Author: Cade Jobe

There’s a lot to love about brewing and beer, and while many brewers and drinkers engage in responsible consumption, some have opted to take periodic breaks from alcohol as a sort of reset. Officially started in 2013, Dry January is a campaign designed not to lambast drinking, but rather raise awareness about the effects it can have on people. For those who participate, satiating the desire for beer has become increasingly easier with the rise in popularity of non-alcoholic (NA) options.

There are a number of unique methods that can be used to brew low and no alcohol beers, with a couple focusing specifically on the mash. Typically, brewers mash between 146°F/63°C and 164°F/73°C, the range where alpha and beta amylase enzymes are able to convert starches from malt into fermentable sugars. A fairly common approach for NA brewers involves mashing at a relatively high temperature to increase alpha amylase activity, which leads to a less fermentable wort. However, others opt for the non-enzymatic method that involves mashing at a significantly cooler temperature where the enzymes remain largely inactive.

As a participant of Dry January, I’ve definitely been excited about the growth of NA beer options and recently decided to try my hand at brewing one myself. While researching the various approaches, the high and low mash temperature methods made sense to me, though both seemed to have potential downsides as well. Rather than choosing to use just one, I designed an xBmt to compare the impact each has on a hoppy lager.

| PURPOSE |

To evaluate the differences between a non-alcoholic hoppy lager made using the high mash temperature method and one made using the non-enzymatic cool mash temperature method.

| METHODS |

For this xBmt, I designed a very simple NA hoppy lager recipe using a fraction of the malt required for a typical batch.

The Elusive One

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 12 | 1.1 SRM | 1.009 | 1.007 | 0.26 % |

| Actuals | 1.009 | 1.007 | 0.26 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pilsner Malt | 2.25 lbs | 100 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Magnum | 5 g | 60 min | Boil | Pellet | 14.2 |

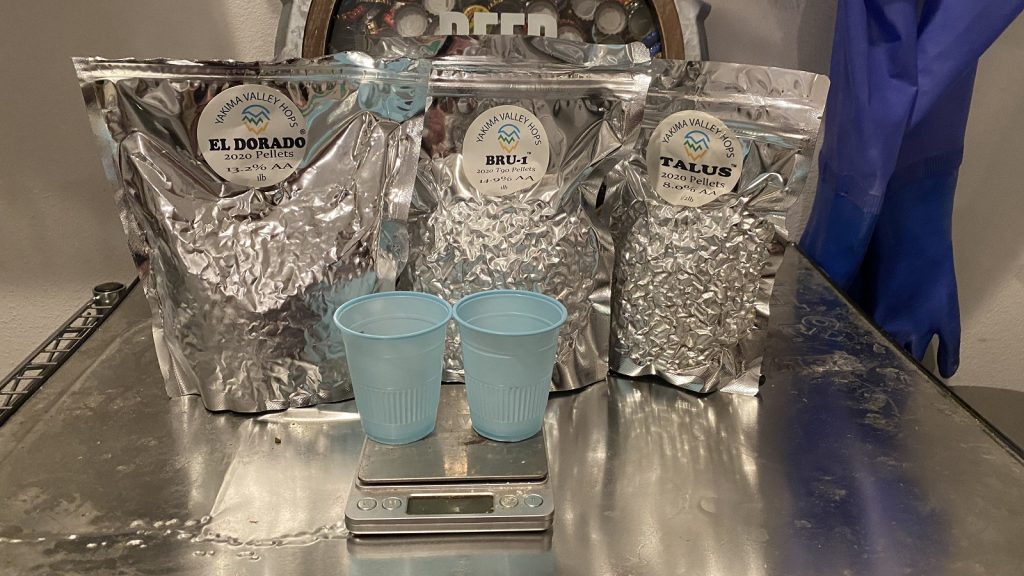

| BRU-1 | 5 g | 5 days | Dry Hop | Pellet | 14.9 |

| El Dorado | 5 g | 5 days | Dry Hop | Pellet | 13.2 |

| Talus | 5 g | 5 days | Dry Hop | Pellet | 8 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

