Author: Mike Neville

Yeast is arguably the most important brewing ingredient, as it’s responsible for turning sugary wort into boozy beer. Additionally, it contributes a range of unique flavor characteristics, which is widely accepted as being influenced by the temperature at which fermentation occurs, with cooler environments yielding cleaner qualities while warm temperatures cause the yeast to be more expressive.

It’s well established that different types of yeast strains perform differently at varying temperatures, for example lager strains do well around 50°F/10°C whereas 68°F/20°C is ideal for ale strains. A few years ago, brewers were introduced to a traditional Norwegian yeast referred to as Kveik, which gained attention for its ability to ferment at temperatures around 100°F/38°C without producing off-flavors. Similar to established brewing yeasts, brewers rely on fermentation temperature when using Kveik as a means of modulating overall yeast expression.

Recently, Imperial Yeast released I22 Capri, which they describe as “an experimental Saccharomyces cerevisiae strain created in our lab by directing brewing yeast through their idle sexual cycle via fungal sporulation.” Essentially, Capri is the offspring of two of Imperial’s most popular strains for Hazy IPA– A38 Juice, which is purportedly sourced from an historic British brewery, and A43 Loki, their version of Voss Kveik. Curious what impact different fermentation temperatures might have when fermenting with this unique new strain, I designed an xBmt to test it out!

| PURPOSE |

To evaluate the differences between a Hazy IPA fermented with Imperial Yeast I22 Capri at 65°F/18°C and one fermented at 75°F/24°C.

| METHODS |

For this xBmt, I designed a Hazy IPA recipe using hop varieties I felt would work well the the juicy characteristics I22 Capri is said to contribute.

Marine Layer

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 54.3 | 4.7 SRM | 1.067 | 1.01 | 7.48 % |

| Actuals | 1.067 | 1.01 | 7.48 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pelton: Pilsner-style Barley Malt | 10 lbs | 65.04 |

| Lamonta: Pale American Barley Malt | 2 lbs | 13.01 |

| Oats, Flaked | 1.5 lbs | 9.76 |

| Wheat | 1.5 lbs | 9.76 |

| Rimrock: Vienna-style Rye Malt | 6 oz | 2.44 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Mosaic | 28 g | 5 min | Boil | Pellet | 11.2 |

| Southern Star | 28 g | 2 min | Boil | Pellet | 13.3 |

| Galaxy | 37 g | 15 min | Aroma | Pellet | 13.6 |

| Columbus LUPOMAX | 28 g | 15 min | Aroma | Pellet | 20 |

| Mosaic | 28 g | 15 min | Aroma | Pellet | 11.2 |

| Southern Star | 28 g | 15 min | Aroma | Pellet | 13.3 |

| Southern Star | 35 g | 4 days | Dry Hop | Pellet | 13.3 |

| Columbus LUPOMAX | 28 g | 4 days | Dry Hop | Pellet | 20 |

| Galaxy | 28 g | 4 days | Dry Hop | Pellet | 13.6 |

| Mosaic | 28 g | 4 days | Dry Hop | Pellet | 11.2 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Capri (I22) | Imperial Yeast | 74% | 68°F - 86°F |

Notes

| Water Profile: Ca 106 | Mg 20 | Na 5 | SO4 77 | Cl 148 |

Download

| Download this recipe's BeerXML file |

After collecting the water for a single 10 gallon batch, I weighed out and milled the grain.

With the water properly heated, I incorporated the grains then checked to make sure the mash was at my target temperature.

During the mash rest, I prepared the kettle hop additions.

Once the mash was finished, I batch sparged to collect my target pre-boil volume then proceeded to boil the wort 60 minutes, adding hops at the times listed in the recipe.

When the boil was complete, I used by JaDeD Brewing Hydra to quickly chill the wort.

Next, I transferred identical volumes of wort to separate fermenters.

