Author: Andy Carter

Homebrewing beer is, without a doubt, my favorite hobby. The combination of science, art, skill, and camaraderie all appeal to me and make brewing a very worthwhile experience. However, there are times I desire something a little different, and over the last few years, I’ve developed a rather strong liking of wine.

While I’ve had rather positive results in my attempts at making mead, I hadn’t really thought much about making my own wine, largely because acquiring the right kind of grapes seemed a bit of a hassle. That is until I learned about a local shop, The Home Wine, Beer, and Cheese Making Shop Wine (HWBC), hosts an annual grape sell for home vintners.

Similar to homebrewing, there are wine kits people can purchase that come with concentrated grape juice that gets mixed with water prior to fermentation. I’ve had some tasty examples of kit wines and trust they’re a solid option, but I was excited to make my first wine from freshly harvested 2020 Sauvignon Blanc grapes from Lucas & Lewellen Vineyards out of Solvang, CA.

| Making Ohmic Valley Sauvignon Blanc 2020 |

While some choose to do their own grape pressing, I opted to have mine crushed for me since this was my first attempt at making wine.

Ohmic Valley Sauvignon Blanc 2020

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 6 gal | 0 min | 0.0 IBUs | 16.2258192 | 1.093 | 0.995 | 13.2 % |

| Actuals | 1.093 | 0.998 | 12.8 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Sauvignon Blanc Grape Juice (Fresh Pressed) | 54.729 lbs | 100 |

