Author: Phil Rusher

Boiling wort is an imperative part of the production of beer that serves various purposes. Prior to modern day water treatment and campaigns for clean water, potable water supplies were not always readily available, and boiling wort sufficiently sanitized it for safe consumption. Additionally, it’s during the boil that alpha acids from hops are isomerized and proteins from malt coagulate.

Another boon of boiling wort is that it drives off dimethyl sulfide, an undesirable compound that’s commonly described as having creamed corn or ketchup characteristics. In order to best facilitate this process, it’s commonly recommended to boil wort vigorously, while weaker boils are associated with increased levels of DMS.

I’ve always tended boil my wort quite vigorously, which is easy to do with my 240v electric setup. However, for those with less powerful energy sources, weaker boils are routine. Does this have a noticeable impact on beer character? With one past xBmt showing it didn’t on an Amber Ale, I was curious if a pale lager made with a large portion of Pilsner malt would produce different results and put it to the test.

| PURPOSE |

To evaluate the differences between two beers where one was boiled vigorously and the other was simmered.

| METHODS |

Wanting to showcase any impact of the variable, I designed a German Helles Exportbier recipe with a grist consisting primarily of Pilsner malt.

Other Side Of The Coin

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 6 gal | 60 min | 25.6 | 3.5 SRM | 1.059 | 1.01 | 6.43 % |

| Actuals | 1.059 | 1.01 | 6.43 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| BEST Pilsen Malt | 11 lbs | 99.44 |

| Swaen©Melany | 1 oz | 0.56 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Hallertau Magnum | 15 g | 0 min | First Wort | Pellet | 11 |

| Tettnang | 20 g | 20 min | Boil | Pellet | 3.9 |

| Tettnang | 30 g | 5 min | Boil | Pellet | 3.9 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Harvest (L17) | Imperial Yeast | 72% | 32°F - 32°F |

Notes

| Water Profile: Ca 50 | Mg 0 | Na 34 | Cl 70 | SO4 100 |

Download

| Download this recipe's BeerXML file |

After collecting the water for a single 10 gallon batch, I weighed out and milled the grain.

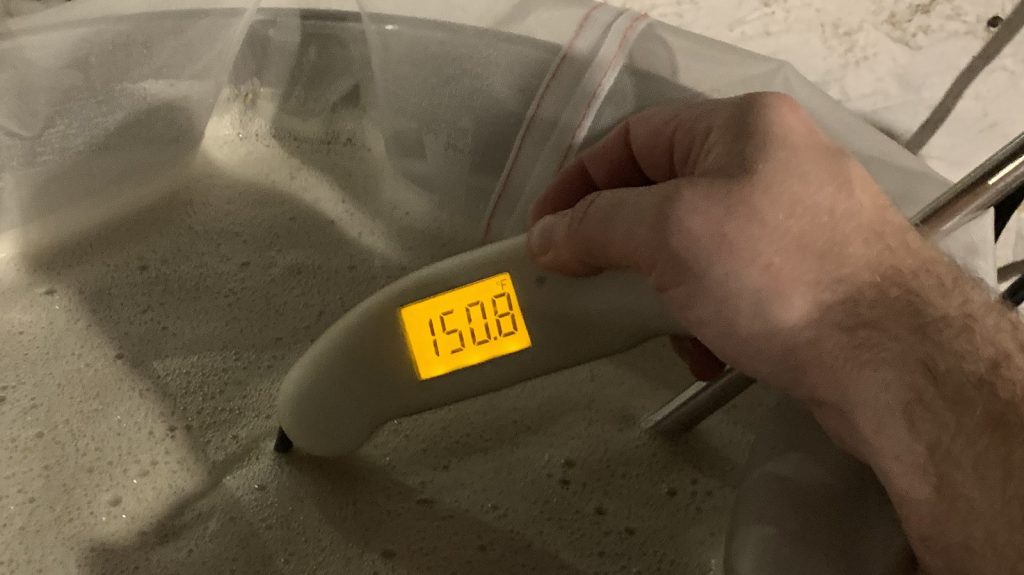

With the water properly heated, I incorporated the grains then checked to make sure the mash was at my target temperature.

I then turned on the pump to recirculate the sweet wort during the hour long mash rest.

When the mash rest was complete, I collected the entire volume of wort and gently stirred to ensure homogeneity before evenly splitting it between two kettles.

As the worts were heating up, I prepared the kettle hop additions.

As the worts were reaching a boil, I set one Clawhammer controller to 40% power to maintain a gentle simmer while the other was set to 80% to maintain a vigorous boil.

Following each 60 minute boil, the worts were quickly chilled with my CFC on their way to sanitized Ss Brewtech Unitanks.

With the kettles empty, I noticed the trub at the bottom of each kettle looked quite a bit different.

Refractometer readings showed the weak boil wort was 0.006 SG point lower than the wort boiled vigorously.

With the wort at my desired fermentation temperature of 68°F/20°C, I pitched a single pouch of Imperial Yeast L17 Harvest into each batch.

The beers were left to ferment under 15 psi for 1 week before I raised the temperature to 75°F/24°C.

After a 2 day diacetyl rest, the beers were cold crashed to 34°F/1°C for 2 more days before I took hydrometer measurements showing the weak boil beer was at 1.009 FG and the vigorous boil beer was at 1.010 FG. At this point, I proceeded with pressure transferring the beers to CO2 purged kegs.

