Author: Cade Jobe

Experienced brewers of good beer are keenly aware of the impact water chemistry has on the ultimate character of their product, hence the importance they place on ensuring desired mineral profiles to enhance certain perceptible qualities. One relatively simple approach to brewing water chemistry involves adjusting the ratio of sulfate (SO4) to chloride (Cl), ions commonly known to accentuate hop crispness and malt roundness, respectively.

When contemplating mineral adjustments to brewing water, many focus on total ion amounts, which can certainly produce positive results. However, it’s been contended that sulfate and chloride have the effect of sort of cancelling each other out, suggesting that adjustments to the ratio of each may be more effective. This is supported by a past xBmt where blind tasters were unable to distinguish beers made with water adjusted to have vastly different amounts of sulfate and chloride but nearly identical ratios of the ions.

I started brewing during a time when the importance of water chemistry was acknowledged, and as such, I’ve always made adjustments to achieve my desired profile. After reviewing past xBmts on this topic, it occurred to me they’ve focused on IPA. As a lover of malty styles, I began to wonder if water profiles favoring chloride really do accentuate malt roundness and decided to test it out for myself!

| PURPOSE |

To evaluate the differences between a British Brown Ale brewed with a high sulfate to chloride ratio and one brewed with a high chloride to sulfate ratio.

| METHODS |

My goal being to test the impact sulfate to chloride ratio has on a notably malty style, I went with a simple British Brown Ale recipe for this xBmt.

Level With Yourself

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 23.4 | 16.9 SRM | 1.043 | 1.009 | 4.46 % |

| Actuals | 1.043 | 1.009 | 4.46 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Lamonta: Pale American Barley Malt | 8.75 lbs | 89.74 |

| Caramel Malt 120L | 8 oz | 5.13 |

| Special B Malt | 8 oz | 5.13 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Willamette | 28 g | 60 min | Boil | Pellet | 5.4 |

| Willamette | 28 g | 5 min | Boil | Pellet | 5.4 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Pub (A09) | Imperial Yeast | 74% | 32°F - 32°F |

Notes

| Water Profile (High SO4): Ca 117 | Mg 20 | Na 14 | SO4 159 | Cl 39 Water Profile (High Cl): Ca 117 | Mg 20 | Na 14 | SO4 37 | Cl 156 |

Download

| Download this recipe's BeerXML file |

I started my brew day by collecting the full volume of water for each batch before setting my Bräu Supply controllers to heat them up.

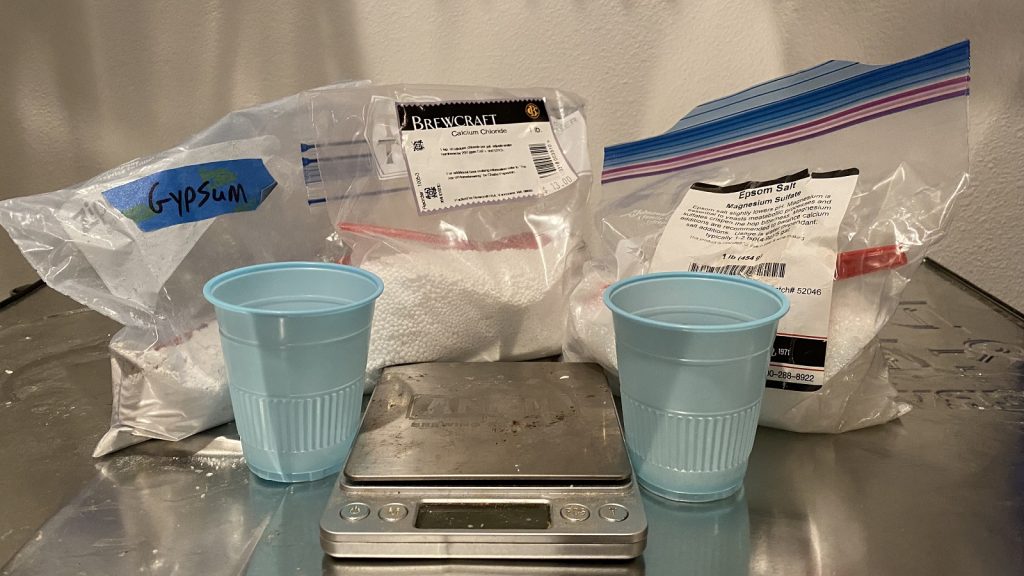

At this point, I measured out the amounts of gypsum and calcium chloride to achieve sulfate to chloride ratios of 4:1 (4.0) for one batch and 1:4 (0.25) for the other batch.

