Author: Phil Rusher

The use of caramel malts has been lauded for improving beer foam as well as imparting a range of desirable flavors including sweet, toasty, and even raisin-like. While all caramel (and crystal) malts are produced using the same general process, the various types are distinguished by the degree to which they are kilned or roasted, which ultimately determines their color and the consequent flavor contribution.

One caramel malt commonly used by brewers as a means of improving foam quality and body while imparting a rich malt character is Carahell. Produced by Weyermann, Carahell is kilned to just 10 °L and is viewed by some as being a slightly darker dextrin malt with properties similar to Carapils and Carafoam, though with the ability to have a stronger flavor impact.

I am no stranger to dextrin malts and have used Carapils many times, though my experience with Carahell is limited to a single batch years ago. While designing a Festbier recently, I considered using a dose of Carahell and was reminded of a past xBmt where tasters were able to tell apart a Kellerbier made with 10% of this caramel malt from one made with just Pilsner malt. Might it have a positive impact on my Festbier? I designed an xBmt to test it out for myself!

| PURPOSE |

To evaluate the differences between a Festbier made with 10% Carahell and one made without Carahell.

| METHODS |

Since the last Carahell xBmt was done on a simple Kellerbier, I opted to go with a slightly more characterful and potent Festbier for this one.

Second Level

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 6.2 gal | 90 min | 25.4 | 6.2 SRM | 1.062 | 1.01 | 6.83 % |

| Actuals | 1.062 | 1.01 | 6.83 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Gateway: Under-modified Barley Wind-Malt | 11 lbs | 73.33 |

| Vanora: Vienna-style Barley Malt | 2.5 lbs | 16.67 |

| Carahell | 1.5 lbs | 10 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Hallertau Magnum | 10 g | 90 min | First Wort | Pellet | 12 |

| Perle | 28 g | 20 min | Boil | Pellet | 6.7 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Harvest (L17) | Imperial Yeast | 74% | 32°F - 32°F |

Notes

| Water Profile: Ca 70 | Na 29 | SO4 123 | Cl 81 |

Download

| Download this recipe's BeerXML file |

I made identically sized starters of Imperial Yeast L17 Harvest a couple days ahead of time.

On brew day, after collecting the water for a single 10 gallon batch, I weighed out and milled the grain. For the batch made without Carahell, I substituted an equal amount of additional Gateway malt.

Given the undermodified malt and the style, I opted to do a step mash.

While waiting on the mashes, I weighed out the kettle hop additions.

Once the mash rests were complete, I removed the grains and proceeded to boil the worts for 90 minutes, adding hops at the times stated in the recipe.

At the end of each boil, the worts were quickly chilled with my CFC on their way to sanitized Ss Brewtech Brew Buckets.

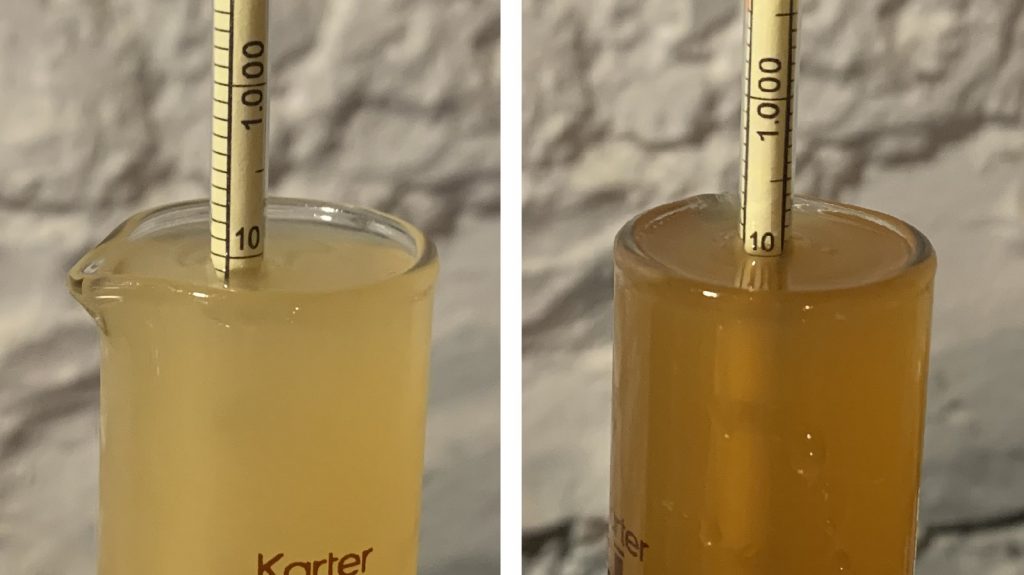

Refractometer readings showing both worts achieved a very similar OG.

