Author: Jordan Folks

Of the various steps involved in making a batch of beer, there are a few viewed widely as contributing to better quality, one of which is yeast pitch rate. Yeast labs tend to aim for a consistent number of cells in each package, and while this may suffice for certain styles and strengths of beer, it’s often lower than the recommended pitch rate, which is especially the case when it comes to fermenting traditional lagers.

Pitching a low amount of yeast cells, known as underpitching, in a cool fermented lager is known to increase the risk of fermentation problems including poor attenuation and off-flavor development. To combat this, it’s become common practice to pitch yeast at a rate of 1 to 1.5 million cells per milliliter per degrees Plato, which can be achieved either by using multiple packs of yeast or through propagation in a starter.

As a devotee to more traditional European lager production methods, I rely on high pitch rates and cool fermentation temperatures as a matter of course. Then, after a week of fermenting at 48°F/9°C, I’ll gradually increase the temperature over a few days to encourage complete attenuation. Curious of the impact underpitching yeast has when using this fermentation profile, I designed an xBmt to test it out!

| PURPOSE |

To evaluate the differences between a cool fermented International Pale Lager pitched with yeast at the recommended pitch rate (1.5 million cells per mL per °P) and one that was underpitched (0.75 million cells per mL per °P).

| METHODS |

I designed a simple International Pale Lager recipe for this xBmt in hopes that any differences would be readily apparent. Big thanks to F.H. Steinbart for hooking me up with the malt for this batch!

A Cozy Lil’ Thing Called Lager

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 4.5 gal | 60 min | 17.1 | 3.5 SRM | 1.046 | 1.011 | 4.59 % |

| Actuals | 1.046 | 1.011 | 4.59 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Brewer's Malt, 2-Row, Premium | 9.5 lbs | 97.44 |

| Carahell | 4 oz | 2.56 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Hallertauer Mittelfrueh | 24 g | 60 min | Boil | Pellet | 3.7 |

| Hallertauer Mittelfrueh | 28 g | 20 min | Boil | Pellet | 3.7 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Hygge (L25) | Imperial Yeast | 77% | 46°F - 56°F |

Notes

| Water Profile: Ca 100 | Mg 4 | Na 10 | SO4 146 | Cl 66 |

Download

| Download this recipe's BeerXML file |

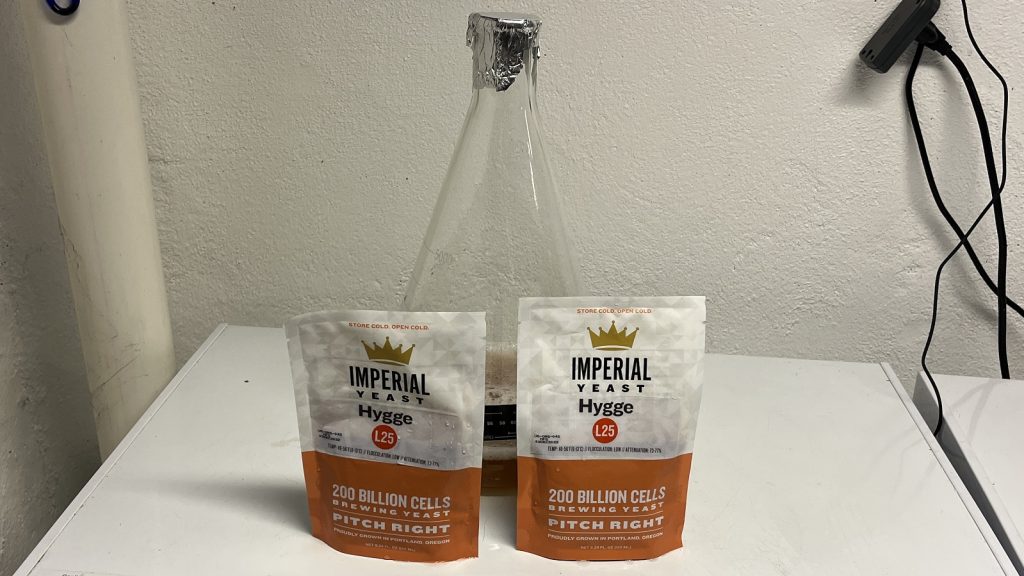

A day before brewing, I prepared a single large starter of Imperial Yeast L25 Hygge. Using a pitch rate calculator, I determined a 1.5 liter starter would yield a combined ~430 billion cells, which was about what I needed for both conditions in this xBmt.

