This xBmt was completed by a member of The Brü Club in collaboration with Brülosophy as a part of The Brü Club xBmt Series. While members who choose to participate in this series generally take inspiration from Brülosophy, the bulk of design, writing, and editing is handled by members unless otherwise specified. Articles featured on Brulosophy.com are selected by The Brü Club leadership prior to being submitted for publication. Visit The Brü Club Facebook Group for more information on this series.

Author: Ben Gansemer

Dry hopping has become increasingly popular over the past several years, especially with the now not-so-recent onset of the Hazy IPA craze. Brewers of hoppier styles, especially those looking for fruity/juicy flavors and aromas, are constantly searching for new ways to get more, and in some cases different, hop character into their beers. One way some brewers do this is by adding dry hops earlier in the process, with some opting to make their dry hop additions as early as at yeast pitch.

As covered extensively by Scott Janish The New IPA, a purported benefit of early dry hopping is the biotransformation of hop compounds, which can lead to bolder fruit character. Another reason brewer might choose dry hop early is to reduce cold-side oxygen exposure, which has been shown to be highly detrimental to a beer, especially hoppier styles. While dry hopping at high kräusen has become fairly standard these days, an even simpler approach that some have starting doing involves adding the dry hop addition at the same time as pitching the yeast. However, some believe adding the dry hop so early results in lost hop character due to the extended time in the beer during fermentation, when volatile compounds are “blown off” by the yeast as CO2 leaves the fermentation vessel.

As someone who currently only bottle conditions, I don’t have the ability to perform closed transfers and must find other ways to reduce oxygen exposure. Given the results of a couple previous xBmts on the subject, dry hopping at yeast pitch is something I’ve incorporated into my process, and while I’ve had good results, I’ve been wondering if it’s had any noticeable impact on my bottle conditioned beers. With the first beer in The Brü Club’s AvgBrü project being a dry hopped American Pale Ale, I took the opportunity to run the xBmt myself.

| PURPOSE |

To evaluate the differences between a bottle conditioned American Pale Ale dry hopped toward the end of fermentation and one dry hopped at yeast pitch.

| METHODS |

For this xBmt, I split my AvgBrü American Pale Ale batch between 2 fermenters such that each could be dry hopped at different times.

Just Your Average Pale Ale

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 2.5 gal | 60 min | 38.4 | 8.1 SRM | 1.053 | 1.011 | 5.51 % |

| Actuals | 1.053 | 1.011 | 5.51 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pale Ale Malt 2-Row | 4.5 lbs | 80 |

| Wheat Malt | 12 oz | 13.33 |

| Caramel Malt 40L | 6 oz | 6.67 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Centennial | 7 g | 60 min | Boil | Pellet | 10 |

| Centennial | 10 g | 30 min | Boil | Pellet | 10 |

| Cascade | 10 g | 0 min | Boil | Pellet | 5.5 |

| Citra | 10 g | 0 min | Boil | Pellet | 12 |

| Cascade | 14 g | 5 days | Dry Hop | Pellet | 5.5 |

| Citra | 14 g | 5 days | Dry Hop | Pellet | 12 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| American West Coast Ale (BRY-97) | Lallemand (LalBrew) | 80% | 32°F - 32°F |

Notes

| Water Profile: Ca 99 | Mg 7 | Na 8 | SO4 174 | Cl 68 |

Download

| Download this recipe's BeerXML file |

The night before brewing, I prepared the water then weighed out and milled the grains.

My typical process for any beer with more than 10% wheat malt is to start the mash with a protein rest, which for this batch was at 130°F/54°C.

