Author: Ryan Hansen

For the better part of brewing history, trub has widely been viewed as a negative, contributing undesirable characteristics to beer. Referring to the sediment that settles to the bottom of both the kettle post-boil as well as the fermenter post-fermentation, trub is made up of lipids, proteins, hops, and in the case of the latter, yeast. One reason many opt to transfer beer out of primary soon after fermentation is finished is to get it off the trub in order to reduce any risk of off-flavor development.

The ingredients, gear, and methods available to modern brewers make separating beer from trub after fermentation a rather easy task, whether it’s through the use of fining agents, manual filtration, or cold-crashing. However, there seems to be a growing number of brewers who are focused on extreme simplification of the process, which given the popularity of fermenting in pressurized vessels, has led some to serve beer directly from the keg it was fermented in. As convenient as this might be, the glaring concern posed by many has to do with the extended time the beer spends in contact with the trub.

While serving directly from the fermenter is something I never really felt compelled to do myself, I’ve certainly wondered about it, especially as options for pressurized fermenters continue to increase. Would longer contact time result in better clarity as has been demonstrated in past kettle trub xBmts, or would the claims of those concerned with off-flavor development be validated? Curious to see for myself, I designed an xBmt to test it out!

| PURPOSE |

To evaluate the differences between a Kölsch-style beer that spent minimal time in contact with trub and one that was in contact with trub for an extended duration.

| METHODS |

For this xBmt, I went with a simple Kölsch recipe that I felt would allow any impact of the variable to shine through.

Gertrude

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 23.1 | 4 SRM | 1.046 | 1.009 | 4.86 % |

| Actuals | 1.046 | 1.009 | 4.86 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pilsner Malt | 10 lbs | 90.91 |

| Munich Malt, Germany | 1 lbs | 9.09 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Horizon | 14 g | 60 min | Boil | Pellet | 12 |

| Tettnang | 14 g | 15 min | Boil | Pellet | 4.5 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Harvest (L17) | Imperial Yeast | 74% | 50°F - 60.1°F |

Notes

| Water Profile: Ca 87 | Mg 1 | Na 8 | SO4 151 | Cl 49 |

Download

| Download this recipe's BeerXML file |

I started this brew day by collecting the full volume of RO water for a 10 gallon/38 liter batch, adjusting it to my desired profile, and flipping the switch on my Clawhammer Supply 120v controller to get it heating up, at which point my assistant helped me weigh out and mill the grain.

With the water properly heated, I incorporated the grains then checked to make sure it was at my target mash temperature.

When the 60 minute mash rest was complete, I removed the grains and proceeded to boil the wort for 60 minutes, adding hops at the times stated in the recipe.

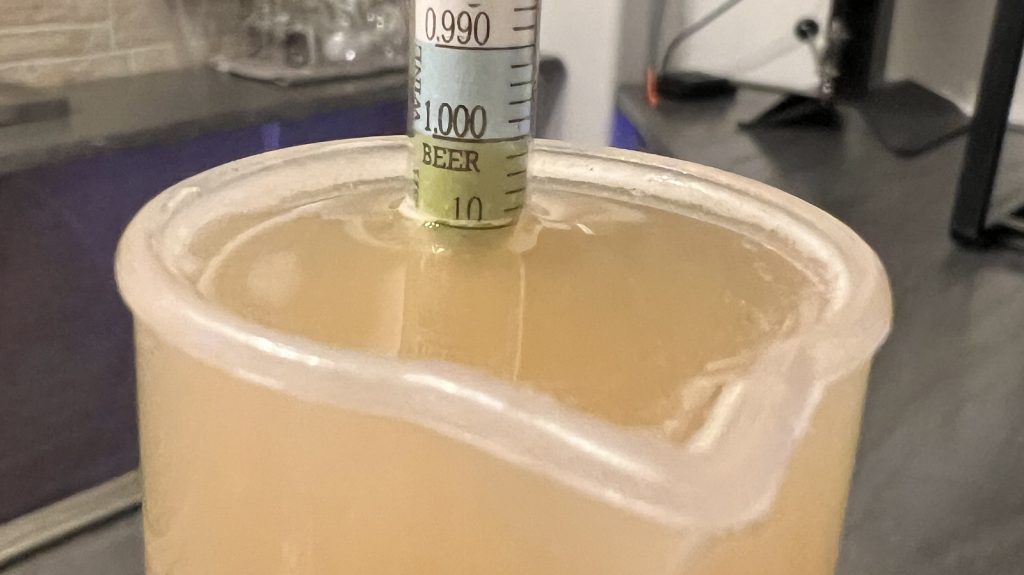

When the boil was finished, I quickly chilled the wort with my CFC then took a hydrometer measurement showing it was at my target OG.

Next, I pitched a pouch of Imperial Yeast L17 Harvest into the wort.

The fermenter was connected to my glycol unit set to maintain a temperature of 68°F/20°C and left to ferment for a week before I took a hydrometer measurement indicating FG had been reached.

After sanitizing and purging 2 Anvil King Chubby PET kegs, which had floating dip tubes installed, I transferred a large amount of trub to one before equally splitting the beer between them.

