Author: Steve Thanos

Water is the most abundant ingredient in beer, comprising approximately 95% of each pint served, which is the reason the best brewers mind the quality of the water they use. Ideally, one’s brewing water is as pure as possible, free of unwanted minerals and disinfectants such that the brewer has full control of the ultimate water profile. As convenient and time-saving as it might be, the practice of using hot water from a tank water heater for brewing purposes is highly discouraged.

Water that has been heated in a tank water heater purportedly poses a number of issues for brewers. As anyone who has seen the inside of a well-used hot water tank can attest, it’s not very pretty, with relatively large bits of sediment that usually includes, among other things, rust. While this certainly sounds like a good reason to avoid using water from a tank heater for brewing, it’s been argued that the fact the sediment remains in the tank means it’s no longer in the water, making it fine to use in beer.

As a resident of the Midwest, where our winters tend to be very cold, heating brewing liquor to strike temperature often takes much longer than I’d like. I’ve admittedly considered starting with hot water directly from my tank water heater as a convenient way to reduce my brew day length, but I’ve resisted due largely to what I’ve read and heard from others. Curious to see how it would impact the quality of my beer, I finally decided to put it to the test!

| PURPOSE |

To evaluate the differences between an American Stout made with unfiltered hot tap water from a tank water heater and one made with unfiltered cold tap water.

| METHODS |

For this xBmt, I went with a fairly simple American Stout recipe.

The Moral and the Virtuous

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5 gal | 60 min | 68.1 | 40.4 SRM | 1.058 | 1.012 | 6.04 % |

| Actuals | 1.058 | 1.012 | 6.04 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Ye Olde Pale Ale | 10 lbs | 85.11 |

| Bourbon Barrel Aged Chocolate Malt | 12 oz | 6.38 |

| Caramel Munich 60L Malt | 8 oz | 4.26 |

| Roasted Barley | 8 oz | 4.26 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Columbus/Tomahawk/Zeus (CTZ) | 28 g | 60 min | Boil | Pellet | 15.5 |

| Columbus/Tomahawk/Zeus (CTZ) | 14 g | 15 min | Boil | Pellet | 15.5 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Darkness (A10) | Imperial Yeast | 75% | 32°F - 32°F |

Notes

| Water Profile: Ca 40 | Mg 13 | Na 9 | SO4 10 | Cl 14 |

Download

| Download this recipe's BeerXML file |

I started my brew day by collecting two identical volumes of water, one from my tank water heater while the other was cool from the tap; seeing as my local water is low in chlorine, I opted to forgo filtering altogether. Despite their disparate temperatures, the waters smelled and looked similar to me.

While the waters were heating up, I milled the grains into separate buckets.

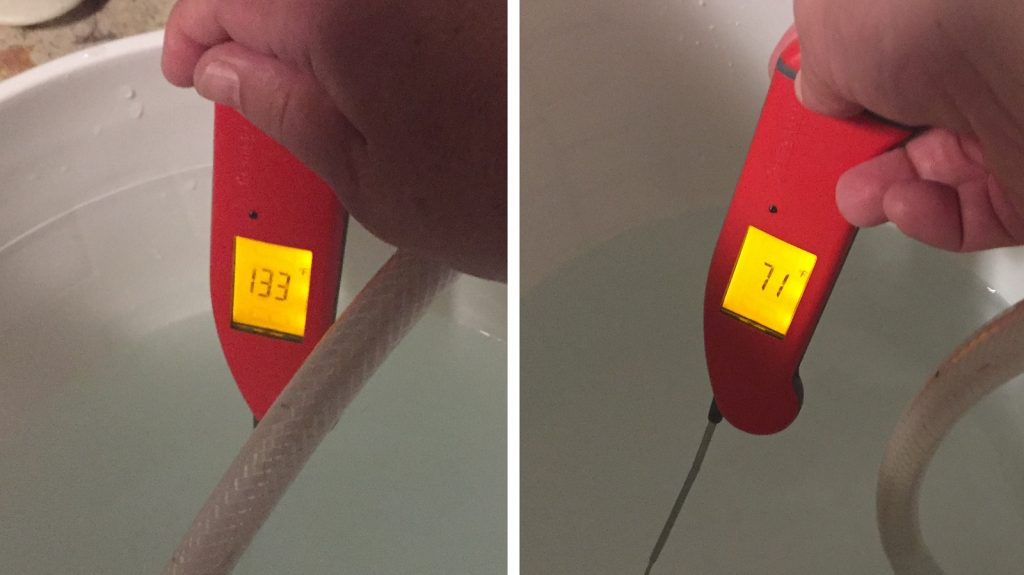

Whereas the water from the tank water heater took just 13 minutes to reach the strike temperature, the cool tap water took 47 minutes, which is typical for me when doing full volume BIAB 5 gallon/19 liter batches. Once the waters were properly heated, I incorporated the grain and checked to ensure they were at the same mash temperature.

