Author: Jordan Folks

While much of the attention it’s received lately has focused on the detrimental effects it can have on the cold-side, oxygen is an essential yeast nutrient that ensures adequate cell growth during the lag and exponential phases of fermentation. Brewers rely on various methods of oxygenation prior to pitching yeast, the most effective of which involves dosing wort with pure oxygen, as it results in a higher level of dissolved oxygen than shaking or aeration with ambient air.

During the initial stage of fermentation, yeast use oxygen for the synthesis of sterols and unsaturated fatty acids that are necessary for cell growth, which subsequently allows them to effectively ferment wort into beer. When oxygen levels are too low, the yeast experience stress that can lead to various negative outcomes including off-flavors and poor attenuation. This is of particular importance when reusing yeast over multiple generations, as prior fermentations may negatively impact the yeasts overall performance.

With a handful of past xBmts indicating oxygenation of wort has minimal perceptible impact on beer, it occurred to me that fresh yeast was used in most of them. As someone who regularly harvests and reuses yeast over multiple generations, I was curious what impact oxygenation might have under these conditions and designed an xBmt to test it out for myself!

| PURPOSE |

To evaluate the differences between a Czech Premium Pale Lager fermented with third-generation yeast that was dosed with pure oxygen at yeast pitch and one that was not dosed with oxygen.

| METHODS |

I designed a simple Czech Premium Pale Lager recipe for this xBmt in hopes that any differences would be easily perceived. Big thanks to F.H. Steinbart for hooking me up with the malt for this batch!

Always Reaching For The Oxygen

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.1 gal | 60 min | 38.2 | 3.6 SRM | 1.051 | 1.013 | 4.99 % |

| Actuals | 1.051 | 1.013 | 4.99 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pilsen Malt | 11.001 lbs | 100 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Saphir | 64 g | 60 min | Boil | Pellet | 2 |

| Saphir | 64 g | 30 min | Boil | Pellet | 2 |

| Tettnang | 64 g | 10 min | Boil | Pellet | 1.8 |

| Saaz | 57 g | 15 min | Aroma | Pellet | 1.8 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Urkel (L28) | Imperial Yeast | 75% | 57.2°F - 51.8°F |

Notes

| Water Profile: Ca 41 | Mg 4 | Na 10 | SO4 47 | Cl 34 |

Download

| Download this recipe's BeerXML file |

After collecting the full volume of water for two 5 gallon/19 liter batches, adjusting each to the same desired profile, and getting them heating up, I milled the grain.

When the waters per properly heated, I stirred in the grains and, seeing as this was a classic Czech lager, performed a step mash with a 45 minute rest at 149°F/65°C, 30 minute rest at 158°F/70°C, and 15 minute rest at 169°F/76°C.

During the mash rests, I prepared the kettle hop additions.

Once the mashes were finished, I collected the worts and proceeded to boil them for 60 minutes before chilling them with my JaDeD Brewing SS Hydra IC.

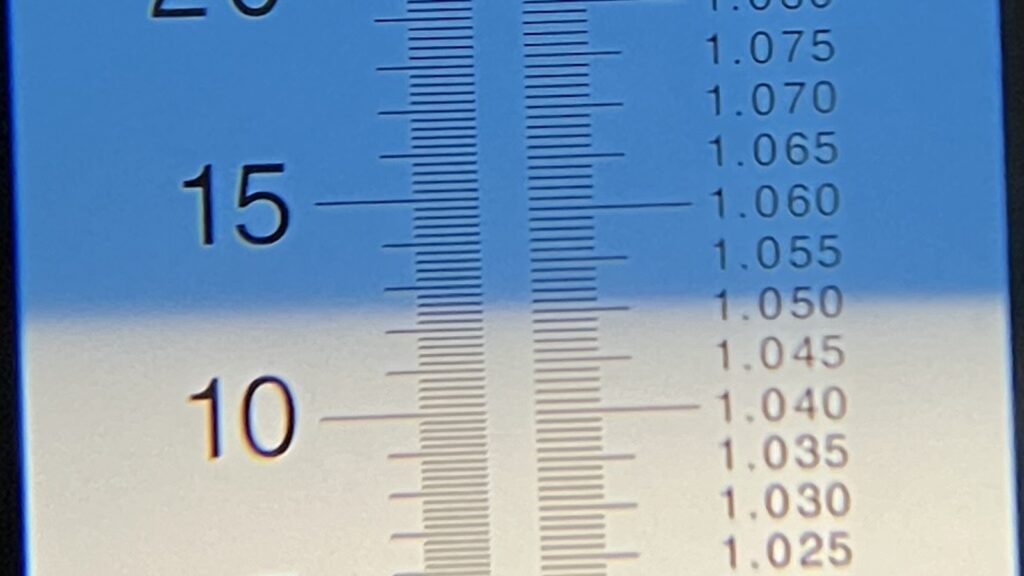

Refractometer readings indicated the worts were at the same expected 1.051 OG.

