Author: Steve Thanos

Every once in a while, a commercial beer comes along that I feel is so uniquely good that I feel inspired to brew a version myself. Unfortunately, attempts to clone recipes are often unfruitful, as brewers are left to guess what ingredients are used in the original recipe, which given the abundance of grains, hops, and yeast available, can be quite difficult. For this reason, I’ve developed a level of comfort reaching out to breweries to ask about certain recipes, one of which is Maplewood Brewery & Distillery’s Charlatan Pale Ale.

Nestled in the Logan Square neighborhood of Chicago, Maplewood Brewery & Distillary has been crafting delicious beers and spirits since 2014, which they serve to patrons in their cozy taproom and cocktail lounge. One of their flagship beers is Charlatan Pale Ale, which beautifully melds toasty malt flavors with the fruitiness of Citra, Centennial, and Simcoe hops to create a moderate strength sipper that stands up to any Midwest season.

I’ve been a big fan of Maplewood Brewery & Distillery since they first opened, and Charlatan Pale Ale is a beer I can confidently say delivers every single time. And I’m not alone, as it has won medals in the American Pale Ale category at the Great American Beer Festival in both 2016 and 2018. As a local offering that’s high on my list of beers to try brewing myself, I reached out to inquire about the recipe and was fortunate enough to be provided a version scaled down to my homebrew batch size!

| Making Maplewood Brewery & Distillery’s Charlatan Pale Ale |

Major cheers to Maplewood Brewery & Distillery’s founding brewer and CEO, Adam Cieslak, for giving me with the recipe for Charlatan Pale Ale, which I followed as closely as possible.

Maplewood Brewery & Distillery’s Charlatan Pale Ale

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 32.5 | 5.5 SRM | 1.062 | 1.007 | 7.22 % |

| Actuals | 1.062 | 1.007 | 7.22 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pale Ale Malt | 8.75 lbs | 82.35 |

| Light Munich Malt | 12 oz | 7.06 |

| Caramalt Malt | 6 oz | 3.53 |

| Dextrin Malt | 6 oz | 3.53 |

| Wheat White Malt | 6 oz | 3.53 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Warrior | 9 g | 60 min | Boil | Pellet | 16.5 |

| Simcoe | 7 g | 15 min | Boil | Pellet | 13 |

| Centennial | 3 g | 10 min | Boil | Pellet | 10 |

| Citra | 3 g | 10 min | Boil | Pellet | 12 |

| Simcoe | 3 g | 10 min | Boil | Pellet | 13 |

| Centennial | 9 g | 10 min | Aroma | Pellet | 10 |

| Citra | 9 g | 10 min | Aroma | Pellet | 12 |

| Simcoe | 5 g | 10 min | Aroma | Pellet | 13 |

| Citra | 35 g | 5 days | Dry Hop | Pellet | 12 |

| Centennial | 21 g | 5 days | Dry Hop | Pellet | 10 |

| Simcoe | 21 g | 5 days | Dry Hop | Pellet | 13 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Flagship (A07) | Imperial Yeast | 79% | 32°F - 32°F |

Notes

| Water Profile: Ca 125 | Mg 20 | Na 8 | SO4 310 | Cl 56 |

Download

| Download this recipe's BeerXML file |

After collecting the full volume of filtered water and adjusting it based on the profile provided by the brewery, I lit the flame under the kettle then proceeded to weigh out and mill the grain.

