Author: Jordan Folks

Barley is the cereal grain most associated with brewing, and while the malted sort is the commonly used, various other types of barley exist as well. However, there are other grains often used to make beer, a popular one being corn, which is said to increase strength while contributing little in the way of aroma, flavor, or mouthfeel. Similar to barley, corn also comes in various forms include flaked and malted.

As the name suggests, flaked corn, or flaked maize as some refer to it, is produced by steaming corn and running it through hot rollers such that it is gelatinized, thus negating the need for a cereal mash. Malted corn, on the other hand, goes through the same germination and drying process as malted barley, which activates the endogenous alpha- and beta-amylase enzymes that ultimately convert starches to sugar during the mash.

The vast majority of the beers I brew are made without adjuncts, in fact I can’t recall a batch I’ve made with any type of corn product. Similarly, I’ve developed an affinity for Cold IPA based largely only versions other people have brewed. As a style that’s known to include a decent portion of corn, I recently began to wonder how the characteristics contributed by flaked corn would compare to a malted version in a Cold IPA and designed an xBmt to test it out.

| PURPOSE |

To evaluate the differences between a Cold IPA where one was made with a portion of flaked corn and the other was made with the same amount of malted corn.

| METHODS |

Wanting to emphasize the impact of the variable, I designed a Cold IPA recipe with a grist consisting of 40% either flaked or malted corn. Big thanks to F.H. Steinbart for hooking me up with most of the grains for this batch!

Bushels Of Corn And The Barley Meal

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.6 gal | 60 min | 71.4 | 4.6 SRM | 1.069 | 1.011 | 7.61 % |

| Actuals | 1.069 | 1.011 | 7.61 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pilsner | 10.5 lbs | 60 |

| Texas Blue Corn Malt | 7 lbs | 40 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Nectaron | 28 g | 60 min | Boil | Pellet | 10.9 |

| Nectaron | 14 g | 10 min | Boil | Pellet | 10.9 |

| Nectaron | 71 g | 10 min | Aroma | Pellet | 10.9 |

| Citra | 57 g | 10 min | Aroma | Pellet | 12.6 |

| Nectaron | 113 g | 2 days | Dry Hop | Pellet | 11 |

| Strata | 85 g | 2 days | Dry Hop | Pellet | 12 |

| El Dorado INCOGNITO | 20 g | 14 days | Dry Hop | CO2Extract | 52 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Pilgrimage (L26) | Imperial Yeast | 77% | 44.1°F - 55.9°F |

Notes

| Water Profile: Ca 103 | Mg 4 | Na 10 | SO4 183 | Cl 43 |

Download

| Download this recipe's BeerXML file |

I prepared a single large starter of Imperial Yeast L26 Pilgrimage a day ahead of time.

The following day, I started by collecting two identical volumes of water, adjusting each to my desired profile, and flipping the switches on my controllers to get them heating up, at which point I milled the barley malt.

Since flaked corn doesn’t need to be milled, I added it to one batch of milled grain before then ran the malted corn through my food processor before adding it to the other batch of grain. Once the waters were adequately heating, incorporated the grains and set the controllers to maintain my desired mash temperature of 146°F/63°C.

During the mash rests, I prepared the kettle hop additions.