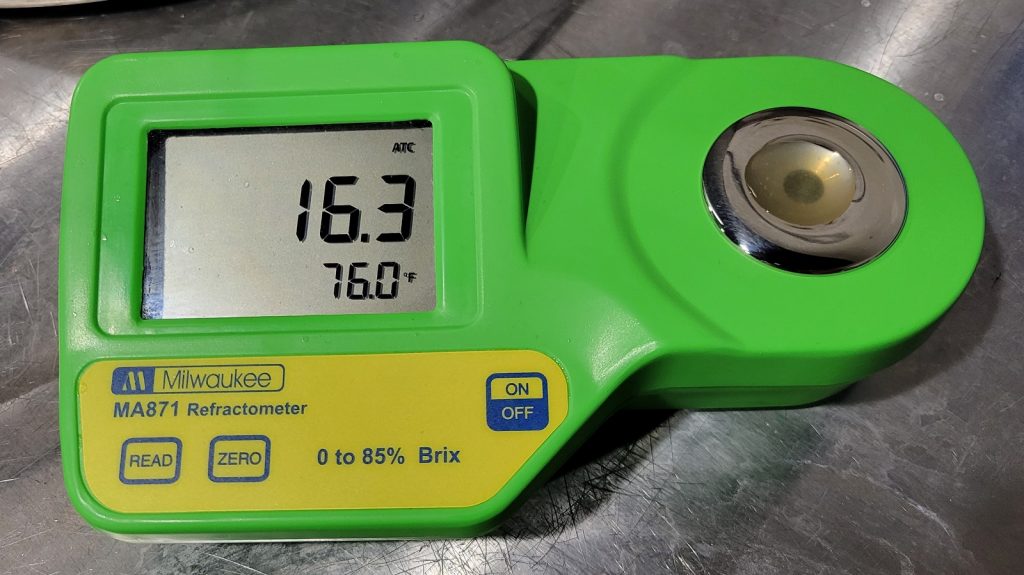

A refractometer reading showed the wort right at my target OG.

The fermenters were connected to my glycol unit and allowed to finish chilling to my desired fermentation temperature of 68°F/20°C, at which point I pitched a single pouch of Imperial Yeast I22 Capri into each batch.

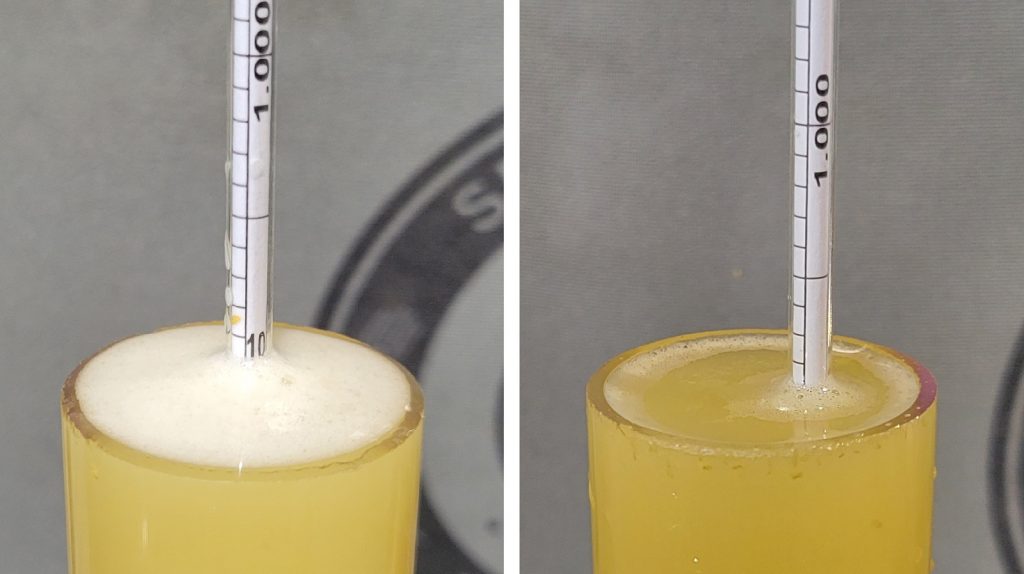

After 3 days of fermentation, I added the dry hops then left the beers alone for another 4 days before taking hydrometer measurements showing a slight difference in FG.

At this point, I cold crashed the beers overnight then pressure transferred them to CO2 purged kegs.

The filled kegs were placed in my keezer and burst carbonated overnight before I reduced the gas to serving pressure. After a week of conditioning, they were carbonated and ready for evaluation.

| RESULTS |

Data for this xBmt was collected at the 2022 Michigan Homebrew Festival where a total of 23 people of varying levels of experience participated. Each participant was served 1 sample of the cool fermented beer and 2 samples of the warm fermented beer in different colored opaque cups then asked to identify the unique sample. To reach statistical significance, 13 tasters (p<0.05) would have had to accurately identify the unique sample, which is precisely the how many did (p=0.028), indicating participants in this xBmt were able to reliably distinguish a Hazy IPA fermented with Imperial Yeast I22 Capri at 65°F/18°C from one fermented at 75°F/24°C.

