Author: Will Lovell

Hops are arguably a requisite ingredient in beer, providing the bitterness necessary for balancing the malt sweetness, as well as the desired flavor and aroma characteristics. Unlike beer, which has hops added at multiple times throughout the process, hop water receives a single hop addition that’s most akin to what brewers might otherwise refer to as a dry hop.

Since first hitting the scene in 2014, hop water has gained a decent amount of popularity as a refreshing beverage that quenches the thirst with neither the alcohol nor calories. Considering its relative novelty, makers of hop water continue to debate the most effective methods for achieving the best result, and one focus has been on how long to keep the hops in contact with the water. Similar to dry hopping, where some believe longer contact time leads to more extraction of desirable aroma compounds, others claim it can lead to vegetal and grassy notes, thus preferring a shorter hop contact time.

Whereas I started out believing that longer dry hop times led to a more hoppy beer, I reduced my dry hop durations based on data from various studies, and I’ve been very pleased with the results. Having more recently developed a liking for hop water, I’ve made a handful of batches in the last couple years and have wondered about the impact contact time with hops might have, so I designed an xBmt to test it out for myself.

| PURPOSE |

To evaluate the differences between a hop water that is in contact with hops for 24 hours and one that is in contact with hops for 7 days.

| METHODS |

For this xBmt, I designed a hop water recipe with Vista and Citra, as I felt their pungency might better display any differences caused by the variable.

