Author: Phil Rusher

Mashing is the necessary process in all-grain brewing where the starches in malted grains are enzymatically converted into fermentable sugar. While the traditional fly/continuous sparge approach involved splitting the brewing liquor into two volumes, many brewers these days opt for a simpler full volume mash method, which has the benefit of reducing not only the amount of gear need to brew, but time as well.

One of the first approaches to full volume mashing that gained traction among brewers is what has come to be referred to as the no sparge method, which involves mashing with the full volume of brewing liquor before transferring the sweet wort to a boil kettle, thus eliminating the sparge step altogether, hence the name. Another full volume mash method that has become very popular involves removing the grains from the sweet wort rather than the other way around, which can easily be done with the use of a fabric bag or stainless basket. Unlike the standard no sparge methods, Brew In A Bag/Basket (BIAB) batches require just a single vessel, making for an even more effortless brew day, though some have claimed it produces perceptibly unique characteristics in beer.

Some evidence exists that suggests various mash methods produce worts of objectively different constitutions, which many believe indicates these methods impart perceptible differences as well. Indeed, tasters in a past xBmt were able to reliably distinguish a Vienna Lager made using the standard no sparge approach from one made using the BIAB method. As a user of an electric brewing system where the grains are hoisted out of the sweet wort in a stainless mesh basket, I wondered if the same results would be observed in a pale lager and decided to test it out for myself.

| PURPOSE |

To evaluate the differences between a Munich Helles made using the no sparge mash method and made using the BIAB method.

| METHODS |

My goal being to accentuate any impact of the variable, I designed a simple Munich Helles recipe for this xBmt.

Why So Urgent?

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 6.5 gal | 60 min | 17.1 | 3.6 SRM | 1.048 | 1.015 | 4.33 % |

| Actuals | 1.048 | 1.015 | 4.33 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pilsen Malt | 11 lbs | 98.88 |

| Swaen Melany | 2 oz | 1.12 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Hallertau Magnum | 12 g | 0 min | First Wort | Pellet | 11 |

| Saaz | 12 g | 20 min | Boil | Pellet | 2.4 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Global (L13) | Imperial Yeast | 77% | 32°F - 32°F |

Notes

| Water Profile: Ca 42 | Mg 0 | Na 28 | SO4 70 | Cl 70 |

Download

| Download this recipe's BeerXML file |

After collecting the water for a single 10 gallon batch, I weighed out and milled the grain.

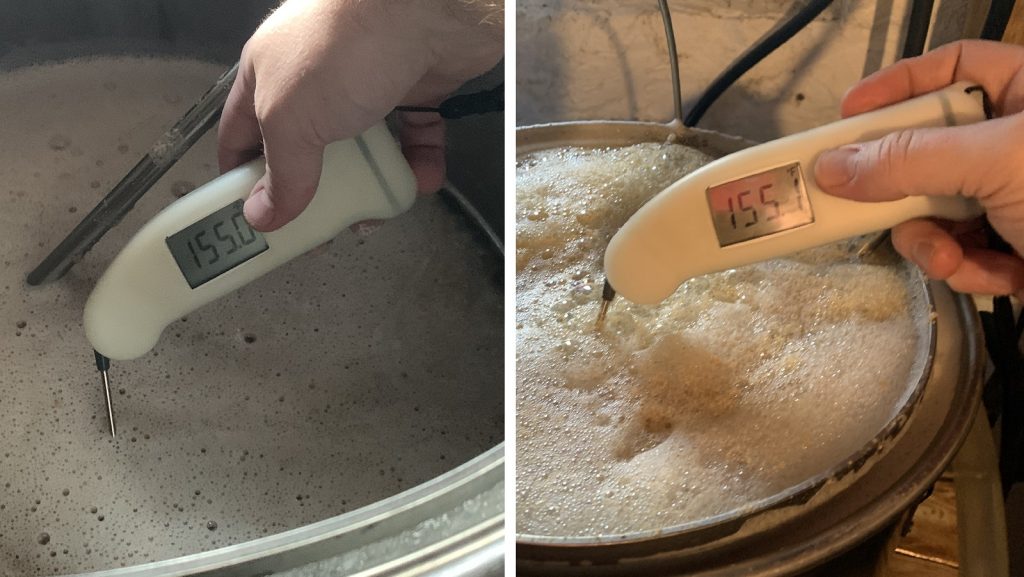

With the water properly heated, I incorporated the grains then checked to make sure the mash was at my target temperature.

