Author: Jordan Folks

There are various points throughout the brewing process where pH is said to be important, and while mash pH is the most discussed, many brewers mind the pH of the wort post-boil as well. When making paler styles absent of notably acidic roasted grains, such as Pilsner, acidification of the wort after the boil can help to expedite the pH reduction that occurs during fermentation, which some believe has a qualitatively positive impact on the finished product.

While reducing that pH is commonly done with exogenous acids such as phosphoric or lactic, adherents of the German Purity Law don’t have this option, as they can only use water, malt, hops, and yeast to make beer. A Reinheitsgebot-approved alternative for acid reduction is sauergut, which is essentially wort that has been soured through the use of the lactobacillus naturally present on brewing grains.

With one past xBmt suggesting post-boil wort acidification with lactic acid has a perceptible impact, and another showing tasters could distinguish beers where the mash pH was adjusted with either sauergut or lactic acid, I wondered if my standard practice of adding sauergut to German lagers at flameout was having a noticeable impact and designed an xBmt to test it out!

| PURPOSE |

To evaluate the differences between a German Pilsner where the post-boil pH was reduced with Sauergut and one where the post-boil pH was not adjusted.

| METHODS |

I brewed a simple German Pilsner recipe that I thought would allow any impact of the variable to show through. Big thanks to F.H. Steinbart for hooking me up with the malt for this batch!

Mit Pils

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 38.7 | 3.3 SRM | 1.054 | 1.007 | 6.17 % |

| Actuals | 1.054 | 1.007 | 6.17 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Barke Pilsner | 12 lbs | 98.46 |

| Carahell | 3 oz | 1.54 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Hallertauer Mittelfrueh | 60 g | 60 min | First Wort | Pellet | 2.5 |

| Hallertauer Mittelfrueh | 60 g | 60 min | Boil | Pellet | 2.5 |

| Hallertauer Mittelfrueh | 69 g | 10 min | Boil | Pellet | 2.5 |

| Hallertauer Mittelfrueh | 50 g | 5 min | Boil | Pellet | 2.5 |

| Hallertauer Mittelfrueh | 50 g | 10 min | Aroma | Pellet | 2.5 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Global (L13) | Imperial Yeast | 77% | 46°F - 55.9°F |

Notes

| Water Profile: Ca 100 | Mg 4 | Na 10 | SO4 146 | Cl 66 |

Download

| Download this recipe's BeerXML file |

After collecting the full volume of filtered tap water for a 10 gallon/38 liter batch and adjusted it to my desired profile, which included acidification with sauergut to achieve the proper mash pH. While the water was heating up, I milled the grain.

Since this was a classic German lager, I decided to perform a step mash.

During the mash rest, I weighed out the kettle hop additions.