Auden’s Elixer

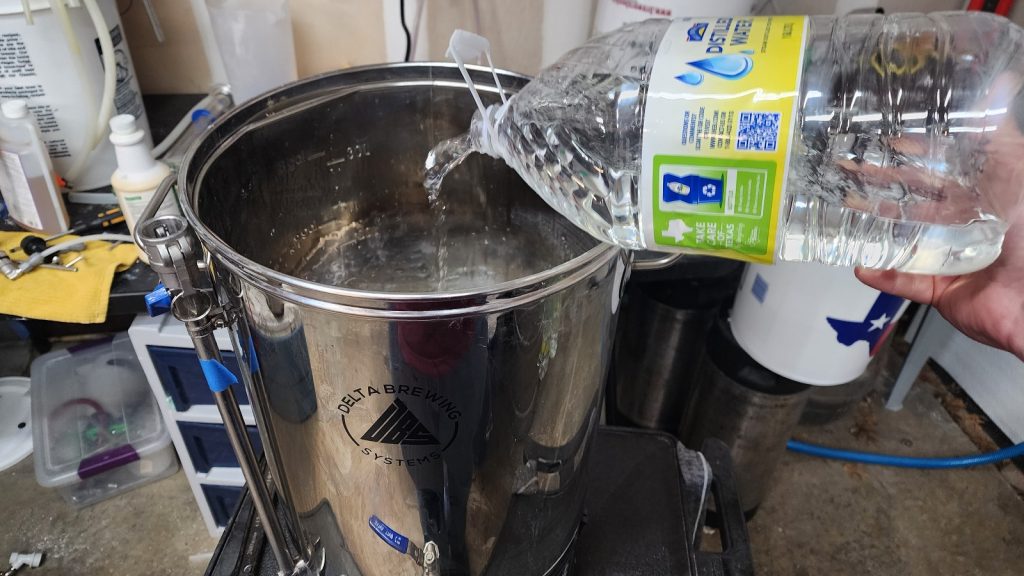

5 gallons/19 liters distilled water

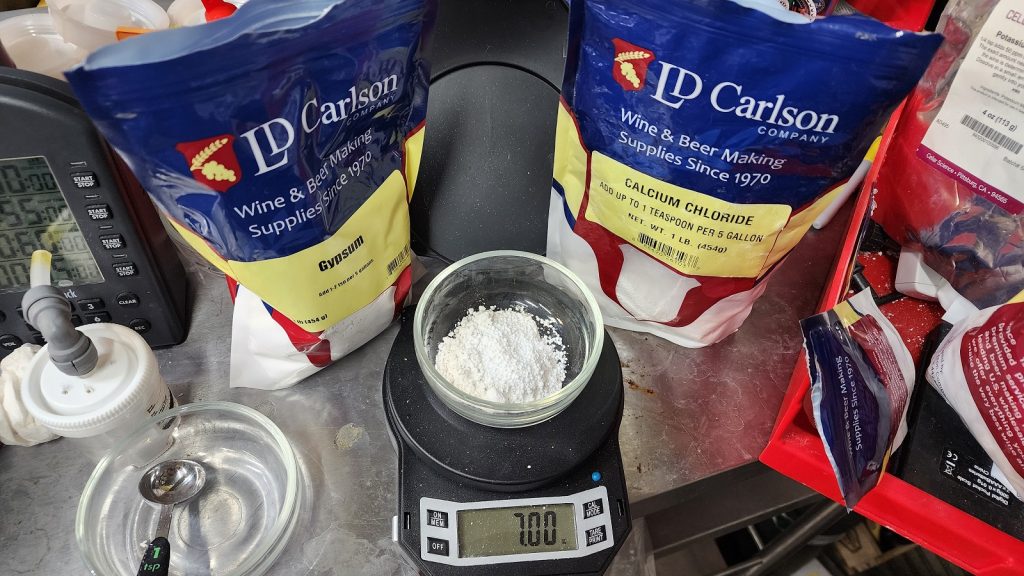

15 g gypsum

7 g calcium chloride

57 grams/2 oz Vista

57 grams/2 oz Citra

I started my brew day by adding 5 gallons/19 liters of distilled water to separate Delta Brewing Systems AIO units then setting the controllers to heat them up.

Next, I added the same amounts of gypsum and calcium chloride to each batch of water.

The waters were then boiled for 15 minutes with deoxygenation as the primary goal.

While the waters were boiling, I prepared the hop additions.

At the completion of each boil, I transferred each batch of hot water to separate sanitized kegs.

The kegs were placed in my chamber and allowed to chill overnight to my desired temperature of 40°F/4°C, at which point I added the hops to each.

After 24 hours, I pressure-transferred the water from one keg into a serving keg to get it off the hops, then placed it back in the same chamber.

After 6 more days, the water from second batch was pressure-transferred to a serving keg. Both kegs were placed in my keezer and placed on 20 psi of CO2 for 2 weeks before they were ready to serve to tasters.

| RESULTS |

A total of 23 people of varying levels of experience participated in this xBmt. Each participant was served 1 sample of the hop water that was in contact with hops for 24 hours and 2 samples of the hop water that was in contact with hops for 7 days in different colored opaque cups then asked to identify the unique sample. While 12 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, just 7 did (p=0.69), indicating participants in this xBmt were unable to reliably distinguish a hop water that was in contact with hops for 24 hours from one that was in contact with hops for 7 days.

My Impressions: Out of the 5 semi-blind triangle tests I attempted, I correctly identified the odd-beer-out just twice, and those were lucky guesses. These hop waters were perceptibly identical in every way to me, possessing a delightful fruitiness on the front-end with a hint of pine in the finish. This was my best batch of hop water yet!

| DISCUSSION |

Over the last few years, there’s been a growing interest in non-alcoholic beverage options, with one such option being hop water. Consisting of little more than water and hops, producing hop water is rather simple, though one decision producers have to make has to do with how long to keep the hops in contact with the water. Interestingly, tasters in this xBmt were unable to reliably distinguish a hop water that was in contact with hops for 24 hours from one that was in contact with hops for 7 days.

With the rise in popularity of dry hopped IPA in the last couple decades came debate about dry hop duration, and while many started off preferring longer contact time, many modern brewers prefer as little as 24 hours as a way to avoid undesirable vegetal and grassy flavors. While the present xBmt was on hop water, which is inarguably less complex than beer, these findings seem to suggest that hop contact time may not have as much of an impact as many believe. Curiously, this contradicts findings from a past xBmt where tasters could reliably tell apart an IPA dry hopped for 48 hours from one dry hopped for 11 days.