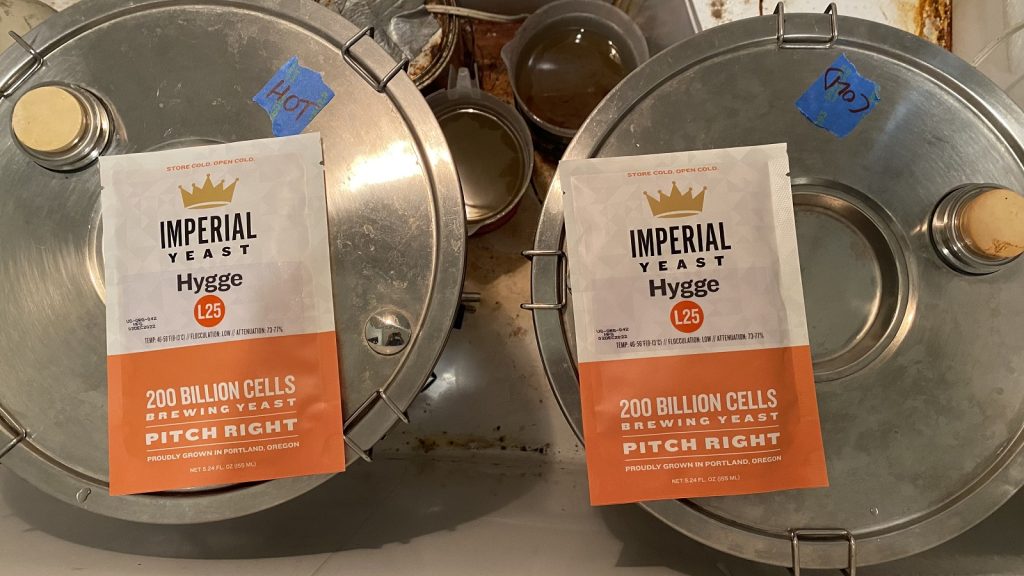

| Hygge (L25) | Imperial Yeast | 77% | 32°F - 32°F |

Notes

| Water Profile: Ca 115 | Mg 17 | Na 13 | SO4 70 | Cl 81 |

Download

| Download this recipe's BeerXML file |

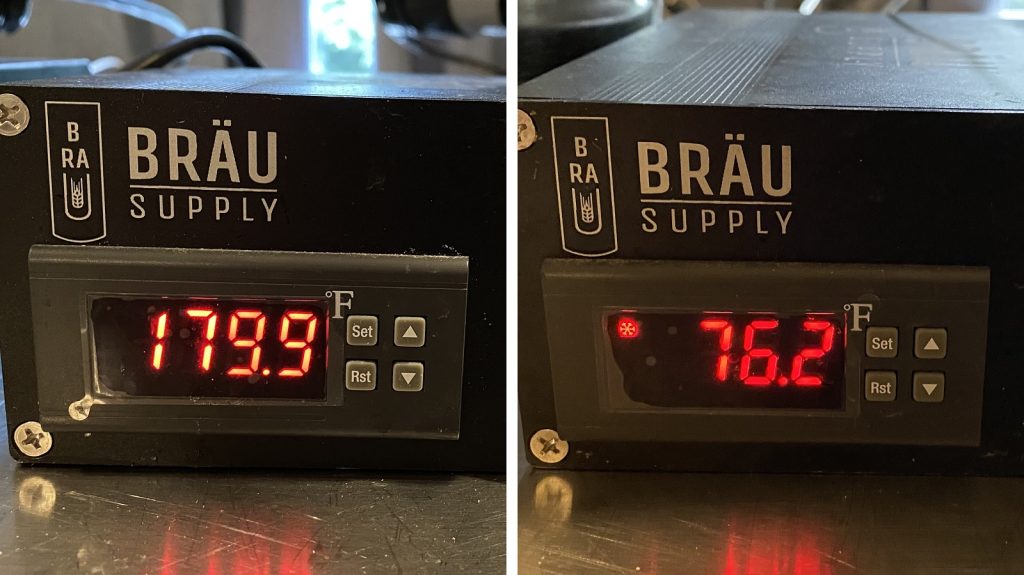

I started my brew day by collecting the full volume of water for each batch, adjusting both to my desired mineral profile, and setting the electric controllers to heat them up.

before weighing out and milling the grain.

With the water properly heated, I added the grains, turned the pumps on to recirculate, and set the controllers to maintain my intended mash temperatures of 180°F/82°C and 76°F/24°C.

