Author: Cade Jobe

In order to produce the best beer possible, there are number of techniques brewers are encouraged to pay close attention to, one of which is yeast pitch rate. Simply put, there’s a sort of Goldilocks zone when it comes to determining the proper amount of yeast to pitch where too little or too much can cause off-flavors while just the right amount leads to the best results.

For the most part, pitch rate is determined based on wort OG and fermentation temperature, though some contend that certain styles benefit from pitch rates that fall outside the normal range. One example is Weissbier, which is known for possessing perceptible levels of certain esters and phenols, namely isoamyl acetate (banana) and 4-vinyl-guaiacol (clove). Brewers looking to amplify these desired characteristics are sometimes encouraged to intentionally underpitch their beer, as it’s believed the added stress on the yeast causes them to produce more of these specific compounds.

While I’ve tended to stick to the recommended pitch rates in my brewing regardless of style, a recent conversation with members of the BUZZ Homebrew Club got me thinking about the impact pitch rate has on various styles. With numerous past xBmts suggesting yeast pitch rate has minimal perceptible impact on cleaner styles of beer, I decided to test it out on a Weissbier to see for myself.

| PURPOSE |

To evaluate the differences between a Weissbier that is underpitched and one that is overpitched.

| METHODS |

For this xBmt, I went with a very simple Weissbier recipe.

Gable

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 13 | 3.7 SRM | 1.046 | 1.006 | 5.25 % |

| Actuals | 1.046 | 1.006 | 5.25 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pelton: Pilsner-style Barley Malt | 6 lbs | 52.17 |

| Wheat (Flaked) | 2.75 lbs | 23.91 |

| Wheat Malt | 2.75 lbs | 23.91 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

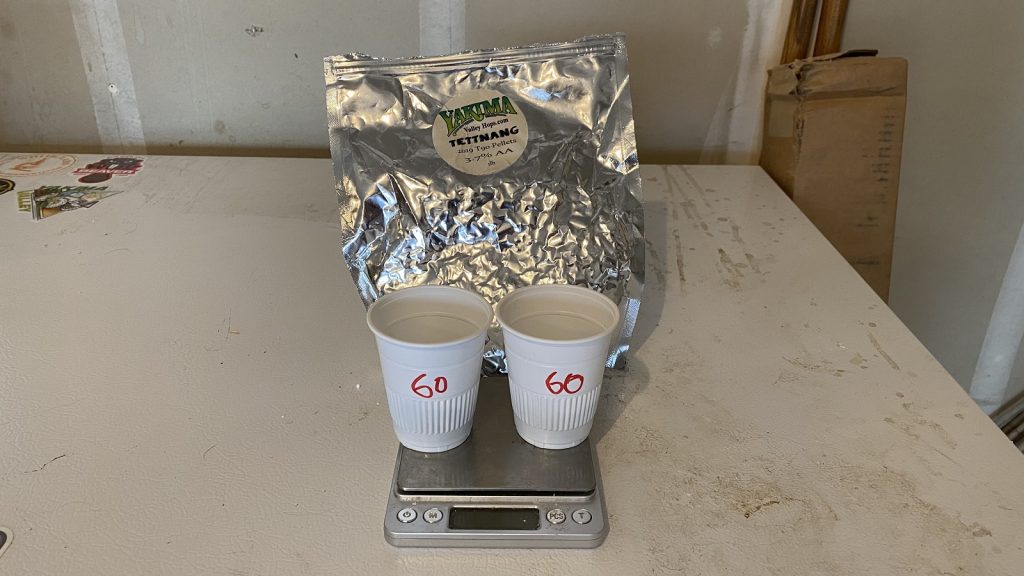

| Tettnang | 28 g | 60 min | Boil | Pellet | 3.7 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Stefon (G01) | Imperial Yeast | 77% | 32°F - 32°F |

Notes

| Water Profile: Ca 50 | Mg 2 | Na 20 | SO4 39 | Cl 62 |

Download

| Download this recipe's BeerXML file |

I started my brew day by collecting the full volume of water for each batch and adjusting both to the same mineral profile before setting the electric controllers to heat them up.

I then weighed out and milled the grains for each batch.

With the water properly heated, I added the grains, turned the pumps on to recirculate, and set the controllers to maintain my intended mash temperature of 149°F/65°C.

While the mashes were resting, I weighed out the kettle hop additions.

Following each 60 minute mash rest, I removed the grains then brought each batch to a boil.

When the 60 minute boils were complete, I chilled the worts and racked identical volumes from each batch to separate Brew Buckets. Hydrometer measurements confirmed both were at the same target OG.

