Author: Steve Thanos

One of the many pleasures of beer is sharing it with family and friends, which for those who keg their own or like to take some home from the local pub, often requires the use of a vessel for transport. Perhaps the most popular package is the glass growler, as they’re relatively inexpensive and come in various sizes.

Despite the general impermeability of glass, the process of filling a growler not only results in exposure to oxygen, but it also forces some CO2 out of solution, leading to hastened deterioration of the beer. For these reasons, it’s often recommended to consume beer from a growler as soon as possible. However, some claim that beer in a glass growler can withstand lengthier storage periods as long as it is filled completely and remains tightly sealed until the beer is to be consumed.

In a recent xBmt performed during the Covid-19 pandemic, the brewer was unable to consistently distinguish a Brut IPA stored in a stainless CO2 pressurized growler for 3 days from one served straight from the keg, which indicated little if any oxidation or carbonation loss occurred. Having experienced issues with glass growlers before, I designed an xBmt to test out the impact storage over a few days would have on a Vienna Lager.

| PURPOSE |

To evaluate the differences between a Vienna Lager served direct from the keg and one stored in a glass growler for 4 days.

| METHODS |

Lager styles are known to be sensitive to oxidation, so I designed a simple Vienna Lager recipe for this xBmt.

Proper Nomenclature

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5 gal | 60 min | 19.2 | 12.2 SRM | 1.053 | 1.012 | 5.38 % |

| Actuals | 1.053 | 1.012 | 5.38 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Vienna Malt | 9 lbs | 97.3 |

| Pale Chocolate | 4 oz | 2.7 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Tettnang | 28 g | 60 min | Boil | Pellet | 4.5 |

| Tettnang | 11 g | 10 min | Boil | Pellet | 4.5 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

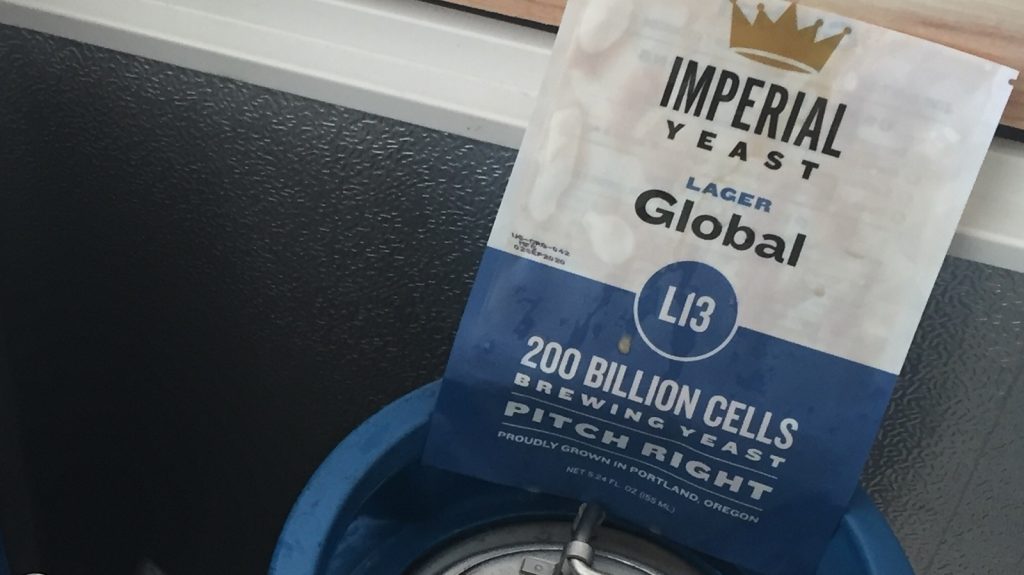

| Global (L13) | Imperial Yeast | 77% | 32°F - 32°F |

Notes

| Water Profile: Ca 55 | Mg 12 | Na 9 | SO4 48 | Cl 35 |

Download

| Download this recipe's BeerXML file |

After collecting the full volume of mash water, which was adjusted to my desired profile, I began heating it up then moved on to milling the grain.

