Author: Alex Shanks-Abel

Modern brewers have ample access to a wide variety of beer ingredients, allowing for the production many styles with relatively little work outside of the standard brewing process. However, some still enjoy engaging in certain DIY aspects of this hobby like, for example, making home-toasted malts, which is a rather easy way to contribute unique characteristics to beer.

While toasting malt typically requires less than an hour of time in a hot oven, it’s widely held that such malts should be cured before use, as undesirable volatile flavor compounds are produced during the toasting process. Indeed, in How To Brew, author John Palmer recommends curing toasted malt for a minimum of 2 weeks in order to allow these harsh flavors to mellow out, though he notes some maltsters cure their malt for 6 weeks or more.

I’m by no means an expert in malting, and while I usually use malt in the condition I received it from the maltster, I’ve had some success toasting my own for certain styles. In the handful of times I’ve done this, I’ve always let the toasted malt cure in a paper bag for a couple weeks, admittedly based off of the aforementioned recommendation. However, while planning a recent home-toasting session, I wondered how important the curing process really is and designed an xBmt to see for myself.

| PURPOSE |

To evaluate the differences between a Märzen made with home-toasted malt that was cured for 5 months and one where the home-toasted malt was not cured.

| METHODS |

For this xBmt, I designed a simple Märzen recipe that included a decent portion of home-toasted malt.

Marzo

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 18.4 | 13.1 SRM | 1.06 | 1.015 | 5.91 % |

| Actuals | 1.06 | 1.015 | 5.91 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Munich Light | 5 lbs | 41.67 |

| North Star Pils | 5 lbs | 41.67 |

| Home-Toasted Malt (North Star Pils) | 2 lbs | 16.67 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Hallertauer Mittelfrueh | 40 g | 60 min | First Wort | Pellet | 4 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Que Bueno (L09) | Imperial Yeast | 75% | 46.9°F - 55°F |

Notes

| Water Profile: Ca 39 | Mg 0 | Na 0 | SO4 53 | Cl 31 |

Download

| Download this recipe's BeerXML file |

My preparations for this xBmt began 5 months prior to brewing when I toasted a batch of Pilsner malt by spreading it out on baking trays then leaving them in a 300°F/150°C oven for 1 hour before placing the cooled grains in a brown paper bag for extended curing; this same exact process sans the curing step was repeated the morning of brew day.

With the toasted malts ready for use, I collected identical volumes of RO water in separate BrewZilla units, adjusted each to my desired mineral profile, then set the controllers to heat them up, at which point I milled the grains.

Once the water for each batch was adequately heated, I incorporated the grains then checked to make sure both were at the same target mash temperature.

Once each 60 minute mash was complete, I removed the grains then boiled the worts for 60 minutes, adding hops at the times listed in the recipe, before chilling and taking refractometer measurements.

After transferring identical volumes of chilled wort to sanitized fermenters, they were placed in my chamber where each was pitched with a single pouch of Imperial Yeast L09 Que Bueno.

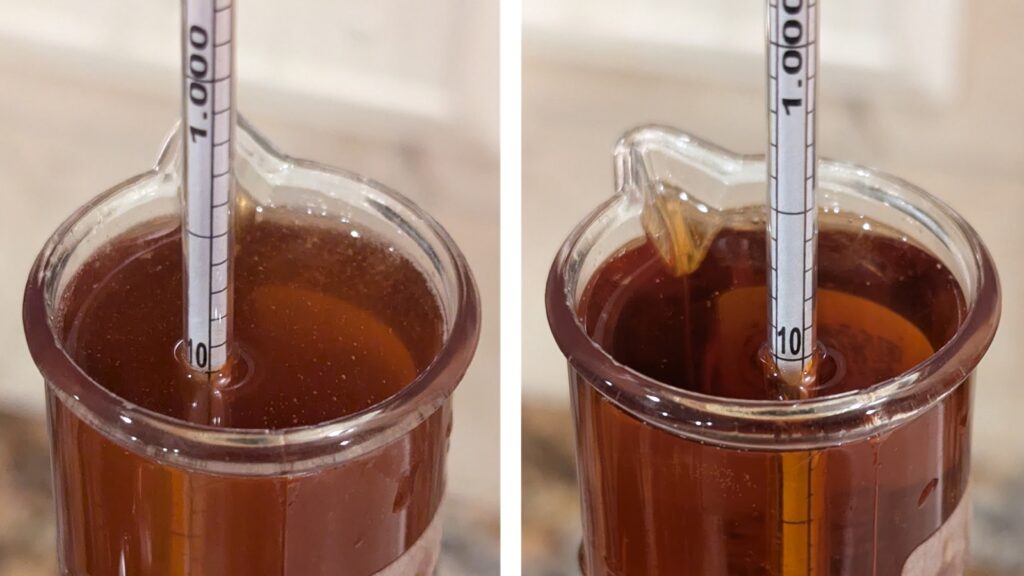

The beers were left to ferment at 68°F/20°C for 10 days before I took hydrometer measurements confirming FG had been reached.

