Author: Andy Carter

Oxygen plays a peculiar role in the brewing process—whereas it’s been getting a lot of attention lately for the detrimental effects it can have on the cold-side, it is essential for ensuring adequate yeast cell growth during the lag and exponential phases of fermentation. Many opt for the simple approach of aerating through agitation, though others prefer dosing their wort with pure oxygen, often with a diffusion stone, which can result in well over double the amount of dissolved oxygen.

The beginning stages of the fermentation process are aerobic, meaning the yeast rely on oxygen for the synthesis of sterols and unsaturated fatty acids, which are necessary for cell growth. When pitched into wort with less than ideal levels of dissolved oxygen, yeast can be stressed to the point that certain negative things occur including poor attenuation and the production of undesirable off-flavors. While pitching adequate amounts of viable yeast can help to mitigate these problems, many view dosing wort with pure oxygen as necessary to producing the best quality beer.

Over the years, we’ve published a number of xBmt results suggesting that aerating wort with pure oxygen may not have the perceptible impact many believe it does. I’ve never been too hung up on wort aeration, in part because I make sure to take good care of my yeast, and I’ve not noticed any faults in my beers that I’d associated with poor oxygenation. However, given how important we know oxygen is for yeast and how much focus some put on it, I decided to test it out for myself on a British Golden Ale.

| PURPOSE |

To evaluate the differences between a British Golden Ale where the wort was dosed with pure oxygen and one where the wort was not oxygenated.

| METHODS |

Wanting to ensure any differences were easily identifiable, I went with a simple single malt recipe for this xBmt.

Hard Spile

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.8 gal | 60 min | 49.8 | 4 SRM | 1.05 | 1.008 | 5.51 % |

| Actuals | 1.05 | 1.008 | 5.51 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Maris Otter® Malt | 10 lbs | 100 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

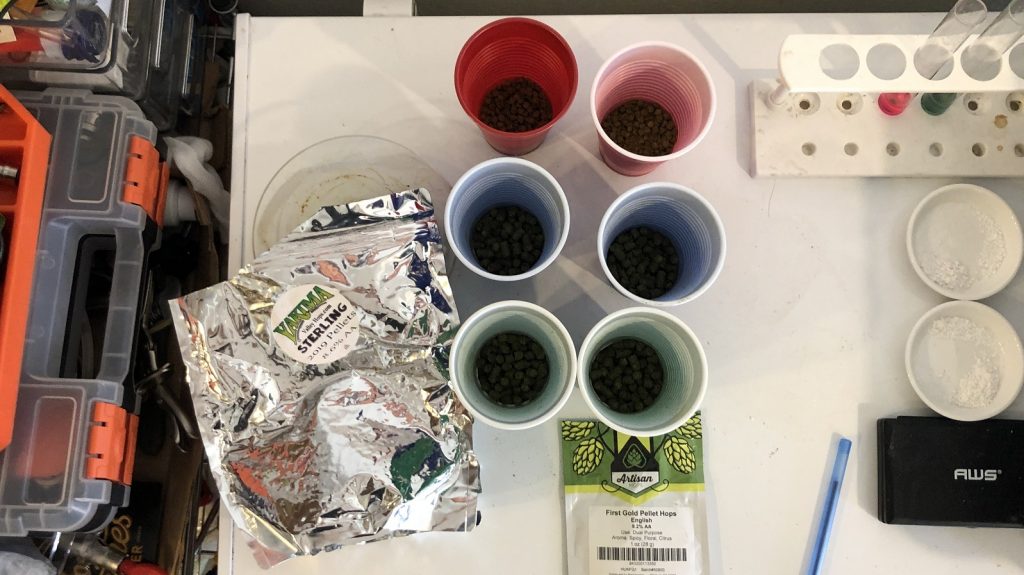

| Sterling | 28 g | 60 min | Boil | Pellet | 8.6 |

| First Gold | 21 g | 20 min | Boil | Pellet | 9.2 |

| First Gold | 21 g | 10 min | Boil | Pellet | 9.2 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Pub (A09) | Imperial Yeast | 74% | 32°F - 32°F |

Notes

| Water Profile: Ca 147 | Mg 13 | Na 6 | SO4 241 | Cl 105 |

Download

| Download this recipe's BeerXML file |

After adding identical volumes of RO water to separate BrewZilla units, I set the controllers to heat them up.