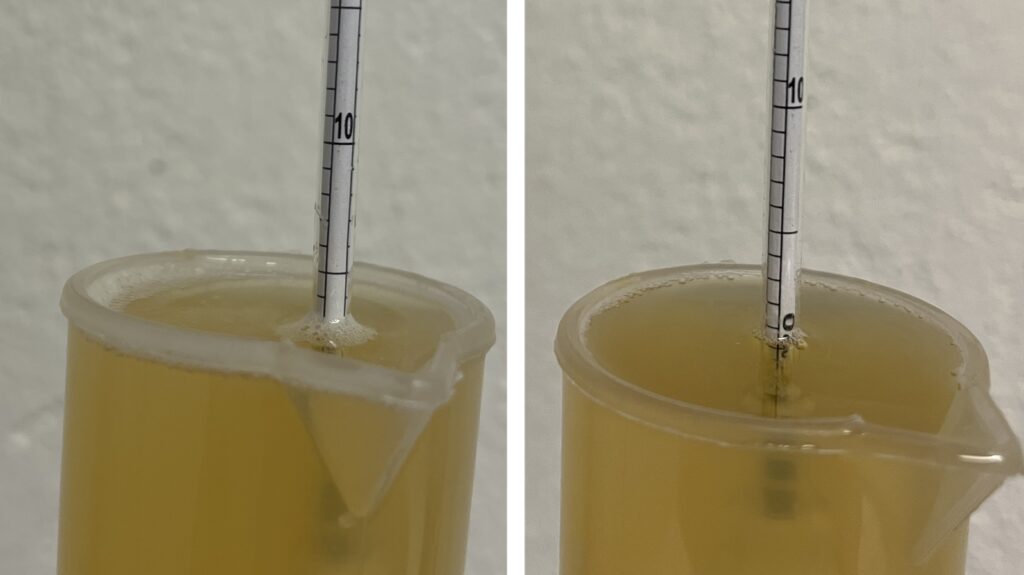

With the wort chilled and clear of trub, I transferred similar volumes to separate fermentation kegs then dosed one with 2 minutes of pure oxygen; the other wort was left alone.

I then pitched identical amounts of Imperial Yeast L28 Urkel that had previously been used to ferment two other batches of beer into each wort.

The beers were left to ferment at 50°F/10°C for two weeks before I hydrometer measurements showing the oxygenated batch had a slightly higher FG, which went against my expectation.

At this point, I gradually reduced the temperature of the beers to 32°F/0°C over the course of a few days then pressure-transferred each to CO2 purged serving kegs. The filled kegs were placed in my keezer and left to lager on gas for a month before they were ready for evaluation.

| RESULTS |

A total of 21 people of varying levels of experience participated in this xBmt. Each participant was served 2 samples of the non-oxygenated beer and 1 sample of the oxygenated in different colored opaque cups then asked to identify the unique sample. While 12 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, only 8 did (p=0.40), indicating participants in this xBmt were unable to reliably distinguish a Czech Premium Pale Lager that was not dosed with pure oxygen from one that received a 2 minute does of pure oxygen prior to yeast pitch.

My Impressions: Out of the 5 semi-blind triangle tests I attempted, I correctly identified the odd-beer-out just twice. These beers were perceptibly identical to me in all ways, presenting as supremely refreshing with ample Pilsner malt and noble hop flavor, clean fermentation, and an absence of any off-flavors.

| DISCUSSION |

Understanding that yeast require oxygen to effectively accomplish the task of fermenting wort into beer, many brewers opt to hit their wort with a hefty dose of pure oxygen prior to pitching yeast as a way to ensure a hospitable environment. Interestingly, tasters in this xBmt were unable to reliably distinguish a Czech Premium Pale Lager that was not dosed with oxygen from one that received a 2 minute dose of pure oxygen prior to yeast pitch.

It’s a well-accepted fact that oxygen is a crucial yeast nutrient, and hence these findings should not be interpreted as suggesting anything otherwise. Rather, these results may indicate that the level of dissolved oxygen in this pale lager wort was sufficient to have no deleterious effects, which is further corroborated by several past xBmts on the same topic. What’s fascinating is that attenuation was actually lower in the oxygenated batch, albeit by a rather small margin, as one would expect the opposite to have occurred, if anything.

Over the years I’ve been making beer, I’ve accepted that many of the methods employed by brewers are done so with the goal of creating the most optimal conditions such that the likelihood of problems is significantly reduced, rather than having a significant perceptible impact. This is how I view oxygenation – we know yeast require oxygen to perform best, and while wort may contain sufficient amounts on its own, dosing with pure oxygen offers a bit of insurance. As such, I’ll continue using pure oxygen in my standard brewing process, though should I discover my canister is empty on a brew day, I certainly won’t freak out.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

2 thoughts on “exBEERiment | Wort Aeration: Impact Oxygenation Has When Repitching Yeast In A Czech Premium Pale Lager”

We find the same thing over and over again in clinical medicine: deep understanding of the physiology doesn’t lead to an effective intervention. I’ve lost faith in reductionism (breaking down a complex system into tiny steps) as a path to a predictable result in any complex system. Reductionism is a form of bias. It takes actual controlled trials, experiments, to actually know.

Based on multiple experiments by Brulosophy, adding oxygen to wort doesn’t appear to be necessary. So, other than blind faith in tradition, does anyone have a solid reason to continue this practice?

I wonder if aeration might be more impactful when intentionally under-pitching to increase yeast expression, as one might do with a hefe yeast?