Author: Cade Jobe

Editor’s Note: Following publication of the original version of this xBmt on January 31, 2022, a number of readers expressed interest in how the results might look if the beer had been given more time to age. Seeing as the author was unable to collect data from participants at the time of original publication due to Covid-19, we listened to reader suggestions and decided to collect actual data after an additional aging period. The following article has been adapted to account for the addition of this variable.

At the risk of oversimplifying, oxidation is a process whereby a substance changes when exposed to oxygen, usually for the worse. This is certainly the case when it comes to beer, particularly on the cold-side where oxygen exposure is known to hasten staling and create unpleasant flavors. For this reason, brewers employ various methods to reduce the risk of oxidation, one of the most common being purging kegs with carbon dioxide (CO2) prior to packaging.

There are a couple approaches to purging kegs, the simplest of which involves simply running CO2 into the bottom of the vessel for a given amount of time, the idea being that the heavier CO2 will ultimately displace the air in the keg. However, since gases readily mix, there’s no good way to know if a keg is in fact free of oxygen, which is why some prefer first filling the keg with a liquid, such as sanitizer solution, then pushing that out with CO2. Unlike the blending that occurs at the CO2-to-O2 interface, the CO2-to-liquid interface ensures all of the oxygen-rich air is removed from the keg once the liquid is pushed out.

When I started kegging, I accepted the importance of reducing oxygen exposure and relied on the simple method of purging empty kegs. It wasn’t until I read about commercial breweries using liquid to purge lines and kegs that I made the switch to filling kegs with sanitizer solution and pushing it out with CO2. The fact I was unable to reliably distinguish the beers after 1 month of aging in the initial iteration of this xBmt seems to suggest both methods are equally as valid; however, many speculated that given even more time, the differences between the beers would become more apparent, so I decided to hold onto the kegs for an additional 2 months and serve them to blind tasters for evaluation.

| PURPOSE |

To evaluate the differences between a German Pils packaged in a keg that was purged empty and one that was first filled with liquid then purged after 3 months of aging.

| METHODS |

Known for being a delicate style, I went with a simple German Pils recipe for this xBmt.

End Of The Quarter

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 39 | 3.5 SRM | 1.049 | 1.009 | 5.25 % |

| Actuals | 1.049 | 1.009 | 5.25 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pelton: Pilsner-style Barley Malt | 11.5 lbs | 100 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Magnum | 20 g | 60 min | Boil | Pellet | 14.2 |

| Tettnang (Tettnang Tettnager) | 20 g | 10 min | Boil | Pellet | 3.9 |

| Tettnang (Tettnang Tettnager) | 20 g | 1 min | Boil | Pellet | 3.9 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Harvest (L17) | Imperial Yeast | 74% | 32°F - 32°F |

Notes

| Water Profile: Ca 39 | Mg 17 | Na 14 | SO4 6 | Cl 5 |

Download

| Download this recipe's BeerXML file |

I started my brew day by collecting the full volume of water for each batch, adjusting both to my desired mineral profile, then setting the electric controllers to heat them up.

I then weighed out and milled the grain for each batch.

With the water properly heated, I added the grains, turned the pumps on to recirculate, and set the controllers to maintain my intended mash temperature of 152°F/67°C.

While the mashes were resting, I weighed out the kettle hop additions.

Following each 60 minute mash rest, I raised the grain baskets out of the kettles and let them drain. The worts were then boiled for 60 minutes with hops added at the times listed in the recipe.