Miscs

| Name | Amount | min | Type | |

|---|---|---|---|---|

| Superfood | 3.00 g | 0 min | Primary | Other |

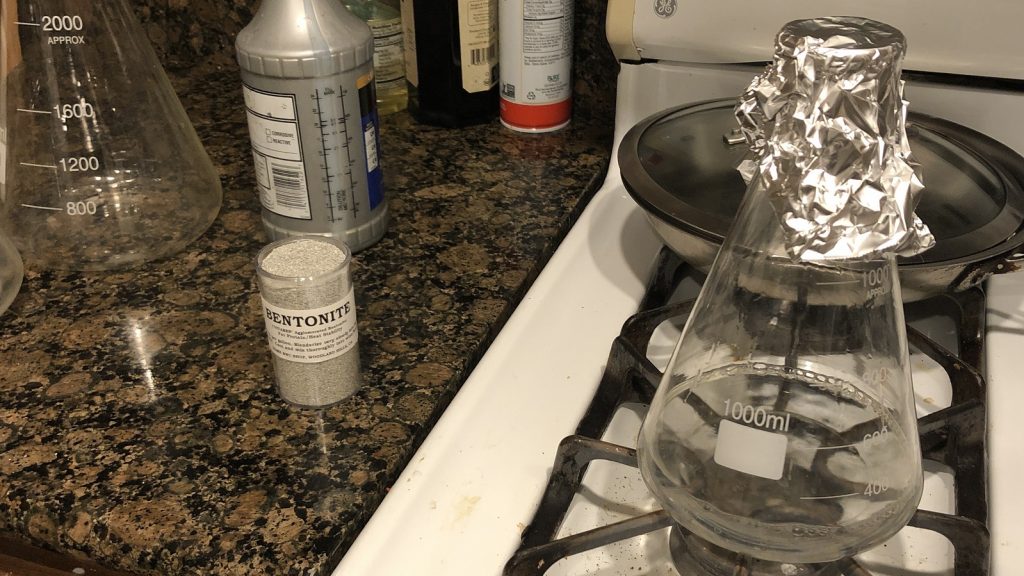

| Bentonite | 53.00 g | 10 days | Secondary | Fining |

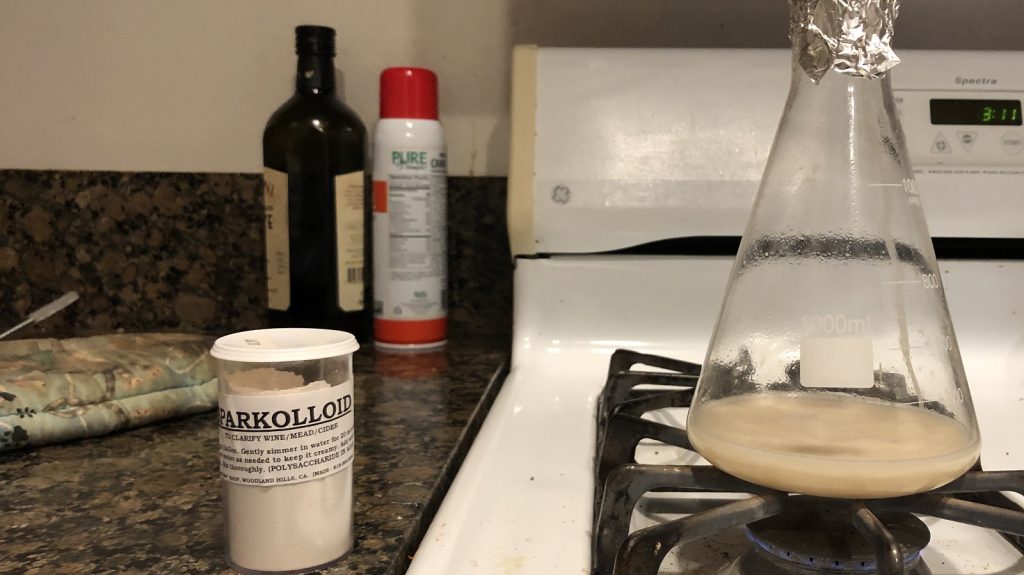

| Sparkalloid | 9.00 g | 14 days | Secondary | Fining |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Lalvin QA23 (QA23) | Lallemand - Lalvin | 75% | 50°F - 86°F |

Notes

| 1.1 grams Potassium Metabisulfite on first transfer 1.1 grams Potassium Metabisulfite on second transfer 1.1 grams Potassium Metabisulfite on final transfer |

Download

| Download this recipe's BeerXML file |

In September of 2020, I got the call from HWBC that the must was ready for pickup, so I drove to Camarillo Custom Crush with my Delta Brewing Systems FermTank and picked up 6 gallons/23 liters.

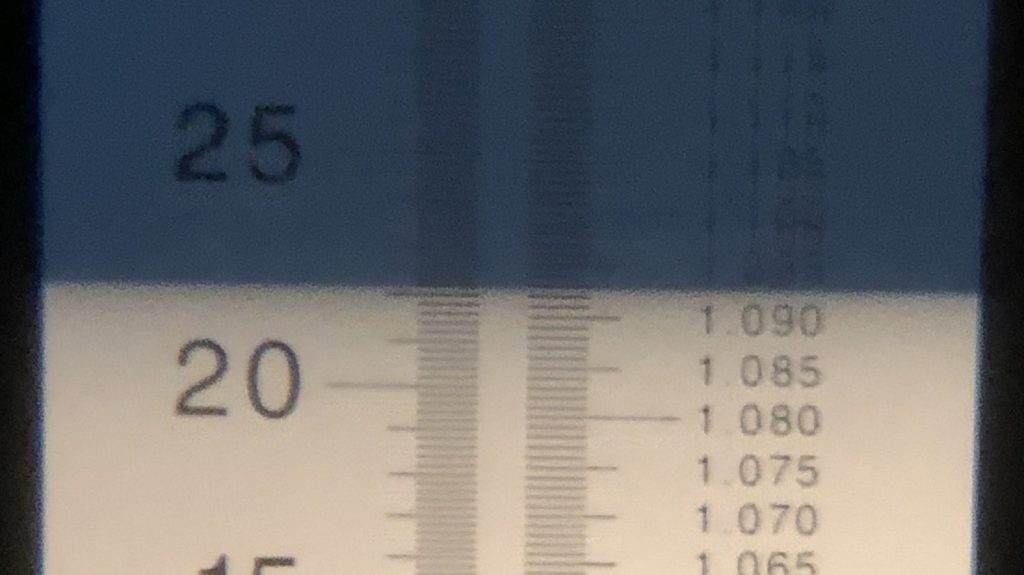

Once home, I placed the must in my chamber to chill to my desired fermentation temperature then took a refractometer reading that confirmed the OG provided by the vineyard.