After adding the salts to their respective batches, I weighed out and milled identical sets of grain.

With the water properly heated, I added the grains, turned the pumps on to recirculate, and set the controllers to maintain my intended mash temperature of 154°F/68°C.

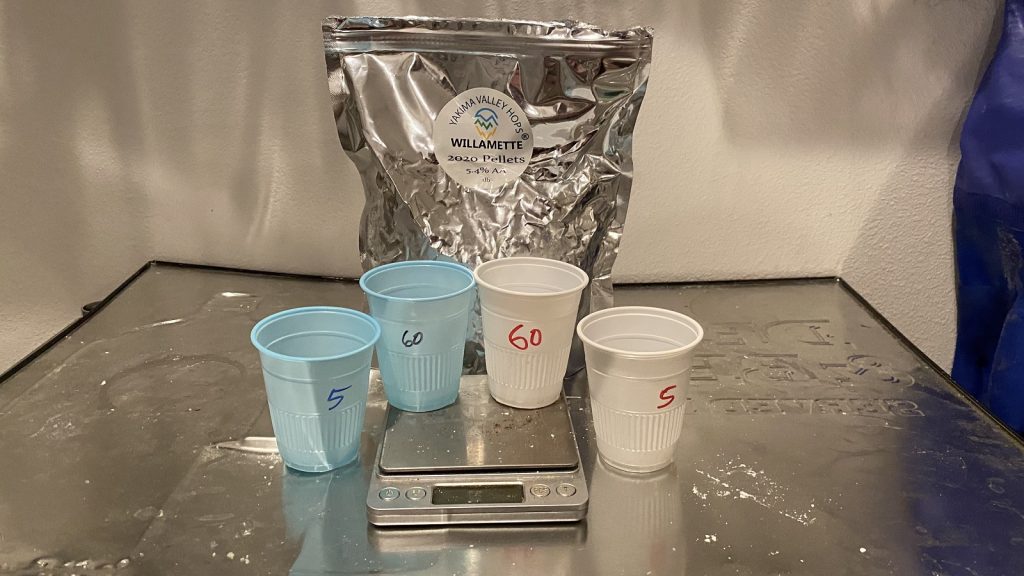

While the mashes were resting, I weighed out the kettle hop additions.

Following each 60 minute mash rest, I removed the grains then boiled the worts for 60 minutes, adding hops at the times listed in the recipe.

