Author: Mike Neville

Barley malt is the building block of beer, and these days, brewers have a wide range of varieties to choose from, allowing them produce the myriad wonderful styles enjoyed around the world. In the earlier days of malting, maltsters relied on a technique called floor malting, which consists of laying steeped barley in piles on a concrete or tile floor then allowing it to germinate. Compared to modern mechanized malting methods, floor malting is more labor intensive, as it requires workers to regularly turn the grain for aerations and to reduce heat build-up.

Despite its historical roots and the advent of advanced malting methods, many maltsters rely on floor malting for certain products, namely Pilsner malt, claiming it imparts a noticeably more complex character compared to malts made using standard procedures. Moreover, maltsters often choose unique barley varieties to use for their floor malted products, often as means of boasting historical authenticity.

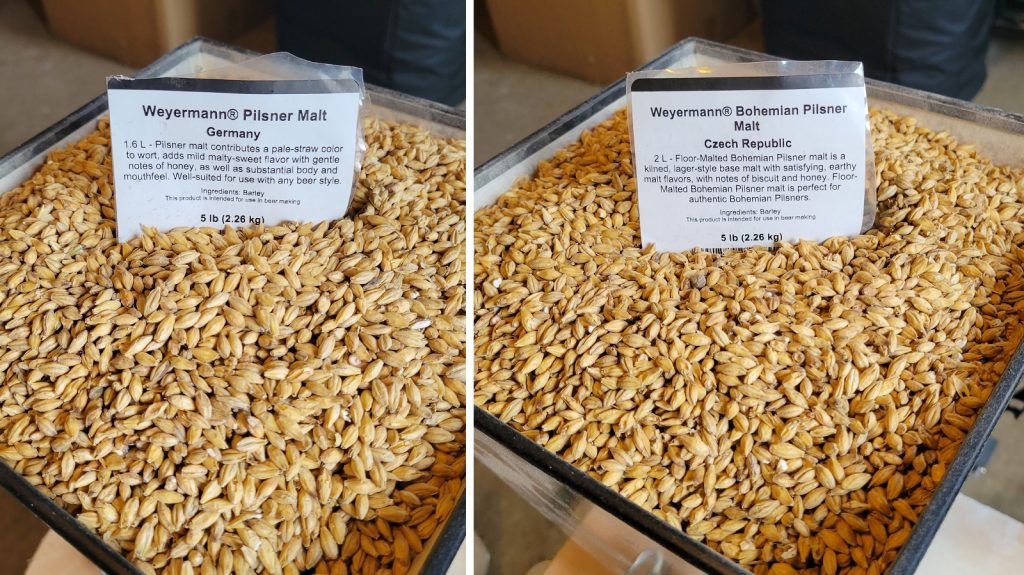

While researching base malts for a past xBmt, I came across Weyermann’s floor malted Bohemian Pilsner, which is a part of their Heirloom line of malts. Curious of claims that floor malted products contribute unique and desirable characteristics to beer, I decided to compare it to Weyermann’s standard German Pilsner malt to taste the difference for myself!

| PURPOSE |

To evaluate the differences between a German Pils made with standard German Pils malt and one made with floor malted Bohemian Pilsner malt.

| METHODS |

In order to emphasize the impact of the each base malt, I designed a very simple single malt German Pilsner recipe for this xBmt.

Wiz Biz Pilz

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 36.2 | 2.5 SRM | 1.049 | 1.007 | 5.51 % |

| Actuals | 1.049 | 1.007 | 5.51 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| German Pilsner OR Floor Malted Bohemian Pilsner | 10 lbs | 100 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Triumph | 21 g | 60 min | Boil | Pellet | 10.7 |

| Tettnang | 28 g | 15 min | Boil | Pellet | 3.9 |

| Tettnang | 28 g | 5 min | Boil | Pellet | 3.9 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Global (L13) | Imperial Yeast | 77% | 32°F - 32°F |

Notes

| Water Profile: Ca 103 | Mg 15 | Na 5 | SO4 145 | Cl 78 |

Download

| Download this recipe's BeerXML file |

After collecting the water for two 5 gallon/19 liter batches, adjusting them to the same desired profile, and flipping the switch on my electric controller to get them heating up, I weighed out and milled the grains.