The filled kegs were placed next to each other in my cold box and left on gas for 4 weeks before they were ready to serve to blind tasters.

| RESULTS |

A total of 26 people of varying levels of experience participated in this xBmt. Each participant was served 1 sample of the beer left in constant contact with trub and 2 samples of the beer that had minimal contact time with trub in different colored opaque cups then asked to identify the unique sample. While 14 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, only 7 did (p=0.81), indicating participants in this xBmt were unable to reliably distinguish a Kölsch that was in direct contact with trub for 4 weeks after fermentation from one that had minimal trub contact.

My Impressions: Out of the 5 semi-blind triangle tests I attempted, I correctly identified the odd-beer-out just twice, indicating how perceptibly similar they were to me. I simply couldn’t tell these beers apart.

| DISCUSSION |

While most brewers recognize the importance of not transferring fermented beer off of trub too early, extended contact time is also believed to increase the risk of off-flavor development. With the rapid rise in popularity of pressurized fermentation vessels, the idea of serving directly from the fermenter has become something many have considered, though it’s often avoided due to concerns related to trub contact time. Interestingly, tasters in this xBmt were unable to reliably distinguish a Kölsch that was in direct contact with trub for 4 weeks after fermentation from one that had minimal trub contact.

One possible explanation for these results is that 4 weeks simply wasn’t long enough for any negative impact of the contact with trub to develop. Whether this is true or not, these results seem to suggest that leaving a style as delicate as Kölsch in contact with trub for as long as a month may not be as detrimental as many believe.

While I’d never considered it prior to this xBmt, serving beer from the vessel it’s fermented in is arguably quite convenient, and these results leave me feeling a bit more confident it’s a viable approach. Of course, longer contact times and different styles may result in different outcomes, which I plan to explore further in the future. Given how familiar I am with my kegging routine, I’ll continue with it for most of the beers I brew, though I wouldn’t have an issue serving directly from the fermenter in the future.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

13 thoughts on “exBEERiment | Impact Extended Time On Trub Has On A Kölsch”

Nice exBieriment, but I‘m unclear as to why you fermented with a lager yeast at 20°C. This temperature is also outside the range give by the manufacturer.

also, Kölsch is an Ale, so I‘m also unclear as to why you fermented with a Lager yeast.

It’s fairly common to treat Kolschs like a cream ale. “Too cold” for an ale or “too high” for a lager. Either way you are getting minimal ester production. I like using White Lab’s Cream Ale Blend WLP080. Clean, clean, clean and clean.

Also, thank you for doing this. I haven’t used secondary in nearly a decade, unless I’m doing an extended bulk aging. If I age a barley wine in bottles or a keg, there isn’t enough left in November – March.

My personal opinion, like a lot of stuff, the moving of the beer is a hold over from the “dark days” of homebrewing. From ’77 to the late 80’s you were luck to find yeast that was only a little expired and you never new how old your cans of Minton’s were. It was probably necessary to move it.

I believe WLP 080 is actually a *blend* of a lager and an ale yeast.

Is the recipe correct? I don’t worry much about style guidelines but that recipe is a dead ringer for a (delicious) helles, vs a kolsch (Munich malt not wheat, Augustiner yeast not a kolsch yeast…)

Love these experiments, however it is always a pale lager or something simple.I would guess people are dry hopping or whirlpooling, so why not do that test and include those findings?

When I look at the method I would argue that both beers were on trub. One just had more. Therefore, I am not surprised that no difference was detected. To avoid this issue a power filtration and force carbonation is needed. I bottle my beers and they always have sediment: mini-trub. Some I keep for many months with no off flavours. Salud!

I’m one of those who serve directly from the fermenting keg. The 6 gallon kegs are perfect for a 5.25 gallon batch, can immediately be cold crashed on gas when fermentation is complete, and if you add a spunding valve to the mix it starts the crash partially carbonated. Floating dip tubes complete the setup. No transfers is better than any transfer, and there’s one less keg to clean and sanitize.

I’ve never detected off flavors, but love the experiment to get some independent verification – thanks for doing it.

Awesome! I serve straight from my Fermzilla. Would be intrigued to see if similar results would happen with a massive dry hop…

I’ve made Kolsch about a dozen times and from these batches the thing that I found made the biggest improvement was using Kolsch yeast and fermenting in the stated temperature range of this hybrid. Order of preference for Kolsch yeast: Wyeast 2565, Wyeast 2575, Imperial G03, White Labs WLP029.

Without Kolsch yeast I don’t think you can say it is a Kolsch. Otherwise, how is the above recipe different than a Helles or German Pilsner? The real eye opener for me was a trip through Germany. When you get to Koln there is no way that you ever think you are drinking a Helles or Pilsner. A fresh bottle of Früh also makes the difference very plain.

I’ve been pressure fermenting and serving out of the same corny keg for 3-ish years now. If I had a dollar for every one who has tried to lecture me about “yeast autolysis off flavors” I’d have a decent chunk of change at this point.

As a homebrewer of 15 yrs these have been the best beers I’ve ever made at home. I end up drinking the 5 gallon keg either by myself or with friends in about 2 or less months after it’s ready and I’ve never experienced off flavors from them during this timeframe.

I’ll never go back to cleaning separate FVs for my homebrews.

Why or why not, given the forgiving lager yeast fermenting warm option …. use lager and ale yeast together … ale yeast working the top the lager yeast the bottom?

Morris