Author: Mike Neville

Of the four main ingredients in beer, hops have arguably become the sexiest, as they’re the feature in some of today’s most popular styles. Once picked off the bine, hop flowers are typically dried down to 8 – 10% moisture, at which point they’re ready for use. However, most hops go on to be further processed by being milled into a powder and pushed through a dye to create small pellets, which take up less space than whole cones and are arguably easier to use.

The most common type of hops used by brewers are T-90 pellets, which are made from the entire flower such that they possess a similar amount of vegetative matter as whole cone hops. A few years back, the innovative team at John I. Haas released an advanced hop product called LUPOMAX that’s described as being “a highly consistent, concentrated lupulin pellet designed to deliver optimized hop flavor.” Containing less vegetative matter and more desirable lupulin, LUPOMAX allows brewers to produce beers with bold character while using up to 30% less hops, thereby reducing beer loss.

While I’ve used T-90 pellets for a majority of the beers I’ve brewed over the years, I recently started relying on LUPOMAX when making hoppier styles and have been very pleased with the results, despite using less hops overall. Recently, I began to wonder how LUPOMAX used at the 70% rate suggested by Haas compares to T-90 and decided to put it to the test.

| PURPOSE |

To evaluate the differences between a single-hop CTZ American Pale Ale made with T-90 pellets and one made with LUPOMAX.

| METHODS |

In hopes of emphasizing any differences caused by the variable, I went with a simple single-hop American Pale Ale recipe for this xBmt.

DYOR

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 6 gal | 60 min | 50.8 | 5.4 SRM | 1.052 | 1.01 | 5.51 % |

| Actuals | 1.052 | 1.01 | 5.51 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pale Malt 2-Row | 11 lbs | 84.62 |

| Munich Malt | 2 lbs | 15.38 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| LUPOMAX CTZ 5 g OR T-90 CTZ | 7 g | 30 min | Boil | Pellet | 15.6 |

| LUPOMAX CTZ 40 g OR T-90 CTZ | 57 g | 10 min | Boil | Pellet | 15.6 |

| LUPOMAX CTZ 40 g OR T-90 CTZ | 57 g | 2 min | Boil | Pellet | 15.6 |

| LUPOMAX CTZ 60 g OR T-90 CTZ | 85 g | 4 days | Dry Hop | Pellet | 15.6 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Flagship (A07) | Imperial Yeast | 77% | 32°F - 32°F |