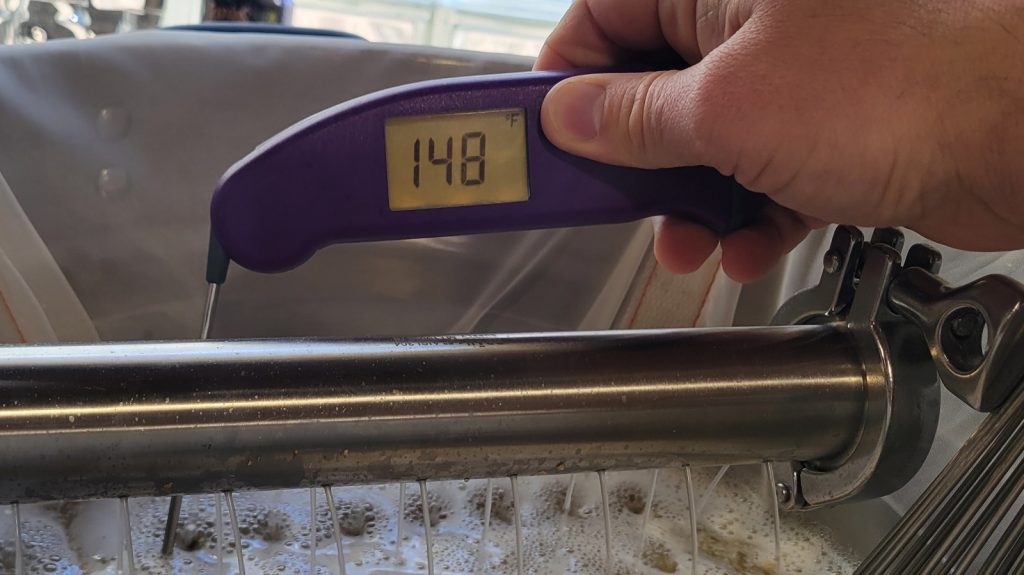

With the waters properly heated, I incorporated the grains then checked to make sure the mashes were at my target temperature.

During the mash rests, I prepared the kettle hop additions.

Once the mashes were finished, I batch sparged to collect my target pre-boil volume then proceeded to boil the worts for 60 minutes, adding hops at the times listed in the recipe.

When the boils were complete, I quickly chilled the worts with my Hydra IC.

Next, I transferred identical volumes of wort from each batch to sanitized fermenters.

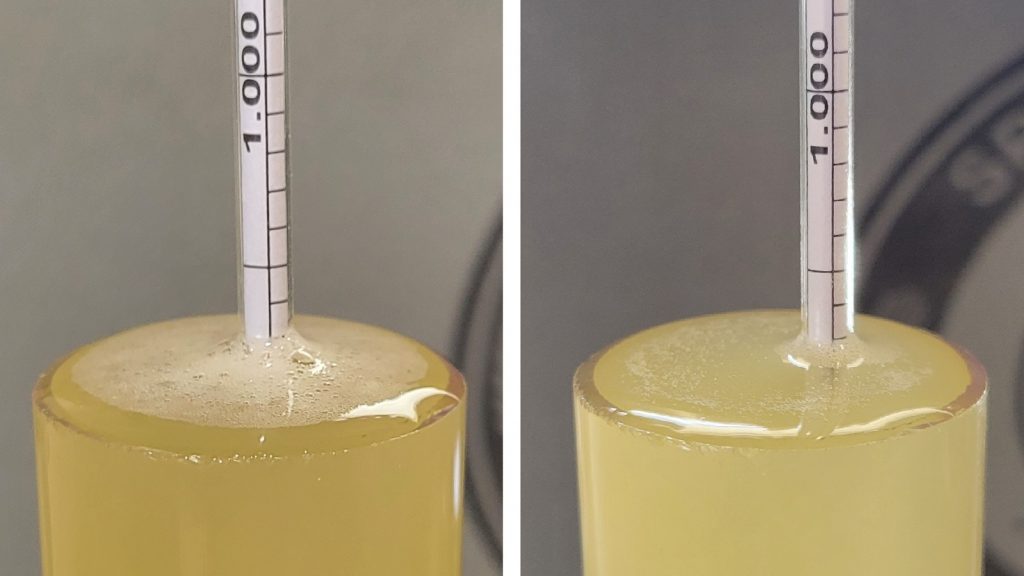

Refractometer readings showed both worts hit my expected OG.

The fermenters were connected to my glycol unit and allowed to finish chilling to my desired fermentation temperature of 55°F/13°C, at which point I pitched a single pouch of Imperial Yeast L13 Global into each batch.

After 5 days of fermentation, I began gradually ramping the temperature up to 66°F/19°C over the course of 4 days, then let it sit there for an additional 3 days before taking hydrometer measurements showing both had reached the same FG.

At this point, I set my glycol controllers to 38°F/3°C and let the beers cold-crash for 3 days, after which I pressure transferred them to CO2 purged kegs.

The filled kegs were placed in my keezer and burst carbonated overnight before I reduced the gas to serving pressure. After a 6 week lagering period, both beers were clear, carbonated, and ready for evaluation.

| RESULTS |

A total of 22 people of varying levels of experience participated in this xBmt. Each participant was served 1 sample of the beer made with standard German Pils malt and 2 samples of the beer made with floor malted Bohemian Pilsner malt in different colored opaque cups then asked to identify the unique sample. While 12 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, only 9 did (p=0.29), indicating participants in this xBmt were unable to reliably distinguish a German Pils made with standard German Pils malt from one made with floor malted Bohemian Pilsner malt.

