Author: Marshall Schott

The most common types of packaging material used for beer are glass bottles and aluminum cans, both of which are essentially impermeable to oxygen and spoilage microbes. More recently, advanced beer storage options have hit the market that promise to even further improve shelf-life, for example, by allowing for the purging of oxygen with CO2.

And then, there are more rudimentary vessels one can store beer in, products that were never really intended for such a purpose. A few years ago, fed up with filling small-mouthed glass bottles and growlers to transport xBmt beers for data collection, I had the idea to try filling one of the 32 oz/1 L Nalgene bottles I use daily for water. With the initial bottle filled, I quickly learned the standard cap would leak if the bottle was even barely agitated, so I swapped it out for an aftermarket cap. Voila! No leaking whatsoever, not even when the bottle was shaken vigorously, which indicated to me it also likely wouldn’t allow oxygen in.

Made from BPA/BPS-free Tritan plastic, Nalgene bottles have been my go-to for transporting beer since then, though I hadn’t really considered actually storing beer in them for longer than a few hours. That is, until I mentioned this practice in an episode of The Brülosophy Podcast, after which I was contacted by many listeners who wondered if doing so has any impact on beer quality. Rather than provide a presumptive response, I thought it’d be better to test it out.

| PURPOSE |

To evaluate the differences between a Dark Mild stored in a plastic Nalgene bottle for 5 weeks and one kept in a keg.

| METHODS |

For this xBmt, I used a Short & Shoddy Dark Mild that I had on tap at the time.

Fraternal

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 30 min | 20 | 19.6 SRM | 1.032 | 1.009 | 3.02 % |

| Actuals | 1.032 | 1.009 | 3.02 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Lamonta: Pale American Barley Malt | 5 lbs | 66.67 |

| Vanora: Vienna-style Barley Malt | 1 lbs | 13.33 |

| Golden Naked Oats | 12 oz | 10 |

| Crystal Medium | 8 oz | 6.67 |

| Roasted Barley | 4 oz | 3.33 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Fuggles (2018) | 30 g | 30 min | Boil | Pellet | 4.9 |

| Fuggles (2018) | 15 g | 15 min | Boil | Pellet | 4.9 |

| Fuggles (2018) | 15 g | 5 min | Boil | Pellet | 4.9 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Pub (A09) | Imperial Yeast | 74% | 32°F - 32°F |

Notes

| Water Profile: filtered Fresno tap water with unmeasured amounts of calcium chloride and gypsum added |

Download

| Download this recipe's BeerXML file |

I started by brew day by collecting the full volume of filtered water, which I adjusted with minerals to achieve a balanced profile.

As the water was heating up, I weighed out and milled the grain.

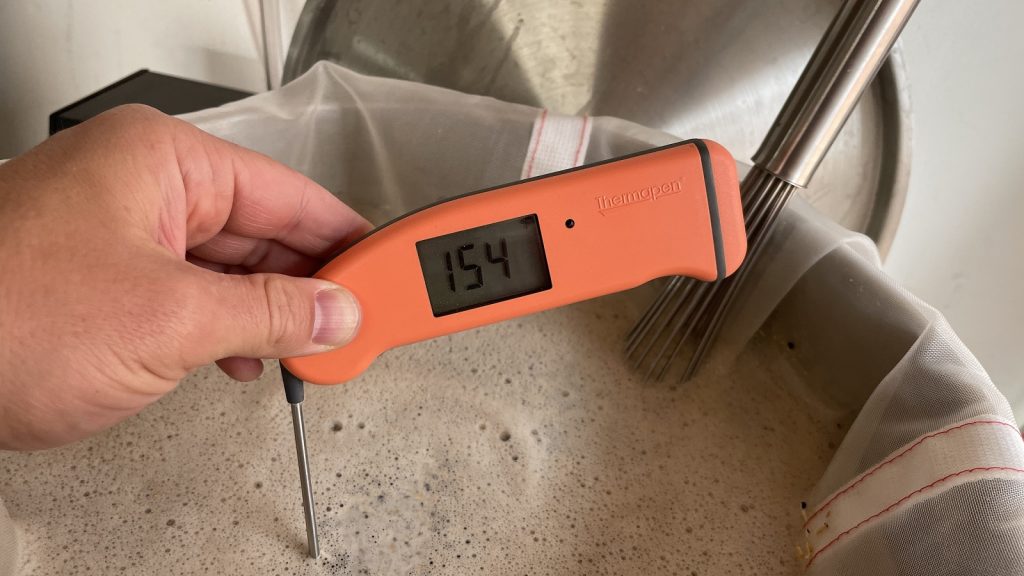

When the water was properly heated, I stirred in the grist then checked to make sure it was at my target mash temperature.

Following a 30 minute rest, I removed the grains and let them drip into the kettle while the wort was heating up.

