Author: Jordan Folks

Diacetyl is a chemical compound produced during fermentation that’s often described as contributing a buttered popcorn characteristic and slick mouthfeel to beer. While the BJCP contends it’s appropriate in small quantities in certain styles, diacetyl is widely viewed as an off-flavor that’s to be avoided at all costs. Every yeast used by brewers can produce diacetyl, though some strains are more apt to do so, especially when fermenting in certain conditions, namely the cooler environments commonly associated with lagers.

Belonging to the vicinal diketone (VDK) chemical group, diacetyl is formed when alpha acetolactate (ɑ-acetolactate) produced during fermentation is oxidized, resulting in the tell-tale buttery aroma and flavor. While certain processes can be used to reduce the chances of diacetyl production, a relatively new product called Alpha Acetolactate Decarboxylase (ALDC), which gets added to the beer at yeast pitch, promises to “prevent the formation of diacetyl by breaking down the precursor, alpha acetolactate, as it is formed during fermentation – converting it quickly and directly into acetoin.”

I absolutely despise diacetyl and consider it the bane of my lager brewing existence, so I was ecstatic to learn ALDC was recently made available to homebrewers. I typically employ methods that result in my lagers having no noticeable diacetyl, like raising the temperature toward the end of fermentation, a practice rendered unnecessary when using ALDC. However, as much as I loathe buttery beer, I had some concern about other potential characteristics this unique enzyme might contribute, so I designed an xBmt to test it out for myself.

| PURPOSE |

To evaluate the differences between a Festbier dosed with ALDC at yeast pitch and one that was not dosed with ALDC.

| METHODS |

I brewed a simple Festbier recipe that I thought would allow any impact of the variable to show through. Big thanks to F.H. Steinbart for hooking me up with the malt for this batch!

Folksfest

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.1 gal | 75 min | 24.6 | 5.2 SRM | 1.054 | 1.011 | 5.64 % |

| Actuals | 1.054 | 1.011 | 5.64 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pils | 9 lbs | 83.72 |

| Barke Munich Malt | 1 lbs | 9.3 |

| Carahell | 12 oz | 6.98 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Saphir | 43 g | 75 min | First Wort | Pellet | 1.7 |

| Hallertauer Mittelfrueh | 35 g | 75 min | Boil | Pellet | 2.3 |

| Hallertauer Mittelfrueh | 43 g | 3 min | Boil | Pellet | 2.3 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Global (L13) | Imperial Yeast | 77% | 46°F - 55.9°F |

Notes

| Water Profile: Ca 55 | Mg 4 | Na 10 | SO4 29 | Cl 72 |

Download

| Download this recipe's BeerXML file |

After collecting the full volume of filtered tap water for two 5 gallon/19 liter batches, adjusting each to my desired profile, and getting them heating up, I weighed out and milled the grain.

Since this was a classic German lager, I decided to perform a step mash with rests at 144°F/62°C, 160°F/71°C, and 170°F/77°C.

During the mash rests, I weighed out the kettle hop additions.

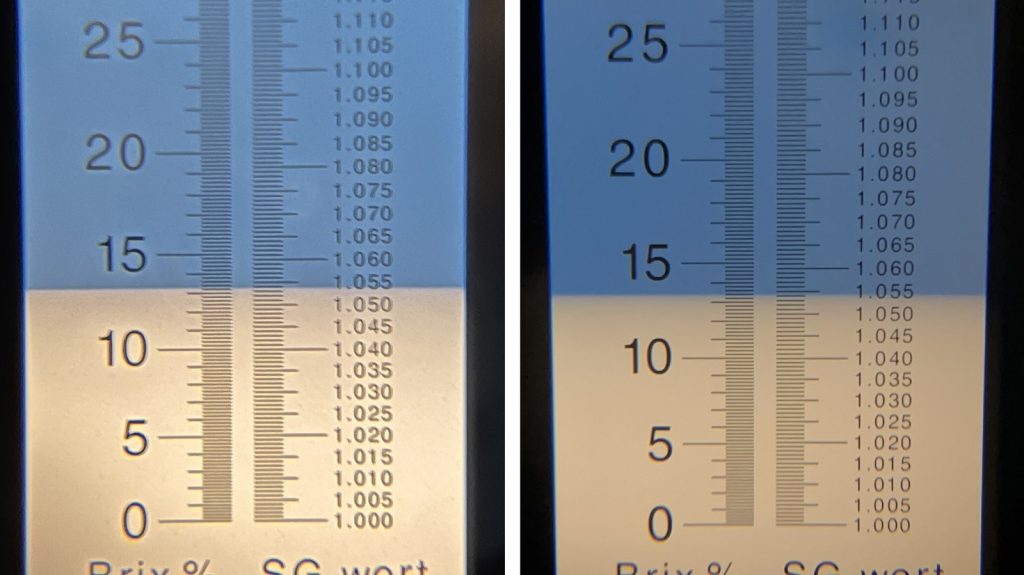

Once the mashes was finished, I removed the grains and proceeded to boil each wort for 60 minutes, adding hops at the times listed in the recipe. When the boil was complete, I chilled the worts during transfer to identical carboys, which were placed in my chamber where they were allowed to settle. Refractometer readings showed the worts were at the same target OG.