I added the same amount of minerals to each kettle then weighed out and milled the grains.

Once the water for each batch was adequately heated, I incorporated the grains then checked to make sure both were at the same target mash temperature.

Following each 60 minute mash rest, I remove the grain baskets and let them drip into the kettle while the worts heated up.

At this point, I prepared the kettle hop additions.

Once each 60 minute boil was complete, I chilled the worts on their way to sanitized PET carboys.

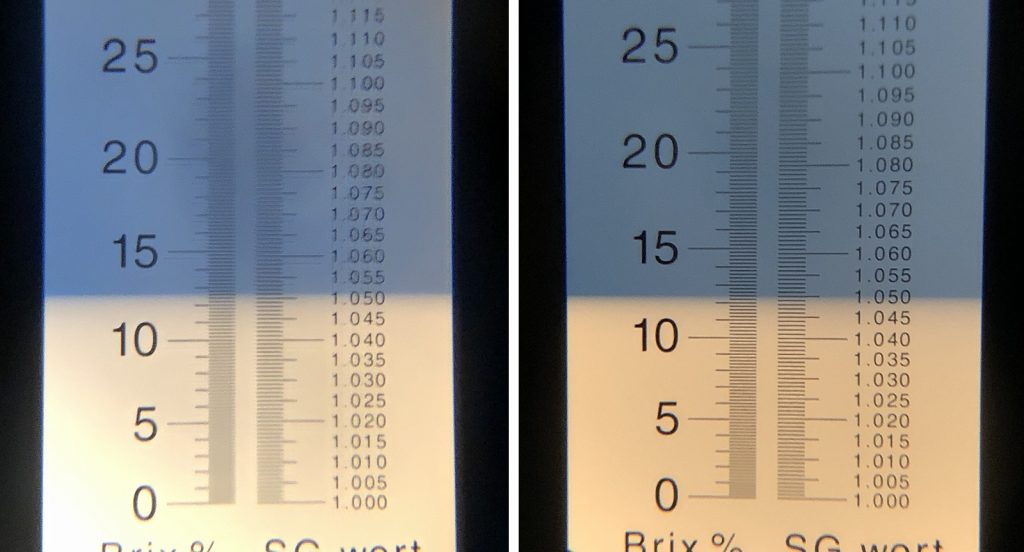

Refractometer readings showed both worts were about 0.001 SG apart.