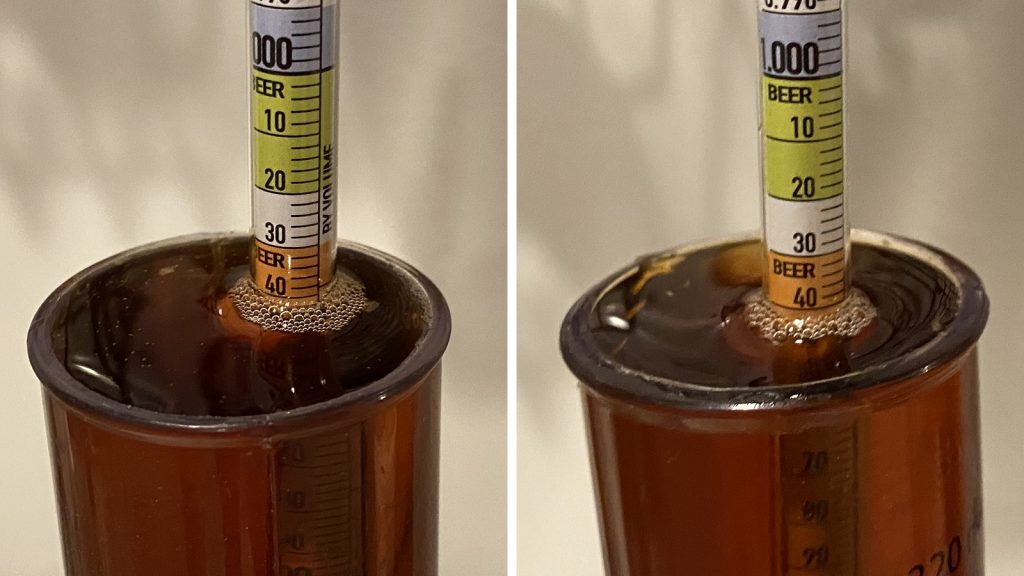

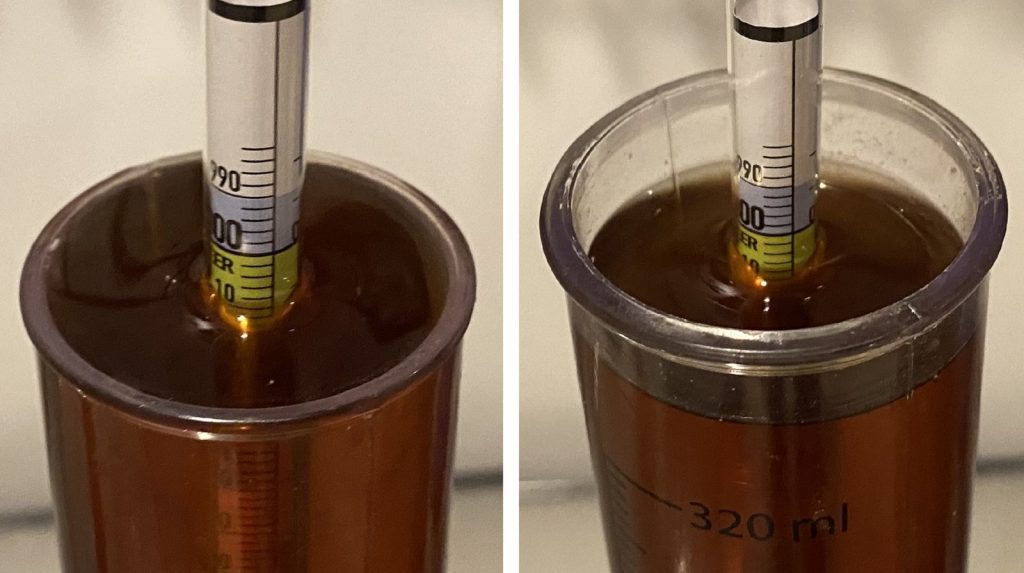

When the boils were complete, I quickly chilled the wort then took hydrometer measurements showing both were at the same OG.

After transferring the worts to sanitized Brew Buckets, they were placed next to each other in my fermentation chamber and I pitched a single pouch of Imperial Yeast A09 Pub into each.

The beers were left to ferment at 66°F/19°C for a week before I took hydrometer measurements showing the high sulfate beer finished with a slightly higher FG.

At this point, the beers were pressure transferred to CO2 purged kegs that were placed on gas in my keezer. After a week of conditioning, they were ready for evaluation.

| RESULTS |

Due to social distancing practices as a result of the COVID-19 pandemic, data for this xBmt was unable to be collected in our typical manner. As such, temporary adaptations were made involving the author completing multiple semi-blind triangle tests in as unbiased a way as possible.

Utilizing 4 opaque cups of the same color where 2 were inconspicuously marked, one set was filled with the high sulfate (4:1) beer while the other set was filled with the high chloride (1:4) beer. For each triangle test, 3 of the 4 cups were indiscriminately selected, thus randomizing which beer was the unique sample for each trial. Following each attempt, I noted whether I was correct in identifying the unique sample. Out of the 10 semi-blind triangle tests I completed, I needed to identify the unique sample at least 7 times (p<0.05) in order to reach statistical significance. In the end, I correctly identified the unique sample 9 times (p=0.0004), indicating my ability to reliably distinguish a British Brown Ale made with water adjusted to a 4:1 sulfate to chloride ratio from one adjusted to a 1:4 sulfate to chloride ratio.