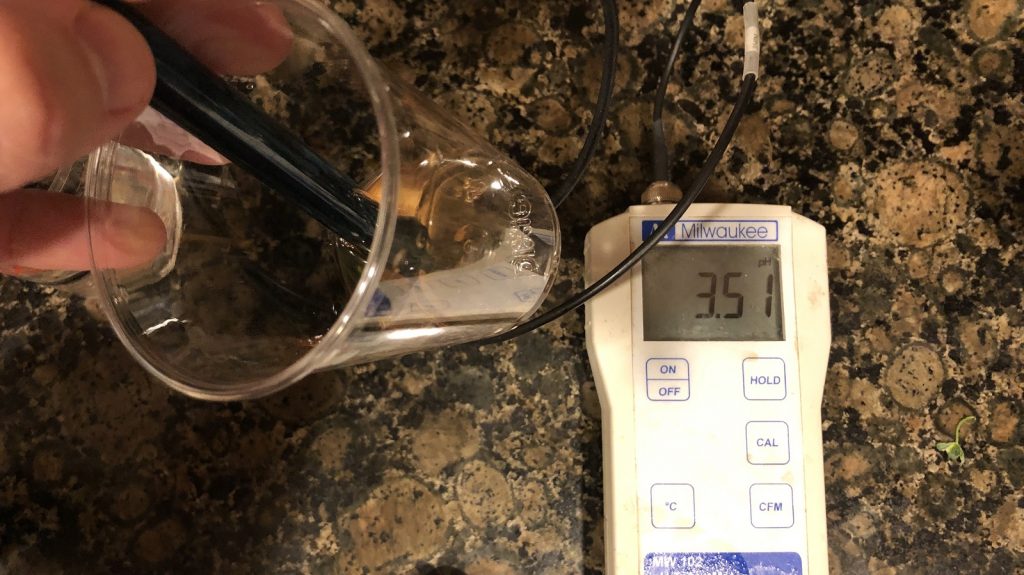

I also double-checked the pH, just to be sure.