Notes

| Water Profile: Ca 81 | Mg 9 | Na 8 | Cl 45 | SO4 177 |

Download

| Download this recipe's BeerXML file |

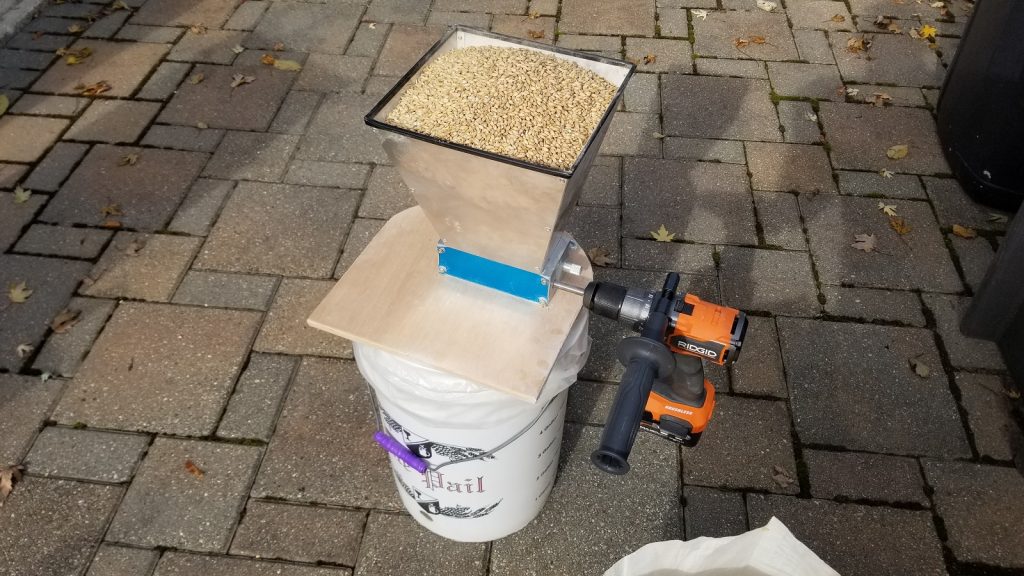

After collecting the full volume of water for two batches and adjusting both to my desired profile, I flipped the switch on my controller to get them heating up then proceeded to weigh out and mill the grain.

With the water properly heated, I incorporated the grains then checked to make sure the mashes were at my target temperature.

The mashes were left alone for 60 minutes.

During the mash rests, I prepared the kettle hop additions, using 70% the amount of LUPOMAX as T-90 pellets per Haas’ recommendation.

Once the mashes were finished, I removed the grains then proceeded to boil the worts for 60 minutes, adding hops at the times listed in the recipe.

When the boils were complete, I quickly chilled the worts with my IC.

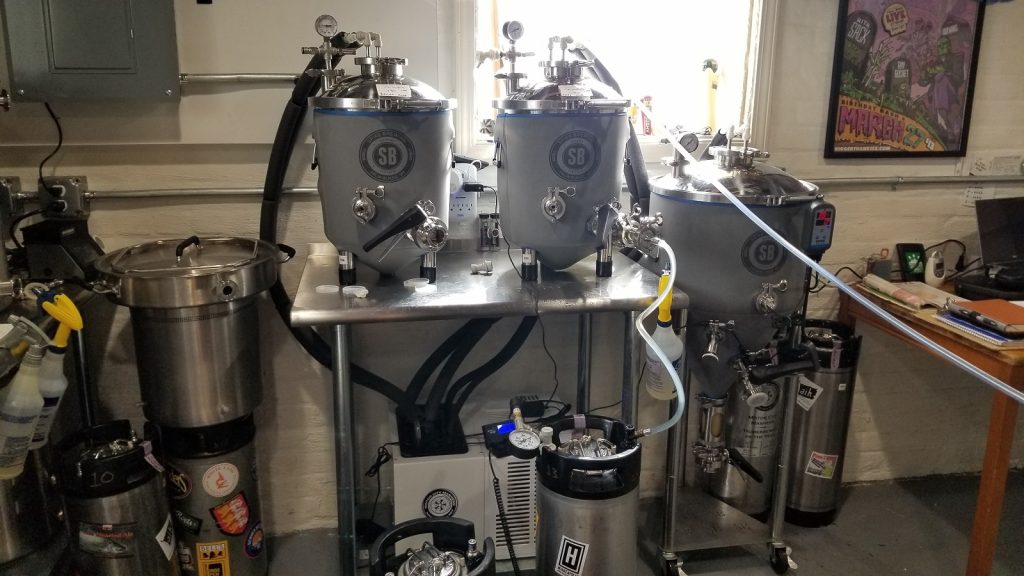

Next, I transferred identical volumes of wort to sanitized fermenters.