In designing this xBmt, I was forced to choose between two potential extraneous variables due to gear limitations. In order to avoid the additional splashing that would occur by transferring the no sparge sweet wort from a collection vessel back into the boil kettle, I opted to mash in a larger vessel then collect the runnings in the boil kettle; both mash tuns were stainless steel from the same manufacturer. This decision was influenced by a prior xBmt showing tasters were unable to distinguish beers mashed in completely different types of mash tuns.

When the no sparge mash rest was complete, I ran the sweet wort off into the boil kettle, whereas I removed the grain basket from the BIAB batch and let it drip until the proper pre-boil volume was reached. I then powered up the elements then prepared the kettle hop additions as the worts heated up.

The worts were boiled for 60 minutes with hops added at the times stated in the recipe.

Following each boil, the worts were quickly chilled with my CFC on their way to sanitized Ss Brewtech Unitanks.

Refractometer readings showed the no sparge wort was 0.002 OG points higher than the BIAB wort.

I used my glycol chiller to drop the worts to my desired fermentation temperature of 51°F/11°C, at which point I pitched a single pouch of Imperial Yeast L13 Global into each batch.

The beers were left to ferment for a week before I raised the temperature to 63°F/17°C for a diacetyl rest. After 3 more days, I took hydrometer measurements showing the no sparge batch finished 1.011 FG while the BIAB batch was at 1.015 FG. At this point, I pressure transferred the beers to CO2 purged kegs.

The filled kegs were placed in my keezer and burst carbonated overnight before I reduced the gas to serving pressure. After a month of conditioning, they were carbonated and ready for evaluation.

| RESULTS |

Due to social distancing practices as a result of the COVID-19 pandemic, data for this xBmt was unable to be collected in our typical manner. As such, temporary adaptations were made involving the author completing multiple semi-blind triangle tests in as unbiased a way as possible.

Utilizing 4 opaque cups of the same color where 2 were inconspicuously marked, one set was filled with the no sparge beer while the other set was filled with the BIAB beer. For each triangle test, 3 of the 4 cups were indiscriminately selected, thus randomizing which beer was the unique sample for each trial. Following each attempt, I noted whether I was correct in identifying the unique sample. Out of the 10 semi-blind triangle tests I completed, I needed to identify the unique sample at least 7 times (p<0.05) in order to reach statistical significance. In the end, I correctly identified the unique sample 5 times (p=0.21), indicating my inability to reliably distinguish a Munich Helles made using the standard no sparge method from one made using the BIAB method.

There was nothing about that beers that made them distinguishable to me when doing my triangle tests, they were identical. As is often the case, when sampling them side-by-side prior to blinding myself, I felt there might be something different about them, but I suppose that’s how bias works. Both were crisp, malt forward, and distinctly “beery.”

| DISCUSSION |

It’s common for new brewers to start out using multiple vessels for wort production, as methods like fly/continuous sparging are often believed to produce a superior product, likely because it resembles commercial breweries. However, on the smaller scale, many have accepted such an approach to be quite cumbersome, leading to the adoption of arguably simpler full volume mash methods including no sparge and BIAB. As is often the case in brewing, opinions abound as to the impact each of these methods has on beer quality, though my inability to reliably distinguish a Munich Helles made using the no sparge method from one made using the BIAB method suggests any difference were slight enough to imperceptible to me.

