Author: Phil Rusher

Hazy NEIPA has become the standard for many beer drinkers because they often exhibit a hop character that’s reminiscent of juicy fruit, which is highly sought after. While there’s been much recent exploration into this relatively newfangled style, there’s little consensus as to what exactly imparts the characteristic juiciness, though it’s widely accepted to be a function of hop variety, amount, and the points at which they’re added during the brewing process. In contrast to traditional American IPA, brewers of NEIPA tend to reserve the majority of their hops for whirlpool and dry hop additions as a way to keep the bitterness restrained while amplifying desirable hop aroma and flavor.

One unique method some brewers believe enhances the perception of juicy hop character in beer involves adding a hefty dry hop charge at high kräusen, which is said to encourage a chemical process known as biotransformation. Generally defined as the process by which a substance changes from one compound into another by way of chemical reactions, biotransformation purportedly occurs in beer when certain terpenoids in hops are in the presence of specific yeast strains during active fermentation, which transforms them into other terpenoids. The most discussed example of this involves the transformation of floral geraniol into citrusy citronellol, which is far more desired in NEIPA.

A few years ago, when NEIPA was on its meteoric rise to the top and people were trying to figure out what exactly this style is all about, we performed an xBmt showing tasters were unable to distinguish a version dry hopped later in fermentation from one dry hopped at high kräusen. While those findings have aligned with others’ experimentation and personal anecdote, I wondered if the outcome might be different in a beer fermented with Imperial Yeast A24 Dry Hop, a blend that includes a Saccharomyces cerevisiae var. diastaticus strain, and put it to the test.

| PURPOSE |

To evaluate the differences between a NEIPA fermented with Imperial Yeast A24 Dry Hop that’s dry hopped toward the end of fermentation (standard) and one dry hopped at high kräusen to encourage biotransformation.

| METHODS |

Relying on past successful batches for inspiration, I designed a NEIPA recipe I felt would exemplify any differences caused by the variable being tested.

10 Ply

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 6.5 gal | 30 min | 26.8 | 5.4 SRM | 1.068 | 1.015 | 6.96 % |

| Actuals | 1.068 | 1.015 | 6.96 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Super Pale Malt | 11 lbs | 61.11 |

| Oats, Flaked | 3 lbs | 16.67 |

| Vanora: Vienna-style Barley Malt | 2 lbs | 11.11 |

| Wickiup: Red Wheat Malt | 2 lbs | 11.11 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Amarillo | 15 g | 10 min | Boil | Pellet | 9.5 |

| Cascade | 50 g | 10 min | Aroma | Pellet | 6.7 |

| Idaho #7 | 50 g | 10 min | Aroma | Pellet | 13.8 |

| Amarillo | 35 g | 10 min | Aroma | Pellet | 9.5 |

| Idaho #7 | 75 g | 5 days | Dry Hop | Pellet | 13.8 |

| Cascade | 50 g | 5 days | Dry Hop | Pellet | 6.7 |

| Sabro | 50 g | 5 days | Dry Hop | Pellet | 14 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Dry Hop (A24) | Imperial Yeast | 78% | 32°F - 32°F |

Notes

| Water Profile: Ca 77 | Mg 0 | Na 30 | SO4 50 | Cl 150 |

Download

| Download this recipe's BeerXML file |

It was determined the best approach for keeping extraneous variables to a minimum in this xBmt was to brew the standard dry hop batch 2 days before the biotransformation dry hop batch, as this would allow the beers to be dry hopped and packaged at the same time, meaning each beer would spend the same amount of time in contact with the dry hops.

The grains for each batch were weighed out and milled as the strike water was heating up.