While the mashes were resting, I prepared the kettle hop additions.

Once each 60 minute mash was complete, I sparged to collect the same pre-boil volume then boiled the worts for 60 minutes before quickly chilling them.

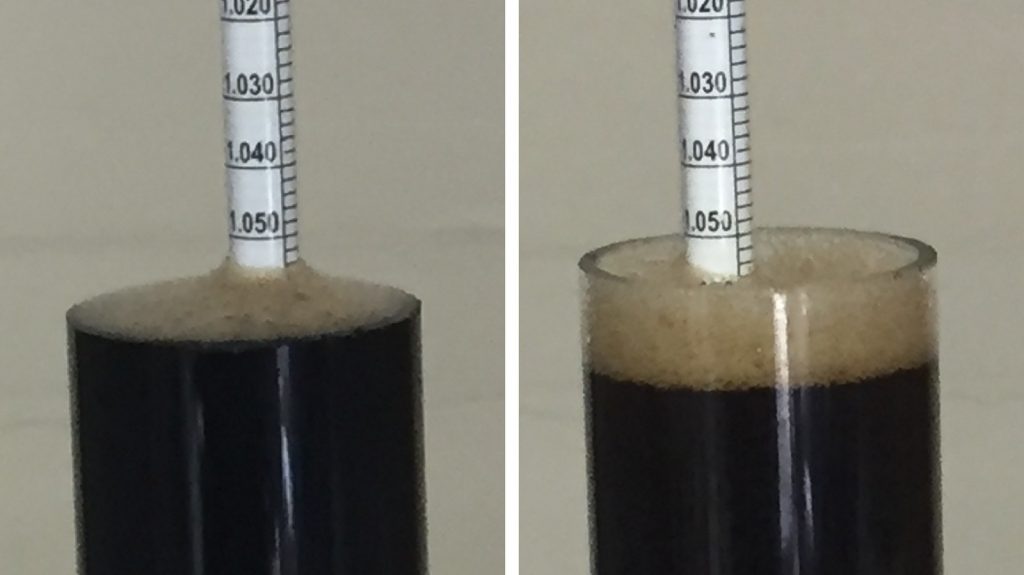

Hydrometer readings showed the wort made with hot water was slightly lower OG than the wort made with cool water.

The filled carboys were placed in my chamber and left to finish chilling to my desired fermentation temperature of 68°F/20°C for a few hours before I pitched a pouch of Imperial Yeast A10 Darkness into each.

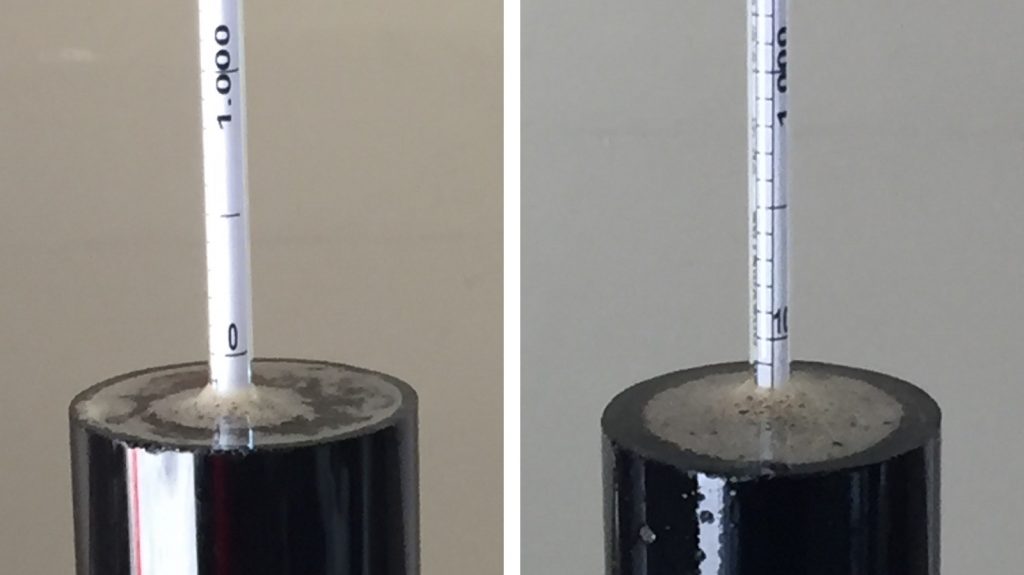

After a couple weeks, I raised the temperature in the chamber to 70°F/21°C and let it sit for an additional week before taking hydrometer measurements showing both beers were at the same FG.