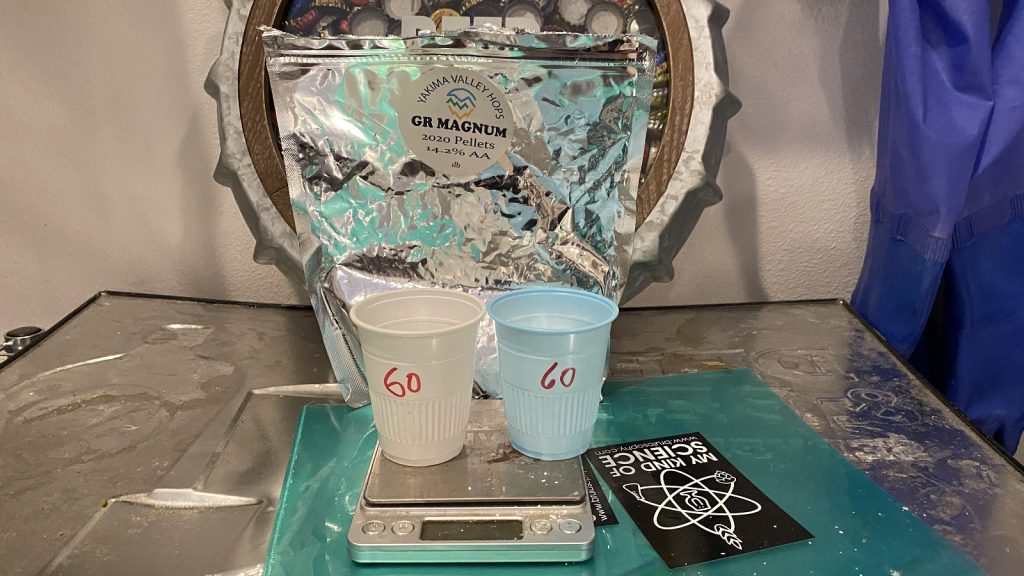

While the mashes were resting, I weighed out the kettle hop additions.

Following each 60 minute mash rest, I raised the grain baskets out of the kettles and let them drain, which is when I noticed a good amount of unconverted starch in the low mash temperature spent grain.

The worts were then boiled for 60 minutes with hops added at the times listed in the recipe.