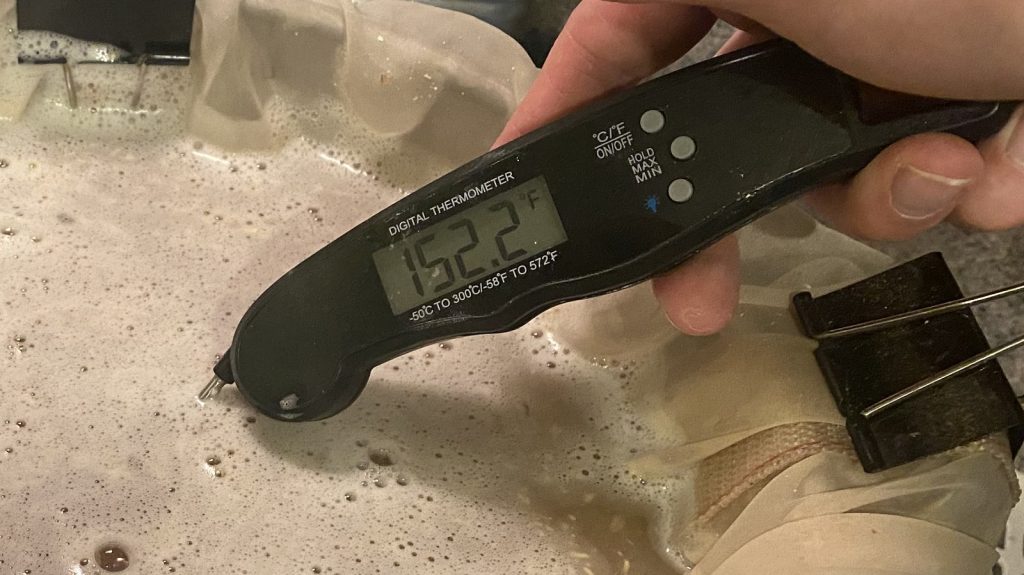

After the 10 minute protein rest, I added near-boiling water to reach my target saccharification rest temperature of 152°F/67°C.

During the mash rest, I weighed out the kettle hop additions.

When the mash was complete, I removed the grain bag and brought the wort to a boil, relying on my little helper to add hops at the times listed in the recipe.

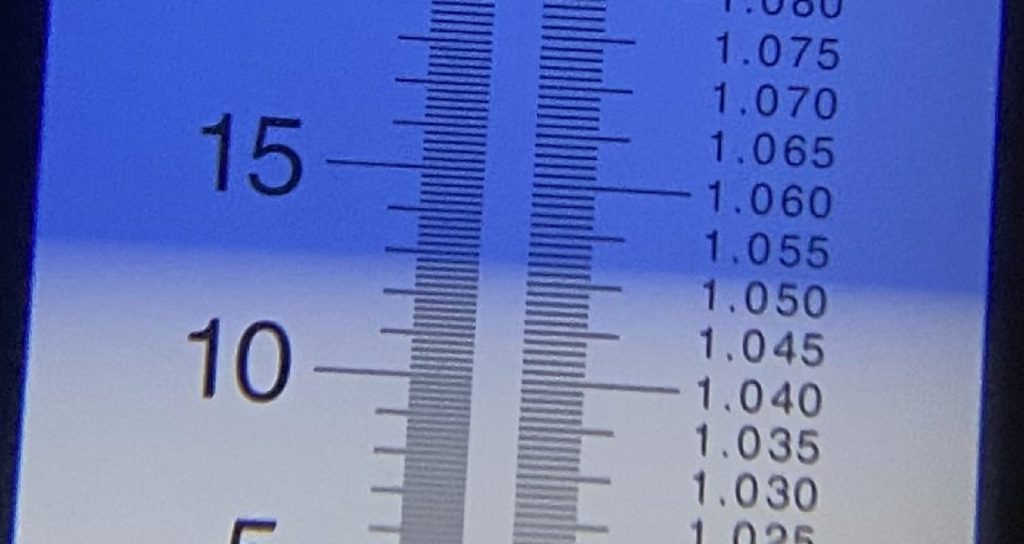

When the 60 minute boil was finished, I took a refractometer reading showing the wort was at my target OG.

I then transferred equal volumes of wort to identical 1.5 gallon fermenters.

I placed the worts in my chamber to finished chilling to my desired fermentation temperature of 66°F/19°C, at which point I split a rehydrated pack of LalBrew BRY-97 American West Coast Ale yeast evenly between the batches. It was at this point I added the full dry hop charge to one of the batch. When checking on the beers the following day, I noticed both were actively fermenting.

With fermentation activity noticeably slower 4 days later, I added the dry hop charge to the second batch then let the beers sit another 6 days before taking hydrometer measurements showing the beer dry hopped at yeast pithc was 0.001 SG higher than the one dry hopped toward the end of fermentation.

I proceeded to bottle the beers with identical amounts of priming sugar solution then let them sit at room temperature for 2 weeks before they were ready for evaluation.

| RESULTS |

Due to social distancing practices as a result of the COVID-19 pandemic, data for this xBmt was unable to be collected from participants. As such, adaptations were made involving the author completing multiple semi-blind triangle tests in as unbiased a way as possible.