The next morning, after collecting the full volume of water, adjusting it to my desired profile, and getting it heating up, I weighed out and milled the grains.

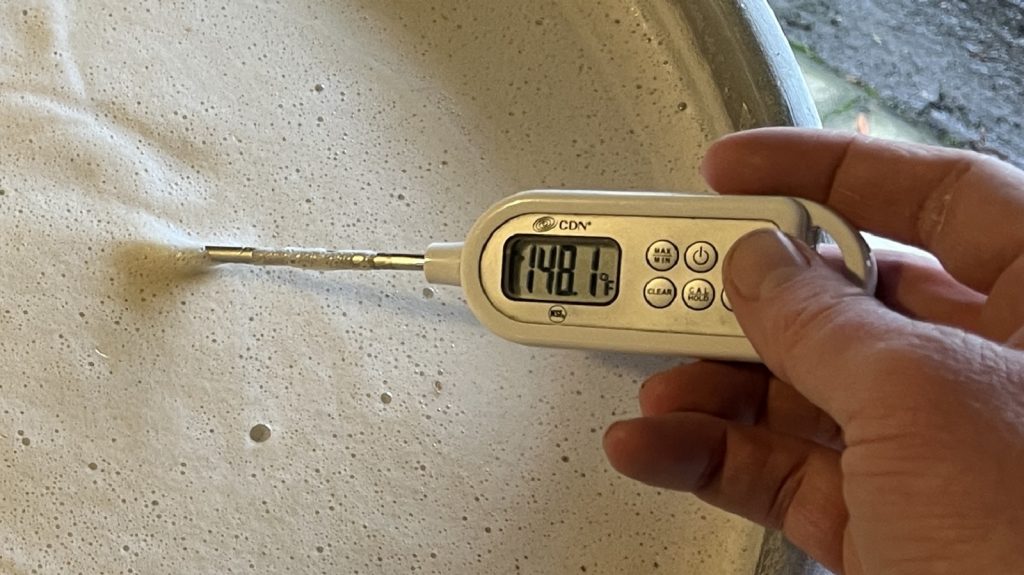

With the water properly heated, I incorporated the grains then checked to ensure it was at my intended mash temperature.

While the mash was resting, I weighed out the kettle hop additions.

Following the 60 minute mash rest, I collected the sweet wort and proceeded to boil it for 60 minutes before running it through my plate chiller on its way to a sanitized vessel that I placed in my fermentation chamber where it was allowed to finish chilling.