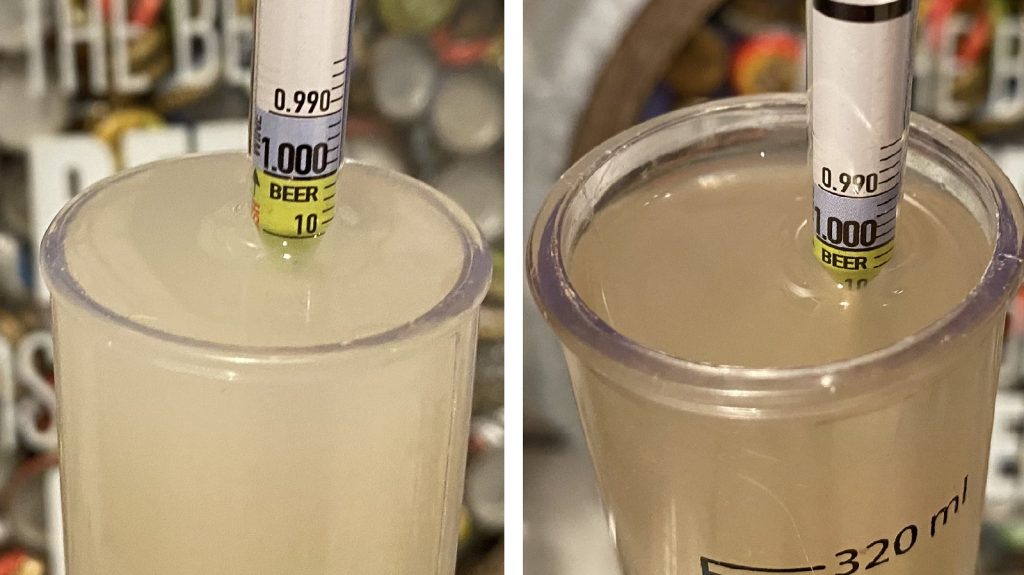

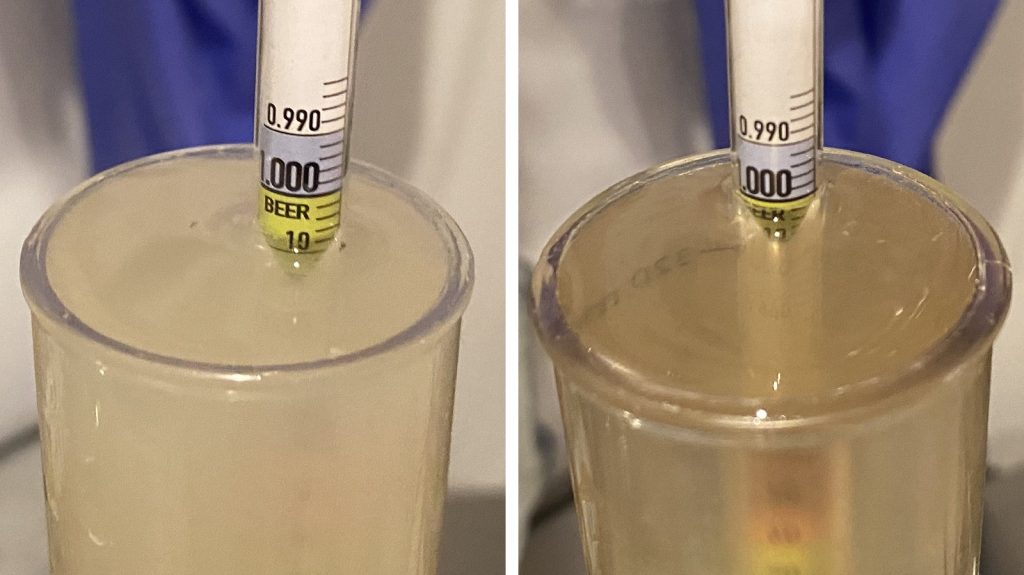

When the boils were complete, I quickly chilled the worts then took hydrometer measurements showing the high mash temperature wort was 0.005 SG points higher than the low mash temperature wort, though both were very low.

After transferring the worts to sanitized Brew Buckets, they were placed next to each other in my fermentation chamber and allowed to chill to my desired fermentation temperature of 50°F/10°C, at which point I pitched a pouch of Imperial Yeast L25 Hygge into each.

The beers were left to ferment for 5 days before I returned to add the dry hops.

After another 2 days, I took hydrometer measurements showing the high mash temperature beer was at 1.007 FG while the low mash temperature beer was at 1.001 FG, equating to estimated alcohol levels of 0.3% and 0.4%, respectively.

At this point, I cold-crashed the beers overnight then pressure transferred them to CO2 purged kegs.

The filled kegs were placed on gas in my keezer and allowed to condition for a couple of weeks before they were ready for evaluation.

| RESULTS |

A total of 17 people of varying levels of experience participated in this xBmt. Each participant was served 1 sample of the high mash temperature beer and 2 samples of the low mash temperature beer in different colored opaque cups then asked to identify the unique sample. While 10 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, 15 did (p=0.000004), indicating participants in this xBmt were able to reliably distinguish a non-alcoholic hoppy lager made using the high mash temperature method from one made using the non-enzymatic low mash temperature method.

The 15 participants who made the accurate selection on the triangle test were instructed to complete a brief preference survey comparing only the beers that were different. A total of 9 tasters reported preferring the high mash temperature beer while the other 6 said they liked the low mash temperature beer more.

My Impressions: Out of the 5 semi-blind triangle tests I attempted, I correctly identified the odd-beer-out every time. To my palate, the high mash temperature beer tasted a lot like many of the commercial NA beers I’ve tried– nice mouthfeel and body with pleasant hop character and mild bitterness. On the other hand, I perceived the low mash temperature beers as being a bit watery and thinner bodied, a bit more like I’d expect from a typical American Light Lager. While I thought both were quite drinkable, I had a slight preference for the one made using the high mash temperature method.

| DISCUSSION |

Non-alcoholic beer has seen a rather massive rise in popularity over the last few years, stretching beyond the boundaries of big commercial outfits and being embraced by the wider craft beer community. Numerous methods have been developed to brew such beers, one of which involves mashing warmer than normal and another that involves mashing cooler than normal. The fact tasters in this xBmt were able to reliably distinguish a hoppy lager mashed at 180°F/82°C from one mashed at 76°F/24°C suggests each method has a unique perceptual impact.