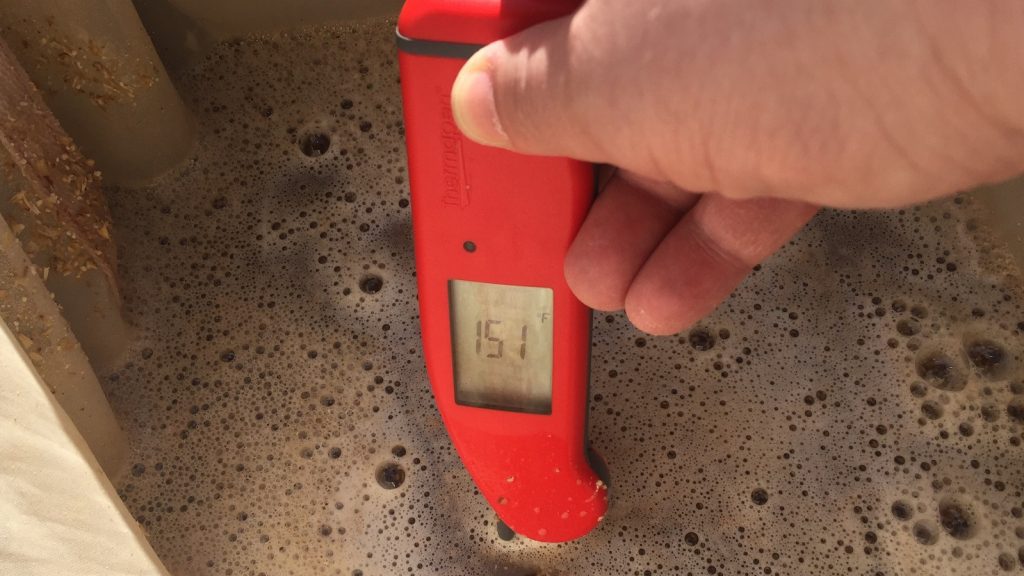

Once the water was adequately heated, I incorporated the grains then checked to make sure it was at my target mash temperature.

The mash was left to rest for 60 minutes, during which I intermittently stirred it.

While waiting on the mash to finish up, I weighed out the kettle hop additions.

When the mash rest was complete, I removed the grains and boiled the wort for 60 minutes before chilling it with my IC.

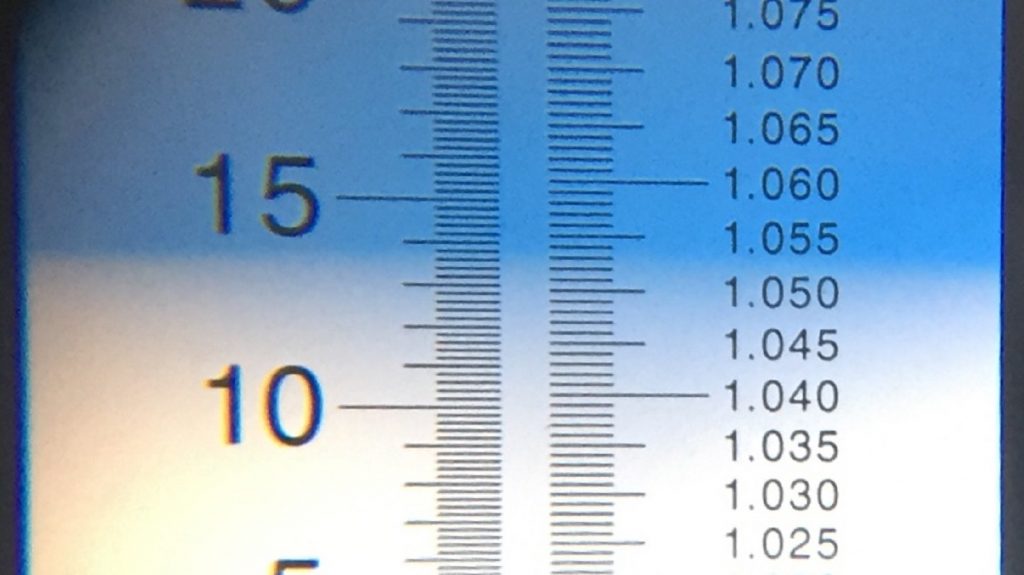

A refractometer reading showed the wort was right at my target OG.

Next, I racked the chilled wort to a fermentation keg and place in my chamber to finish chilling to my desired fermentation temperature of 50°F/10°C, at which point I pitched a pouch of Imperial Yeast L13 Global.

After 2 weeks, I raised the temperature in the chamber to 68°F/20°C and let it sit for an additional 3 days before taking a hydrometer measurement indicating it was at my target FG. At this point, I cold crashed the beer to 32°F/0°C overnight then transferred it to a CO2 purged keg that was placed in my keezer. Following 12 hours of burst carbonation, I reduced the gas to serving pressure and let it condition for 2 weeks before filling a 64 oz/1.9 L glass growler.

The filled growler was placed in my keezer where it remained 4 days before I began my evaluation.

| RESULTS |

Due to social distancing practices as a result of the COVID-19 pandemic, data for this xBmt was unable to be collected in our typical manner. As such, temporary adaptations were made involving the author completing multiple semi-blind triangle tests in as unbiased a way as possible.