Utilizing 4 opaque cups of the same color where 2 were inconspicuously marked, one set was filled with the beer dry hopped toward the end of fermentation while the other set was filled with the beer dry hopped at yeast pitch. For each triangle test, 3 of the 4 cups were indiscriminately selected, thus randomizing which beer was the unique sample for each trial. Following each attempt, I noted whether I was correct in identifying the unique sample. Out of the 10 semi-blind triangle tests I completed, I needed to identify the unique sample at least 7 times (p<0.05) in order to reach statistical significance. Ultimately, I identified the unique sample just 4 times (p=0.44), indicating my inability to reliably distinguish a bottle conditioned American Pale Ale dry hopped toward the end of fermentation from one dry hopped at yeast pitch.

These beers were identical to me, to the point all of my triangle test attempts were guesses. Both had the same fruity hop aroma with a nice stone fruit flavor and a pleasant bitterness.

| DISCUSSION |

While brewers often change hop variety and amount when dry hopping to modulate overall hop character, the impact dry hop timing has on beer is not as well understood. Many brewers of hop-forward styles, especially of the hazier sort, advocate for earlier dry hop additions to promote biotransformation while reducing the risk of cold-side oxidation, though others argue that adding dry hops too early results in diminished hop character. The fact I was unable to distinguish a bottle conditioned American Pale Ale dry hopped toward the end of fermentation from one dry hopped at yeast pitch suggests any differences were minimal enough as to be imperceptible to me.

One possible explanation for this result is that the dry hop addition made toward the end of fermentation simply was late enough, meaning there was still time for any biotransformation and oxygen uptake to occur. That said, dry hopping 4 days into fermentation is fairly common practice, so I view it as a valid comparison. It’s also possible that the refermentation that occurred in the bottle mitigated any oxidation effects.

Given the results of a couple past xBmts, I incorporated dry hopping at yeast pitch into my normal process, and I certainly won’t be making any changes based on these results. In addition to being simpler, it reduces the risk of oxygen exposure, plus I’ve been pleased with the outcome in the time I’ve been doing it. Still, I look forward to exploring the impact dry hop timing has on beer character in the future!

Ben is a proud husband and father and is currently located in Iowa. His background in biology fueled his foray into homebrewing and experimenting with beer. Ben enjoys spending time with his amazing wife (who graciously helps with triangle tests) and son (who enjoys adding hops on brew days). He started brewing in 2019 and blames Brülosophy for sucking him into the hobby so rapidly. When he’s not brewing or spending time with his family, Ben enjoys fly fishing and cooking/baking.

Ben is a proud husband and father and is currently located in Iowa. His background in biology fueled his foray into homebrewing and experimenting with beer. Ben enjoys spending time with his amazing wife (who graciously helps with triangle tests) and son (who enjoys adding hops on brew days). He started brewing in 2019 and blames Brülosophy for sucking him into the hobby so rapidly. When he’s not brewing or spending time with his family, Ben enjoys fly fishing and cooking/baking.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

7 thoughts on “The Brü Club xBmt Series | Impact Dry Hopping At Yeast Pitch Has On A Bottle Conditioned American Pale Ale”

I would say there are also other possible explanations:

1 – beers were refermented in the bottle, which means that another “biotransformation step” occurred inside the glass. That plus the one occurred in the fermenter could have reached the same perception threshold for both beers.

2 – Citra has lots of free thiols. Its perception threshold are way lower than oils that biotransform. Could be the case that beer dry hoped at pitching had indeed more oils biotransformed when compared to beer dry hopped at tail end of fermentation, but the benefit from biotransformation is covered by the “thiol layer” aroma.

yet another possibility: there was no biotransformation in either beer, because the yeast used doesn’t do biotransformation. not all yeasts have the ability, and west coast american yeasts aren’t listed as biotransformation-promoting. the usual suspects are british yeasts like London Ale III and Conan (brett can also do it). perhaps this experiments needs a do-over with a more transformative yeast?

Based on the official lallemand site, BRY-97 is in fact capable of biotransformation.

https://www.lallemandbrewing.com/en/canada/product-details/bry-97-west-coast-ale-yeast/

Did one have better head retention than the other or is that just the picture making it look that way?

So, according to this experiment no flavour or aromas are removed due to the fermentation. Maybe another brewing myth busted? Interesting, because I also have a very simple setup. Perhaps I should also do this experiment again.

Re MSkills, I also noticed the difference in the head on the beer, with a much better head on the later hop addition. Was this a reproducible effect? These visual effects presumably don’t get noticed on the tasting trials.

For bottling, did you do the typical “bottling bucket” setup or just add the priming sugar directly to the bottles? If the latter, how did you figure how much to add? I’ve been adding sugar directly to the bottles for hoppier beers to try to reduce oxidation, but that leaves me just dumping sugar granules in the bottles. Wondering if there’s a better way, or if I should just try the bottling bucket on pales, etc…