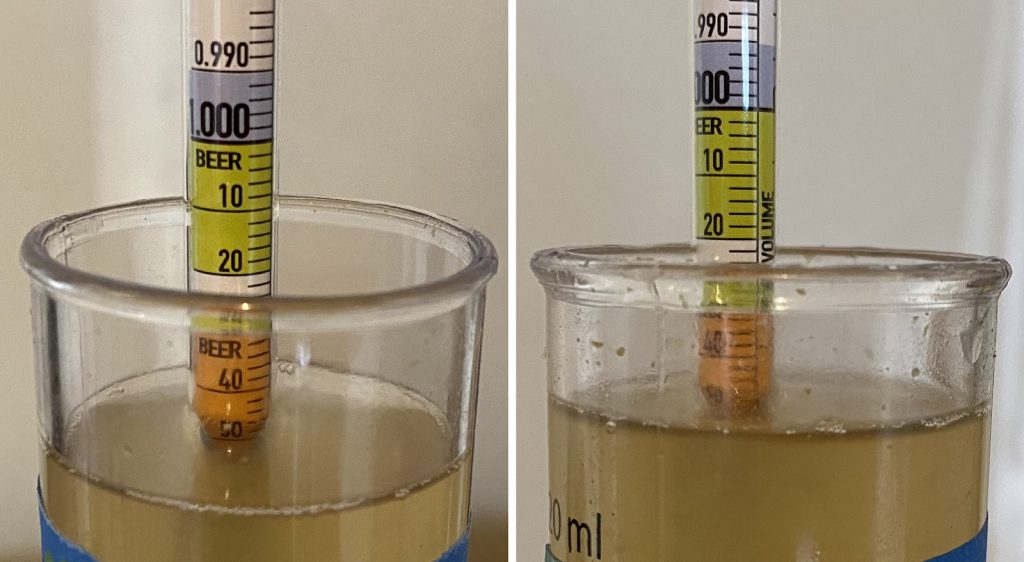

I placed both filled fermenters in my chamber and left them alone for a few hours to finish chilling to my target fermentation temperature of 66°F/19°C, at which point I prepared the yeast. After measuring the total volume of yeast slurry from two pouches of Imperial Yeast G01 Stefon, I split it into separate graduated cylinders such that the underpitch batch would receive one-third the amount as the overpitch batch. Considering the yeast was manufactured just 13 days prior, this would amount to approximate pitch rates of 100 billion and 300 billion cells, respectively.

When checking on the beers 18 hours later, I noticed the overpitch batch was fermenting far more vigorously than the underpitch batch, as evidenced by blowoff activity.

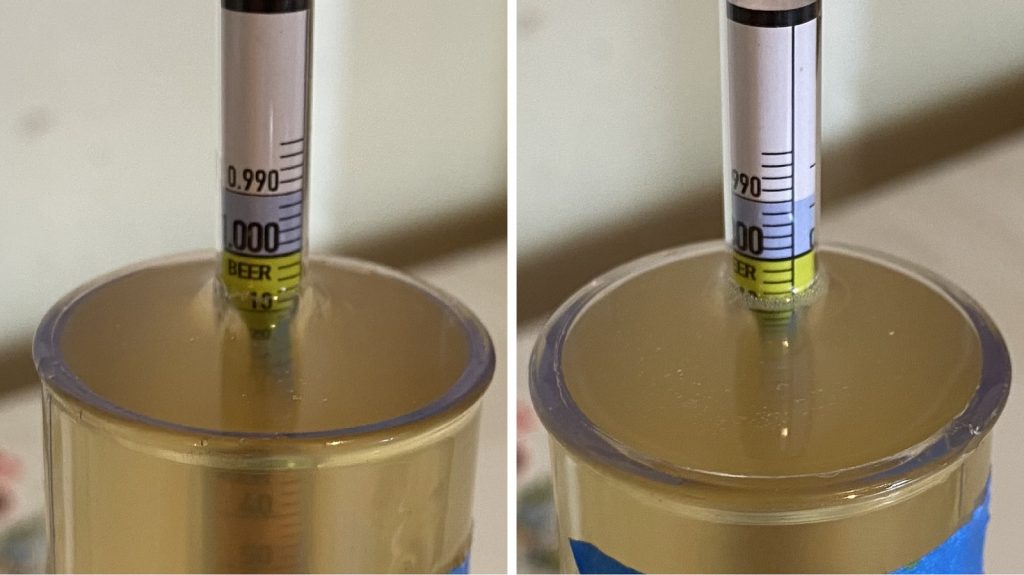

After 14 days of fermentation, I took hydrometer measurements showing each batch had reached the same FG.