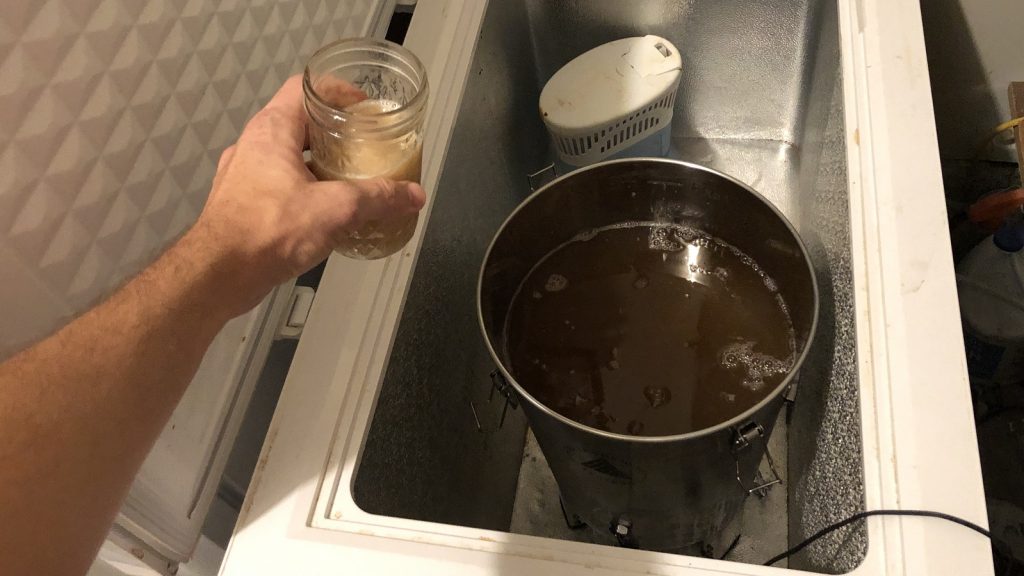

Next, I prepared the recommended Lalvin QA23 yeast by rehydrating it with nutrients in 100°F/38°C water before gradually adding cool must to reduce it to my desired fermentation temperature of 59°F/15°C, at which point I pitched the slurry into the must.

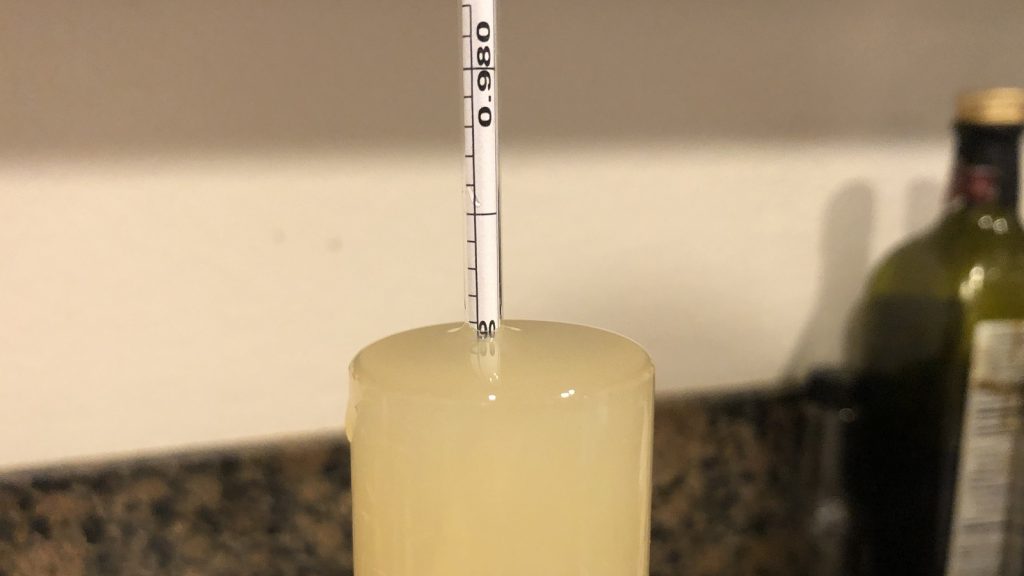

After dosing the wine with oxygen, I sealed up the fermenter, attached a blowoff tube, and left it to ferment. Since grape juice doesn’t contain the micronutrients necessary for optimal fermentation, I followed HWBC’s recommendation for staggered additions by adding equal amounts at yeast pitch, after dropping 3 to 4 °Bx (1.012 to 1.016 SG), then after reaching 10 °Bx (1.040 SG). Rather than wasting precious wine to test the specific gravity multiple times, I kept a hydrometer in a jar of the fermenting wine in my chamber to roughly gauge the fermentation progress. Just 3 days after pitching the yeast, the wine was ready for more nutrients, then it received the final addition 3 days after that.

After 3 more weeks, the wine had stabilized at a very dry 0.989 SG.

Wanting this wine to be as clear as possible, I dosed it with bentonite at this point, adding the rehydrated solution directly to my fermentation bucket. Bentonite is an absorbent clay material that binds to haze-causing particulates in wine then drops out of solution.

After 4 days on the bentonite, I prepared the Sparkolloid, a positively charged polysaccharide that aids in wine clarification by attracting negatively charged particles.

I added the Sparkolloid solution to a sanitized keg along with the potassium metabisulfite, which is used to halt yeast activity and reduce oxidation, before transferring the wine.

Three weeks later, I pressure transferred the wine to another CO2 purged keg and with an additional dose of potassium metabisulfite.