Utilizing 4 opaque cups of the same color where 2 were inconspicuously marked, one set was filled with the beer poured from a keg while the other set was filled with the beer stored in a glass growler for 4 days. For each triangle test, 3 of the 4 cups were indiscriminately selected, thus randomizing which beer was the unique sample for each trial. Following each attempt, I noted whether I was correct in identifying the unique sample. Out of the 10 semi-blind triangle tests I completed, I needed to identify the unique sample at least 7 times (p<0.05) in order to reach statistical significance. In the end, I correctly identified the unique sample just 4 times (p=0.44), indicating my inability to reliably distinguish a Vienna Lager served direct from the keg from one that was stored in a glass growler for 4 days.

Based on past experiences with glass growlers, I went into this evaluation confident I’d be able to tell these beers apart, but that was not the case at all. Both beers were equally carbonated and perceptibly identical in terms of aroma, flavor, and mouthfeel.

| DISCUSSION |

Glass growlers are popular in breweries for a number of reasons, namely their cost and general oxygen impermeability. However, it’s widely believed that the process of filling a growler from a tap exposes beer to enough oxygen to significantly reduce shelf life, hence the common recommendation to consume beer from growlers as soon as possible. My inability to reliably distinguish a Vienna Lager poured straight from the tap from one that was stored in a glass growler for 4 days indicates the storage vessel had minimal if any perceptible impact.

While certain gadgets exist that allow for purging of growlers with CO2 prior to filling, I’ve not seen one used at any of the breweries I frequent. Rather, the growler is usually fill to the brim directly from the tap and immediately capped. It’s possible this process results in the oxygen in the growler being completely displaced by the beer and CO2 expressed during filling, reducing the chances of oxidation, which might explain these results.

I was admittedly surprised with my inability to tell these beers apart. It’s true that most of the negative experiences I’ve had in the past have involved opening a growler for samples multiple times over the course of a few days, but given what we know about cold-side oxidation, I was convinced the process of filling the growler would expose the beer to enough oxygen to have a detrimental effect. The fact it didn’t in this xBmt suggests to me that glass growlers may be better for beer storage than I presumed, at least when its filled to the brim with Vienna Lager and remains sealed. I’d be curious to see how a more sensitive style like NEIPA reacts to such storage as well as the impact taking samples from a growler has on beer quality.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

11 thoughts on “exBEERiment | Impact Of Storing Beer In A Glass Growler”

Don’t let the oxygen spectre haunt you. (I don’t say that beer oxidation does not exist, but I sometimes get the impression that many homebrewers live under the impression that the slightest atmospheric exposure equates to ruined beer.)

Gave two growlers of Munich Helles to a friend. He drank the first one right away, and said it was very good. They waited a few days to drink the 2nd one. It did not taste at all like the first one, and they dumped it.

They were both filled at the same time, straight from the tap all the way to the top, and then capped.

So…who knows?

As far as Social Distancing goes, you can still invite 6, 8, or more guests over for beer samples. We do that all the time. Big beer party in a couple days here, with 6 guests. And we won’t be wearing masks!

People like Coldplay and voted for the nazis – you can’t trust people

Last week I opened a 32oz growler of stout I had filled 17 months ago and had forgotten about. I didn’t know what to expect and figured it had gone flat, but when I tried it, it was every bit as good as the day I filled it. Carbonation was still good, and no presence of off flavors whatsoever. Completely shocked me.

What kind of beer faucet do you use to fill the growler? When I try to fill glass growlers with my Perlick faucets I get a ton of foam at the point where the bottle neck begins, making it very hard to fill all the way to the rim. I don’t have that problem with the wide mouth insulated growlers though.

The standard process is to chill the shit out of the growler itself, reduce pressure to 1 or 2 psi, and fill it slowly. At least that how I bottle beer from the tap. Works like a charm to reduce foam but I also use a bottling wand. Looks like he just letting it splash in the pic so, yeah, need info.

Hi Jeff, I have perlicks as well and the growler filler attachment has worked really well for me. Little foam when I fill from the bottom.

As far as Social Distancing goes, I am sure you have considered all of your benefits and risks to make the well informed choices you have made. Please keep doing the best you can. Thank you!

Please describe the process you used to fill the growler. Was it just straight from the tap w/ it wide open with foam, did you use tubing, a fancy gadget, did you allow it to spill over, did you fill/pause/fill? This is where a video of the short process would be very cool. I think the importance may be in the small details. Thanks!

I too have had mostly good experiences when doing this but once and awhile run into issues.

WooHoo – Shout out for Werk Force!

Yeah, nice growler choice!

Choice of growler is the biggest hurdle. I highly suggest using those German ones that are rated to hold pressure. Like a giant grolsch bottle with a swing top. Fill up to about 1″ below the lip and let foam fill the neck and put the top on. Should keep beer fresh for weeks if not longer