The 13 participants who made the accurate selection on the triangle test were instructed to complete a brief preference survey comparing only the beers that were different. A total of 4 tasters reported preferring the beer fermented cool, 4 said they liked the beer fermented warm more, 3 had no preference despite noticing a difference, and 2 reported perceived no difference.

My Impressions: Out of the 5 semi-blind triangle tests I attempted, I correctly identified the odd-beer-out 4 times. While both beers had a burst of mango and citrus character with some piney notes on the back-end, I perceived slightly less bite in cool fermented batch that made it stand out to me. Ultimately, the difference was very slight, and I felt both beers were very enjoyable.

| DISCUSSION |

Fermentation temperature is widely viewed by brewers as a sort of lever that can be adjusted to modulate yeast character in beer, with ideal temperatures being dependent on both yeast strain and beer style. Seeing as Imperial Yeast’s new strain, I22 Capri, is a hybrid of a traditional British ale yeast and Voss Kveik, not only does it have a wider recommended range, but different temperatures can purportedly be selected by brewers to produce unique characteristics. Supporting this claim, tasters in this xBmt were able to reliably distinguish a Hazy IPA fermented with I22 Capri at 65°F/18°C from one fermented at 75°F/24°C.

An oft expressed concern when we choose hoppier styles for certain xBmts is that the hop character will in some way hide any impact of the variable. The fact enough tasters in this xBmt perceived a difference to reach significance, despite how heavily hopped this Hazy IPA was, seems to suggest I22 Capri is rather sensitive to fermentation temperature, especially considering the delta was just 10°F/6°C.

When I first learned about I22 Capri, I was excited to get my hands on some and, even more, to see how it performs at different temperatures. While I was able to consistently tell these xBmt beers apart, I felt the difference was pretty small, leaving me curious how a similar comparison with a simpler style might play out. Considering how much I liked these beers, I’ll certainly be using I22 Capri more in my brewery and look forward to learning more about it with additional xBmts!

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

8 thoughts on “exBEERiment | Fermentation Temperature: Imperial Yeast I22 Capri In A Hazy IPA”

“… I perceived slightly less bite in cool fermented batch that made it stand out to me.” This statement made me wonder if perhaps you were detecting differences due to dry hopping at different temperatures rather than fermenting at different temperatures. I’ve never dry hopped at different temperatures (hell I rarely dry hop at all) so I’ve got no experience to base that off of. Just a thought.

Dry-hopping temp is indeed a confounding variable here…if they were in fact dry hopped at different temps, because there is this in the text: “The fermenters were connected to my glycol unit and allowed to finish chilling to my desired fermentation temperature of 68°F/20°C, at which point I pitched a single pouch of Imperial Yeast I22 Capri into each batch.”

This says they were both fermented at the same temp. Let me guess: a typo?

Yes i was wondering the same. must be a typo!

Always enjoy your articles, but could you give more details of exactly how you did the statistical analysis? Saying 13/ 23 making a correct choice is significant at p < 0.05 seems a bit odd to me. There are 3 possible outcomes…correct choice, incorrect choice and no difference.

Just curious…..won't make your articles any less interesting……

Are the hop amounts in the recipe for your 10 gallon batch or are they scaled down to match the 5 gallon version for the grist.

The whole recipe is scaled to a five gallon version.

Would it be useful to try this again and ferment the warmer beer towards the top end of the recommended temp, ie 30c / 86F against a cooler one at 20c, 68F. What was the thinking in not doing this also? Great work as always. I think there’s a typo in the part where you mention chilling to desired temp – you only mention 20c in this section and not the warmer one. Cheers!

Anyone experienced high sulfur aromas during active fermentation of this yeast? I started this at 68F had no activity for 24 hours, roused the fermenter and bumped to 72F within a few hours fermentation took off . It did not have a significant krausen which I thought was interesting. Shortly after I could smell a significant amount of sulfur from the fermenter and it subsided after a 4 days. I don’t perceive it in the finished beer though.