While HWBC recommends cold conditioning at this point, I didn’t have the space in my chamber and placed the filled keg in the coolest part of my house, which ranged between 65°F/18°C and 75°F/24°C. Over the following 8 months, I took periodic samples that revealed the wine was not clarifying as expected, so I turned to a common beer fining agent, Biofine Clear, which I injected into a new CO2 purged keg that the wine was pressure transferred to.

In order to remove as much CO2 from the wine as possible without exposing it to oxygen, I purged the wine with pure nitrogen by running it through the liquid out tube of the keg while keeping the relief valve open. In addition to ensuring the wine is properly still, CO2 removal reduces the risk of corks being pushed out of the bottles. At this point, I placed the keg in my 45°F/7°C keezer and left it alone for 4 weeks before racking it into a purged keg with a final dose of potassium metabisulfite.

Next, I pressure transferred the wine to sanitized bottles that were sealed with corks.

While not necessary, I let the wine rest for a few days before chilling a bottle and opening it up to enjoy.

| IMPRESSIONS |

Brewing has been a longstanding passion of mine and beer easily tops my list of favorite things to drink, but my appreciation for other fermented beverages continues to grow, and this certainly includes wine. Whereas a batch of beer is relatively inexpensive and can be turned around in as little as 2 weeks, the ingredients for wine costs more and the process to make a quality batch requires considerably more time.

While I enjoy red wine, I opted to go with a Sauvignon Blanc for my first batch, in part due to its approachability and likeness to certain hop characteristics, but also because that’s the grape variety I had available to me at the time. After picking up the fresh-pressed juice in September of 2020, I embarked on a year-long journey that was entirely new to me, one that was equally as educational as it was rewarding.

Crystal clear with a gorgeous light yellow color, I perceived the aroma of Ohmic Valley Sauvignon Blanc as a blend of pear, pineapple, and candied lemon with a whisper of cinnamon, all of which carried through nicely in the flavor. Despite finishing as dry as it did, I experienced a slight viscosity in the mouthfeel leading to a sustained finish that was quite enjoyable. At 12.8% ABV, the alcohol was noticeable but not at all offensive, leaving a slight warming sensation in the throat after swallowing. All in all, I couldn’t be happier with my Ohmic Valley Sauvigon Blanc 2020 and absolutely plan to repeat this process on an annual basis!

If you have thoughts about this recipe or experience making something similar, please feel free to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

2 thoughts on “Brü It Yourself | Ohmic Valley Sauvignon Blanc 2020”

Andy, I also have had wonderful experiences securing my grapes through the Beer Wine and Cheese Making Shop located in Woodland Hills, CA. They provide a lot of great instruction as well as the use of a press. My 2020 harvest Syrah was provided by the Lucas & Lewellen Valley View Vineyard located in Santa Ynez Valley. I was encouraged to go through the red wine/pressing process two harvests ago to fully understand and experience the wine making process. For the 2020, I blended in some of my 2019 Cab Franc in celebration of my father, who had failed and then passed away during the making of the Cab Franc, delaying my scheduled pressings. In the end, I had to use free-run juice only for the 2019 and I named the vintage after my father. Both wines have turned out well and have been very satisfying to make. Thanks for sharing your experience and cheers! Lyne Noella

There was a time when crates of wine grapes would appear in the wholesale produce markets far from the California growing regions. In the 1980’s, I was a produce buyer for food coop in western New York. Each year, at some point in late September, one of the wholesale dealers would arrange for a truckload of California wine grapes (red). On grape day, one would see a horde of vehicles ranging from station wagons to dump trucks pull into the market and get loaded with dozens (and more) crates of grapes. At that time, the produce business was controlled by and most of the grape customers were of Italian background. They had been doing this for decades. Having been out of that business since the mid 80’s I don’t know whether the tradition continues. It was pretty cool to watch at the time. I even managed to get some taste samples of the grapes: super sweet with intense flavor.