My Impressions: Out of the 5 semi-blind triangle tests I attempted, I correctly identified the odd-beer-out just once, a lack of consistency that indicates my own inability to tell these beers apart. I perceived both beers as having identical white bread and cracker notes supported by a firm bitterness and floral hop characteristics with a clean fermentation profile.

| DISCUSSION |

Seeing as they make up the majority of the grist for nearly all beer styles, base malts are unquestionably one of the most important brewing ingredients. When making clean and crisp lagers, the go-to base malt is typically lightly kilned Pilsner malt, of which there are various types including floor malted Bohemian Pilsner that’s said to impart beer with unique and complex characteristics. The fact tasters in this xBmt were unable to reliably distinguish a German Pils made with standard German Pilsner malt from one made with floor malted Bohemian Pilsner indicates any differences were minimal enough as to be imperceptible.

What makes this results all the more confounding is that the malting process wasn’t the only difference between the grains, as the barley variety was different as well. We’re unable to make any statements of fact based on this single data point, though considering the grist for each batch consisted of 100% of either malt, one would expect there to have been perceptible differences between these beers.

I love the history of brewing and appreciate what those who came before me did to advance the craft. While I understand the desire to appeal to antiquity and view laborious processes as leading to a generally better outcome, these results have definitely caused me to question the claims I’ve heard about floor malted grains. I’m not ready to throw in the towel on this one just yet and look forward to future xBmts on this topic, but for now, I’ll be sticking to standard Pilsner malts largely because they tend to be a bit less expensive.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

12 thoughts on “exBEERiment | Grain Comparison: German Pils Malt vs. Floor Malted Bohemian Pilsner Malt In A German Pils”

This is something I’ve wondered about for a long time, as a good German pils is one of my favorites. I liked that you used the same mash schedule between the two batches. The mash efficiency of the two beers was identical, which is not what many would have predicted. Great job, thank you!

Can you explain or direct me to any resources that explain your pressure transfer. Specifically how you utilize the spunding valve? Thanks.

The idea with the spunding valve is that it keeps pressure in the keg, which will reduce foaming during the transfer. This matters less if you’re not capping the fermenter to retain some of that CO2. Additionally, the spunding valve keeps the keg free of oxygen, where as if you open the PRV on the lid there is a chance O2 gets in the keg. The downside, of course, is overfilling the keg and beer spitting out the valve, which I then disassemble and clean. I fill my kegs on a scale so when they get to about 40.5lbs, I pull the spunding valve to prevent overfilling.

Thanks for reporting this comparison. I’ve been wondering whether there’s anything behind the hype over floor malting.

Great experiment! I always like the grain comparisons you guys do, as I think the differences between malts is a relatively unexplored topic. Much like with hops, the subtle characteristics maltsters claim their products have often fail to show up in finished beers. I wonder if there are actually significant differences between similar malt products (domestic vs UK pale ale malt, for example), or if color, extract, and protein content are all that really matter. This experiment seems to support the latter claim. Look forward to seeing more, cheers!

The subtle characters are there, most just don’t have the experience to tell the difference. I’ve brewed the same single decoction pils with every pils weyermann carries and believe me, they are different.

Yeah, that is surprising. I wonder if a decoction or maybe even just a step mash would have brought differences out. Still very surprising.

I’m sad this isn’t significant… but also happy that I don’t have to spend more for the same result

Tasting the raw grains side by side, they are rather different – I’d say the floor malted is somewhere between Pilsner and Maris Otter. The fact that this difference did not carry over – or at least: not as strongly – in the final product indicates that flavour has been lost along the way. Proponents of LODO would certainly have a guess as to the root cause.

I’m curious whether the unfermented worts tasted differently…

I would have gone for a lower level of bitterness than 36 IBU. If you want to see if there is a difference in flavor from the malts then why not go for a maltier beer. If you make a well hopped beer with a classic yeast, you could probably use almost any source of starch/sugar.

while it’s a shame that there wasn’t a noticeable difference, it also amazing that an outdated, old fashioned barley variety and malting procedure produced the same result as a modern “improved” barley and highly efficient modernised/industrialised malting process!

Firstly, a proper lager requires a step mash with a protein rest. Secondly, DMS in pils malts requires a 90 minute boil to completely remove and can mask some of the malt character. Thirdly, the Germans and Czechs do a decoction mash for a reason. And the floor malted malt lends itself to that mash process. The actual differences in the two malts are negligible unless you have an extremely trained or experienced palate, so for personel gratification it probably makes no difference which you use. But for those who are interested, locate the fine German and Czech pils examples out there and determine for yourself if you think there is something more there or not. Do your own experiment using a decoction mash. Also, Greg Noonan wrote a great book called Brewing Lager Beer and I recommend it (if you can fine it).

Dave

Readington Hop Brewery and Hop Farm