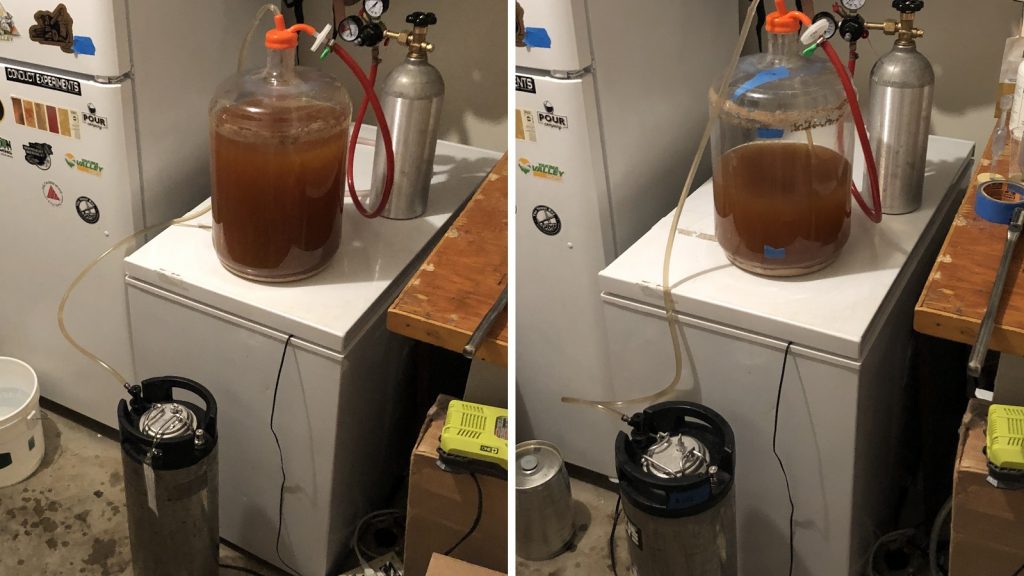

The filled carboys were placed in my chamber and left for a couple hours to finish chilling to my desired fermentation temperature of 66°F/19°C, which is when I hit one batch with a 30 second dose of pure oxygen while the other was left alone.

Next, I pitched a pouch of Imperial Yeast A09 Pub into each batch.

When I peaked at the beers 12 hours later, they appeared to be progressing similarly.

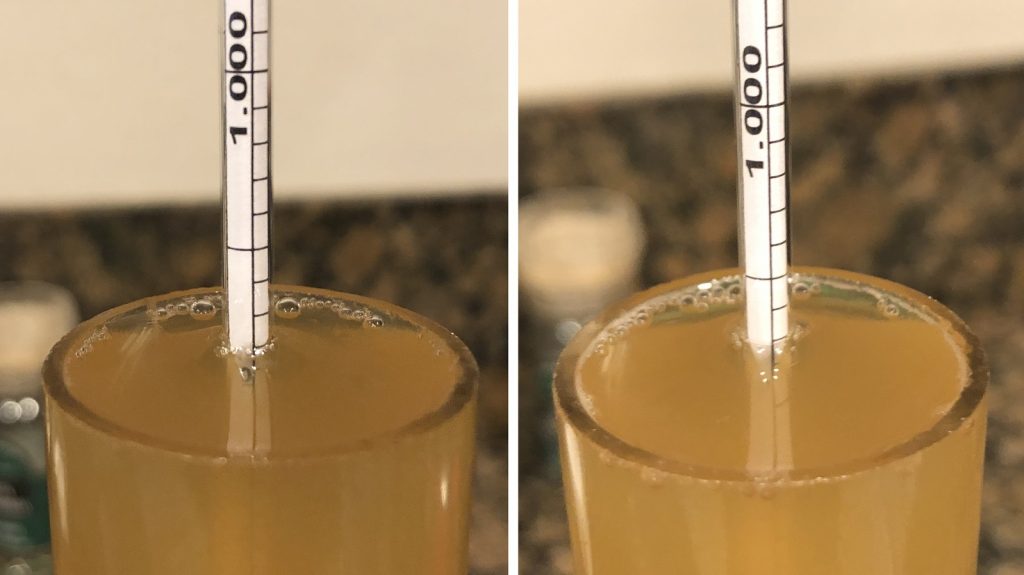

After 5 days, I raised the temperature in the chamber to 70°F/21°C and let it sit for an additional week before taking hydrometer measurements showing the oxygenated beer was 0.001 SG lower than the non-aerated batch; it should be noted the oxygenated beer also started 0.001 SG lower, meaning both batches had the same attenuation.

At this point, I racked the beers to sanitized kegs.

The filled kegs were placed in my keezer and left on gas for 3 weeks before I began my evaluations.

| RESULTS |

Due to social distancing practices as a result of the COVID-19 pandemic, data for this xBmt was unable to be collected in our typical manner. As such, temporary adaptations were made involving the author completing multiple semi-blind triangle tests in as unbiased a way as possible.