I perceived the beer made with higher sulfate as have accentuated earthy notes with a crisp finish, whereas the higher chloride version had more caramel and toffee with softer finish. While I enjoyed both beers, I felt the one made with higher chloride was more in line with what I expect from a British Brown Ale and preferred it over the higher sulfate batch.

| DISCUSSION |

The most prevalent single ingredient in any batch of beer is water, hence the importance brewers place on ensuring its quality, which is often improved by adjusting with minerals to achieve a desired soluble ion profile. Two of the most common ions focused on by brewers are sulfate and chloride, with many relying on the ratio of each rather than just the actual amounts. My ability to reliably distinguish a British Brown Ale made with a 4:1 sulfate to chloride ratio from one made with a 1:4 sulfate to chloride ratio suggests the adjustments had a perceptible impact.

Admittedly, these results are not ideal considering my lack of access to blind participants due to Covid, but they do corroborate findings from a number of past xBmts on water chemistry, adding further support to the idea that water quality is worth paying attention to.

As someone who has taken the quality of my brewing seriously since the beginning, adjusting to specific profiles depending on the style, I view these results as validating of my approach. As much as I trust that good beer can be made from unadjusted water, I will definitely continue to adjust mine, and my go-to will be focusing primarily on sulfate to chloride ratios.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

13 thoughts on “exBEERiment | Water Chemistry: Impact Sulfate To Chloride Ratio Has On A British Brown Ale”

Thanks for the informative experiment. I come a part of the world that has naturally high calcium carbonate content but is low in sulphate. I adjust my water chemistry for some styles but typically would not for something like a brown ale. High carbonates are associated with harsh hop bitterness. It would be great to see this experiment repeated with calcium/magnesium carbonate to round out the picture. Cheers.

Nice experiment! Years ago, water chemistry resulted in the first major improvement in my homebrewed beer (not switching to AG, not paying attention to yeast like are commonly suggested to newer brewers). Nice to see Willamette too, I love that hop.

As much as I love to read about all of these tests and comparisons, I cannot put much faith in the results from just one person. It is too easy to unknowingly skew the results. Even 30 people, testers, would be suspicious. But keep up the good work. Still interesting results.

Puzzled by this phrase, “Following each 60 minute mash rest, I removed the grains…”. I assume you ran off the wort, perhaps sparking as you did. This would actually be removing the wort, not the grain.

The UniBräu is an all-in-one system. The grains are in a basket that you lift out of the wort. The runnings drip down while the wort is heating to boil.

Jeff, good to hear from you. It appears the grain was held in a basket, like my Spike Solo, which is similar to a brew in a bag, so you lift the basket out of the kettle, instead of running of the wort. Cheers!

Thank, Dave! That would explain it.

Hello Jade,

I have experimented for many years with brewing salts. Never happy with results.Living in Melbourne Australia, we have fantastic pure water ,minimal salts , like Pilsen. Best results from untreated water every time. The Bavarians and Czechs have same water type as here. They Don,t using additional salts. After some research, I discovered malted barley contains adequate calcium for mashing. Tried a bitter recently with addition of salts. Unhappy with outcome. Will go back to plain water plus lactic acid for ph adjustment if required. Like your report though.

cheers,

Andy Graham

Great experiment. Was your ale Southern or Northern English brown ale? There’s a huge difference in style. I find with my water (NW England) that higher chloride to sulphate ratios suit darker ales generally, particularly London porter and Irish stout. As you found, it tends to give a softer edge to the beer

I’m not sure that I could tell you the difference! Haha. I’ve never had an example of Southern or Northern. Interesting info about the water chem in NW England.

Awesome stuff cade sounds about right

I find that fresh beers with different salts are noticeable but as the beer ages the differences seem to fade. When I made a NEIPA with 150ppm SO4 and 30 or so CL it did taste sharper, crisper and less full bodied than all my previous attempts but after approx 2 months the difference was less clear comparing to other high CL beers. Sample of 1 but there you go

Interesting results, but 2 weeks from grain to glass seems a bit rushed at the home brew level. How did it taste after 3 weeks?