At this point, I racked the beers to sanitized kegs that were placed in my keezer and left on gas for 2 weeks before I began my evaluations.

| RESULTS |

Due to social distancing practices as a result of the COVID-19 pandemic, data for this xBmt was unable to be collected in our typical manner. As such, temporary adaptations were made involving the author completing multiple semi-blind triangle tests in as unbiased a way as possible.

Utilizing 4 opaque cups of the same color where 2 were inconspicuously marked, one set was filled with the beer made with water from the tank water heater while the other set was filled with the beer made with cool tap water. For each triangle test, 3 of the 4 cups were indiscriminately selected, thus randomizing which beer was the unique sample for each trial. Following each attempt, I noted whether I was correct in identifying the unique sample. Out of the 10 semi-blind triangle tests I completed, I needed to identify the unique sample at least 7 times (p<0.05) in order to reach statistical significance. In the end, I correctly identified the unique sample just 4 times (p=0.44), indicating my inability to reliably distinguish an American Stout made with unfiltered hot tap water from one made with unfiltered cool tap water.

To my palate, everything about these beers was identical, from their full body and creamy mouthfeel to the pleasant roast and chocolate flavors.

| DISCUSSION |

As the most prominent ingredient in beer, water is vitally important when it comes to the overall quality and character of the finished product. When using tap water, brewers are encouraged to run it through a filtration system and adjust it to a desired profile, while being cautioned against using hot water from a tank water heater, as this can lead to undesirable off-flavors. My inability to reliably distinguish an American Stout brewed with hot water from a tank water heater from one brewed with cool tap water suggests any impact of the water source was minimal enough as to be imperceptible by me.

Given the fact the water used in this xBmt came from my house, these findings are arguably less generalizable, as its possible different water quality, tank heater types, and even home plumbing could result in a different outcome. Still, the fact these beers were perceptibly identical to me was surprising, particularly considering how strongly some speak against using hot water from tank heater.

Despite these results, I have no plans to regularly use water from my tank water heater to brew with, even if it adds a bump of convenience by reducing my total brew day time. For those looking interested in trying this out, I’d recommend first comparing a cooled glass of water from your tank to a glass of cool tap water, and if they are similar, perhaps shipping it off for testing just to be sure.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

23 thoughts on “exBEERiment | Impact Using Water From A Tank Water Heater Has On American Stout”

I always fill my HLT from my hot water supply, as that means I only need to raise the temperature by about 25°C (77°F) rather than 65°C (149°F) if I was using the cold feed, cutting a good amount of time from the brew day.

My water heating uses a natural gas fired combi boiler rather than an electrical/tank based system, meaning that I not only get a saving in time, but in cost too – electrical energy here is around 3x more expensive per kWh than natural gas. It’s probably only pennies, but in my mind it’s still a win.

Fortunately my water supply is also great for brewing, nice and soft with low ion levels across the board.

With a different water supply, or with a different heating system I might rethink that practice, but for now it works well for me.

Out of curiosity, I tested hot water vs. cold water using my personal water test kit, and found pretty much identical mineral contents for each sample (looking at carbonates, sulfates, etc.). I wasn’t testing for trace stuff (e.g., iron), so maybe there is a difference on that end that I missed. I also suspect there may be a difference if the hot water isn’t cycled regularly (e.g., if it sits in the tank for a few days while the household is away for a weekend)…but either way, I’ve concluded that in the case of my water and my house, it just doesn’t make a difference.

Interesting findings. I’ve never tested my hot water. I do agree that the hot water pulled from a tank(heater) can be different if the water sits for an extended period of time.

I was kind of wondering what the mash pH was or at least what the TDS was of the 2 different water sources. Regardless of whether you’re using hot or cold water, it’s still potable. The biggest difference is typically going to be the built up mineral load in the tank water, which would likely make the tank water harder, if anything. So you’re brewing with hard and harder water in your test samples. Given that this was a stout, your water profile would need to be pretty out whack for your mash to be out of the optimal pH range. To really test the variable of tank water impact, it seems you’d really need to normalize the mineral content and pH of both samples and then see if you find a difference.