At this point, I cold crashed the beers under pressure to 32°F/0°C overnight before proceeding with packaging.

The filled kegs were placed on gas in my keezer and allowed to condition for a couple weeks before they were ready for evaluation.

| RESULTS |

Due to social distancing practices as a result of the COVID-19 pandemic, data for this xBmt was unable to be collected in our typical manner. As such, temporary adaptations were made involving the author completing multiple semi-blind triangle tests in as unbiased a way as possible.

Utilizing 4 opaque cups of the same color where 2 were inconspicuously marked, one set was filled with the beer that was underpitched while the other set was filled with the beer that was overpitched. For each triangle test, 3 of the 4 cups were indiscriminately selected, thus randomizing which beer was the unique sample for each trial. Following each attempt, I noted whether I was correct in identifying the unique sample. Out of the 10 semi-blind triangle tests I completed, I needed to identify the unique sample at least 7 times (p<0.05) in order to reach statistical significance. In the end, I correctly identified the unique sample just 5 times (p=0.21) indicating my inability to reliably distinguish a Weissbier that was underpitched with yeast from one that was overpitched. Coming into this xBmt, I fully expected to perceive stronger esters and phenols in the underpitched batch, but this simply wasn’t the case, the beers looked, smelled, and tasted identical to me. Both were refreshing and crushable with identical levels of expected fermentation character given the style.

| DISCUSSION |

Produced by yeast during fermentation, esters and phenols are responsible for the distinct banana and clove flavors in German Weissbier, and their concentration in the finished beer is said to be dependent on a variety of factors including yeast pitch rate. While the ideal pitch rate for most standard strength ale is 6 million cells per milliliter, some believe that underpitching a Weissbier leads to greater ester and phenol production. My inability to reliably distinguish a Weissbier that was underpitched from one that was overpitched indicates any differences caused by the disparate pitch rates was minimal enough to be imperceptible by me.

In considering possible explanations for these findings, it seems plausible that the 200 billion cell difference in pitch rate between the batches wasn’t vast enough to produce a noticeable difference. According the Brewfather calculator, the ideal pitch rate for this 1.046 OG Weissbier was 179 billion cells, meaning one was underpitched by 79 billion cells while the other was overpitched by 121 billion cells. Based on what many brewers have come to accept about pitch rate, this certainly seems like enough to cause a noticeable difference, but perhaps an even lower pitch rate would produce the expected increase in esters and phenols.

Objectively, the overpitched beer did ferment more vigorously than the underpitched batch, though both finished at the same FG and ultimately tasted the same to me. Still, I have no plans to abandon pitching yeast at the proper rates, though I am admittedly less concerned about the impact pitch rate might have when making Weissbier.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

18 thoughts on “exBEERiment | Yeast Pitch Rate: Underpitch vs Overpitch In A Weissbier”

I did some research on the banana thing as well recently and read that a higher mash temp and a fermentation temperature of 21-23 C would be more appropriate to get the banana esters. Maybe that would be worth a try.

My very first two brews were fermented at room temperature. (Internally they were probably 24-25C) Talk about “monkey beer”, it was very strong. It did diminish over a few weeks, or maybe I just grew to like it?

I use a single pack of Nottingham for 15 gal. However, I use the “secret” Coors vitality starter technique. Love the simple and cheap approach.

T

Confused by the photo of the graduated cylinders, 100ml v 200ml, but you stated that it was a 100 vs 300 billion cell experiment.

For a great review of Weissbier:

https://braumagazin.de/article/brewing-bavarian-weissbier-all-you-ever-wanted-to-know/

Agree,

It looks more like 133 vs 266 billion split.

You are correct. This was a clear error in the experiment.

You are correct. This was clearly an error in the experiment. I first heard the error when I listened to the podcast, and then I confirmed the error when I saw the two cylinders in this post.

I know this is going to get mentioned (although I do believe it still wouldn’t show a difference), but is 100B cells/5.5Gal batch really under pitching (i.e. are you comparing normal pitch vs overpitch)? For a commercial lager of same strength it’s probably 50% down but certainly right in the middle of a typical homebrew pitch (most smack packs are 100B) and may be also similar to a commercial weissbier pitch rate given the gravity?

Was there a difference in lag time? That would show if there was a significant different it growth rate.