I’m a fairly patient person, but when I’m making a batch of hop water, my preference is to have it ready to drink as soon as possible. Given my experience with these hop waters and the blind taster results, I’ll definitely be sticking to shorter hop contact times in future batches, though I won’t fret if I’m unable to get to kegging until a little while after that. One thing’s for sure – I’ll definitely be making a lot more hop water!

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

14 thoughts on “exBEERiment | Hop Water: 24 Hour vs. 7 Day Hop Contact Time”

no citric acid?

I considered Citric and Lactic acid, but decided to keep it simple for the sake of the xBmt.

How do you avoid clogging the dip tube with all them hops loose in the keg?

I have floating Dip Tubes in those kegs with filters on them. Basically, even after 24 hours at 40F, most of the hops settle towards to bottom, so didn’t experience any issues with the transfer.

Boiling water for 15 minutes does absolutely nothing for deoxygenation. For one, it needs to be for at least 30 minutes and even then, it is the most ineffective method for removing dissolved oxygen from water. Nitrogen purging for 20-40min at a flow rate of 25 mL/s is the most effective oxygen removal method.

Hops dissolve in water. Once the pellets fully break up in water, shake the keg to disperse the particles. It’s just like adding powdered kool-aid with water.

N2 Purging is definitely a more effective method and also an expensive one that most homebrewers, including myself, don’t have access to.

While I’m not expert, my understanding of Deoxygenation through boiling is that its less of a function of boil length and more of a function of temperature. There will be fewer dissolved gases in water that is 100C v water that is 50c. While there are a lot of processes out there quote a 30 minute boil to deoxygenate, I would be curious if you have a source that correlates boil length with dissolved gasses.

Lastly, I wouldn’t go so far to say hops dissolve in water. There are oils that are water soluble, but if you throw some hope pellets in a glass of water and stir, you’re going to have a lot of green matter at the bottom of that glass. I’d also wager it won’t taste all that great.

I would be inclined to think that you could better identify dry hopping times in beer because the alcohol will extract from the terpenes better than pure water.

We have done hop contact time in beer xBmts. This xBmt I was strictly focused on the effects in Hop Water.

Sure, I was commenting on the discussion portion of the article- I think your IPA was notably different because the alcohol is better at extracting non-polar substances from the hop. Ethanol is commonly used for a wide variety of natural product extracts.

Overall a great experiment though! It will definitely help me on my first batch of hop water when I try it soon.

It’s not surprising contact time with beer does make a difference, while contact time in hop water does not.

Beer is a whole concoction of sugars, yeast (most importantly imo), and enzymes, with all sorts of reactions happening, even at terminal gravity. I’d wager in that other hop contact time xBmt, yeast sitting for 11 extra days created some unsavory character such as autolysis. I’d be more concerned with that than grassy or vegital flavors extracted from the hops.

To me, it makes sense that in water all those other reactions are eliminated. That would be my main takeaway from this xBmt: that with beer dry hopping, you want enough contact time for the hops to mix, but after that, funky stuff could start happening related to yeast.

In a professional setting, my goal is to get the hops to travel through the product and then get them out, especially because they drag unhappy yeast down with them. That process in a heavily dry hopped IPA could take 2-3 days (dumping what’s on the bottom and rousing to knock down what is still afloat on top, sometimes both of those processes twice a day). I believe this xBmt validates my own process, so that’s cool!

Can hop water also get oxidised? Do you purge kegs with co2 before transferring?

Hop water can oxidize. When I make hop water, I CO2 purge my kegs and I tend to keep it cold, ~35-40F. While I have a few speculative thoughts around what that looks like and what processes exaggerate it, we know hop compounds react to O2 and that it happens faster at warmer temps. Definitely a topic I want to explore more to better understand.

I want to know if using yeast will have a positive effect on the taste of hop water.

Check out this article that Jordan did: https://brulosophy.com/2023/07/17/exbeeriment-impact-yeast-has-on-hop-water/

I’ve never made hop water with yeast, but then again I’ve never ‘whirlpooled’ the hops for hop water. I just add hops to water in a keg, then transfer off after 24-48 hours.