At this point, I cold crashed the beer overnight then pressure-transferred them to CO2 purged kegs that were placed on gas in my keezer and left to lager for 8 weeks before they were ready to serve to tasters.

| RESULTS |

A total of 21 people of varying levels of experience participated in this xBmt. Each participant was served 1 sample of the beer made with toasted malt cured for 5 months and 2 samples of the beer made with toasted malt that was not cured in different colored opaque cups then asked to identify the unique sample. In order reach statistical significance, 12 tasters (p<0.05) would have had to accurately identify the unique sample, which is precisely the number that did (p=0.02), indicating participants in this xBmt were able to reliably distinguish a Märzen made with toasted malt that was cured for 5 months from one made with toasted malt that was not cured prior to use.

The 12 participants who made the accurate selection on the triangle test were instructed to complete a brief preference survey comparing only the beers that were different. A total of 4 tasters reported preferring the beer made with the cured toasted malt, 5 said they liked the beer made with the toasted malt that wasn’t cured, 2 had no preference despite noticing a difference, and 1 person reported perceiving no difference.

My Impressions: Out of the 5 semi-blind triangle tests I attempted, I correctly identified the odd-beer-out 4 times. While I perceived both beers as having a strange nutty and bacon-like character, it was noticeably stronger in the beer made with the non-cured toasted malt. I wasn’t a huge fan of either of these beers, but I preferred the version made with cured toasted malt due to the more subtle “home-toast” characteristics.

| DISCUSSION |

There is a wide selection of malts available to brewers these days, making it easy to produce beers with a vast array of colors and flavors. While some of these malts impart notably toasty characteristics to beer, some brewers enjoy the process control of toasting their own malt to contribute an element of uniqueness, and in doing so, it’s recommended these home-toasted malts go through a curing period to reduce certain undesirable flavors. Indeed, tasters in this xBmt were able to reliably distinguish a Märzen made with toasted malt that was cured for 5 months from one made with toasted malt that was not cured prior to use.

Most recommendations for curing toasted malt are hinged on the idea that the toasting process produces volatile flavor compounds that have a rather unpleasant harsh flavor, which curing reduces. While this xBmt data provides little explanation as to what exactly tasters perceived as being different between these beers, a plausible assumption is that the version made with cured toasted malt had a more rounded, developed flavor profile.

I’ve toasted my own malt several times and always allowed them to cure for at least a month, usually longer, though always wondered if it was a necessary step. Based on both the blind taster data and my own triangle test performance, I’ll definitely be continuing to cure my home-toasted malt, as the Märzen made with freshly toasted malt was more reminiscent of a Rauchbier. While I was admittedly a bit disappointed in these results, as it’d be nice to not have to worry about curing, it’s good to know my waiting on toasted malt hasn’t been in vain.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

5 thoughts on “exBEERiment | Impact Curing Toasted Malt Has On A Märzen”

68 deg f is a extremely high temperature for a lager beer. Was it brewed as an ale? If not, that might explain the off flavors.

I also noticed that the So4 to Cl ratio is reversed for a malty profile.

If you toast then cure for a long time, what’s the advantage over just buying a pound of a similar product and having it in stock? There a few things you can make at home that can’t be readily bought. I’ve always thought the benefit of home toasting was freshly toasted malt. Back when I was doing extract plus steeping (late 80’s/early 90’s) I pulled it out of the oven and used it as soon as it cooled.

If your malt tasted bacon-y that might be your oven…

Personally I’m a stickler for Vienna vs. Pils in a Märzen, but either way, I would have toasted the Munich instead for better flavor. (or both) The toasting time and temp is also important. I toasted Maris to ‘brown’ once, but that only took 30 minutes at the same 300℉ in a very clean toaster/convection oven with the malt in a single layer. (not bunched up in any way)

I agree, the high fermentation temp is likely what produced the Bacon/Ham notes. (if not also the oven) And those are some hazy beers having lagered for 8 weeks. Something is off with them. (not that they *need* to be clear, but after that amount of time, they *should* be)

Also, I’ve noticed several xBeeriments result with exactly the right number of tasters perceiving a difference, then for the preference survey, one taster perceives no difference. I’d say they have to be tossed out and note that significance wasn’t reached. They were just guessing the first time.

Short response – guesses are required with this type of hypothesis testing, tasters are told to guess if they do not perceive a difference. What is being tested is how different the results are from what would be achieved from random guessing alone. For this example, that would be around 7 correct guesses if no tasters detected a difference (i.e., a 1 in 3 chance of guessing correct). If the number of correct results is high enough, it is decided that a difference exists.

Additional info:

Obviously the probability that a difference exists increases as the correct selection result increases above the random guess value. The p value that is reported with the result represents this probability. The test designer decides at what maximum level it is acceptable to be incorrect in the conclusion that there is, or is not, a difference between the samples. When the consequence of being wrong is small, a default value of p<0.05 is common. This is another way of stating that the tester wants to be at least 95% sure of there being a difference if the test value (minimum number of correct results) is achieved.

Because the sample population (number of tasters) is small, there is a fairly large difference in the p values associated with subsequent result values. This means the lowest value that meets the significance criteria of p<0.05 often has a much lower p value and the value just below the criteria can be very close to the selected significance criteria. In this example, p=0.0557 for 11 correct tasters and p=0.0212 for 12. Therefore at 12 correct results, the confidence level is ~98% and even at 11 correct results, the confidence level is ~94.4%.