Author: Cade Jobe

Of the several things that can ruin beer, contamination by wild yeast and bacteria is one of the worst, as it can lead to a number of undesirable off-flavors and usually results in a dumped batch. It’s for this reason that cleanliness and sanitation of gear are viewed with such importance, and these days, brewers have a number of sanitizer options available to them, two of the most common being Iodophor and Star San.

Iodophor is a sanitizer that relies on iodine to quickly rid the surfaces of brewing gear of living microbes that could spoil beer. While known to be very effective, Iodophor has a rather strong aroma that’s noticeable even after emptying a fermentation vessel of a diluted solution, leading some to believe it can impact beer character. Alternatively, Star San is a phosphoric acid based sanitizer that, once properly diluted, has virtually no aroma and requires no rinsing, as the acid breaks down into what is essentially a yeast nutrient.

Following a past xBmt showing tasters could not reliably distinguish a beer packaged with a bunch of Star San foam from one packaged with very little foam, I wondered if other types of sanitizers might impact beer character. While I primarily use Star San in my brewery, I have plenty of experience with Iodophor and have definitely noticed its pungent aroma, as well as how easily it stains certain materials. Curious if this had a perceptible effect, I decided to put it to the test.

| PURPOSE |

To evaluate the differences between beers fermented and packaged with gear sanitized with either Star San or Iodophor.

| METHODS |

My goal being to ensure any impact of the variable was on full display, I designed a simple low OG Cream Ale recipe for this xBmt.

Bunker Buster

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 22.3 | 2.9 SRM | 1.034 | 1.001 | 4.33 % |

| Actuals | 1.034 | 1.001 | 4.33 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pale Malt (Wintmalt) | 6 lbs | 70.59 |

| Corn, Flaked | 2.5 lbs | 29.41 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

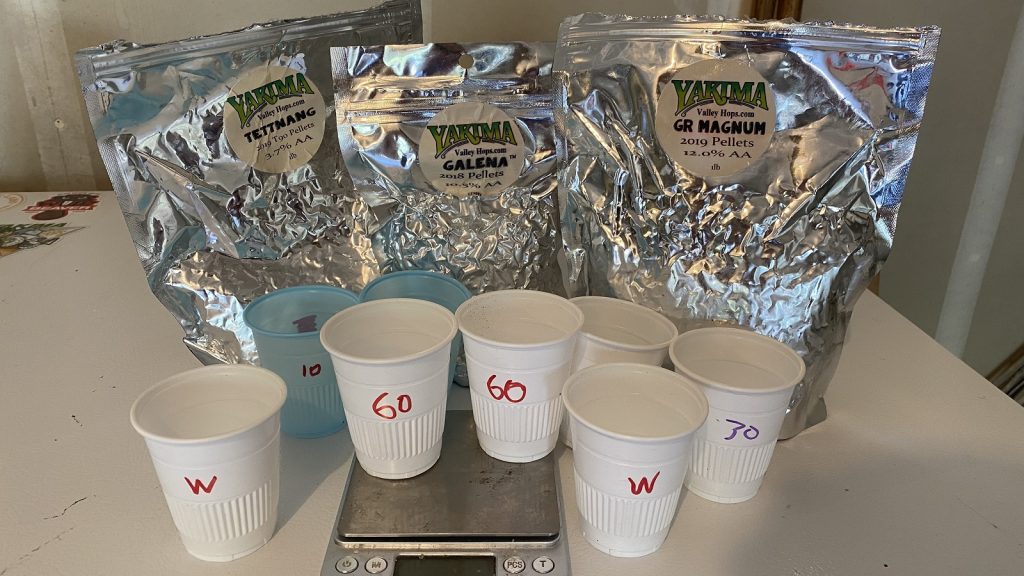

| Hallertau Magnum | 7 g | 60 min | Boil | Pellet | 12 |

| Galena | 7 g | 30 min | Boil | Pellet | 10.5 |

| Tettnang | 15 g | 10 min | Boil | Pellet | 3.7 |

| Tettnang | 15 g | 0 min | Boil | Pellet | 3.7 |

| Tettnang | 15 g | 5 days | Dry Hop | Pellet | 3.7 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Flagship (A07) | Imperial Yeast | 77% | 32°F - 32°F |

Notes

| Water Profile: Ca 50 | Mg 2 | Na 20 | SO4 62 | Cl 40 |

Download

| Download this recipe's BeerXML file |

I started my brew day by collecting the full volume of water for each batch, adjusting both to my desired mineral profile, then setting the electric controllers to heat them up.

I then weighed out and milled the grain for each batch.

With the water properly heated, I added the grains, turned the pumps on to recirculate, and set the controllers to maintain my intended mash temperature of 148°F/64°C.

While the mashes were resting, I weighed out the kettle hop additions.

Following each 60 minute mash rest, I raised the grain baskets out of the kettles and let them drain. The worts were then boiled for 60 minutes with hops added at the times listed in the recipe.