While I was unable to tell these beers apart based on aroma, flavor, and mouthfeel, there was a rather noticeable difference in appearance with the no sparge beer possessing slightly more haze. It’s difficult to pinpoint what exactly is responsible for this, though it seems plausible the increased amount of kettle trub in the BIAB batch contributed to its clarity. Curiously, in a past xBmt on this same variable where a fabric bag was used instead of a stainless mesh basket, a Vienna Lager made using the BIAB method was hazier than one made using the no sparge approach. Does this have something to do with the material of the mash filter? I look forward to exploring this possibility further.

I’ve brewed many batches of beer over the years using various mash methods, from multi-vessel fly sparge to single vessel BIAB, and I haven’t noticed any marked impact on the quality of the beers I brew. For this reason, I don’t view any method as being necessarily better or worse than another, rather I feel the decision of which approach to use should be based on the needs of the brewer and their own limitations. Personally, I have no plans to exclusively brew one way or the other and will continue to do what I’ve been doing for years, which means BIAB for smaller batches and no sparge for larger batches.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

25 thoughts on “exBEERiment | Mash Methods: No Sparge vs. BIAB In A Munich Helles”

Nice one. I have an issue where the resulting beer is grainy and stripped of all flavour when I do a full volume mash in my stainless basket. And this is with an RO base, salts and acid to put pH in the right range. I have had to stay with a thicker mash with a sparge because the beer turns out awesome that, vs a drain pour when I go for the easier full volume option. What could be going on, microns of basket not low enough ? It’s drilled into us that tannins are only possible at high temps coupled with high pH. But I avoid those conditions.

I don’t know if your resulting beer being grainy and otherwise stripped of flavor is a result of your mash method. And if this was a tannin issue then you’d probably be reporting different sensory results, most often this is described as a mouth puckering astringency that you can *feel* in your mouth.

Usually when I see flavor impacts like what you’ve described I’d look first at the ingredients. I’d also considering whether the instruments I’m using are really truly accurate.

It’s definitely related to mash because I’m talking about the same recipes, system and ingredients (and pH). But when I try full volume biab (6.5L/kg) instead of thicker mash (3.5L/kg) with sparge, it’s a clear fail. It’s almost if having the grains as a filter bed prevents husk material getting into the wort. I’m wondering if my stainless mesh is not fine enough to be the sole filter.

I am not sure why this experiment was even done. In my experience, the two ending results would be expected to be nearly identical therefore, it’s no wonder why the beers are indistinguishable.

Agreed. Had that question when reading the title, then read the article and still have that same question.

It’s the same method. The only way it would change is if you used a flavoured grain bag.

No sparge is very plainly not the same method as BIAB.

Are you familiar with confirmation bias?

Maybe, but I can’t confirm it…….

How are you confirming the pH for each mash type?

No sure why it would matter because Ice Cream doesn’t have any bones…..lol

Do most BIAB brewers recirculate the mash? It looks you do that maybe? Just curious.

A local brewery closed recently, partially due to Covid, partially due to very mediocre beer. The first and only time I went in there I saw this super over-the-top steel framing system and winch. It looks like he was using a commercial scale BIAB setup! I had to chuckle.

I recirculate, yes. I can’t speak for the rest of the BIAB folks out there but I know that many others do as well.

I’ve seen people report commercial scale BIAB but I’ve never seen it in the flesh!

Hmm. Interesting. I wonder what the hybrid thing I do would be called? Because of equipment limitations, I don’t sparge 3.5 gallon brews but I do 5 gallon and higher. (I step mash 100%)

However, I no longer vorlauf. I stir the mash rapidly all the while draining it, full tilt, through an old fine mesh BIAB into my boil kettle.

Easy-peasy.

BTAB – Brew Through A Bag?

As a coffee nut as well as home brewer, my biggest concern with full volume or BIAB (or even batch sparging for that matter) is not extracting as much of the less soluble molecules from the grain (which includes, but isn’t limited to sugars). Diffusion is most efficient where the difference in concentration is highest, which is why percolation can give higher dissolved solid results than infusion coffee brewing methods. BIAB and full volume mash would theoretically yield the same level of extraction if all other factors are equal (though squeezing the bag might confound the result), but the question remains whether the molecules you leave behind in the grain could have made the beer taste better. I’d argue that for a malt-driven beer, you’d almost certainly get a more complex-flavoured result (which is usually a good thing), though for a hop driven beer it probably doesn’t matter. Extraction of sugars can easily be corrected post-mash, but you only get one shot at getting the good bits from the grain.