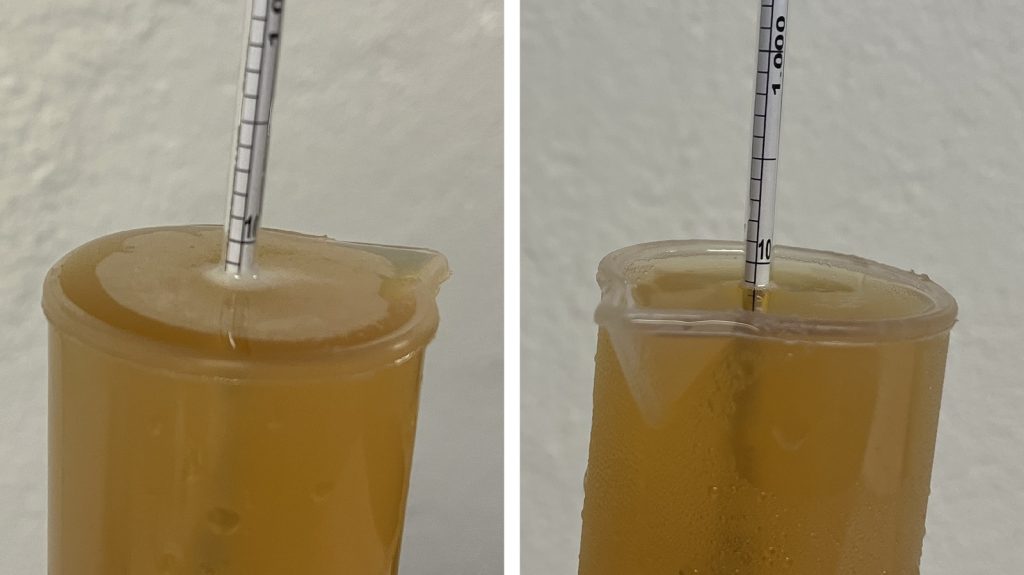

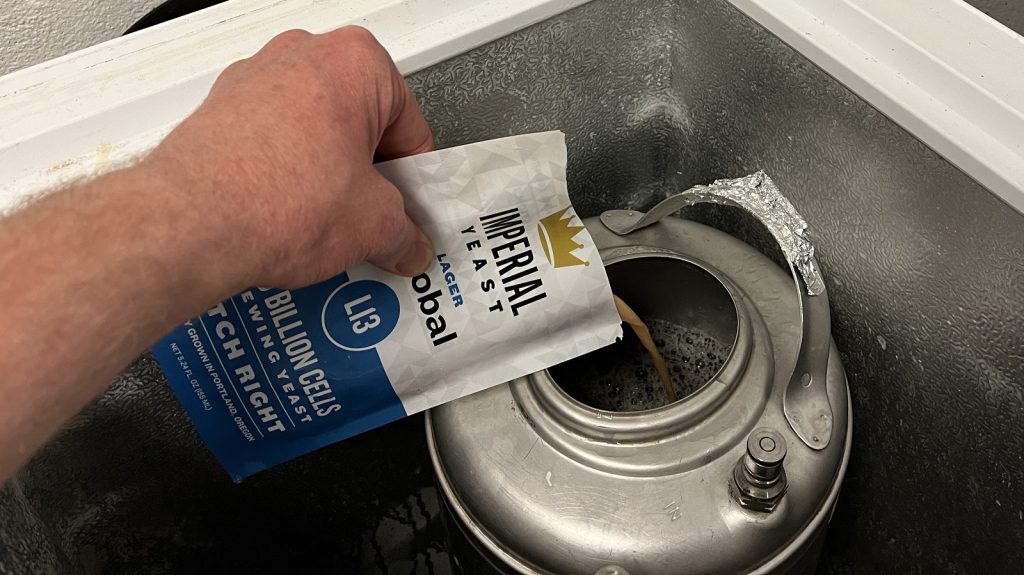

Once stabilized at my preferred pitching temperature of 47°F/8°C, which took a couple hours, I transferred the worts to separate fermentation kegs then pitched 2 pouches of Imperial Yeast L13 Global into each.

At this point, I added the recommended amount of ALDC to one of the batches.

The beers were left to ferment at 47°F/8°C for two weeks before I began spunding and gradually reducing the temperature; given the variable, I opted to skip my regular diacetyl rest step. When the beers were at 32°F/0°C a week later, I took hydrometer measurements showing they were at the same FG.