The fermenters were hooked to my glycol rig and left for a few minutes to finish chilling to my desired fermentation temperature of 52°F/11°C, at which point I pitched the yeast.

After 8 days of fermentation, I raised the temperature to 63°F/17°C and left the beers alone for 3 more days before taking hydrometer measurements showing the beer made without Carahell finished 0.001 SG point higher than the one made with it.

I then crashed the beers to 38°F/3°C and let them lager for 18 days before pressure transferring them to CO2 purged kegs.

The filled kegs were placed in my keezer and burst carbonated overnight before I reduced the gas to serving pressure. After about a week of conditioning, they were carbonated and ready for evaluation.

| RESULTS |

Due to social distancing practices as a result of the COVID-19 pandemic, data for this xBmt was unable to be collected in our typical manner. As such, temporary adaptations were made involving the author completing multiple semi-blind triangle tests in as unbiased a way as possible.

Utilizing 4 opaque cups of the same color where 2 were inconspicuously marked, one set was filled with the Festbier made without Carahell while the other set was filled with the Festbier made with Carahell. For each triangle test, 3 of the 4 cups were indiscriminately selected, thus randomizing which beer was the unique sample for each trial. Following each attempt, I noted whether I was correct in identifying the unique sample. Out of the 10 semi-blind triangle tests I completed, I needed to identify the unique sample at least 7 times (p<0.05) in order to reach statistical significance. In the end, I correctly identified the unique sample 7 times (p=0.02), indicating my ability to reliably distinguish a Festbier made without Carahell from one made with 10% Carahell.

To my palate, the beer made with Carahell had a slightly stronger caramel-like sweetness than the other beer, though I didn’t notice any real difference in terms of body or mouthfeel. Both beers tasted great, just slightly different, and I didn’t have a strong preference for one over the other.

| DISCUSSION |

Brewers have a rather large amount of specialty grains available to them, nearly all of which the maltster claims will have a positive impact on beer. In addition to contributing a perceptibly rich malt flavor, Carahell malt is also said to contribute to the body and foam quality of beer. The fact I was able reliably distinguish a Festbier made with 10% Carahell from one made without the malt suggests it does have a perceptible impact.

Seeing as the Carahell is 10 °L while Mecca Grade’s Gateway malt is a much lighter 1.2 °L, it makes sense that the former would contribute a noticeably different flavor profile. Indeed, I perceived the Festbier made with Carahell as having a richer malt note whereas the batch made without it had a stronger grainy flavor.

This being only my second time using Carahell, there was something satisfying about being able to taste a difference, even with just 10% usage rate. I enjoyed both beers and can see how Carahell would be a good fit in various styles, so I’ll certainly be keeping it in my brewing tool belt.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

18 thoughts on “exBEERiment | Impact Carahell Malt Has On Festbier”

Did you notice any impact on foam? Your picture looks like the carahell beer has a larger head of finer bubbles.

It wasn’t drastic or the type of thing where I’d say that I’d prefer using Carahell in the vast majority of my beers, but there did seem to be a modest difference in foam quality.

That’s a really well attenuated beer even with 10% Cara Hell! I would have thought that not to be the case. Anyway, I’d probably use more like 5% and some Munich Malt for a Festbier 🙂

Agreed! I think the step mash was quite effective in getting full conversion. The Munich malt I have from Mecca Grade, while fantastic in its own way, is less suited toward Festbier to my palate. Their Vienna is something else, though.

I’d really like to see more details on the Gateway malt. I saw there was a brief comment in the carbonation article earlier this month, but some attempt to dig into how it compares to more commonly available malt would be really interesting, if there is more left in that sack.