The wort was boiled for 25 minutes with hops added at the times stated in the recipe.

At the completion of the boil, I quickly chilled the wort with my IC.

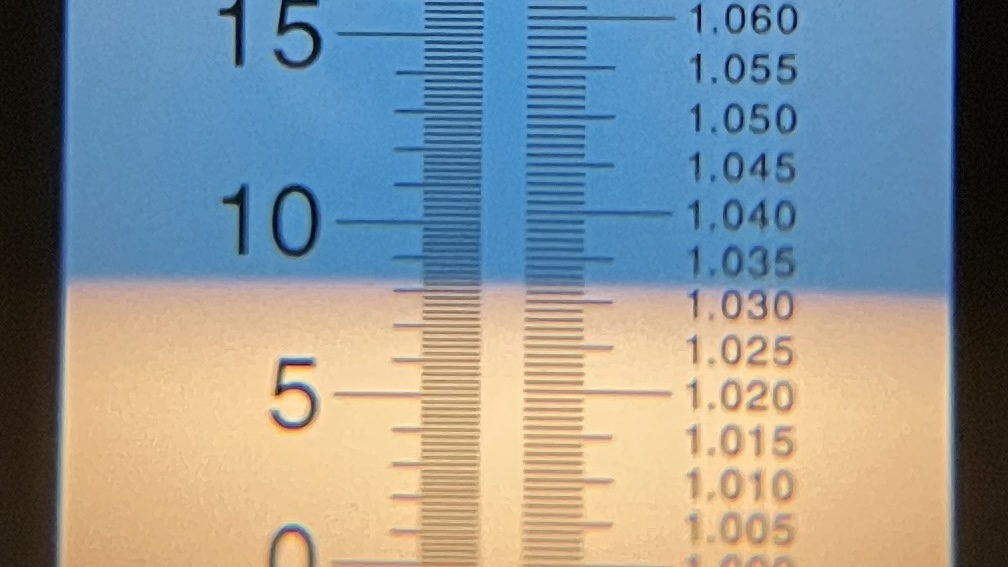

A refractometer reading was taken to confirm the OG.

I then transferred the wort to my fermentation vessel.

Next, I direct pitched a pouch of Imperial Yeast A09 Pub into the wort.

Finally, I connected the fermenter to my glycol rig set to hold the beer at 66°F/19LC.

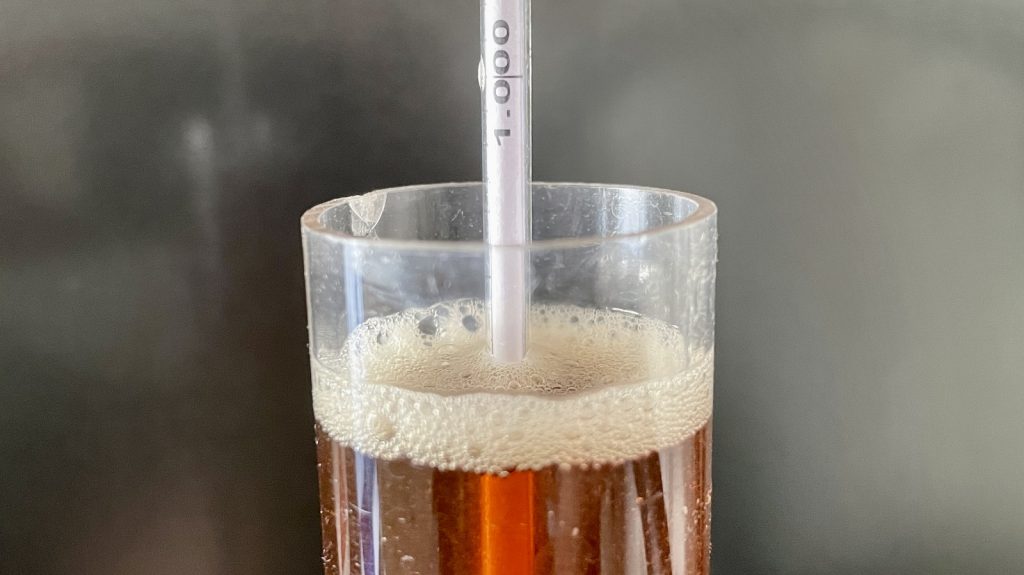

After 4 days, I noticed fermentation activity was absent and took a hydrometer measurement showing FG had been reached.

At this point, I cold crashed the beer to 34°F/1°C and left it alone for 2 weeks before proceeding with packaging.

The filled keg was placed in my keezer and burst carbonated at 50 psi for 13 hours before I reduced the gas to serving pressure. With the beer carbonated and clear after a week of conditioning, I gently filled a sanitized 32 oz/1 L plastic Nalgene bottle to the brim and tightly secured a Humangear cap.