It’s possible that 100 Billions cells of very fresh yeast doesn’t result in a significant enough difference in cell growth to impact flavor. (well, I guess I’m only restating the result of the experiment)

It seems to be less of an underpitch that what most people think of. And maybe even less if it’s 133 Billions vs 266 BiIllions (if the volumes of 1000mL vs 2000mL are correct).

I wouldn’t lose much sleep if I had to pitch 133 billions cells of very fresh yeast (less than 2 weeks from the manufacturing date) into a 5 gallon batch of 1046 OG.

Anyway, I guess one of interesting conclusions is that overpitching a Hefe didn’t do any damage to the beer and that one can err in the direction of overpitching?

I don’t think that purposefully underpitching for flavor purpose is a practical approach for homebrewers anyway. It would be really difficult to obtain a specific cell count within a reasonable margin of error. For example, when I hear some homebrew aiming for cell count that is 20% lower than the typical cell/OG/mL for their belgian beer because it makes their beer “better”, I roll my eyes: I would be surprise if the actual cell count of the pitch doesn’t vary by a factor a 2 from starter to starter.

Lulu:

I agree wholeheartedly!

Would like to see a more extreme experiment that halves the yeast one more time.

As we learn from starters, a small amount of yeast can happily become a much greater amount in a controlled setting. The question still remains (for me) “how low can you go?”

Tom

I wouldn’t consider this under pitching. If you are using half an Imperial Yeast pack that would be the equivalent of using one White Labs yeast packet. Using the White Labs yeast calculator it suggested one pack of yeast for the gravity and temperature you fermented at.

But this experiment sounds interesting.

In my experience with dry yeast WB-06 neither temperature or underpitch have impact. However adding at leats 10 grams per liter of table sugar(sucrose) produce banana esters.

High temperature(22°C-24°C) some times prodce esteres but not in predictable or pleasant way.

A few people have mentioned, so I don’t mean to beat a dead horse, but 100 million cells isn’t really an under-pitch. Pitch rates definitely can have an effect on flavor and aroma, though, but if what you’re used to is only “clean” fermentations from the massive over-pitches resulting from using a whole pack of Imperial Yeast, then perhaps you wouldn’t have much experience with flavor control from varying pitch rates.

I did a similar weissbier experiment: two batches, same recipe, different pitch rates. In one batch, I pitched a large starter propped up from bottle dregs of a commercial weissbier. In the other batch, I pitched the dregs of a single bottle – no starter at all. So the comparison was a normal to large healthy pitch vs an extreme under-pitch.

The starter batch fermented fast and clean. The bottle dregs batch was slower, and had a lot of fermentation character, including some super interesting Juicy Fruit gum flavors.

I’ve heard that the yeast’s contribution to flavor and aroma tends to come mostly during the growth phase. That theory makes sense to me because large pitches would ferment fast without time for the yeast to grow, resulting in “clean” beers, while significant under-pitches should allow the yeast more time to grow before the sugars are consumed, resulting in more yeast character.

How about another iteration: prepare starter from bottle dregs, but now drop the temperature?

Why did you cold crash a hefeweizen?

Hi, what was the aeration method used in your experience? Are you using pure O2 or some other way?

Wow.. I am amazed you got what you expected with the overpitch batch… I am currently struggling with making hefes.

Made 50/50 wheat/pils with WB-06 (18L, oxygenated 60sec with pure O2, 1/2 pack, 22C) – bland. Blamed it on the yeast.

Made 50/50 wheat/pils, with WLP300 (18L, 1L starter oxygenated with stir plate for 10min, later cold crashed and decanted, 22C) – vigorous fermentation, but then … nothing! Just some sulfur…

Could it be the oxygen? Actively oxygenating with O2 is probably inappropriate for this application, but it would appear that oxygenating a starter does something similar…

Admittedly, this is all anecdotal, but if anyone has made similar observations – please share.

My suggestions to you would be to not oxygenate the wort, open ferment for 5-6 days, under pitch your yeast(use 3068 or equivalent), and ferment at 62° for 5 days then increase temp to 65-68°. I’ve made 9 batches of hefeweizen in the last year and these changes brought me success.

I know this was mentioned before, but there was clearly an error in your calculation of how much yeast you pitched into each batch. You clearly stated on the podcast and demonstrated in the photo of the two cylinders that you divided the entire yeast volume into one-third for the underpitched batch and two-thirds for the over pitched batch. That is not a ratio of one-to-three, that is a ratio of one-to-two, and the over pitched batch received only twice as much yeast (not three times as much yeast) as the under pitched batch.