Mecca Grade’s Gateway is what they call an heirloom malt. It’s unique, and unlike any other base malt I’ve used. I wouldn’t switch to using it as the base malt for 100% of my beers, but I’ve definitely enjoyed using it. It’s got a grainy, almost hay-like sweetness, and I’ve come to think of it as being a very rustic, more flavorful Pilsner style malt.

Thanks, maybe a tasting sort of like the Hop Chronicles for malts would be worth considering some day. Side by side comparisons of malts in a systematic comparison could be really interesting.

Question on your brewery set up. Do you find that the fan above your kettles is enough to handle the steam from the boil?

It gets the job done. I’ve had better experiences with ensuring that there’s airflow coming from the other end of the basement while the exhaust fan is on. I’d like to get a hood installed but we’re slated to be moving in the not so distant future, so I’m keeping my brewery/general house updates to a minimum.

What mash steps did you use? What is the reasoning behind your water profile? I’ve been trying to figure out a water profile for a vienna lager, but honestly, I need to read more on how to design water profiles.

From the Beer XML files:

127.9 °F for 15 min

147.9 °F for 30 min

158 °F for 30 min

Right, Josh is on top of the mash temps!

If you’re using RO or distilled water you can adjust these pretty easily with most any brewing calculator. Martin Brungard’s spreadsheet works fantastically well while also providing a ton of interesting information on how these things affect beer. That’d be my suggestion for getting started with water chemistry. There are quite a few things to consider when thinking about how minerals will affect the perception of the beer, but generally you can start with the sulfate:chloride ratio. When the concentration of SO4 ions is about or equal to Cl ions the beer will likely take on a balanced bitterness. The higher the SO4 concentration relative to Cl, the sharper/more bitter the beer will be. Conversely, the higher the Cl concentration relative to SO4 the softer/less bitter the beer will be.

As for my brewing water, I went with what I consider to be a balanced profile, if not slightly on the bitter side because that’s what I was looking for in a Festbier; malty yet noticeably bitter and inviting to drink. I usually like to aim for ~100 ppm Ca for yeast health and beer clarity. I’ve also found that ~30 ppm of Na helps with rounding out the malt profile, particularly when the other ions are balanced.

Did you forget the Vienna malt in the non-Carahell batch? Color difference seems a bit too much comparing the grain bills.

Ha! No, I did not forget the Vienna malt, the Carahell beer just turned out a bit darker. My brewing calculator put it around 6.5 SRM or something, but the final beer did seem to be a bit darker than that at times. I think this may in part be related to the beers being presented side by side and our perception of differences. Another factor to consider is the lighting; both of these beers seem a bit darker in my light box than they actually are. I would have preferred to take the pictures outside, but alas, the weather and scheduling/availability to do so were not aligned.

Unrelated to this specific experiment, I’m just curious if you (or any of the Brulosophy authors) aerate/oxygenate your cooled wort? I don’t ever see it mentioned, but wasn’t sure if it was simply an omission in the write-up or a practice you’ve actually discontinued. Thank you!

I can’t speak for the others, but I generally only oxygenate my wort when I’m making high gravity beers. The oxygenation port is one of the features of the Ss unitanks that’s really nice and convenient for that.

Thanks. So you just let the cooled wort splash into the fermenter and leave it at that? No further shaking or agitation? I know there were some exbeeriments on this subject a number of years back, but wasn’t sure if they were conclusive enough to have become standard practice. I generally use a drill and paint stirrer to whip the wort for a couple minutes after pitching, mostly as an insurance policy, but if I could skip this step I just might.

Right, I’m just transferring to my FVs with a pump and calling it a day. Unitanks get less agitation since I am racking in from the bottom.

One could argue that none of the experimental work we do is enough “evidence” for anyone to conclude that they should alter their standard of practice because our sample sizes are too small etc. I’d say that if you’re taking anything away from the Brulosophy posts, you should feel empowered to try new/different processes and to not be afraid of things going badly. Sometimes the new stuff can lead to making a shit beer, and that’s just fine because this is not our livelihood! But as long as you learn from your experiences it’s worth it because those new/different processes or ingredients also lead to us honing our craft and improving our brew day, and an occasional shitty beer is worth that price in my opinion.