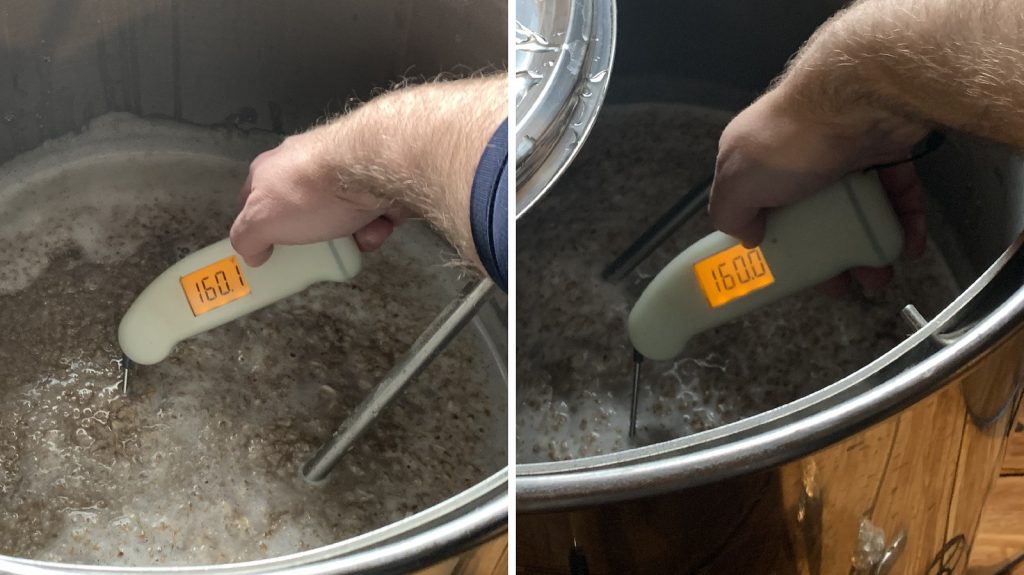

With the water properly heated, I incorporated the grains then checked to make sure the mash for each batch was at my target temperature.

The kettle hops for each batch were measured out during the mash rests.

When each mash rest was complete, I collected identical volumes of wort and proceeded to boil them for 30 minutes, adding hops at the times stated in the recipe.

Once the boils were complete, the worts were quickly chilled on their way to sanitized Ss Brewtech Unitanks.

Refractometer readings showed worts were at the same exact OG, a validating indication of my process consistency.

Each batch was pitched with a single pouch of Imperial Yeast A24 Dry Hop.

The beers were left to ferment at my desired fermentation temperature of 68°F/20°C.

The second batch I brewed was at high kräusen 2 days post-pitch, at which point the first batch I brewed had been fermenting for 4 days as was showing signs of reduced activity. It was at this point I added identical dry hop charges to each batch and let them sit for 6 more days before taking hydrometer measurements showing the standard dry hop batch finished at 1.014 FG while the biotransformation dry hop batch finished at 1.015 FG. Next, I pressure transferred the beers to CO2 purged kegs.

The filled kegs were placed in my keezer and burst carbonated overnight before I reduced the gas to serving pressure. After a couple weeks of conditioning, they were carbonated and ready for evaluation.

| RESULTS |

Due to social distancing practices as a result of the COVID-19 pandemic, data for this xBmt was unable to be collected in our typical manner. As such, temporary adaptations were made involving the author completing multiple semi-blind triangle tests in as unbiased a way as possible.

Utilizing 4 opaque cups of the same color where 2 were inconspicuously marked, one set was filled with the beer dry hopped toward the end of fermentation while the other set was filled with the beer dry hopped at high kräusen. For each triangle test, 3 of the 4 cups were indiscriminately selected, thus randomizing which beer was the unique sample for each trial. Following each attempt, I noted whether I was correct in identifying the unique sample. Out of the 10 semi-blind triangle tests I completed, I needed to identify the unique sample at least 7 times (p<0.05) in order to reach statistical significance. Ultimately, I identified the unique sample only 5 times (p=0.213), indicating my inability to reliably distinguish a NEIPA dry hopped toward the end of fermentation from one dry hopped at high kräusen.