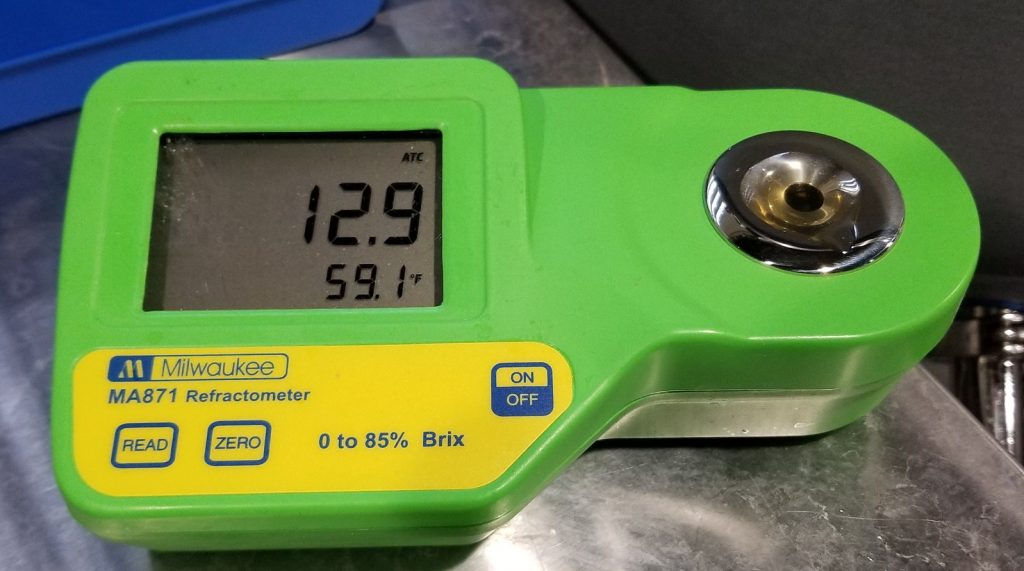

Refractometer readings showed both worts were at the same target OG.

The fermenters were connected to my glycol unit and allowed to finish chilling to my desired fermentation temperature of 68°F/20°C, at which point I pitched a single pouch of Imperial Yeast A07 Flagship into each batch.

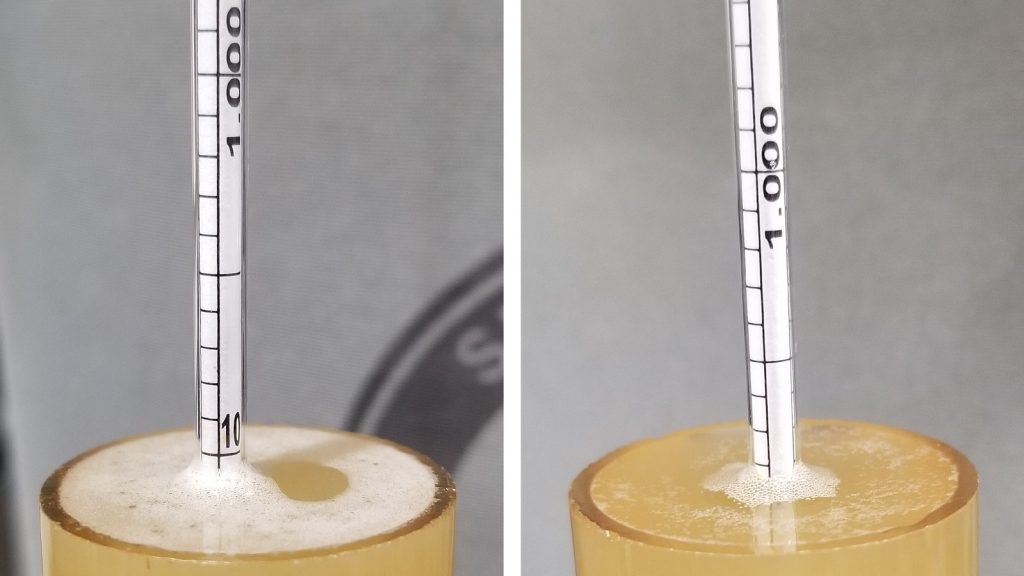

The beers were left to ferment for 5 days before I added the dry hop charges, after which I left them alone for an addition 4 days before taking hydrometer measurements showing the T-90 batch had a slightly higher FG than the LUPOMAX batch.

At this point, I cold-crashed the beers and returned the following day to pressure-transfer each to CO2 purged kegs.