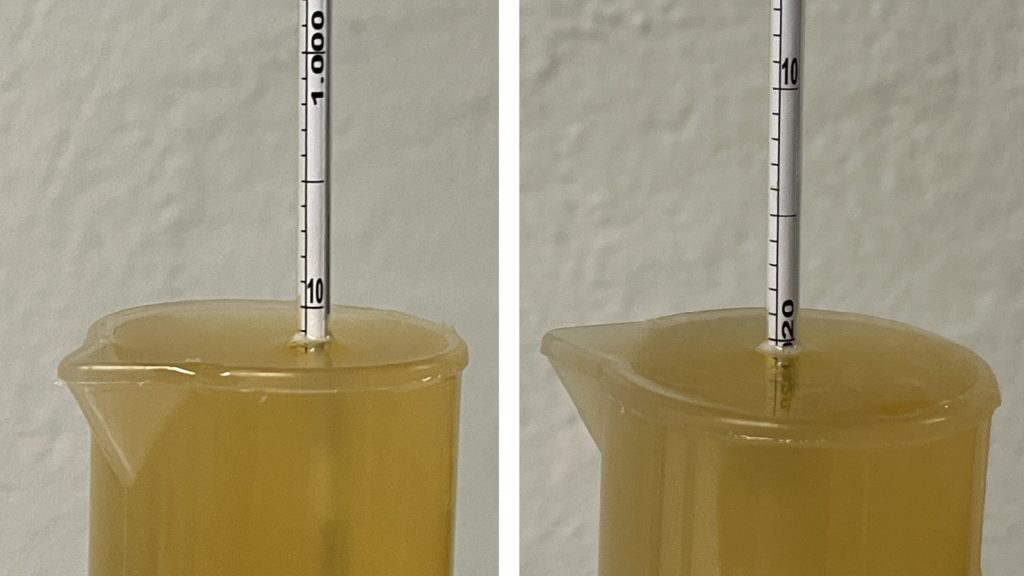

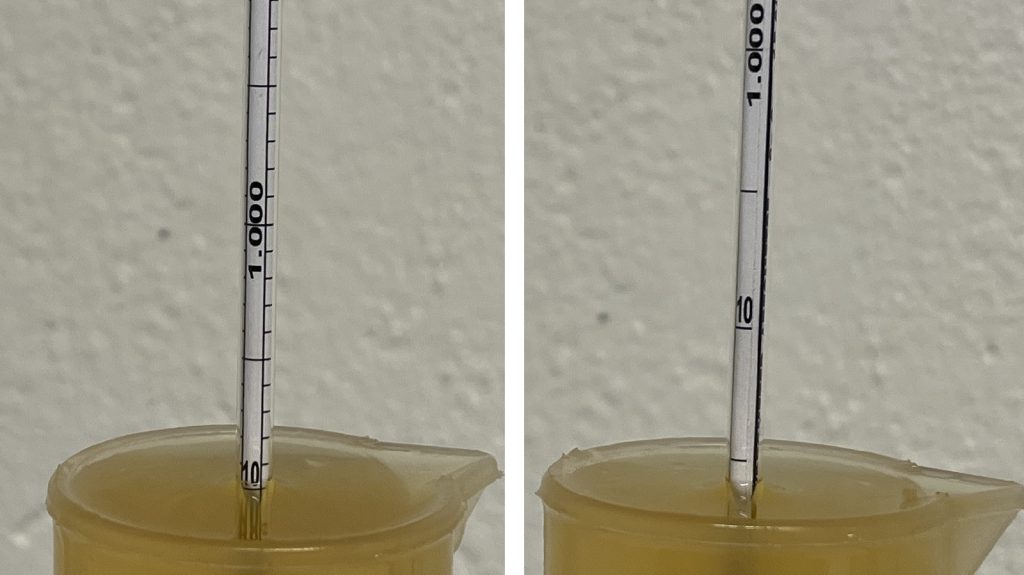

A hydrometer measurement showed the wort was at my target 1.046 OG.

Once the wort was at my target pitching temperature of 46°F/8°C, I evenly split the wort between two sanitized fermentation kegs, making sure to leave any trub in the settling vessel. Next, I pitched 1 liter of the yeast starter into one batch while the other received the remaining 0.5 liters, for calculated pitch rates of 287 billion cells and 143 billion cells, respectively.

The beers were left to ferment at 48°F/9°C for 1 week before I began gradually increasing the temperature every few days. Two weeks later, with the beers sitting at 60°F/16°C, I took an initial set of hydrometer measurements showing a rather vast difference in SG.

When a second set of hydrometer measurements taken a week later indicated the underpitched beer was still a few SG points higher than the properly pitched batch, I let them sit a few more days before confirming no change in FG.

