Author: Jake Huolihan

Oxygen, while necessary for yeast to efficiently ferment wort, is generally viewed as the enemy of beer, and one of the primary points of oxygen exposure is at packaging. For this reason, many brewers employ various steps to reduce the amount of oxygen that comes into contact with their beer once fermentation is finished.

Whereas some brewers fail to see the value in purging kegs at all, a growing number have taken to completely purging kegs by pushing liquid out with CO2, which requires the use of a decent amount of gas. A sort of hybrid approach that demands less CO2 involves purging just the headspace of a keg after it has been filled with beer. This simple process consists of transferring the beer from the fermenter to a non-purged keg then, with the lid in place, hitting it with CO2 and releasing the gas multiple times to rid the headspace of oxygen.

I’ve been purging kegs by pushing sanitizer solution out with CO2 for the last few years, but prior to that, I relied on just purging the headspace after filling. With one past xBmt showing this arguably simpler method had minimal perceptible impact on a Hazy IPA, I was curious to see how it might affect a stronger dark ale and designed an xBmt to test it out for myself!

| PURPOSE |

To evaluate the differences between an American Stout that had the headspace in the keg purged multiple times with CO2 and one where the headspace was not purged.

| METHODS |

For this xBmt, I designed a simple American Stout recipe consisting of 13% dark roasted grains.

Extra Buckets

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 30 min | 40.6 | 34.2 SRM | 1.063 | 1.013 | 6.56 % |

| Actuals | 1.063 | 1.013 | 6.56 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Genie Pale Malt | 12.75 lbs | 87.18 |

| Roasted Barley | 1.375 lbs | 9.4 |

| Chocolate Malt | 8 oz | 3.42 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Loral | 40 g | 30 min | Boil | Pellet | 11.5 |

| East Kent Goldings (EKG) | 30 g | 15 min | Boil | Pellet | 5 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

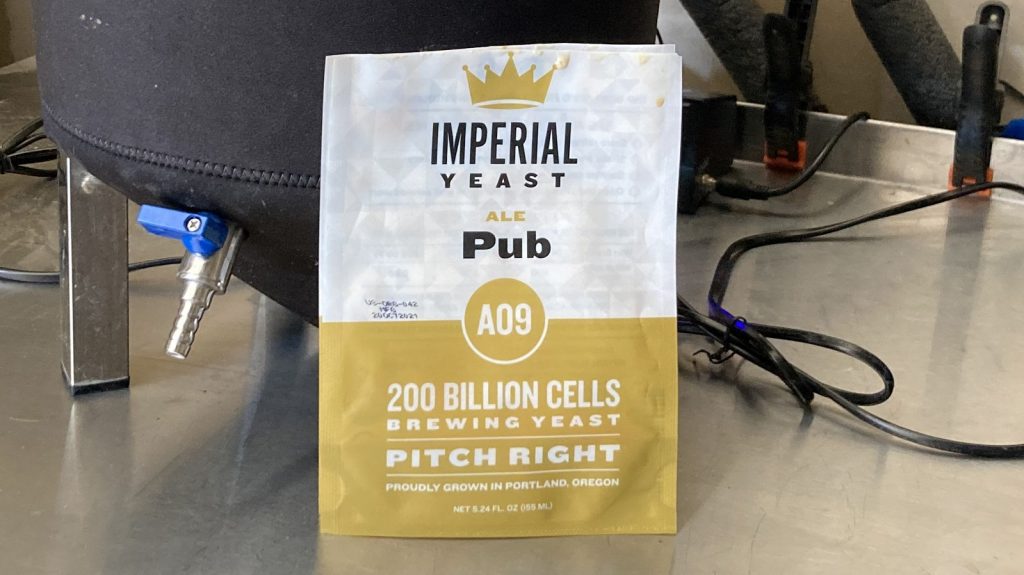

| Pub (A09) | Imperial Yeast | 74% | 32°F - 32°F |

Notes

| Water Profile: Ca 60 | Mg 5 | Na 10 | SO4 53 | Cl 77 |

Download

| Download this recipe's BeerXML file |

I started my brew day by collecting RO water for a 10 gallon/38 liter batch, adjusting it to my desired profile, then flipping the switch on my controller to get it heating up, after which I weighed out and milled the grain.

With the water properly heated, I mashed in then checked to ensure it was at my target temperature.

