Author: Jordan Folks

The use of certain adjuncts in beer is a rather polarizing topic, with some considering anything beyond malt, hops, yeast, and water unacceptable while others couldn’t care less. Corn, and its derivative corn syrup, is one such controversial adjunct. Viewed by many as a cheap alternative to malt, an increasing number of brewers are embracing the use of this once loathed adjunct as a way to lighten body and boost alcohol content without contributing additional flavors.

Similar to crystallized corn sugar in that it’s made up of dextrose and is entirely fermentable by brewer’s yeast, corn syrup is made by breaking down corn starch into simple sugars through a process of hydrolysis, resulting in a sweet, viscous liquid. While this counters claims that corn syrup is simply corn sugar dissolved in water, it’s not that far off, and in fact many believe the different forms of corn sugar can be used interchangeably to achieve identical results.

In addition to being used to make American staples like Miller Lite, Coors Lite, and Pabst Blue Ribbon, I recently had a corn syrup-laden lager made by my Wisconsin-born brewing buddy that I perceived as having an astonishingly pure corn character. I told myself this was from the use of corn syrup, though I began to question if expectation bias might be at play, as I was aware of how this beer was made. Curious to see for myself, I designed an xBmt to test it out!

| PURPOSE |

To evaluate the differences between a Pre-Prohibition Lager made with 30% corn syrup and one made with all Pilsner malt.

| METHODS |

Typified by its heavy use of corn, I went with a simple Pre-Prohibition Lager recipe for this xBmt. Big thanks to F.H. Steinbart for hooking me up with the malt for this batch!

Bumper Crop

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.8 gal | 60 min | 28.3 | 2.8 SRM | 1.046 | 1.014 | 4.2 % |

| Actuals | 1.046 | 1.014 | 4.2 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pilsner | 7 lbs | 70 |

| Corn Syrup OR 3 lbs more Pilsner malt | 3 lbs | 30 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Mount Hood | 21 g | 60 min | Boil | Pellet | 4.6 |

| Mount Hood | 21 g | 40 min | Boil | Pellet | 4.6 |

| Mount Hood | 43 g | 10 min | Aroma | Pellet | 4.6 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Global (L13) | Imperial Yeast | 77% | 46°F - 55.9°F |

Notes

| Water Profile: Ca 51 | Mg 4 | Na 10 | SO4 52 | Cl 49 |

Download

| Download this recipe's BeerXML file |

After collecting the full volume of filtered water for two 5 gallon/19 liter batches, adjusting them to the same mineral profile, and getting them heating up, I milled the grain.

During the mash rests, I weighed out the kettle hop additions.

Once the mashes were complete, I removed the grains and set the controllers to heat the worts up, adding the corn syrup to one batch just as it reached a boil.

When each 60 minute boil was finished, I quickly chilled the worts with my JaDeD Brewing SS Coil Hydra.

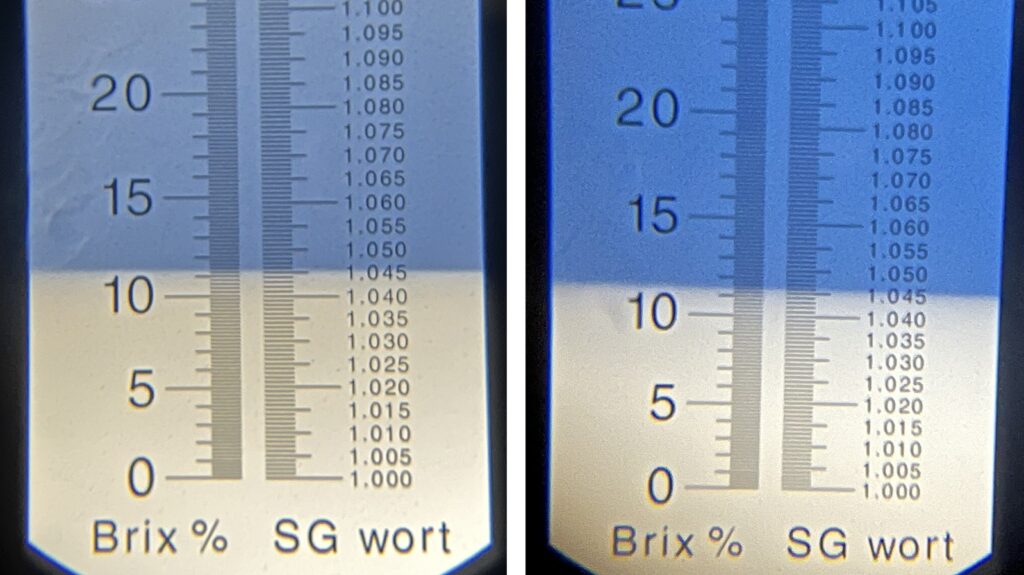

Refractometer readings indicated both worts were at the same expected OG.

After transferring the worts to separate fermentation kegs, I placed them in my chamber to finish chilling to my desired pitching temperature of 48°F/9°C, at which point I pitched two packs of Imperial Yeast L13 Global into each one.