The filled Nalgene bottle was then placed in my refrigerator, which is controlled to same temperature as my kegerator.

After 5 weeks, I filled 2 more sanitized Nalgene bottles of the same size then immediately transported them to Crow & Wolf Brewing where data collection was completed less than 2 hours later. The color and foam quality of the beers appeared identical.

| RESULTS |

A total of 21 people of varying levels of experience participated in this xBmt. Each participant was served 1 sample of the beer stored for 5 weeks in a plastic bottle and 2 samples of the beer stored in a keg in different colored opaque cups then asked to identify the unique sample. While 12 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, only 7 did (p=0.58), indicating participants in this xBmt were unable to reliably distinguish Dark Mild stored for 5 weeks in a plastic Nalgene bottle from one that was kept in a keg.

My Impressions: Out of the 3 semi-blind triangle tests I attempted, I didn’t pick the odd-beer-out a single time and will concede that all of my attempts were mere guesses. Shockingly to me, these beers were identical to my senses, even in terms of carbonation and foam quality, which I did not expect.

| DISCUSSION |

When it comes to beer storage, a primary concern of brewers is prolonging shelf-life, which can only be done by restricting exposure to oxygen and contaminants. While glass, aluminum, and stainless steel are the most common materials used for storage vessels, some people (ahem) choose the convenient option of storing beer in plastic bottles, leading to questions about the qualitative impact this might have. Interestingly, tasters in this xBmt were unable to reliably distinguish a Dark Mild stored in a plastic Nalgene bottle for 5 weeks from one that was kept in a keg.

Understanding what we do about the relationship between temperature and chemical reactions, there’s no denying that the 36°F/2°C storage temperature reduced the rate of any potential oxidation of the beer kept in the Nalgene bottle. And while the bottle wasn’t first purged with CO2, it was filled to the brim, ostensibly ridding it of any oxygen. It’s possible a more sensitive style would react differently to this condition, though detriment may also be avoided or markedly reduced with careful filling and cool storage.

Even after prior xBmts suggesting glass and stainless steel growlers are rather effective beer containers, I fully expected the beer stored in a Nalgene bottle for 5 weeks to be noticeably different than one kept in a keg. The fact neither blind participants nor I were able to tell these beers apart suggests Nalgene bottles with an aftermarket cap are likely a viable storage option with limited oxygen permeability. While previously I’d only used Nalgene bottles for brief transport of beer, I definitely plan to rely on them for longer term storage when camping or travelling, as they’re both affordable and very durable.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

6 thoughts on “exBEERiment | Impact Of Storing Beer In A Plastic Nalgene Bottle”

I frequently brew and ferment more beer than will fit into a corny keg. The excess goes into the 2 liter pop bottles which are flexible enough that I can expel all of the air out of the bottle. I will, at a later date, put a carbonator cap on the bottle and connect it to a CO2 tank to carbonate. How do you think the plastic pop bottles would compare to the Nalgene bottle for storage?

They’re fine in a pinch but have some issues.

PET bottles are relatively brittle, more so as they age, so there’s a bigger risk of accidents. Coke and Pepsi aren’t worried about skunking, so light needs to be thought about in storage. And they can have issues long term regarding letting CO2 out and O2 in.

I think issues with lids not seating right on threads is part of it — bottle makers aren’t conducting QA based on multiple openings and closings of screwtops over time. They’re also not worried about going from carbed to flat and back again. They’re manufacturing to use the least amount of material possible based on the planned use only.

I don’t think the risk of failure is that high, so for an occasional place for overflow I think they’re fine, but for a lot of uses it’s probably a false economy.

I noticed the filter system for your brewing water in one of the pictures. Can you describe the filter system?

I admittedly don’t remember my college physics, but I don’t see how there would be issues with O2 passing through a barrier into a pressurized container, regardless of the materials permeability. I don’t think air leaks into a balloon while it still has a higher pressure helium inside, why would it pass into a closed container of beer that is still carbonated?

Great experiment. Have to say that I am not surprised by the result at all, though. Over here in Germany, LIDL and ALDI sell dirt cheap lager and pilsener style beers in PET plastic bottles. The beer from these bottles is completely fine and can be stored normally for a long time.

I started my brewing career with plastic bottles as I was initially very concerned about bottle bombs. The IPAs a made were bottle fermented in different PET bottles, which worked just fine.

This is extremely useful information, so thanks for taking the time to do the experiment and write it up. I only bottle to share with friends for consumption within the week (if not the day). Even with an effective counter pressure filler it’s a tedious/messy process with the swing top glass bottles. The wide mouth Nalgene bottles will be easier to fill and clean, and I’ll be much more inclined to bring something on the spur of the moment because I won’t dread the setup and cleanup. Cheers!