Despite my awareness of the variable and expectation of a difference, I simply could not tell these beers apart, they both had a soft mouthfeel with citrusy tangerine and orange flavors up front that was supported by tropical fruit notes of guava and passionfruit. I haven’t brewed NEIPA that often, but I can say without a doubt that these were some of the best beers I’ve ever made.

| DISCUSSION |

Brewers use various methods to maximize juicy hop characteristics in their hazy NEIPA, chief among them being to add large amounts of hops to the beer on the cold side. In addition to mitigating the risk of oxidation, dry hopping during active fermentation is also believed to encourage biotransformation of certain terpenoids into other more desirable terpenoids, making it the option of choice for many. However, my inability to reliably distinguish a NEIPA that was dry hopped toward the end of fermentation from one that was dry hopped at high kräusen suggests any unmeasured and/or unquantified differences between these approaches to dry hopping are slight.

To be clear, biotransformation is real, that is not in question. There are numerous studies documenting how S. cerevisiae has the ability to biotransform hop compounds, and there are numerous studies discussing the ramifications of dry hop timing. Rather, the fact my experience in this xBmt corroborates the findings from a previous xBmt indicates whatever biotransformation may be occurring when dry hopping at high kräusen is minimal enough as to be imperceptible. One potential explanation for these results is that the yeast I chose to ferment with is incapable of biotransformation, though given Imperial Yeast A24 Dry Hop is a blend containing a strain made popular by its use in The Alchemist’s classic NEIPA, Heady Topper, it seems unlikely to hinder opportunities for biotransformation. Perhaps the sheer amount of dry hops I added masked any impact of the biotransformation that did occur and a smaller dose would have made for easier detection of differences.

I find the concept of biotransformation as it relates to beer very interesting and certainly plan to continue exploring it more in the future. At this point, I see no reason to obsess over when dry hop additions are made and will continue to approach it as I have for a while– add dry hops when it is convenient and prudent for the style and situation.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

24 thoughts on “exBEERiment | Biotransformation: Impact Of Dry Hopping NEIPA At High Kräusen When Fermented With Imperial Yeast A24 Dry Hop”

Hi Phil,

Thanks for the insight here, pretty interesting stuff and the beers look delicious. I’d love to have a crack at brewing this recipe but I just don’t understand the hop schedule as you have 2 additions of amarillo at 10 minutes? Or is the second one whirlpool?

Thanks.

Yeah I can see how it can be confusing given how they’re listed here! Just pay attention to the part that says boil or aroma. If it’s listed as “boil” then that hop was added in the boil, whereas if it’s listed as “aroma” then it was added during the hopstand/whirlpool.

Also, for whatever it’s worth I’d consider doing a smaller dry hop charge that’s more in line with 8 grams of hops per liter of beer. That would effectively cut the amount of dry hops in half here.

Thanks for the content! Wondering if these stayed around long enough to see any signs of oxidation. Curious if the idea of dry hopping at high krausen eats up more of the oxygen from popping the fermenter open.

They did not last long! My hunch is that as long as you’re dry hopping prior the end of fermentation then the yeast will be able to scrub any oxygen that’s introduced.

160 mash temp?!! Due to lack of high-color malts, or maybe highly attenuative yeast?

Don’t fear the high mash temperatures! I chose 160F because I wanted to facilitate the outcome of a higher terminal gravity.

What is your take on dry hopping in the keg, or adding your dry hop charge at the end of fermentation and slow crash the beer? Adding hops to the keg, what would be considered to much in a 5 gallon batch neipa?

I’ve heard people say that hops need to be in contact with the beer for 36hrs and after that they could reabsorb the oils. Is this true?

I have very limited experience with keg-hopping, but the one time I did do that I used 30g in 5 gallons of beer and it worked great. I’d probably max out at 40-50g just because of the risk for the beer to turn grassy with the prolonged exposure.

I wouldn’t know the 36 hour rule you’re speaking of without looking it up, but it sounds dubious to me. I’d imagine that any flavor compounds that get extracted from the hops will never be reabsorbed by the hops under normal conditions.