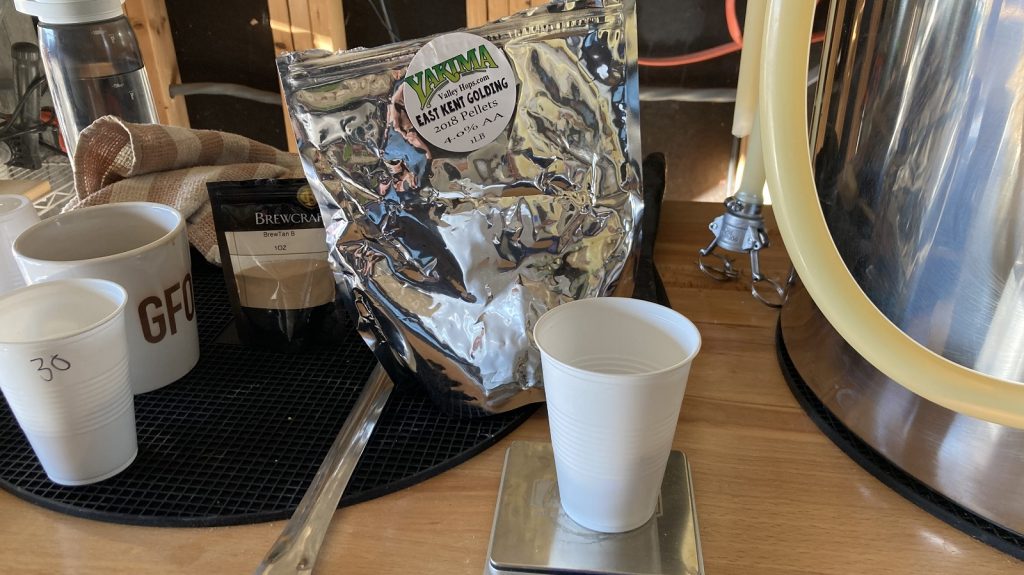

During the mash rest, I prepared the kettle hop additions.

Once the 60 minute mash step was complete, I collected the sweet wort in my kettle.

The wort was then boiled it for 30 minutes with hops added as stated in the recipe.

When the boil was finished, I quickly chilled the wort with my IC.

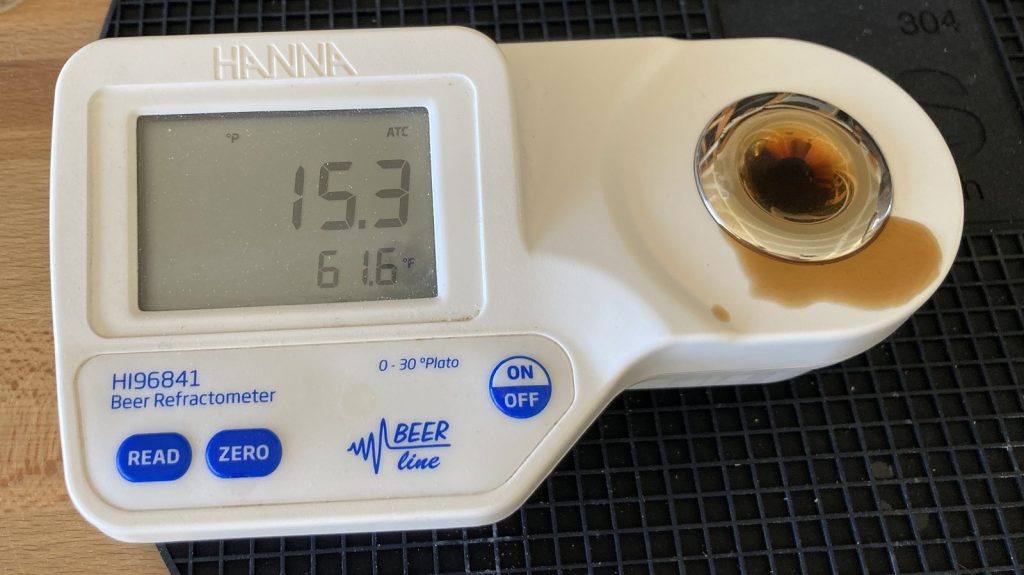

A refractometer reading showed the wort was right at my intended OG.

The chilled wort was then evenly split between two fermentation vessels.

Next, I connected the fermenters to my glycol unit set to 66°F/19°C before pitching a single pouch of Imperial Yeast A09 Pub into each.