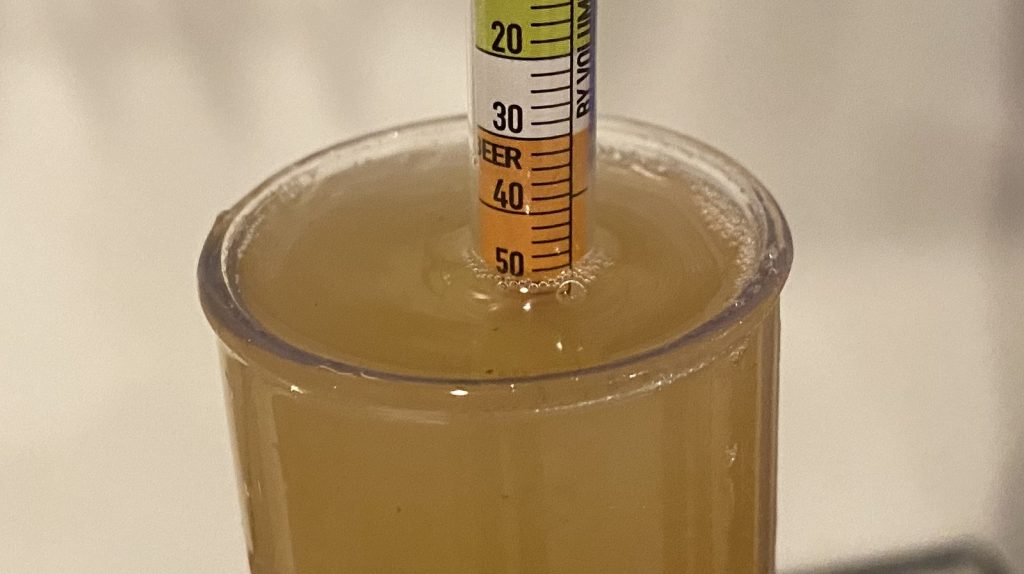

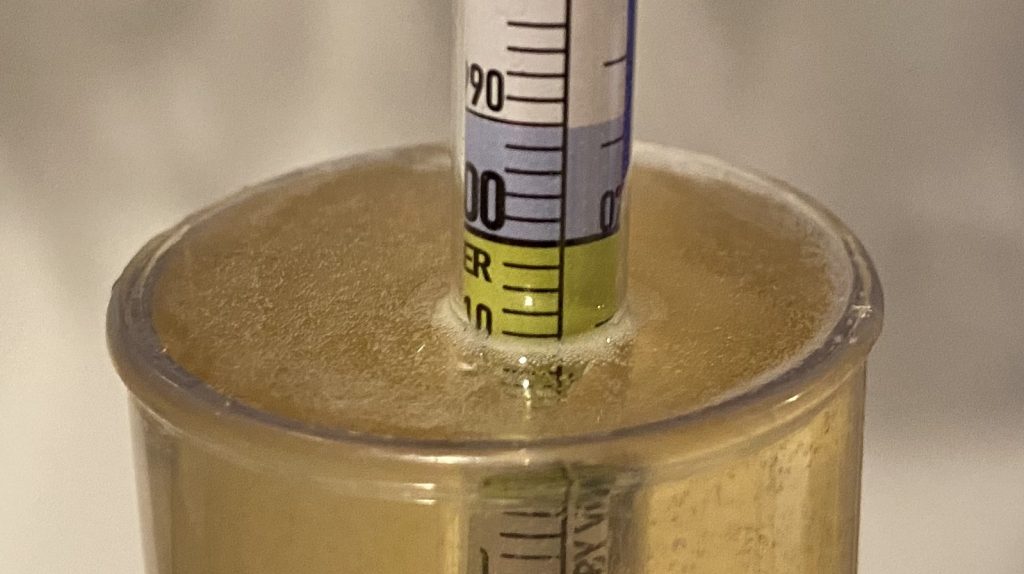

When the boils were complete, I quickly chilled the wort then took hydrometer measurements showing both were at the same OG.

After combining the worts in a 14 gallon/53 liter Brew Bucket, I placed it in my fermentation chamber and pitched 2 pouches of Imperial Yeast L17 Harvest.

After 3 weeks of fermenting at 66°F/19°C, I took a hydrometer measurement indicating FG had been reached.

At this point, I proceeded with purging the kegs, one of which was left empty while the other was filled with sanitizer solution. After turning the CO2 to each keg on at the same time, I let them run until the keg filled with liquid was empty, at which point I cut the gas to both kegs off.

The filled kegs were placed on gas in my keezer and allowed to condition for a month before they were ready for the initial evaluation.