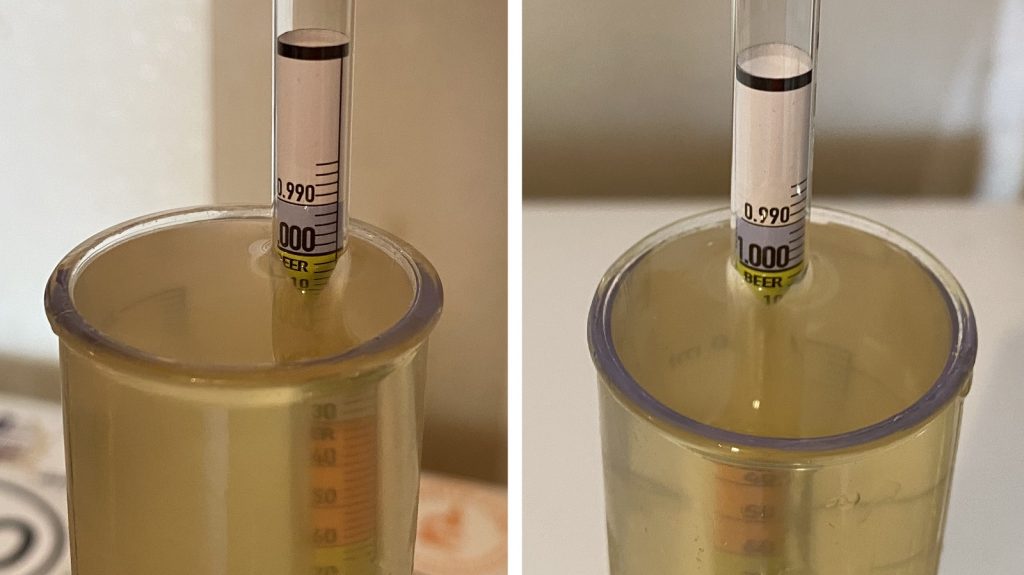

When the boils were complete, I chilled then blended them together in a large kettle to homogenize before taking a hydrometer measurement.

At this point, I evenly split the wort between Brew Buckets sanitized with either Star San or Iodophor, using tubing that was also soaked in the different sanitizers, before pitching a single pouch of Imperial Yeast A07 Flagship into each.

The beers were left to ferment at 66°F/19°C for 2 weeks before I took hydrometer measurements indicating both achieved the same FG.

At this point, I prepared 2 kegs by filling one with Star San and the other with Iodophor before pushing the solutions out with CO2 to purge any oxygen.

Using tubing that was sanitized with either Star San or Iodophor, I pressure transferred the beers into their respective kegs.

The filled kegs were placed on gas in my keezer and allowed to condition for a week before they were ready for evaluation.

| RESULTS |

A total of 29 people of varying levels of experience participated in this xBmt. Each participant was served 2 samples of the beer where the gear was sanitized with Star San and 1 sample of the beer where the gear was treated with Iodophor in different colored opaque cups then asked to identify the unique sample. A total of 15 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, but only 14 did (p=0.07), indicating participants in this xBmt were unable to reliably distinguish a Cream Ale fermented in a vessel sanitized with Iodophor from one fermented in a vessel sanitized with Star San.

My Impressions: Out of the 5 semi-blind triangle tests I attempted, I correctly identified the odd-beer-out 3 times, though I admittedly guessed on each attempt. These beers tasted identical to me—light bready malt with a slight lemony note, which when paired with the lower ABV, made it incredibly refreshing.

| DISCUSSION |

Sanitation is viewed by many as being one of the most important components to making quality beer, as the failure to properly sanitizer gear, particularly on the cold-side, can lead to off-flavor producing contaminations that swiftly spoil a batch. Two of the most common sanitizers used by brewers are Star San and Iodophor, which some claim can have a perceptible impact on beer. The fact tasters in this xBmt were unable to reliably distinguish a beer where all the gear was treated with Star San from one where Iodophor was used for sanitation suggests any differences were minimal enough as to be largely imperceptible.

Given the actual amount of solution that’s left on gear post-sanitation, it makes sense that it’d have little impact on beer character, even in more delicate styles that offer little to hide behind. There’s no question the concentrated forms of both Star San and Iodophor smell different, and as such I trust there’s a point at which leaving too much behind would have a noticeable effect, but this doesn’t seem to be the case with standard usage.

Personally, I have nothing against either sanitizer and have tended to use them interchangeably. While I trust both are effective at ridding my gear of unwanted microbes, I like the idea of mixing it up with chemicals that work in different ways, which may be complete hogwash, but that’s okay with me.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

23 thoughts on “exBEERiment | Brewery Sanitation: Star San vs. Iodophor”

We always use One-Step No Rinse. Sometimes household bleach is used. Both are very good and effective. No problems at all. I never use Star San, or Iodophor.

I had massive problems using bleach. I was making up Charlie Talley’s no-rinse bleach sanitiser and it worked for a while then I got batch after batch of phenolic plastic tasting beers.