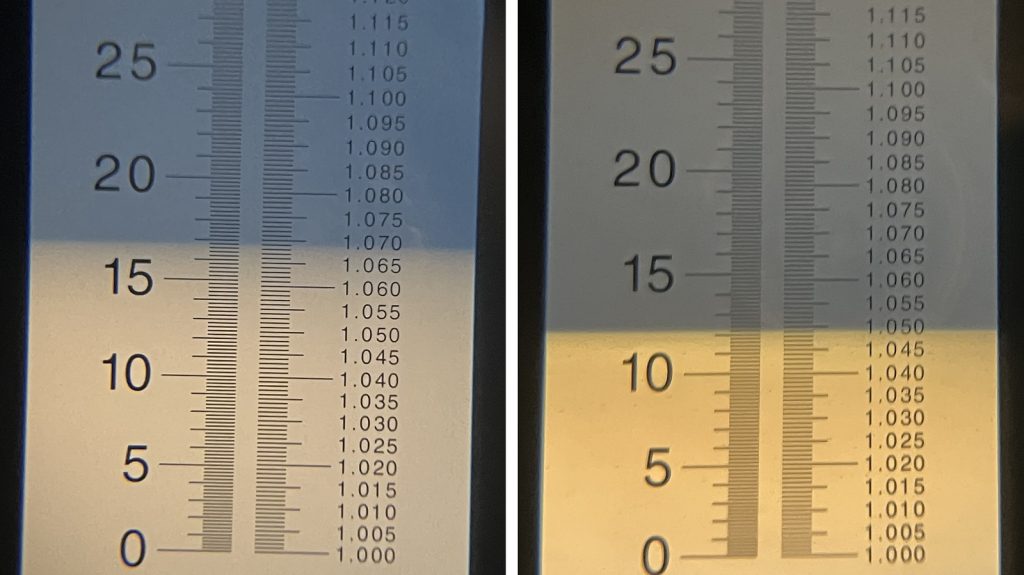

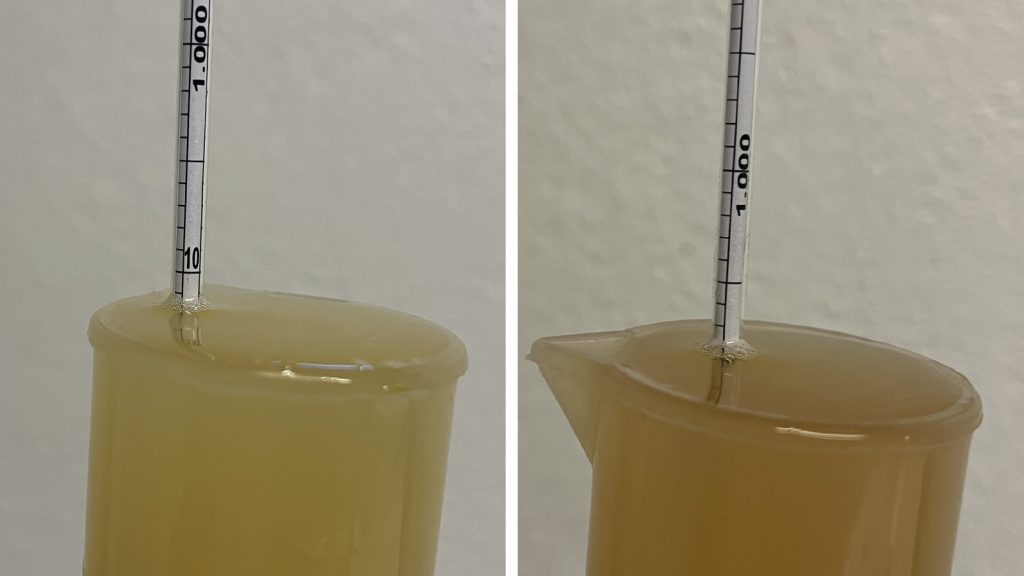

Once the 60 minute mashes were finished, I removed the grains and proceeded to boil the worts for 60 minutes, adding hops at the times listed in the recipe. With the boils complete, I chilled the worts and transferred equal amounts from each batch to separate fermentation kegs before taking refractometer readings showing the one made with flaked corn had a shockingly higher OG.

The worts were placed in my chamber and left to chill to my target fermentation temperature of 59°F/15°C, at which point I evenly split the starter between them.

At 2 weeks into fermentation, the dry hops were added.

Hydrometer measurements taken 24 hours later indicated the batch made with flaked corn finished a few points higher than the version made with malted corn, though the difference was nowhere near as stark as the OG.

At this point, the beers were cold-crashed overnight, fined with gelatin, then pressure transferred to separate CO2 purged serving kegs before being placed in my keezer. After a week of conditioning, the beers were carbonated and ready for evaluation.

| RESULTS |

A total of 23 people of varying levels of experience participated in this xBmt. Each participant was served 2 samples of beer made with flaked corn and 1 sample of the beer made with malted corn in different colored opaque cups then asked to identify the unique sample. In order to reach statistical significance, 13 tasters (p<0.05) would have had to accurately identify the unique sample, which is precisely the number who did (p=0.019), indicating participants in this xBmt were able to reliably distinguish a Cold IPA made with 40% flaked corn from one made with the same amount of malted corn.