Based on the suggestion of many readers of the initial xBmt on this topic, I held off on drinking too much of these beers, leaving them in my keezer for an additional 2 months before collecting data from actual tasters.

| RESULTS |

A total of 22 people of varying levels of experience participated in this xBmt. Each participant was served 2 samples of the beer packaged in a keg that was purged empty and 1 sample of the beer packaged in a keg that was purged after being filled with sanitizer solution in different colored opaque cups then asked to identify the unique sample. At this sample size, 12 tasters (p<0.05) would have had to identify the unique sample in order to reach statistical significance, though only 10 did (p=0.16), indicating participants were unable to reliably distinguish a German Pils served from a keg purged empty with CO2 run into the bottom from one where liquid was pushed out after 3 months of aging.

My Impressions: Out of the 5 semi-blind triangle tests I attempted, I identified the odd-beer-out just 3 times, though I’m willing to admit these were just wild guesses, as the beers tasted identical to me. Even after an additional 2 months of aging, I didn’t notice any differences between the beers, and neither had what I perceive to be oxidation off-flavors.

| DISCUSSION |

Cold-side oxidation is a destroyer of beer, which is why brewers make the effort to avoid exposing their beer to oxygen, and one primary way to do this is by purging kegs with CO2 prior to filling. Whereas some simply run CO2 into an empty keg for a certain amount of time, others prefer pushing liquid out of the keg due to concerns related to the mixing of gases. Moreover, many contend that oxygen often takes time to have its damaging effect on beer, especially when the exposure is kept to a minimum. The fact tasters in this xBmt were unable to reliably distinguish a German Pils served from a keg purged empty with CO2 run into the bottom from one where liquid was pushed out seems to indicate both methods had the same result, even after 3 months of aging.

Gases mix, this is well established, though given the results of this xBmt as well as the prior one on the same topic, it’s possible filling from the bottom of a non-purged keg may be less risky than many have come to accept, at least as it pertains to German Pils. It’s entirely possible both beers were equally oxidized, though I’m personally not convinced that’s the case, as I’ve had oxidized Pils before and neither of these beers had any of the telltale characteristics.

It’s been my experience that cold-side oxidation occurs quite rapidly, even when beer is stored cool, which is why I chose to collect data on the original version of this xBmt after a month of conditioning. Still, a number of people expressed their belief that this wasn’t nearly enough time for the negative effects caused by racking into a non-purged keg to take effect, so we heeded their suggestion to let the beers age even longer before collecting another set of data. The fact the results were the same is certainly intersting, though as someone who prefers to go the extra mile to avoid cold-side oxidation, I’ve no plans to go away from purging kegs by pushing liquid out with CO2 prior to filling.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

14 thoughts on “exBEERiment | Cold-Side Oxidation: Impact Purging An Empty Keg vs. A Keg Filled With Liquid Has On A German Pils That Was Aged For 3 Months”

I’m curious how much CO2 you used to purge the empty keg. It takes me about 10 minutes to fill each keg. That seems a really long time to leave a bottle of gas open and flowing. If someone really does this would be interesting to weigh your CO2 bottle before and after purging this way.

I fill the keg with CO2 prior to filling with beer. My theory is that the beer pushes out most of the gas in the keg, leaving only a tiny space at the top. Air is only 21% oxygen before mixing with CO2, perhaps 10% after. Ten percent of a cupful of gas at the top of your keg is not enough to hurt your beer.

What pressure do you fill the keg to with CO2? In order to reduce the O2 to 50% of the concentration you’d have to pressurize it to 1 atm with co2 or some other non-O2 containing gas, which is about 15 psi.

I haven’t run the numbers but as oxygen can have effects at the 1 or less parts per million level I’d be wary of discounting 1 cup of 10% O2.

Thanks, Cade and greetings from back in Austin!

I may be opening the door for all the low-O zealots to chime in with their favored trick to keep oxidation at bay. On top of purging, I typically spund or naturally carbonate in the keg so the yeasts can eat up stray oxygen. Also it’s been pointed out to me (thanks Ric) that unless you are buying medical-grade CO2 there are several percent O2 in the gas. Remember that commercial brewers are striving for 10’s of parts per billion in canned product. They are looking for shelf-life.

Is an effort at home necessary or worth it? Dunno. If you are going to drink it all up in a month it’s not going to make much difference. If you are trying to win a big competition that has good judges it very well could.