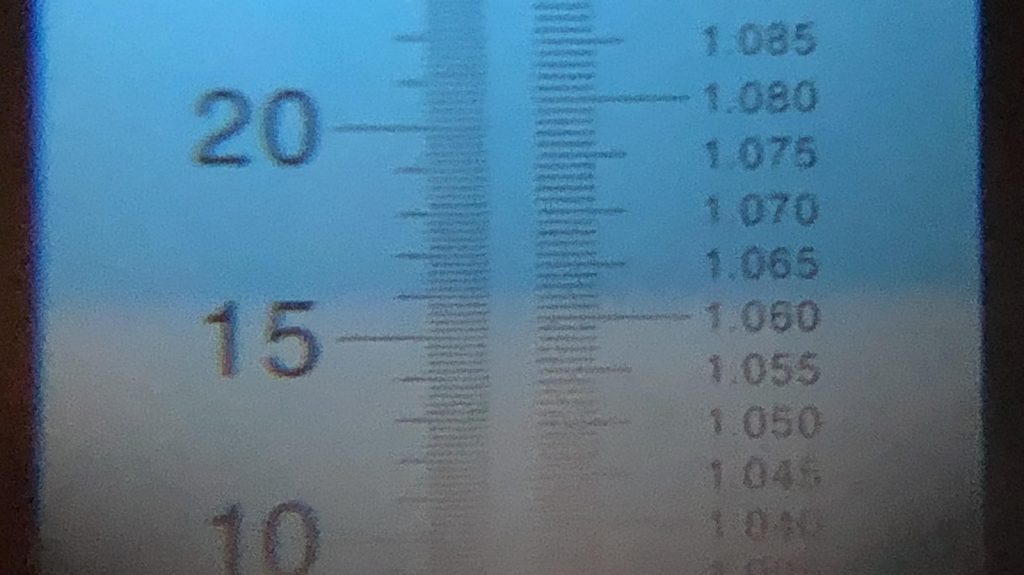

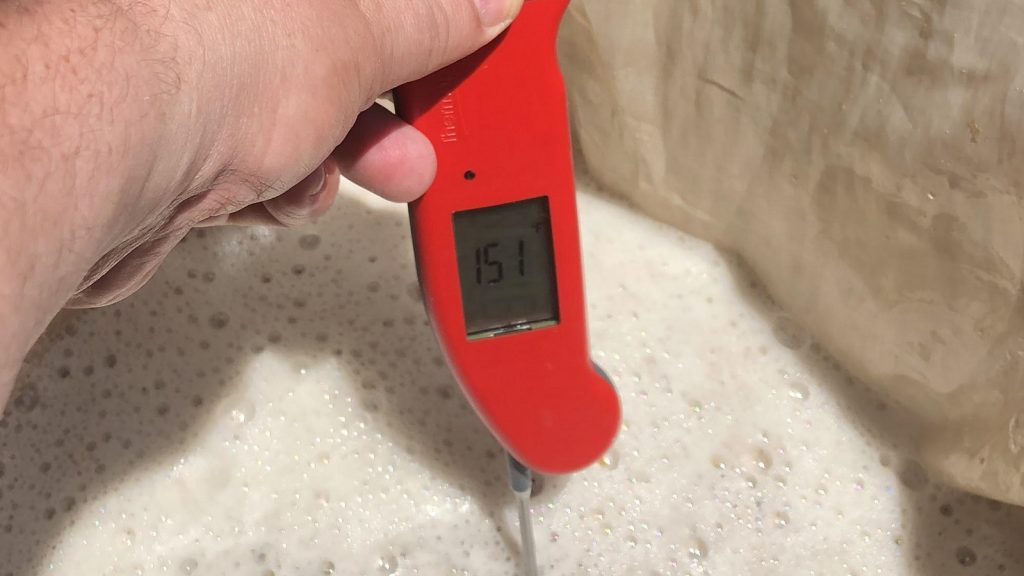

Once the water was adequately heated, I incorporated the grains then checked to make sure it was at my target mash temperature.

While the mash was resting, I prepared the kettle hop additions.

Once the 60 minute mash was complete, I removed the grains then boiled the wort for 60 minutes before rapidly chilling it with my JaDeD Brewing Hydra IC.

Refractometer readings showed the wort was at my target 1.062 OG.

After transferring the chilled wort to a fermenter, I placed it in my chamber for a couple hours to finish chilling to 68°F/20°C, at which point I pitched a pouch of Imperial Yeast A07 Flagship.

At 1 day into fermentation, I added the dry hops then left the beer for another 5 days before taking a hydrometer measurement confirming FG had been reached.

At this point, I cold crashed the beer to 36°F/2°C and left it for 5 days before transferring it to a CO2 purged keg. The filled keg was placed in my fridge and left to condition for a week before it was ready to drink!

| IMPRESSIONS |

With its assertive hop character, malty backbone, and crisp finish, Maplewood Brewery & Distillery’s Charlatan Pale Ale has rightfully earned the reputation of being a solid beer for drinkers in Chicagoland. However, for those outside of the region, landing some of this tasty elixir can be quite difficult, which is why I reached out to the brewery and was thrilled when they offered to share the recipe with me.

Having consumed quite a bit of Charlatan Pale Ale over the years, I admittedly went into this with a bit of skepticism, though I was pleasantly surprised with just how great my version turned out. Despite being a bit stronger than the real deal, I felt the batch of Charlatan Pale Ale I brewed was nearly identical in terms of aroma, flavor, and overall drinkability.

One thing I appreciate about this beer is the pungent hop character, which is largely a function of the relatively hefty dry hop addition for an American Pale Ale. When I brew this beer again in the future, I’ll be more mindful of my efficiency in order to achieve a similar strength as the original Charlatan Pale Ale. Other than that, I wouldn’t change a thing, this was an excellent homebrewed version of an excellent commercial beer!

If you have thoughts about this recipe or experience making something similar, please feel free to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

7 thoughts on “Brü It Yourself | Maplewood Brewery & Distillery’s Charlatan Pale Ale”

Thanks for putting the recipe in Brewfather!

Man, you’re getting some mad efficiency with your brew system. I figure it to be 88%. Thanks for the recipe.

I was wondering the same thing. >84% Efficiency is super high for a BIAB system. I’m using a recirculations BIAB and I’m at like 74% Mash Efficiency and 65% BHE. That’s a huge difference.

The recipe sounds solid – was wondering about the small late-boil and WP additions but after all this is a pale ale not an IPA. Reads very drinkable and I love the good old grapefruity hops!

I understand that the pictures are largely illustrative of the process, rather than being documentation. However, the extent to which pictures are being recycled from previous brews (including showing that you supposedly hit your target mash temp, no less!) is getting a bit absurd, and IMO is getting to the point where it undermines the legitimacy of the content.

If someone forgets to snap a picture of a step, so be it. But please don’t try to pass off a picture from an entirely different brew day as though it represents the subject brew.

Nah, Steve is *so* consistent that he’s pixel-perfect. Can’t beat that.

Are the aroma hops really added at 10 minutes?

Is the fermentation temperature really 32 degrees F?

Did you mean to do two different additions of the same hops at 10 minutes? You have a 9/9/5 addition of Centennial/Citra/Simcoe and then a 3/3/3 at the same time?