The 13 participants who made the accurate selection on the triangle test were instructed to complete a brief preference survey comparing only the beers that were different. A total of 10 tasters reported preferring the beer made with flaked corn while the other 3 liked the malted corn version more.

My Impressions: Out of the 5 semi-blind triangle tests I attempted, I correctly identified the odd-beer-out every time. I perceived the version made with flaked corn as having a brighter hop character with a slight alcohol bite, while the beer made with malted corn was slightly earthy with muted hops and a subtle medicinal quality. I handily preferred the Cold IPA made with flaked corn.

| DISCUSSION |

There’s no denying that barley is the grain most associated with brewing, but numerous other cereal grains have and continue to be used to make beer as well, one of the most common being corn. While flaked corn appears to be the go-to for most brewers, malted corn is another option that is purported to contribute its own unique characteristics to beer. Indeed, tasters in this xBmt were able to reliably distinguish a Cold IPA made with 40% flaked corn from one made with the same amount of malted corn.

One possible, and perhaps likely, explanation for these results is the fact the one made with flaked corn was over 2% ABV higher than the one made with malted corn, something I felt was quite noticeable. Then again, many tasters commented that the beers tasted differently as well, which considering past xBmts on both flaked and malted corns that were non-significant, suggests it may be a function of the proportion of corn used in this recipe.

Having had a variety of beers made with corn that I enjoyed, I’m compelled to believe the sheer amount I used in this Cold IPA was at play in the final outcome. In addition to the odd flavor characteristic, I wasn’t a fan of the low efficiency I got from the malted corn, and as such, I’m inclined to use flaked corn going forward.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

11 thoughts on “exBEERiment | Grain Comparison: Flaked vs. Malted Corn In A Cold IPA”

Twenty gravity points and 2 % difference in ABV is why they invented gelatinization. You clearly did not extract the starches from the malted corn — they were still all bound up and not available to be converted to sugar. Please consider repeating the experiment with a gelatinization step for the malted corn. I have no idea if the beers will still be perceptively different, but the OG, FG, and ABV should be much closer between the two beers. There would need to be big, positive flavor impact for me to chose malted corn over the much-more-convenient flaked corn!

Correct me if I’m wrong, but shouldn’t the fact that the blue corn was malted imply it can be used without a cereal mash? Or perhaps the maltster didn’t modify it very well.

That was my understanding – but in retrospect I wonder if my mash temp was too low for this particular malt.

Malting develops the amylases but has little effect on loosening up the starch granules, regardless of the grain. The gelatinization temp of corn is ~190F+. Malted corn still needs a cereal mash.

Properly steeped and kilned malted corn does not require a cereal mash and is gelstinized, but the key word there is “properly”. I’ve used malted corn from other maltsters and had no issue hitting my efficiency numbers with a proper crush just using a normal sacrification mash. If anything it seems like someone might need to talk to Tex Malt about their process insuring they are properly malting this product for typical brewing use.

Wouldn’t you need to add another gelatinization step for the malted corn to get the starches out, which would account for the difference in OG.

I think also that the malted corn mash wasn’t fully converted which resulted in the lower gravity as well. I like to do an iodine whenever I try a new grain just to be sure.

Probably also a factor is if you actually count the same number of flaked kernels and malted kernels and weigh each, the flaked version is a lot lighter than the whole corn. Therefore 7 lbs of flaked corn is more product, more starches, and more converted sugars than 7 lbs of malted corn.

The only way this is true is if the water content of malted corn is substantively higher than flaked corn, which I highly doubt is the case.

The malted corn was bone dry!

That earthiness falls in line with my experience with malted corn. Unlike flaked maize, malted corn needs to be kilned. The kilning process adds a fair amount of flavor. The malted corn I used gave flavors of tamale dough, Vienna malt toastiness, and a subtle earthy character. For me, flaked maize gives me a light sweet-corn/corn flakes character without toast or earthiness.