Thanks for checking on this experiment. I was one that had questions about long term storage. I do push sanitizer but only to flush my beer lines. I usually end up opening the keg to add gelatin or dump out the last bit of starsan(cut dip tubes) then flush with C02 before filling with beer.

Really appreciate your testing a well lagered beer (i.e., months down the road)!

Interesting to see another addition to the popular topic of oxidation. Here is a summary (I hope complete) of the 14 Brü/Ex I found.

9 Neg results

February 7, 2022 p=0.38

November 15, 2021 p=0.83

August 2,2021 p=0.90

July, 13, 2020 p=0.21

March 23, 2020 p=0.45

August 26, 2019 p=0.65

July 30, 2018 p=0.83

June 19, 2017 p=.019

December 19, 2016 p=0.14

5 Pos results

June 8, 2020

April 13, 2020

September 23, 2019

February 11, 2019

September 11, 2017

Prior to kegging I’ll _slowly_ flow CO2 into the bottom, venting thru the normally CO2 IN post into water or sanitizer to judge the flow rate. Slow flow minimizes mixing at the air/CO2 boundary. I don’t try to push all the air out, only forming a layer of CO2 at the bottom. The beer siphons into the BEER OUT post at about the same flow rate as indicted by the bubbling via the CO2 post.

After the keg is filled I’ll sweep it with CO2 thru the IN post and out the PRV.

One other thing. Is there really substantial liquid/(O2 in air) diffusion while the beer fills the keg? To get O2 into solution, consider how that’s done prior to pitching yeast: Vigorous shaking in air for a minute or more, or pure O2 though a stone for 60s. It’s not normally pumped in, unlike a commercial operation where all sorts of agitation can occur.

I would speculate there’s very little O2 absorption during transfer, and sweeping the headspace with CO2 gets all remaining gaseous O2.

I brew strictly lagers. I purge the empty tanks 2 times a 10 psi. 3rd time I let it sit 10min before purging the last time. I than pressure transfer thru a closed system. Filling the keg from the out port. When transfer is done I blow co2 in the out port forcing any headspace to be purged. Never had any oxidation!

Strikes me the experiment would be more rigorous if you’d done a third keg with no purging at all.

They’ve done that experiment separately and the results came back not significant*: https://brulosophy.com/2020/07/13/cold-side-oxidation-impact-of-transferring-a-pale-lager-to-a-non-purged-keg-exbeeriment-results/

*Caveats: COVID-era testing with a single taster, and doesn’t appear to have lagered very long.

Feel like I’ve seen this before with lager. Why not NEIPA, the canary in the cold-side-oxidation coalmine?

I do not pre-purge, but syphon the beer into the keg allowing it to push the air out. Typically this leaves a very small volume of air in the keg of which as someone else mentioned, only 18% is oxygen. Having sealed the keg I carbonate through the out port. This means the CO2 is rising through the beer and will speed carbonation (like a giant sodastream). It also leaves the in port free. I close the CO2 then release the head pressure through the in port. This purges the small volume of air from the head space. Doing this once is likely more than adequate to virtually eliminate the oxygen from the keg, but it seems OCD is a part of the home brewer mentality so I re-pressurize and vent the headspace several times. If nothing else, it increases the amount of CO2 injected at the bottom of the keg, therefore accelerating carbonation. Have not had oxidation and have had kegs last as long as a year.

Why bother doing the xBmt if you’re going to ignore the results?

I typically don’t purge the keg, but have pushed sanitizer out on occasion. I normally fill it

from the bottom through the bev out with tubing on the threads of the keg connector (aothough not always, sometime I am lazy and just drop the hose into the bottom of the keg, being careful not to agitate the liquid. Once the keg is full, I blanket the top of it with CO2 through the gas line prior to sealing it, for 5 to 10 seconds or more. I then let the pressure seal it. I might even open the PRV and run CO@ through it for a few more seconds. After sealing it, I purge it under pressure with the PRV or gas port poppet if it doesn’t have a PRV, at least 15-20 times.

This is most likely overkill but I have never had problems with cold side oxidation.