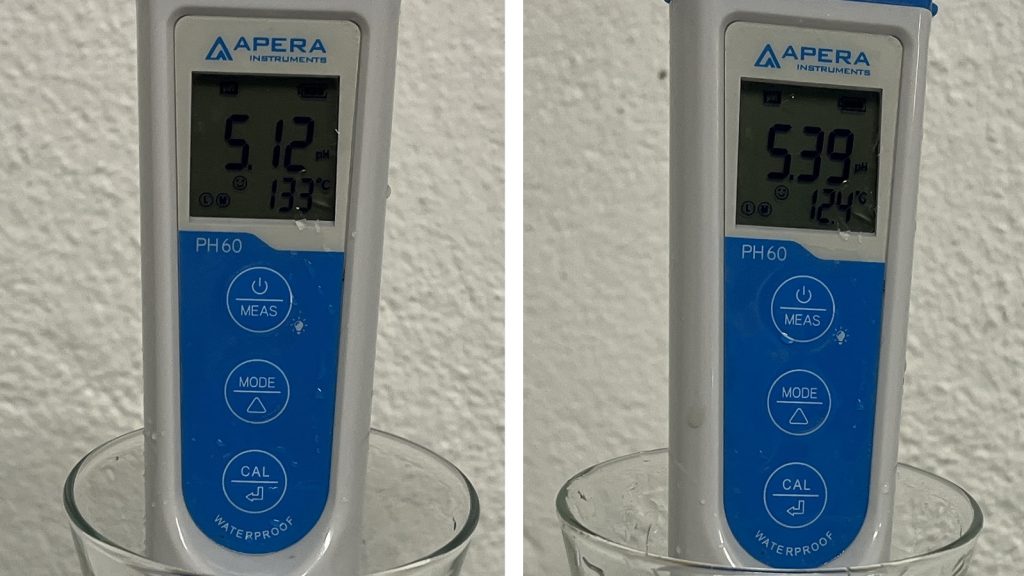

Once the mash was finished, I collected the wort and proceeded to boil it 60 minutes, adding hops at the times listed in the recipe. When the boil was complete, I ran approximately 2 liters/0.5 gallons of hot wort into fermentation kegs before adding enough sauergut to acidify one of them to 5.1 pH.

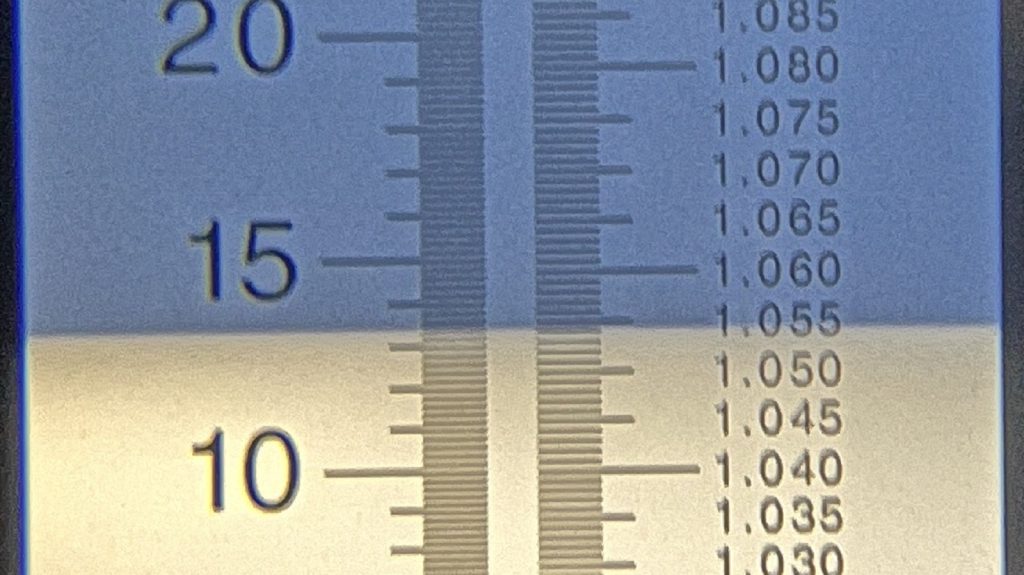

I then used my plate chiller to chill the rest of the wort during transfer to a cold break settling tank, which was placed in my chamber to finish chilling to my desired pitching temperature. A refractometer reading indicated I’d exceeded my target OG by 0.005 SG points. Meh.

With the wort chilled and clear of trub, I split it evenly between the two fermentation kegs, one of which contained sauergut, before taking pH measurements.

I then pitched two packs of Imperial Yeast L13 Global into each batch of wort.

The beers were left to ferment at 48°F/9°C for a week before I began very gradually raising the temperature to 60°F/16°C over the following 2 weeks, at which point I took hydrometer measurements the beers were at the same FG.

Subsequent pH measurements showed the batch dosed with sauergut post-boil ended with a slightly lower pH.

At this point, I gradually reduced the temperature of the beers to 32°F/0°C over the course of a few days, at which point they were pressure-transferred to CO2 purged serving kegs that were were placed in my keezer. After a 2 week lagering period, the beers were carbonated and ready for evaluation.

| RESULTS |

A total of 20 people of varying levels of experience participated in this xBmt. Each participant was served 1 sample of beer that was acidified with sauergut post-boil and 2 samples of the beer that was not acidified in different colored opaque cups then asked to identify the unique sample. While 11 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, only 8 did (p=0.34), indicating participants in this xBmt were unable to reliably distinguish a German Pilsner that was dosed with sauergut post-boil for pH reduction from one that was not acidified.