At this point, I began slowly reducing the temperature of the beers under a small amount of pressure over the course of a few days, and once they were at 32°F/0°C, I pressure-transferred them to CO2 purged serving kegs. The filled kegs were placed in my keezer and slow carbonated during the lagering phase. After three weeks of conditioning, they were clear, carbonated, and ready for evaluation.

| RESULTS |

A total of 20 people of varying levels of experience participated in this xBmt. Each participant was served 1 sample of the beer pitched with the recommended rate of yeast and 2 samples of the underpitched beer in different colored opaque cups then asked to identify the unique sample. While 11 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, only 8 did (p=0.34), indicating participants in this xBmt were unable to reliably distinguish a cold fermented International Pale Lager that received the recommended yeast pitch rate from one that was underpitched.

My Impressions: Out of the 5 semi-blind triangle tests I attempted, I correctly identified the odd-beer-out just twice, indicating my inability to consistently tell the beers apart. To my palate, both had a similarly grainy, doughy malt character with supporting hop bitterness and clean fermentation character.

| DISCUSSION |

Pitch rate is a variable viewed as being highly important by many brewers, especially when it comes to lager styles where higher pitch rates are believed to ensure complete attenuation while suppressing undesirable ester development. Countering this claim, tasters in this xBmt were unable to reliably distinguish an cool fermented International Pale Lager pitched with the recommended rate (1.5 mil/mL/°P) of Imperial Yeast L25 Hygge from one that was underpitched (0.75 mil/mL/°P).

While likely surprising to those who have adhered to the idea that yeast pitch rates are essential to making good beer, these results corroborate those from numerous past xBmts, whether the focus was on cool fermented lager or higher OG ales. One objective observation from this xBmt is that the underpitched batch did not attenuate as well as the higher pitch rate beer, so that’s one argument in favor of proper pitch rates, even if it had no perceptible impact.

As dogmatic as I’ve been when it comes to yeast pitch rates, especially regarding lagers, these results totally challenged my belief that it’s absolutely necessary in order to produce a quality product. While I’ll continue relying on established pitch rates when making lagers, I won’t stress as much in situations where I might come up a bit shorter than planned, at least when fermenting with Imperial Yeast L25 Hygge.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

20 thoughts on “exBEERiment | Yeast Pitch Rate: Impact Underpitching Has On An International Pale Lager”

I think you are right in the conclusion that there is some tolerance on pitch rates, but the pitch rates in this experiment are all assumed based on the count in the packs and the pitch calculator.

Pack counts and starter growth can and do vary significantly from the assumptions.

So I think you might be successful with lower pitch rates some of the time but there’s a risk in doing so.

I dont think my comment is out of line with your conclusion though.

Thanks

I just did a little experiment with low pitch rate with that same yeast in a pilsner. I used one pack of quite fresh Hygge in 25+ liters, and fermented it at 8-9 degrees C – same as in the exbeeriment. That is 200 billion cells (well, slightly less, as I held just a little back to progate for more batches:)) in 6 and a half gallons.

I’ll normally use double that cell count, but the beer went from 1.050 to 1.010, as I would expect with a normal pitch, in normal time, and it tastes to me no different from my other pilsners – which I think are fairly clean and nice. To me this indicates that if you have yeast you can trust to be in perfect shape, you really don’t need to use twice as much for cold fermented lagers.

I have one question: The picture shows two pouches of L25, totalling 400 billion cells. So why did you make a starter? I must assume you used just the one of those two, or else this doesn’t make sense.

This was a 9 gallon batch – 4.5 of which would require ~290 billion cells for a lager pitch rate of 1.5 mil/ml/P. Due to estimated viability loss considering the packs’ age, I needed a starter to get the total estimated cell count for the exBEERiment.

Sir, the maths don’t add up. 94G cells in 17 liters at 11.5 °Plato is 0.5M cells/ml/°P not 0.75M cells/ml/°P… Just looking at the volumes of starter used for both conditions, it’s obvious the cell pitch rate reported is wrong.