The beers were pressure-transferred to CO2 purged serving kegs that were placed in my keezer and left to lager for 8 weeks before they were ready for evaluation.

| RESULTS |

A total of 20 people of varying levels of experience participated in this xBmt. Each participant was served 2 samples of the beer dosed with ALDC and 1 sample of the beer that was not dosed with ALDC in different colored opaque cups then asked to identify the unique sample. While 11 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, only 9 did (p=0.19), indicating participants in this xBmt were unable to reliably distinguish a Festbier that was dosed with ALDC at yeast pitch from one that was not dosed with ALDC.

My Impressions: Out of the 5 semi-blind triangle tests I attempted, I correctly identified the odd-beer-out just once. As someone who is pretty sensitive to diacetyl, I was pleased to have perceived none in either of these beers, both had similar sweet malt notes with supporting hop bitterness and clean fermentation character.

| DISCUSSION |

As a style of German lager intended to be consume in rather large quantities, Festbier is expected to be completely free of off-flavors that might impede it’s drinkability, especially the buttery compound known as diacetyl. While brewers have developed methods to ensure imperceptible levels of diacetyl, a relatively new chemical option is Alpha Acetolactate Decarboxylase (ALDC), which when added at yeast pitch, prevents the formation of the diacetyl precursor. Interestingly, tasters in this xBmt were unable to reliably distinguish a Festbier that was dosed with ALDC at yeast pitch from one that was not dosed with ALDC.

One possible, and perhaps the most plausible, explanation for these results is that neither beer possessed detectable levels of diacetyl to start with, meaning the use of ALDC was essentially pointless. The lack of a perceptible difference between these beers also suggests the use of ALDC contributed no other characteristics to the beer, which is a win for those relying on this product as a means of protecting their beer against diacetyl.

For this xBmt, I skipped my typical use of a diacetyl rest in order increase the chances detectable amounts might remain in the beer; however, it would appear other factors are responsible for both beers lacking this undesirable off-flavor. While I plan to continue using ALDC purely for the sake of insurance, as I’ll do anything to ensure my lagers are the best they can be, these results certainly validated the methods I use to brew lager beers.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

16 thoughts on “exBEERiment | Impact Alpha Acetolactate Decarboxylase (ALDC) Has On A Festbier”

I’ve experimented with Omega’s DKO yeast that creates ALDC with split batching like this and found the one thing that ALDC does not do is prevent acetaldehyde problems. The D-rest also hedges against that so I will not be skipping it in the future with or without ALDC.

Acetaldehyde is an entirely different issue. Not sure why you would think ALDC or a D-rest would help with that.

Freeheeler, I stand by exactly the words I already used but I’ll say it a different way so you don’t misunderstand me. I don’t recommend using ALDC exclusively as a method of skipping a temperature push at the back end of fermentation because diacetyl is not the only reason such a higher temp rest is beneficial to the beer. Beers that skip a D-rest will sometimes crash the yeast out and leave a major acetaldehyde problem, especially if there’s question of yeast viability in the first place.

45% of the taste testers were able to reliably pick the odd beer. That is a significant number. Most people have a very low threshold for detecting this off flavor.

45% isn’t really significant. They had a 33% chance of guessing correctly. P values lower than .05 are the standard for significance in most studies.

What is your understanding of a p value of 0.19?

In the context of statistics, the word “significant” does not mean what you think it does.

Jordan, great work. I’ll be interested to see how this product works on a highly dry hopped beer, which I’m sure is already on the brew schedule.

I have the same product and my only complaint is that the dosages isn’t clear for batches smaller than 5 gals. A dropper with gradations on it would be super helpful.

Dwayne, what is your understanding of a p value of 0.19?

Learn how to prevent diacetyl rather than piss away $30 for an ounce of ALDC as a crutch. Hint: pitch healthy yeast and avoid cold-side oxidation. You’re welcome!

What about dry hopped ipas 👀

Oxidation doesn’t create diacetyl. If you use ALDC or give your beer the right amount of D rest. Your DO could be in the 500ppb and you won’t get Diacetyl.

Indeed, diacetyl is not necessarily a product of the type of cold-side oxidation brewers often talk about. It is, however, formed when alpha acetolactate that’s produced during fermentation is oxidized, turning it into 2,3 butanedione – aka diacetyl.

And diacetyl is so easy to remove from fermented beer. Simply add some fresh yeast slurry with the beer near room temperature. Let it work for 5 to 7 days. I have made some of my best beers doing this!

I think Jordan hit the nail on the head by saying he’ll use ALDC as insurance. That’s exactly the point of these products. Having car insurance for example doesn’t mean you can just drive like a total d*ckhead. Same with stuff like ALDC. You should absolutely still follow very consistent, controlled, and sanitary brewing practices. It’s much more a safety net than a crutch. And btw, sure its $30 for a 1-ounce bottle, but there are 35 doses (for 5-gallon batch size) per ounce. That’s 86 cents per 5 gallon batch. A pretty reasonable premium IMHO.

I heard from a legend in brewing that if you KO and ferment at 47f your chances of having diacetyl form are near nil. I have no sources or other info to back this up but it comes from a brewery in St Pete that produces world class beers and he swears by it. So if you did them both at 47f that might explain the absence of it in both beers.