My Impressions: Out of the 5 semi-blind triangle tests I attempted, I correctly identified the odd-beer-out 2 out 5 times. To my palate, both beers had the same grainy and doughy malt notes with supporting hop bitterness and clean fermentation character. I detected no off-flavors in either of these beers, both were equally enjoyable.

| DISCUSSION |

While ensuring mash pH is within the purportedly ideal range has been shown to have a questionable perceptible effect on beer, some brewers have begun acidifying their wort post-boil as a way to improve the overall quality by decreasing “flabbiness.” Interestingly, tasters in this xBmt were unable to reliably distinguish a German Pilsner that was dosed with sauergut post-boil for pH reduction from one that was not acidified.

Considering the results from a past xBmt where tasters could reliably tell apart an American IPA that was acidified with lactic acid post-boil and one that was not, it’s possible the sauergut didn’t have the same flavor impact as the lactic acid. Another plausible explanation is that pale lagers don’t respond to post-boil acidification the same way American IPA does. Finally, while I make mash pH adjustments as a matter of course, and both beers were treated identically seeing as this was a post-boil split batch, I do wonder if the boil pH difference would have been more perceptible had I not acidified the mash.

As a rule of thumb, I always acidify my wort prior to yeast pitch, as it’s said to provide a variety of benefits such as reducing total fermentation time and encouraging complete attenuation, as well as providing flavor benefits. While the results of this xBmt didn’t necessarily support those claims, I’ll continue acidifying my lagers post-boil, even if just for insurance purposes, though I won’t stress if I forget this step in the future.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

8 thoughts on “exBEERiment | Impact Post-Boil Acidification With Sauergut Has On A German Pilsner”

You don’t say if you used commercially available sauergut or you made it yourself so we don’t know what the pH of it was or the percentage of lactic acid. Regardless, it would be nice to know how much you put into the mash to bring it down to (presumably) 5.2 and also how much went into the variable post boil wort.

I used Weyermann Sauergut which is 5.5% strength. I used enough to bring the mash to 5.4 pH. For a 5 gallon batch (and given my tap water/grist), I use about 100ml Weyermann Sauergut in the mash and about 75ml at knockout.

I just listened to the podcast. In Australia you can buy a litre of phosphoric acid 85% for $A18 to $A50 a litre depending on seller. Kegland sells 500 ml for $9.95.

I use 1-3ml per batch if needed.

Jealous! The US homebrew standard seems to be 10% and yet it is about the same price as 88% lactic.

Another user of phosphoric acid here chiming in to defend it as being dirt cheap and easy. I buy it at 85% from DudaDiesel (https://www.dudadiesel.com/choose_item.php?id=FGphos) and water it down to 25% in another bottle to make it easier to dose in 5ml increments. $13 bottle lasts *forever*.

Interesting discussion on the show covering this (just getting around to that one…) about what likely was a creative work around by German brewers to comply with aged rules and regulations and make great beer. Understand the risk of making and storing your own, not dissimilar to washing yeast and reusing that (which ended up causing me to dump a 10 gallon batch recently, first time I had done it in years and likely the last, but I digress.) Back on the point, wonder how one might do a variation on this, specifically create a very lightly Kettle Soured wort (pH 5ish) with a German Pils wort, and then just brew on? Seems like it would create the same sour flavor that the sauergut would have and eliminate the need to store the stuff. Thoughts?

Sure, one could use a kettle sour in place of sauergut, but I don’t think it would provide an identical flavor impact. That being said, making your own sauergut (via sour mash-type process) is arguably just as easy as a LAB pitch kettle sour (and no need to store it – just make a gallon for a five gallon batch and add until you reach desired mash pH). Also, I want to caution you on making a kettle soured wort with a pH of 5ish – do not do that! For one, that is not sour enough to work (the main batch of boiled wort would already have a pH of 5ish). But two, unfermented wort needs a lower pH (below 4.6 I think) to avoid botulism contamination risk. If you want to try this, kettle sour down to 3.5 or lower.

Thanks Jordan! Cheers!