The article has a typo which we just fixed. A 1.5L starter was split into 1L and .5L increments for each respective batch. According to my yeast calculator, this achieved the reported yeast pitch rates.

I would also be interested in the final cell count in the two beers. Given that it took more time to attenuate for the underpitched beer, I am curious to know whether the same cell count was achieved, but that it took longer. Fermentation rate was different, but how did the growth rate of the yeast compared?

It’s highly unlikely that the lower pitch beer ended up with the same cell count. Generally speaking, the more cells you add, the more new cells will be created. Not proportionally, but still. The reason for that is that the cells brings resources in form of energy and lipid reserves.

You pitched 1,5L starter in one and .5L starter in the other, that is a 3:1 pitch ratio which only makes this result stronger.

The result matches my own experience. I consistently “underpitch” all my beers and it works just fine. I have tried a couple of times to use recommended amount of yeast but it makes no perceivable difference to me at all.

I don’t see why it wouldn’t work. The yeast will multiply in the fermenter just as it multiplies in the starter. What’s the difference? There might possibly be a difference if the wort is very high OG but you did an exbeeriment on that too.

This is just another homebrewing myth, there are quite a few of them.

I guess the difference is the time to ferment but that only applies if you don’t count the time it took to make the starter.

The article has a typo which we just fixed. A 1.5L starter was split into 1L and .5L increments for each respective batch.

I think the underpitched and under-attenuated beer would be a potential bottle-bomb if it were bottled and left at room temperature, for example, if you wanted to enter it in a competition. Apparenlty, it still has enough fermentable sugar to produce about 5 volumes of CO2.

There was a final result difference in gravity, a rather large difference… Yet neither you nor others could notice a taste difference. Seems like you should have but you didn’t…

That is really interesting. I brew high percentage lager over ale (at least 2/3 lager). Normally all turns out well, re-pitching yeast from sloppy slurry until it is up to six months old (and always do a starter if more than a couple months since last batch). Occasionally something is slightly off, and so I do not save the yeast again. And I attribute it to the yeast.

With your experiment, it would be interesting if you could pour samples of each into some bottles and taste them after time. So like + 6 months and + 12 months after bottling. Maybe there would be no difference in quality over time, but maybe there would…? If you still have beer remaining anyhow.

I am genuinely shocked at how close these taste! I wonder if the high-ish level of carbonation helps smooth out some of the theoretical sweetness present in the higher FG batch. I’ll try to save some bottles to personally assess at a later date, but I don’t anticipate having enough for a large enough taster sample size to revisit this xbmt in another formal article.

Wait how did you divide 1.5 L into 281 billion cells and 94 billion cells by cutting it 2:1? That doesn’t seem possible if the yeast slurry is homogeneous. By definition there would be twice the cells in twice the volume.

Ugh, math is hard! This is my bad – actual [estimated] cell counts in the xbmt were legit, but had some transcription errors published here. I’ve updated the cell counts throughout – all is accurate now!

As other have noted – such a big difference in attenuation should be noticeable, not sure why it didn’t make any difference in taste… Layering (this is lager right?) may make it more obvious.

The primary benefit of over pitching is a shorter ferment. Under pitching will just need more time in the tank.

Ok here’s a tangent: Did you happen to have separate temperature control/monitoring for each batch? Like separate controllers or Tilts or something? The reason I ask is because the biggest difference I have noticed from under vs over pitching is that the over pitched batches freakin take off and get very exothermic and try to push the temperature up. I’m wondering if there was a difference in temperature profile for these two batches.

These were both in the same temp-controlled chest freezer set to 48f for a week before gradually raising to 60f over the course of another week.

Gotcha, so the air around the fermenters was 48 F, but you don’t know what the actual temperatures of the beers were?

Via Tilt I’ve confirmed that beer temp matches chest freezer temps