Turns out the bleach, which was thin bleach – well it wasn’t thin bleach. I found shaking the bottle left bubbles and there was clear evidence of a surfactant. I bought two more bottles from different supermarkets and found exactly the same thing. These were the budget brands from Tesco, Asda and I can’t remember the other. It’s not always that way so I suspect they don’t care after a run of thick bleach or something.

Screw that – got some Star San and I’ve never had that worry again. The stuff lasts forever and you can reuse it. It’s absolutely worth the layout.

i only use Iodophor after cleaning conical when using lactobacillus or brettanomyces

Looks like a copy/paste error slipped through.

“replacing a portion of the pale malt in one batch with acidulated malt.”

This p value is low… Very low… Only 7 percent chance of getting these results if the beers were identical.

I know it’s tricky to try to interprete non-significant results, but I wouldn’t have expected something this low.

I agree… p < .07 could be considered "marginally significant". I'm guessing that a subgroup of people are sensitive enough to taste the difference.

Definitely tasted iodine in beers, especially when used to sanitize bottles. The directions say to let air dry for Iodophor btw. This eliminates all iodine residue. I’ve heard iodine is much more effective than Star San but that we don’t really need it to be surgical quality for brewing!

Why do people always say Starsan has no odour? I can smell it a mile away when diluted. Very chemically !

I suppose it’s relative to iodophor or bleach

Interesting read, as always.

The FG is surprisingly low..

I was one of the participants. Personally, I was able to easily tell a difference in the aroma – what turned out to be the iodophor sample had a much stronger dry hop aroma (so much so that I was convinced the variable was dry hop vs none!). I could not taste a difference though. There seemed to be two camps of tasters – some that could confidently pick the iodophor sample out, and some that couldn’t tell. Personally, I’m inclined to interpret these results as “there is a marginal difference, and many people CAN tell a difference (at least in terms of dry hop aroma).” Going forward, I will continue to use Sani Clean for my cold-side sanitization, as it allows me to purge my kegs of virtually all oxygen (as it is non foaming) and it apparently can better ensure retainment of dry hop aroma.

Jordan – thanks for your comment. It adds a lot to my understanding of the results.

I’d like to see this exbmt repeated with an NEIPA. I’ve found that the residue from StarSan oxidizes sensitive compounds quickly – made a large batch of beet mead and have packaged in bottles sani’d with either StarSan or Iodophor, the latter kept its color much longer. Would corroborated Jordan Folks’ comment about a stronger dry hop aroma. From this experience I’ll use SS and IP interchangeably pre-ferm, but only IP post-ferm.

For the Iodophor, did you perhaps use the rather common 1 cap-full to 5 gallons trick? I emailed National Chemical on this method a few years ago and I was informed that this trick puts you into an Iodophor overload situation that is no longer in the safe realm of “no rinse”.

One mashed at 148.2 and the other at 148.6? Experiment ruined!! lol

I’m definitely intrigued by the idea that CO2-purging a star-san-sanitized keg could be inferior to using Iodophor. Has anyone else had experience with this? I’d love to see an exbeeriment using a star san vs iodophor purged keg with an ipa to see if there is a difference.

when i saw this i thought for sure there would be a difference. most people don’t let their iodophor-sanitized stuff dry, per the instructions. the fact that it was so close to p of 0.05 indicates to me that this is one that could use some further experimentation. most exbeeriments don’t really come close to this it seems…

Interesting! When I first got into homebrewing 25-30 yrs ago, I used chlorine. I eventually started using Iodophor as it is easier to use and didn’t smell as strong. Always diluted it per specifications. I also rinsed afterward with boiled water. Felt justified later on when I got into all grain and read in JP’s book where he did the same thing. I’ve never had any issues with off flavors. Haven’t ever used Star San but I’d still rinse if I did.

Thanks for the Xbmt. I’ve been using Iodophor for a few months. It’s easy, hasn’t stained my Speidel fermenter noticeably, is MUCH easier on my hands that Starsan (Starsan dries out my cuticles resulting in peeling, bloody fingernails). But I’m still not comfortable with that skull & crossbones warning that the shit can kill you dead. I know I know, read the directions, but still POISON!

I have used both Star San and iodophor reliably, if I’m cleaning or sanitizing for wine, I make up a proxy mix which is sodium carbonate peroxihydrate. And then mix up some citric acid in water and drain and add the citified solution which neutralizes the proxy and then rinse with purified distilled water and problem solved clean and sanitary this is what is done in commercial wineries.

I strongly recommend that in future experiments in which the variable is introduced after the boil that you either produce a double-sized batch of wort or combine the two batches of wort before dividing the double batch to administer the variable. There is no reason to introduce the numerous potential unintended variables that comes with producing separate worts for the two sanitizers.

The article says that he combined the worts before splitting them again into the fermenters.

15 was the threshold and 14 picked it out. Yeah you can say thats not statistically “accurate” but boy thats awful close

Dose anyone have any experience with Quat sanitizers? I have used it every time and haven’t noticed the flavor but I’m curious of others experience.