Isn’t this what was preached as a must for dry hopping 10 years ago? With regards to a secondary fermenter.

Yup! My hunch is that a bigger perceptible impact from biotransformation might be observed when dry hopping at a lower rate, something along the lines of less than 6g/L (0.83 oz/gallon). But we beerfolk (especially homebrewers) tend to err on the side of more is more so it can be challenging sometimes.

In your Hops pic you have Idaho7, was that part of the recipe at all?

That is a good catch, thanks for pointing it out. The recipe was corrected to reflect this.

Fascinating stuff Phil. I’d be very interested to see the outcome of an experiment using the same recipe with a more extreme delta: one batch with the dry hop charge added at yeast pitch, vs. one batch with the dry hop charge added in a secondary vessel (with hop contact time the same for both).

I know no one conditions in a secondary vessel anymore, and it’s a pretty mad idea for a NEIPA, but for the purposes of this experiment it would certainly extenuate the variable.

One reason this appeals to me is that I’ve always been curious as to whether active yeast contact with hops contributes to the cloudyness of NEIPA. An ‘old school’ dry hop in secondary would certainly help answer this question.

I don’t know why I hadn’t replied to this sooner! But I agree, testing a “secondary” step would be interesting. That could be easily done by utilizing the trub dump ports with my unitanks.

I’ve been meaning to ask this for a while. Why are all the measurements in US imperial and hops are in metric. I wish you’d show imperial in the hops part of the recipe.

Love the content and thanks!

Don’t fear the light use of the metric system! It’s far better than the US Imperial units, I promise.

I like to measure hops with grams because I am far less frequently using such large quantities of hops so it’s easier for me to conceptualize a few grams instead of subdividing ounces. I do go back and forth between thinking about lager hop doses in terms of ounces and grams, though. It’s kind of like a thought exercise.

This.

hi. I’m always impressed by the final color and clarity (even/especially on the hazy ones, which have a nice hazy sheen, as opposed to the milky cloudiness I always get when using oats…) of your beers. I‘d like to know in which way, if any, you contain your hops when whirlpooling and especially dry hopping…are they in a spider (whirlpool) or a bag/strainer (dry)? and whether you filter (150um monofilament nylon?) your beer when racking to the fermenter?

Right, it can be difficult to ensure that these styles of beer look appealing. And for what it’s worth, I’ve also made some cloudy versions of these too! Usually they’re still pretty tasty.

For these particular beers I used the grain basket that came with Clawhammer Supply’s BIAB system because there was a ludicrous amount of whirlpool hops that would have otherwise clogged up and made a mess of the hop spider, leading to not fully utilized hop pellets. They don’t list the specs of the mesh on their site, but I’d wager it’s around 84 micron/200 mesh. I’ve also got unitanks with trub dump ports so I made sure to dump the trub and hop material prior to kegging in order to avoid any of the vegetal matter making its way into the kegs.

Using the grain basket to contain the hops is a great idea, thx! (don’t know why i didn’t think of that…probably cuz it’s usually sitting on the side filled w/ spent grains! will have to clean it immediately, I guess…)

do you contain your dry hops?

do you run your wort thru a (nylon monofilament) filter on the way to the fv?

anything else to get hazy sheen and not milky cloudiness?

cheers!

josh

(oops, missed the part about dumping the hop trub, so you’re ob-iosly not containing the dry hops…)

Hi Phil! Have you noticed any differences in hop character after some weeks? Some brewers believe that dry hopping at high kräusen gives hop character more stability than late additions. Thanks!

Neither of these beers lasted that long 😉

I hadn’t noticed substantial differences between the beers when they were still in the kegs. I am curious how biotransformation might be more apparent in a beer that did not have such a massive amount of hops, though. I’m also curious about how beers might turn out when (modestly) dry hopped at high krausen as well as after fermentation is over and the beer is separated from the trub & yeast.