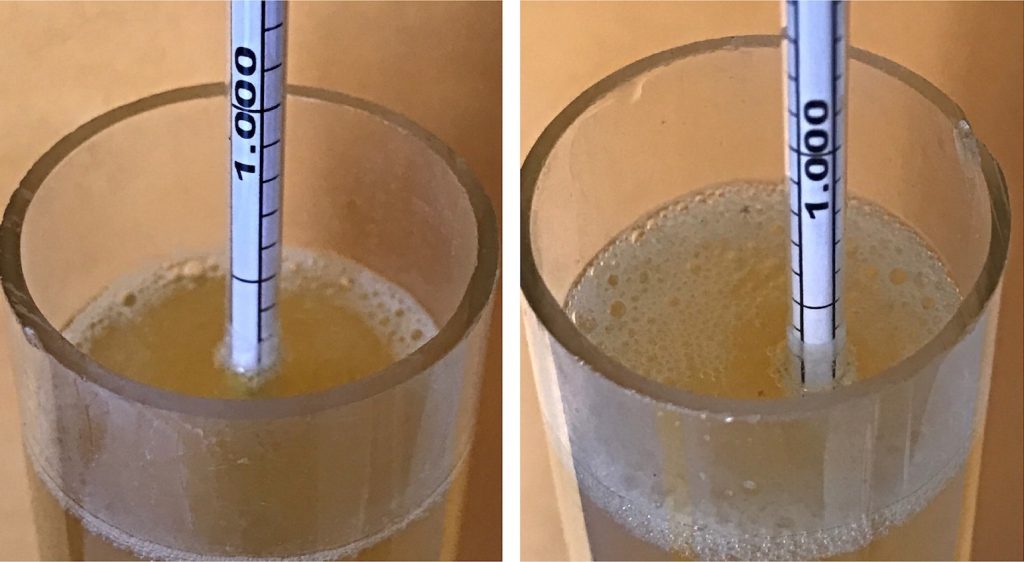

After taking a refractometer measurement showing I’d hit the my planned OG, I filled 2 Brew Buckets with 5.5 gallons/21 liters of chilled wort, moved both to a temperature controlled chamber, then pitched equal amounts of yeast into each. Airlock activity was observed in both just 4 hours later and they proceeded similarly. I noticed signs of fermentation dwindling 3 days post-pitch and raised the temperature to 72˚F/23˚C to encourage complete attenuation. After another 4 days, I took a hydrometer measurements that indicated FG had been reached in both batches.

It was time to introduce the variable. I weighed out two equal doses dry hops, one that was added directly to a fermentor and the other charge was put in a sanitized hop bag before being dropped into the other beer.

I gave the beers 3 days to mingle with the dry hops before cold crashing, fining with gelatin, and kegging.

The kegs were placed in my cold keezer and burst carbonated for 18 hours before I reduced the CO2 to serving pressure and allowed the beer to condition for another few days before presenting them to participants.

| RESULTS |

A total of 21 people of varying levels of experience participated in this xBmt. Each participant was served 1 sample of the loose dry hop beer and 2 samples of the bagged dry hop beer then asked to identify the sample that was unique. While 12 tasters (p<0.05) would have had to correctly identify the unique sample in order to reach statistical significance, only 9 (p=0.24) picked the odd-beer-out, indicating participants in this xBmt were not able to reliably distinguish a beer dry hopped loosely from one where the dry hop addition was bagged.

Since significance was not reached, the following preference data collected from the 9 participants who were correct on the triangle test is statistically meaningless and should be taken with a huge grain of salt. Out of the 9 correct participants, 3 reported preferring the loose dry hop beer, 4 said the preferred the bagged dry hop beer, and 2 had no preference despite noticing a difference.

My Impressions: Before attempting any triangle tests, when sampling the beers side by side, I quickly realized any differences caused by bagging the dry hops were incredibly subtle and that the beers were obviously the same. However, as I hyper-focused on the differences, I thought the bagged dry hop beer had an ever so slightly malty edge compared to the loose dry hop beer, which I suppose had a tad more hop aroma and flavor. Would I be able to tell them apart reliably in a series of blind triangles? Not so much. Out of 5 attempts, I picked the odd-beer-out once, any differences I thought I detected when searching all but vanished.

| DISCUSSION |

The idea that bagging a dry hop charge would in some way impact the ultimate character of beer differently than adding the dry hops directly sort makes sense to me, particularly the claim hop oils that would normally make its way into the beer can cling to the bag fabric, which gets removed before packaging. It also seems plausible that something in the bag, especially one that’s been used multiple times, could leech into the beer in such a way that it affects the flavor and aroma. The results from this xBmt showing participants were unable to reliably distinguish beers made using either method seems to support the opposite notion, that a beer dry hopped loosely produces a beer of similar quality as one dry hopped in a bag.

I have no plans to go back to bagging my dry hops after this xBmt, largely because given my gear and process, it really is a non-issue. However, for brewers who make smaller batches and want to ensure maximum volume or those who don’t have the ability to cold crash, bagging dry hop additions can be helpful and, based on these findings, likely won’t have a negative impact.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

New Brülosophy Merch Available Now!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

23 thoughts on “exBEERiment | Loose vs. Bagged Dry Hops In An American Pale Ale”

Interested in your typical cold crash process. I use Fermonsters (thin wide mouth plastic carboy) in a mini fridge to ferment. I’ve yet to cold crash at this point due to fear of introducing oxygen as the air pressure within the fermenter contracts as the temp drops. I guess that may be less of an issue in the SS Brew Buckets.