The filled kegs were placed in my keezer and burst carbonated overnight before I reduced the gas to serving pressure. After a week of conditioning, they were carbonated and ready for evaluation.

| RESULTS |

Big thanks to my homebrew club, the Motor City Mashers, for assisting with data collection! A total of 24 people of varying levels of experience participated in this xBmt. Each participant was served 2 samples of the beer made with T-90 pellets and 1 sample of the beer made with LUPOMAX hops in different colored opaque cups then asked to identify the unique sample. While 13 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, 15 did (p=0.003), indicating participants in this xBmt were able to reliably distinguish a single-hop CTZ American Pale Ale made with T-90 pellets from one made with 70% the amount of LUPOMAX hops.

The 15 participants who made the accurate selection on the triangle test were instructed to complete a brief preference survey comparing only the beers that were different. A total of 5 tasters reported preferring the beer made with T-90 pellets, 7 said they liked the beer made with LUPOMAX more, 2 had no preference despite noticing a difference, and 1 person reported perceiving no difference.

My Impressions: Out of the 5 semi-blind triangle tests I attempted, I correctly identified the odd-beer-out every time, and I was able to do so based on aroma alone. While I perceived both beers as having pleasant grapefruit notes, I felt the one made with T-90 pellets was less assertive than the one made with LUPOMAX. Both beers were very good, though I preferred the expressiveness of the LUPOMAX version.

| DISCUSSION |

LUPOMAX hops are a relatively new product that have a higher concentration of lupulin and reduced vegetal matter, which the manufacturer claims imparts beer with “hop flavors that are bigger, bolder, and brighter” than T-90 pellets, even when less are used. The fact tasters in this xBmt were able to reliably distinguish an American Pale Ale made with T-90 pellets from one made with 70% the amount of LUPOMAX suggests the different hop types impart unique characteristics.

One possible explanation for these findings is that the perceived difference was a function of the amount of hops used in each batch, though in post-survey conversations, tasters tended to describe the LUPOMAX beer as being more pungent. It’s also possible that, despite being from the same crop year and grown in the same region, the CTZ hops used to produce the T-90 pellets came from a different source than those used to make LUPOMAX.

Given the subjectivity of preference, it’s impossible to say that one type of hop is objectively better than the other, and in fact preference ratings among those who were correct on the triangle test were almost evenly split. Personally, I found the beer hopped with LUPOMAX as being more pungent, which was impressive considering how much less I used than the T-90 pellets. I certainly plan to continue using LUPOMAX in my hoppy beers at the suggested rates, though I look forward to seeing what happens when used in higher amounts as well.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

7 thoughts on “exBEERiment | Hop Comparison: T-90 vs. LUPOMAX CTZ In An American Pale Ale”

Useful info. Thanks.

Weird, I made a nearly identical all-Columbus Lupomax pale just yesterday. Main difference is that I’m fermenting with Imperial A24 Dry Hop.

Are these lupomax pellets just T-45 pellets with a fun name?

The difference in FG is interesting. I wonder if anything is behind it or if it would be atypical over a lot of repeats.

Did it look like there was a significant difference in volumes of hop residue after the boil?

Interesting. Any idea how they come up with the 70% dosage rate? & what do they mean by “optimized”?

If T90 are 90% vegetative matter, & T45 are 45% vegetative mater, then there should be approximately 10% & 55% lupulin respectively? By my bad maths the equivalent ratio to add the same amount of lupulin would be 18% T45 of the T90 dosage?

I’m assuming that lupomax, being newer technology, should have even less vegetative matter than T45?

To my thinking T90 are actually more effective use of a raw product.. before beer wastage is taken into account?

Really cool! Thanks for the results! I wonder if the lupomax could be more concentrated than their 70% guideline suggests. Or maybe the T90 pellets just result in some of the hop character getting masked behind the higher level of plant matter. Either way it’s super helpful to know.

I believe all you discovered is that their 70% number is too high for equivalency. If you had pushed the dry hop to closer to the maximum efficiency number of around 1.2 oz hops per gallon beer, your results would probably be different.