Utilizing 4 opaque cups of the same color where 2 were inconspicuously marked, one set was filled with the beer where the wort was oxygenated while the other set was filled with the beer where the wort was not aerated. For each triangle test, 3 of the 4 cups were indiscriminately selected, thus randomizing which beer was the unique sample for each trial. Following each attempt, I noted whether I was correct in identifying the unique sample. Out of the 10 semi-blind triangle tests I completed, I needed to identify the unique sample at least 7 times (p<0.05) in order to reach statistical significance. In the end, I correctly identified the unique sample 4 times (p=0.44), indicating my inability to reliably distinguish a British Golden Ale where the wort was dosed with pure oxygen from one where the wort was not aerated.

There were times when I was evaluating these beers that I thought I picked up a slight difference in the aroma, but then I’d select the wrong sample in the triangle, which proved I was just guessing. When brewing English styles, I typically gravitate toward the darker styles, so it was refreshing to brew something lighter, and I really enjoyed the graham cracker malt flavor and balanced floral hop note in this recipe.

| DISCUSSION |

There’s no question that yeast require oxygen in order to replicate, which occurs during the first phases of fermentation, hence dosing wort with pure oxygen makes practical sense, as it ensures ideal conditions for yeast growth. Naturally, fermentation that occurs in such an environment is less likely to result in problems such as poor attenuation and the production of undesirable off-flavors. My inability to reliably distinguish a British Golden Ale where the wort was dosed with pure oxygen from that was not aerated indicates the practice did not produce a perceptible difference in this instance.

In considering possible explanations for this result, my first inclination was to blame myself, as it is entirely possible my palate simply isn’t good enough to have detected the differences. However, it’s important to note that these results corroborate those from many past xBmts on oxygenation, which suggests perhaps something else is at play. One oft cited idea is that the yeast we’re using today is so much better than yeast was in the past that oxygenation is no longer necessary. It’s also possible the amount of oxygen the wort was dosed with wasn’t enough to make a difference and that both suffered from the same insufficient oxygen levels, though I detected no off-flavors I associate with such issues.

I chose British Golden Ale for this xBmt because I hypothesized that ester production might be a function of oxygen levels, which the findings did not support. I’ve tended to oxygenate my wort ver rarely, and this xBmt did little to sway my opinion that it’s largely unnecessary for most beers. I’ll likely still reach for my oxygen tank when making higher OG styles or if I happen to be re-pitching harvested yeast, but outside of that, I’ll be sticking to the simpler approach of racking with vigor and making sure to pitch healthy yeast.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

13 thoughts on “exBEERiment | Wort Aeration: Impact Of Wort Oxygenation On A British Golden Ale”

What you’ve shown here is something that any professional brewer might have told you, had you asked. That at the home 20 litre scale, the act of allowing the wort to fall into the fermenter entrains enough oxygen for the yeast to form the required membrane materials to multiply. Oxygen is only really needed when you transfer large volume of wort into the bottom outlet of a full scale fermenter. What is also worth noting at this point, to aid others, is that if you use a spray dried yeast, no oxygen is needed at any scale because the required sterols are already present due to the nature of the yeast manufacturing process, it is only needed for re-pitching or yeast from a slurry source.

Chat gpt says a typical a beer of British ale sg needs 1lpm for one minute of pure p2 through a .5micron stone. It would be interesting to do a similar experiment with different o2 levels.

Try this on a big beer where stalling will likely occur in the one without oxygen. The other should be dosed and again at 18 hours.

This would be good to see, do a big beer with and without oxygen

Thank you for your article describing your experiments. I agree with the suggested reasons as to why no differences were found, below you will find some additional thoughts and ideas:

Similar to the idea that yeasts these days are much better, I would think that in both cases, pitching 200 billion yeast cells is sufficient to kick start growth/fermentation and reach the levels of attenuation. There simply is enough biomass to ferment all substrate. The fact that you start to see fermentation already in both vessels after only 12 hours (if i interpret your pictures correctly) adds weight to that possibility.

In this experiment (and if true), deliberately applying suboptimal conditions (fewer cells to start with, demanding more initial growth) would have enabled you to assess for such differences more robustly. Another (and positive control) treatment could have been to try and displace all oxygen with CO2 before the pitch. That could have told you about the energy stores/capacity of the pitched yeast culture.