After confirming both beers were at the same 1.013 FG 10 days later, I racked each to sanitized by non-purged kegs

After placing the lid on one of the kegs, I proceeded to purge the headspace of the other by hitting it with CO2 and pulling the PRV to fully release it; I repeated this process 15 times. The filled kegs were then left to carbonate and condition in my keezer for 5 weeks before they were ready for evaluation.

| RESULTS |

Due to social distancing practices as a result of the COVID-19 pandemic, data for this xBmt was unable to be collected in our typical manner. As such, temporary adaptations were made involving the author completing multiple semi-blind triangle tests in as unbiased a way as possible.

Utilizing 4 opaque cups of the same color where 2 were inconspicuously marked, one set was filled with the beer from the keg that had the headspace purged while the other set was filled with the beer from the non-purged keg. For each triangle test, 3 of the 4 cups were indiscriminately selected, thus randomizing which beer was the unique sample for each trial. Following each attempt, I noted whether I was correct in identifying the unique sample. Out of the 10 semi-blind triangle tests I completed, I needed to identify the unique sample at least 7 times (p<0.05) in order to reach statistical significance. In the end, I correctly identified the unique sample just 2 times (p=0.90), indicating my inability to reliably distinguish an American Stout served from a keg that had the headspace purged from one served from a non-purged keg.

From my first side-by-side samples to my last triangle test, these beers tasted identical to me. Both had a pleasant rich malt character marked by notes of coffee, chocolate, and toast with minimal hops and the subtle ester character I’ve come to expect from Imperial Yeast A09 Pub.

| DISCUSSION |

The negative impact oxygen exposure has on beer has been known for a long time, though with the rise of more sensitive styles, it seems to be receiving much more focus lately. With packaging being a main vector for oxidation, some brewers opt to purge the headspace of kegs after filling as a means of flushing any residual oxygen out. My inability to reliably distinguish an American Stout from a keg where the headspace was purged 15 times from one served from a non-purged keg suggests any impact was minimal enough as to be imperceptible to me.

In considering explanations for these results, it’s possible that, since both beers were racked to kegs that had not been fully purged, they were equally oxidized and the purging of headspace wasn’t enough to overcome the oxidative effects. However, I did not perceive either beer as possessing the tell-tale signs of oxidation. Another possibility is that, as many have claimed in the past, filling kegs from the bottom forces most of the air out, while the agitation releases CO2 that displaces any remnant oxygen. Finally, there’s also the fact that roasted grains have antioxidant effects, which may be the reason neither were perceptibly oxidized.

This being the second xBmt on this topic with similar results, I can’t help but question whether the process of purging a keg’s headspace really has an impact at all, rather it seems like it may be a waste of CO2. Given my admitted phobia of cold-side oxidation, I’ll continue with my process of completely purging kegs by pushing sanitizer solution out with CO2, and I’m interested in comparing this method to purging just the headspace of a keg in the future.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

4 thoughts on “exBEERiment | Cold-Side Oxidation: Impact Purging Keg Headspace With CO2 Has On An American Stout”

I guess the whole oxidation process depends on time, temperature and oxygen concentration. The fact that you stored it for a short time under low temperatures most likely explains why there is no perceivable difference in taste. An interesting experiment would be to store unpurged and purged bottles or kegs for a year at room temperature and see if there would a difference in taste then. This would be an extreme case, so there would be the biggest chance for a flavour difference. For NEIPAs there was also a study done which showed that storage temperature turned out to be more important than oxygen content. So not perfectly canned NEIPA with some oxygen content but stored cold would hold up better than a perfectly canned NEIPA kept at room temperature.

Interesting. I did forget one time to purge the headspace of a german lager and did not notice any effect of oxidation too. I also filled up from the bottom in a non purged keg.

I agree that it’s a waste to push 5 gal of sanitizer. I hit and purge my keg a few times. Let it rest about 15 min so CO2 can sink to the bottom. Then I fill from the bottom slowly. This keeps a layer of CO2 Between beer and O2. Then I let CO2 flow from empty fermenter into bottom of the keg for a few seconds to clear headspace and mix the gelatin that I placed in the keg at the beginning of the process.

I fill keg to top with sanitized water, push it out with co2 before filling keg (closed pressure transfer). Fill keg until beer comes out the keg’s prv. set at 30psi for a few days. beer does carbonates without headspace.