As expected, the high mash temperature beer started with a slightly higher OG due to alpha amylase activity, which resulted in a wort with minimal fermentability, as evidenced by the drop of just 0.003 SG points. The low mash temperature of the other batch resulted in the gross absence of enzymatic activity, leading to minimal conversion and increased presence of starch. While both mashes were recirculated throughout, one possible explanation for the differences between these beers is that the cooler temperature of the non-enzymatic mash retarded the time it took for starches to solubilize into the wort, which could affect mouthfeel and flavor.

I love beer, but I’ve found taking periodic breaks from drinking can be quite helpful for my physical and mental health. During these times, I’ve discovered NA beer can be quite fulfilling, though the brewer in me has always been curious to explore the impact of different methods. Based on my experience with this xBmt, while I think both approaches resulted in refreshing, drinkable beer, I preferred the mouthfeel and flavor of the high mash temperature version and will likely defer to it in the future.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

17 thoughts on “exBEERiment | High vs. Low Mash Temperature In A Non-Alcoholic Hoppy Lager”

The colour of those beers are just unappetising. Could you as in some of non-fermentable grain to get the colour you want?

Sure! Sounds like a good opportunity for added flavor as well.

Will this only work with lagers, or could you use the same method with ale yeast?

You could also use this method for ale yeast, but fermented at a higher temperature.

Nice work as always Cade. Seeing that the attenuation was about 23% on the high mash temp beer. Do you think starting with a slightly higher OG, 1.015-1.020, would you leave you with a slightly higher FG, 1.013-1.015, thus adding more mouthfeel and flavor?

Also, did you verify your wort pH going into the fermenter? Did you need to add any acid to make sure the pH dropped within safe range?

I did not verify pH. Starting with a higher OG is definitely something to consider, though the high mash temp beer had plenty of body and mouthfeel for a hoppy lager. Just want to keep in mind that increasing the OG increases the sugar content and potentially the attenuation if there happen to be more fermentable sugars available for the yeast to ferment.

that’s what I do, mash a 84C, 33% base malts, 66% special malts.

OD 1020

FD 1017

abv 0,4

I use LA01 as yeast

I’d like to see your recipe, Sven. I had one NA batch that went 1020 -> 1016. All the additional batches have started and ended lower. I suppose I could just use less water…

Great xBmt, Cade! It’s pretty cool that both batches had near identical ABVs.

I’ve seen some brewers cold steep as long as 12+ hours. How long did you mash each batch?

I just did 60-minute mashes. I’ve definitely heard of brewers doing longer mashes for cold steeps, just wanted to keep the mash lengths the same for this xBmt.

I cold mash my NA beer for 18 hours at 45 degrees with good results. I add a small amount of oats for mouthfeel.

Nice work, I myself use the high mash temp on my beers, mashing at 80-82°C for 30 minutes.

I like the information available on http://www.ultralowbrewing.com it has alot of great stuff to help people on their way.

This is a fabulous experiment. I have a group that’s supposed to be trying several techniques on my Rye PA NA recipe, but it’s slow going.

I’m relying on a very flavorful base recipe (minus 90% of the base malt) + dry hopping. I’m still using 4-5lbs malt, and mashing at 180.

The biggest struggle is mouthfeel – it’s just too thin.

I see you used a small load of hops to keep the bitterness ratio reasonable.

To address Russel’s question – absolutely, ale yeast works fine.

I use London ESB because the strain either struggles, or fails (depending on whose description you read) to handle maltotriose – so that’s another win for the NA team.

You could just enjoy real beer in moderation and skip this junk.

I have to say I find it pretty disrespectful to just dismiss the beers he made as “junk”.

Also, I’d challenge your math here: with the beers clocking in at less than a tenth of the ABV of a regular beer, it’s having a pint every day vs only a pint every other week. That’s abstinence beyond just “moderation”, imho.

Interesting experiment and confirmed my worry/suspicion that a low temperature would extract less and result in a low body and thin mouthfeel. (This isn’t explained well in what I have read.)

I want to try something similar but with mainly speciality grains. Target would be SG of 1.050 or higher but under 1% ABV. Looks possible from the above. Good to see you hit your numbers and that software can predict. You only included the high temp predicted numbers. Was the low temp beyond the formulas?

From my understanding, the super low efficiency of the cold Non-Enzymatic Method (NEM) suggests one can use a much larger grain bill for flavor and color contribution while still keeping the OG low. Obviously this would have brought another variable to the table in this experiment so I can see why it wasn’t done, but I think some further exploration of the NEM is still warranted and can perhaps show improvement in the right context.