Unfortunately, you do not report on yeast biomass/cell counts at the end of the brew. Do you see any difference? Measurement of actual growth could have been informative.

As you can see, lots of food for thought. thank you for presenting this cool experiment, addressing an important issue!

As Westonfront has said, I don’t think that this is typically a problem for brewers making small scale batches. I haven’t bothered with oxygenating beer for years, despite transferring hot into a steel fermenter and letting it cool ambiently – this should have virtually no dissolved oxygen, since the boiling would have removed most dissolved oxygen, and the transfer while hot would dissolve very little back into solution. The fact that I use a generous amount of dried yeast (thank goodness for 500g bricks) seems to make up for it.

Even before moving to my lazy no chill method, I found oxygenation had no perceptible effect; I have the O2 cylinder and wand, but when the cylinder would run out of resort to shaking or whisking, and never saw a difference, which had me questioning if there was any need for it.

I can believe it makes little difference… but it’s also a part of brewing that takes very little effort, has very little clean up and is just plain fun 🙂

Hi Andy, thanks for the article. I thought I’d add a couple of points to the other comments already posted. If you wanted to demonstrate that a smaller beer will do fine with a healthy enough pitch cultured yeast and racking with vigor (which does add oxygen), and show that you’ll be ok, I think you demonstrated that (it works for me as well), and you can feel vindicated by those wand-waving O2 lovers who might have told you something different 🙂

It is worth considering what is going on here. The yeast we pitch from yeast suppliers is cultured with oxygen and already has a good store of sterols and UFAs (dry yeast even more so as mentioned by westonfront) and the notion of a lag phase involving aerobic consumption of oxygen to produce sterols assumes oxygen availability. By not having (much) oxygen in the wort you are just leveraging the reserves the yeast brought with them, and now they’re off to the races with anaerobic fermentation. In other words, the yeast producers did the areobic stage of the fermentation for you!

During last summer we had problems with liquid yeast supply and the yeast I did get had to be put on life support (read: a healthy starter with doses of O2) to get it up to making my next beer. In general I tend to rely on assessing my yeast quality and reusing cultures shared among fellow brewers so my aeration regimen varies. Right now I’m playing around with making yeast starters that are preoxygenated so that I don’t have to aerate the wort, in order to minimize the impact of oxidizing my fresh, O2-free wort.

Cheers!

Thanks for all the great content.

Quick question: lately in your recipe description, in the yeast section for TEMPERATURE it always says 32°F – 32°F.

I’m assuming this is a typo that just keeps getting copied?

We are working on this issue. Our XML to HTML converter has a bug.

I think the issue here is that the yeast already comes with all the UFA and sterols it needs to ferment typical homebrew size batch. Adding oxygen to a yeast that is already fully saturated is not going to make any difference.

What would make a difference is if you reused the yeast multiple times. Gino Baart at Fermentis said in a webinar I watched that their yeast already comes with enough of these materials to do 5-6 re-pitches of the yeast.

An interesting test to do but also more demanding is to reuse the yeast cakes over and over, only oxygenating one of the batches every time (the same one of course) and see if there is a difference over time and how many batches it will take for them to diverge. I suspect that number is somewhere around 5.

There might be a correlation/causation problem here. You’ve shown that your process produces good beer, but not that the oxygen addition or absence had any affect. You added oxygen to one, but you don’t know what oxygen level you started at or where the oxygenated wort ended. It’s not clear your non-oxygenated wort was deficient. Both worts might have had enough oxygen necessary for a healthy fermentation for many reasons, and you only showed saturation has no effect.

Another great exbeeriment corroborating with the previous results (and leaving me relieved).

In fact, I wonder how much the aereation could impact on the continous use (repitch) of the same yeast. What do you guys think about design a exbeeriment to see the impact in multiple uses of the same yeast? Maybe the Hop Chronicles would be good a way to do so…

Keep up the great job guys!