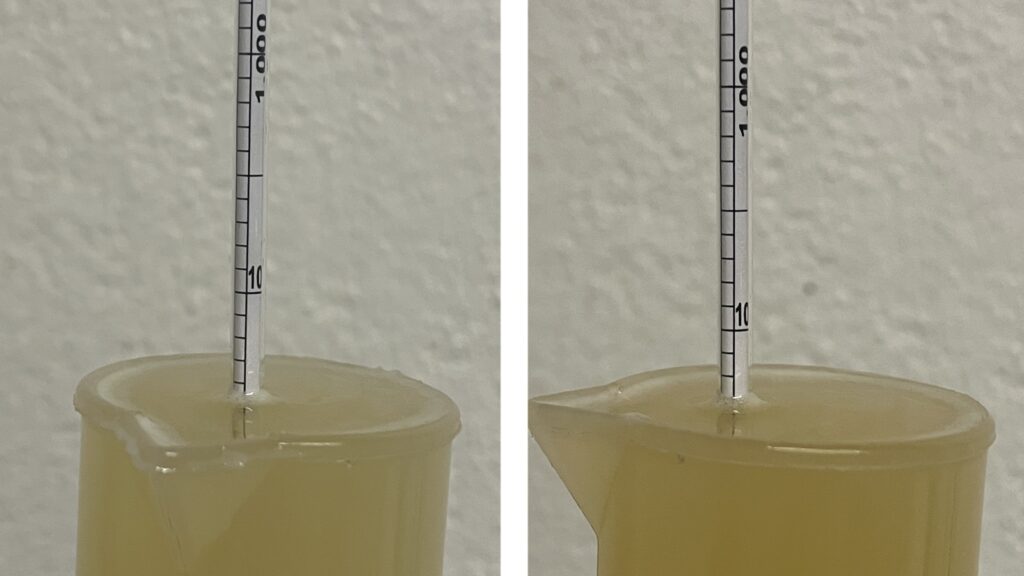

The beers were left to ferment at 50°F/10°C for 2 weeks before I took hydrometer measurements showing a very slight difference in FG.

At this point, I gradually reduced the temperature of the beers to 32°F/0°C over the course of a few days then pressure-transferred each to CO2 purged serving kegs that were placed on gas in my keezer. After a month of lagering, the beers were clear, carbonated, and ready for evaluation.

| RESULTS |

A total of 29 people of varying levels of experience participated in this xBmt. Each participant was served 1 sample of beer made with corn syrup and 2 samples of the beer made with all malt in different colored opaque cups then asked to identify the unique sample. While 15 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, only 12 did (p=0.23), indicating participants in this xBmt were unable to reliably distinguish a Pre-Prohibition Lager made with 30% corn syrup from the same beer made with all malt.

My Impressions: Out of the 5 semi-blind triangle tests I attempted, I correctly identified the odd-beer-out just twice. While I felt I perceived a minor difference in non-blind side-by-side tastings, my triangle test seems to suggest it may have been a function of bias. Ultimately, these beers were shockingly similar in terms or aroma, flavor, and mouthfeel, and both were excellent examples of the style – light and refreshing with ample Pilsner malt and noble-esque hop flavors.

| DISCUSSION |

Used by brewers to lighten body and increase strength without contributing any perceptible flavor and aroma characteristics, corn syrup is a relatively inexpensive adjunct that appears to be gaining acceptance in the brewing world. Curiously, tasters in this xBmt were unable to reliably distinguish a Pre-Prohibition Lager made with 30% corn syrup from the same beer made with all malt.

One potential explanation for this result is that Pilsner malt, while flavorful in its own right, imparts a light enough overall character that the organoleptic delta in flavor between these beers was largely moot. It’s possible that when used in a beer relying on darker grains, the impact of the corn syrup would be more apparent.

Over the years, I’ve brewed with corn in various forms, and while I’ve always felt it had a perceptible effect, I was particularly interested in corn syrup given my experience with a beer my friend brewed. Suffice to say, I was a bit surprised by the fact this xBmt was non-significant, as 30% corn syrup is quite a bit. Regardless, I’ll continue using corn when tradition calls for it as well as in certain styles where it seems more likely to have an impact.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

8 thoughts on “exBEERiment | Impact Corn Syrup Has On A Pre-Prohibition Lager”

Perhaps maybe 6-row would have yielded a larger flavor difference in a Pre-Prohibition Lager than Pilsner? That grain is noticeably less sweet which should highlight the Corn flavor more. Also, it might be possible that 30% simply isn’t enough for a sensory threshold. How does this ratio compare with your friend’s beer?

And once again a non significant result! I love the idea of the experiment tho! Good job keep it up.

I always use flaked corn and at 20 % I get a very distinct corn taste. Works great with Mexican Lager yeast.

Notable that while this test starts by looking specifically at corn syrup, it ends by talking about corn which was actually not used. Perhaps a few too many during the blog writing process? I feel that you need to finish this experiment by comparing corn syrup to corn. I recently made a Mexican lager using flaked corn for 1/3 of the grist with 2 row and Vienna. It has a definite corn flavour that merges nicely with summer days and BBQ.

How did you measure the corn syrup, by volume or weight?

I used weight. Conveniently, one 32 fluid oz container weighed 3 lbs.

Is there a cost advantage to using corn syrup vs. all malt? I assume so but would be curious the cost difference between 3 lbs of pilsener malt and your container of corn syrup.

It’s arguably similar. Although malt is definitely cheaper pound for pound (say $2/lb vs. $5/lb for the corn syrup on Amazon), the corn syrup batch yielded a whole extra gallon of post-boil wort (which I dumped for this xbmt, so that both FVs would have the same wort volume and pitch rate). Using my system efficiency and the costs quoted above, the all malt batch was $3.33 in grain per post-boil gallon vs. $4.14 in grain+syrup for the corn syrup batch. So it is slightly more expensive, but the yield gains help make up for it (and could be a good trick for those with smaller than ideal mash tuns).