I’ve been doing this for years and hadn’t realised it was highly discouraged. You mentioned the convenience factor (due to time saved) but there’s also economy: much cheaper to heat water (as much as you can) using mains natural gas compared to bottled propane.

How are you guys getting the water from the heater into your hot liquor tanks? I have a hot water spigot in my brewing area but getting the water from the spigot to the tank is a real pain. Is there a hose that can handle the hot water that is comercially available?

Good question. I ferry the water from the kitchen tap to the garage HLT using a pair of 3ltr jugs (one filling as the other is carried). It is a bit of a pain but I never need more than 40ltr and just consider it useful physical exercise 🙂

Can you come over to my house and drag my water around;)? I’m 71 with a bad back. 🙁

I used my RV hose attached to my utility sink in my laundry room and obtained the hot water that way.

Any high temperature food grade hose should work, something like this:

https://www.amazon.com/High-Temp-Silicone-Tubing-Hose/dp/B08K8T5M83?ref_=d6k_applink_bb_marketplace

I have an electric setup that uses food grade silicone hoses to/from the pump

I fill a smaller pot from the sink and dump it into my kettle. Couple times.

What is a hot water tank?

I have a tankless that can be put in pro mode and can set to 180. I put a tee and a valve a few feet from my water heater and run it straight into my grains. I adjust the temp with cold water if I have too.

I fill two pot with hot water for sparge and topping up the kettle. A real the saver.

Man, i feel dumb for not thinking of this. You are my new hero.

Hmmm… it’s potentially dangerous to drink the hot water tap water. So I’d be hesitant to make this a habit https://www.nytimes.com/2008/01/29/health/29real.html

Since that is paywalled, if anyone wonders the reference is to lead. Hot water can cause elevated amounts of lead to leach into water from pipes, solder and fixtures. Home water lines in the US were supposed to be lead free after the late 1980s, but it’s hard to know for sure without testing. Boiling will increase the concentration of lead.

It’s one of those things where the odds of contamination are usually low but the consequences are potentially high. For me, I’d rather not risk it since the time savings aren’t that great. That half hour-ish can be used for other chores.

Eh. Just drink and extra glass of milk 🙂

My main concern would be that some water filters may not support hot water, I have an in-line thee filter setup (20 micra, 2x 5 micra w/ active coal)

I’ve done it many times & it worked out well enough for me with no issues noticed. Though, when I’m doing 10gal batches it becomes a real pain to lug that much water out to the garage (no hot water supply out there) I prefer to preheat bigger batches with my hot rod or at least use that on tandem with the burner to cur the heat time. Thanks for testing it out.

Aren’t those hydrometer readings very different? At a minimum all the foam on the right makes that reading unreliable, but ideally you should be measuring a sample with no foam and reading from the bottom of the meniscus.

I highly recommend the water of the Tank Water, I don’t know if you have ever opened one, you would be surprised by the amount of limestone accumulated. Even if there is no impact of flavor, it is not hygienic at all.

I remember reading that off color brewing ( one of my favorites in Chicago ) did not have a HLT and did mash and sparge water directly from a tankless water heater. Of course that means it wasn’t sitting in a tank, but it seems like the way the water is heated shouldn’t be relevant.

Thanks for this experiment, Steve Thanos. I have hard water (120 – 203 CaCO3) and I have to boil it and decant the next day to reduce temporary hardness when I brew light styles.

With regards to this experiment, I wonder if you would find any noticeable differences if this approach was applied to a style that requires soft water, like a pilsner. This experiment reminded me of a water heater/ hardness thread I saw on homebrewtalk.com. In that thread, Martin Brungard said that water coming out of a water heater is actually softer than when it went in. This sounds right, but I don’t know exactly how much hardness can be potentially removed by the passing through a water heater.

Boiling and decanting water is estimated to reduce Ca to about 70-80ppm (according to the formulas), but heaters don’t boil water. I have been looking for more information (e.g., tables, formulas) about the relationships between these variables (temporary hardness, temperature + time) but no luck so far. I think it’s a very important issue. Boiling water is wasteful, and RO water even more so (I live in the desert). Using a water heater, or better yet a passive solar water heater would be ideal if indeed these methods could significantly reduce water hardness. In any case, I think it might be worthwhile to test the water before and after it passes through a heater–or at least use a kit to measure hardness…which I might have to do, eventually.

Anyway…that’s all I got for today…

Cheers,