“…but the question remains whether the molecules you leave behind in the grain could have made the beer taste better.”

I’m not certain that a compulsory enhancement of beer flavor is the result of compounds that would otherwise be left in the grain if using a BIAB setup. In fact, there is a plurality of other anecdotes that say the opposite, especially when big beers are being produced. And I’m a bit skeptical about your claim that you’d almost certainly get more complex and better flavors, because it is highly subjective. To me, this is one of the areas where the brewer’s preferences and artistry come into play. It would be interesting to see some GC/MS studies from worts and beers produced via either 2-3 vessels or BIAB, and it’d be be even more interesting if those studies came with sensory data. Maybe we can convince Cade to do it at OSU.

For sure, brewer’s preferences and artistry are a factor. Again from the coffee world, there’s the same debate about whether higher dissolved solids equal a better flavoured brew.

Somewhat relevant is one of the older exbeeriments testing hot vs cool sparging (https://brulosophy.com/2016/04/11/sparge-temperature-pt-1-standard-vs-cool-exbeeriment-results/). This is an exbeeriment I’d love to see repeated with a more malt-driven beer. The physical differences between the beers were not perceptible in the amber that was brewed.

I’m sorry guys, but your beers are never even ready to drink when you do the final experiments. A mature beer will always be crystal clear, especially a pilsner. And they will taste completely different when all polyphenols have dropped out.

This is the point when we can judge a beer because any financial flaws can be judged accurately. Hop flavours become better pronounced as well as everything else. Malt character, yeast profile etc

I’m surprised by the final gravity differences. No sparge and BIAB are close enough in my mind to suggest that the final gravities would be closer if the pre-boil volumes were broadly the same. I know that differences in final gravity have been shown to not be perceptibly different in the past but this objective difference is puzzling. Any thoughts on what my be leading to this?

Hi Phil,

I’m just trying to figure out what the actual variable was here. Did you sparge the BIAB batch? If not, then it appears both batches are technically “no sparge” and the variable is just the equipment used?

Cheers!

The equipment and processes were slightly different. For the no-sparge batch I used two vessels, a 20 gallon kettle with grain basket for the mash and a 10 gallon kettle for the boil (this smaller kettle is situated behind the larger vessel in the mash pic). This enabled me to separate the liquid from the grain rather than separating the grain from the liquid, as is done with BIAB. The BIAB batch only used a single 10 kettle for both the mash and the boil.

Does that make sense?

Hi Phil – Yeah, it make sense.

However, I think you might have missed my point. This isn’t no sparge versus something else as you’ve not actually sparged either batch. It looks like this experiment is actually “draining the mash tun into another vessel versus allowing the BIAB to drip into the kettle”?

FWIW, I use an all in one BIAB-like system and also allow the wort to drip into the kettle at the end of the mash, but I also sparge at that part of the process to make up my boil volume – This is what I feel was originally implied by the article introduction…

Please explain how using the full volume of water in a mash tun and draining it into a separate boil kettle is not no sparge brewing.

It is no-sparge, so’s your BIAB brew – they’re *both* no sparge, that’s what I’m trying to say (probably badly). However, your article title and the introduction seems to imply that its “no sparge VERSUS something else” when it’s not 🙂

Ah, I see. There’s the disconnect; you’re conflating BIAB with no sparge. These processes are in fact different, most notably the use of two vessels for no sparge, but the act of separating the liquid from the grain (no sparge/fly sparge setups) is quite different from separating the grain from the liquid (BIAB setups), even though the resultant beer may not be all that different.

Hehe fair enough – I guess we differ on that point :D. The way I see it, if you’re doing a full volume mash and not sparging, then *that’s* no sparge regardless of how you separate the grain/wort 🙂