…As long as they fine with gelitan.

So how was the beer? The recipe looked awesome.

It was fine, not as good as I expected, but definitely not bad!

Agree with SnowBeer. I would be interested to know the result without gelatin fining.

Was the bag of hops weighted down in any way? I ask because in my first attempt at dry hopping with a bag, the bag seemed to float on top and I didn’t get the hop pop I was looking for. Since then, my standard practice has been to bag the hops with a handful of sanitized glass marbles so that the hops actually sink into the beer instead of floating on top. My unchecked theory of why this helps is that it maximizes beer-to-hops exposure, and minimizes hops-to-oxygen exposure in the headspace. I know none of it can be proven without experimentation, but I’m hoping you can clarify your methods so I can compare to my own.

They weren’t. While the top of the bag was toward the top of the beer, the hops were definitely dangling in the beer.

I use a fast ferment for my beers and I used to bag the dry hops, otherwise it would/could clog up the works.

I have since bought a hop spider that sits down inside the FF. Pretty much the height of the FF. 4″ diameter, and goes from the bottom to the top of the fermenter. Could seriously pack a crap ton of dry hops in this if you wanted, easily a couple lbs for a 5gal batch if you wanted.

On its second batch since I bought it, first batch was super easy to add the dry hops (both during fermentation and post fermentation). Really easy to use, and kind of the best of both worlds of loose vs bagged dry hops

I have a FastFerment, and I just drop the hops freely in there. I dont use the collection ball when I know im going to dry hop. I harvest my yeast from overbuilding the starter so no worries on yeast collection. I rack from a sampling port with a Bouncer inline hop/trub filter. Works fine.

When removing the hop bag from the fermenter, did you squeeze the bag? In forums I always see conflicting tips about the practice.

I did not.

Is there a difference in the cloudiness/haze of these beers? Kinda looks like it from the pics…

Condensation. They look exactly the same.

Gotcha. Cheers!

We bag our dry hopping….Glad to see this xBmt….We don’t squeeze but we do let the liquid drain from the bag. We also weigh down the hop bag to get more contact.This is all done in secondary(keg) which we then use to carbonate and bottle.

I started out bagging my dry hops, then switched to loose. First couple of bottling sessions were fine – the hop gunk settled out. Oddly, I then had a few brews where it stayed in suspension for a long time and ended up getting into the bottles, where it never settled out. Sometimes blocked the bottling wand, which was a pain. Also lost a lot of beer to the hoppy trub. Now I’ve reverted to bagging. Works much better for brewers who bottle from the FV. Kegs are doubtless a different story.

How tightly packed was the hop bag?

Why the 1min hops? It’ll make it harder to tell the difference.

I’m not denying the lack of professional literature regarding bagging dry hopes, but when I toured SN brewery in Asheville last year, I recalled that being the impetus to the Torpedo. From their website…”Traditional dry hopping uses nylon sacks stuffed with hops and suspended in the tank. We found that as we removed the hop sacks, even after weeks suspended in beer, we’d occasionally find the center to be dry, meaning that the hops never came in contact with the beer. We thought there had to be a better way and, nearly ten years ago, an idea was sketched in a bar that changed the way we dry hop. In 2009, that idea became a reality with the invention of the Hop Torpedo.” While bagging dry hops may not be an industry standard, it certainly is done… On a side note, on that tour, we were able to taste fresh Torpedo Extra IPA right out of the Torpedo and delicious doesn’t begin to describe it! Thanks for the article. Good stuff.

The times I’ve seen the local brewery DH, they used whole leaf in a bag. Any idea what most breweries use, whole leaf or pellet? This would be a hard variable to test unless you knew that the pellets and whole leafs came from the same crop.

Just reviewing this study. How do you reconcile your negative data with what Scott Janish states about the study by Hopsteiner titled, “Dry Hopping – A Study of Various Parameters,” in which beer dry hopped loosely had nearly 50% greater extraction of linalool than the beer dry hopped with the use of a hop sack (http://scottjanish.com/examination-of-studies-hopping-methods-and-concepts-for-achieving-maximum-hop-aroma-and-flavor/)?

Interested to know if a few things would also impact hop flavour in the beer:

1. Would Gelatine fining both batches possibly strip anything from them causing them to test similar?

2. Is there a longer half-life benefit to one method over another (i.e Longer lasting hop aroma/flavour).

3. If a different type of hops (with an distinctive signature) was used to dry hop as opposed to while boiling. Perhaps it may have been easier to detect a difference in the testing, compared to a single hop variety used throughout.

P.S. Love your work, saves me hours of sleepless night wondering what if…

I dry hop in bags as well so interesting to see this. Do you think there’s a chance of oxidation when removing the hop bag prior to cold crashing? Especially when brewing a NEIPA? I have always removed mine when brewing this style and haven’t perceived any problems from oxygen but I’ve never done an experiment to prove this theory.