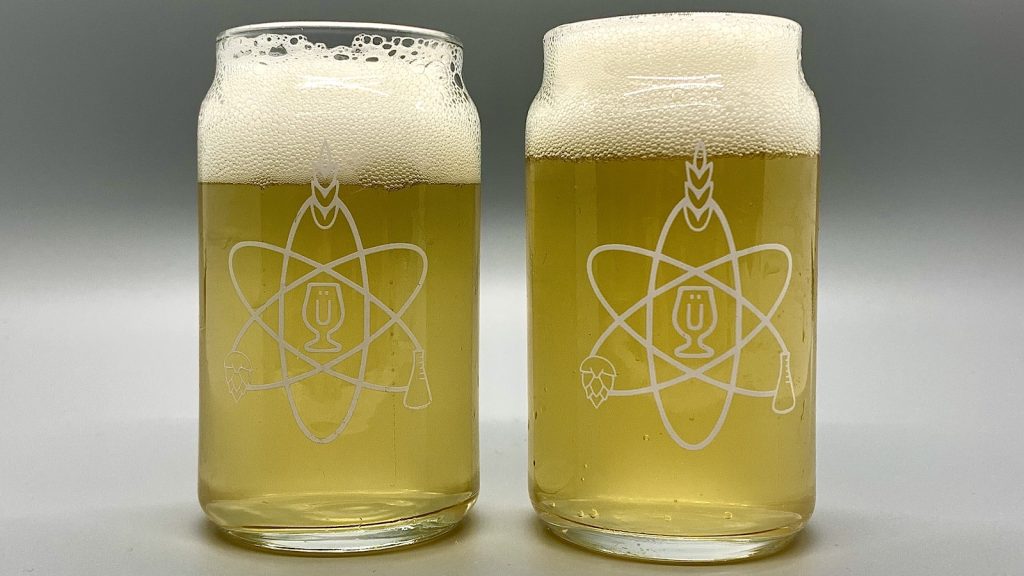

The filled kegs were placed in my keezer and burst carbonated overnight before I reduced the gas to serving pressure. After 3 weeks of conditioning, they were carbonated and ready for evaluation.

| RESULTS |

Due to social distancing practices as a result of the COVID-19 pandemic, data for this xBmt was unable to be collected in our typical manner. As such, temporary adaptations were made involving the author completing multiple semi-blind triangle tests in as unbiased a way as possible.

Utilizing 4 opaque cups of the same color where 2 were inconspicuously marked, one set was filled with the weak boil beer while the other set was filled with the vigorous boil beer. For each triangle test, 3 of the 4 cups were indiscriminately selected, thus randomizing which beer was the unique sample for each trial. Following each attempt, I noted whether I was correct in identifying the unique sample. Out of the 10 semi-blind triangle tests I completed, I needed to identify the unique sample at least 7 times (p<0.05) in order to reach statistical significance. In the end, I correctly identified the unique sample 4 times (p=0.441), indicating my inability to reliably distinguish a German Helles Exportbier where the wort was boiled weak from one that underwent a very vigorous boil.

Initially, I thought I noticed some differences between these beers, but that was highly likely due to my awareness of the differences in ABV. Both of these beers were quite nice and easy to drink with no detectable DMS, and they tasted identical to my palate.

| DISCUSSION |

Dimethyl sulfide (DMS) is a compound that, for the most part, is considered an off-flavor, particularly in delicately flavored pale lager. In order to keep DMS levels as low as possible, brewers are encouraged to boil wort vigorously to assist in the driving off of this undesirable off-flavor. Interestingly, I was unable to reliably distinguish a German Helles Exportbier where the wort was boiled weak from one where the wort was boiled vigorously.

While I didn’t detect any DMS in either of these xBmt beers, my inability to tell them apart suggests, at the very least, levels of the compound were similar enough in each as to be imperceptible. What’s striking is that the beers did have objectively different amounts of alcohol, with the weak boil version being at 5.78% ABV while the vigorous boil beer was 6.43% ABV, and yet they still tasted the same to me. This corroborates past xBmts focused on mash temperature where beers with even more disparate levels of alcohol were indistinguishable.

I’m fortunate enough to have powerful enough electric brewing system that makes boiling vigorously very easy, so despite that fact I couldn’t tell the beers apart in this xBmt, I have no plans to change my standard boil routine. However, for brewers with less powerful energy sources, these results indicate there’s likely little negative of weaker boils, at least when using modern base malts.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

29 thoughts on “exBEERiment | Boil Vigor: Weak vs. Strong In A German Helles Exportbier”

You state that the weak boil beer ended with lower ABV, despite having previously said that its final gravity was 1.009, versus 1.010 for the vigorous boil beer? Also, I think the first sentence of the article is missing.

Starting gravities were also different

Right, I didn’t get to proof this prior to scheduling the post. Fixed the first sentence! And Steve is correct; the original gravities were different for the weakly vs strongly boiled beers, 13.0°P vs 14.5°P respectively.

The weak boil beer was quite a lot lower in OG at 1.053 to 1.059, No wonder, because less of the wort was evaporated by the slower boil. So the final volume of the boiled wort was greater in the weak boil sample and the concentration of sugars lower. I calculate the ABV of the vigorous boil was (according to a formula I use) 6.65% compared with 5.97% for the weak boil beer. The final volume of the wort after boil should really have been the same if testing for how vigorous the boil was, as opposed to any difference in alcohol strength.

Chrisgg,

I think you make a good point, and perhaps a good way to have gotten identical final volumes of wort for this experiment would have been to have added some distilled water to the “vigorous” batch following the boil. This would have controlled for the varying OGs produced by the different boils.

Phil,

I am not understanding why this experiment does not convince you to reduce your power during the boil. Reducing power will save you money, will save energy, and will not harm your beer. Why don’t you plan to change your standard boil routine?

The decision not to dilute the vigorously boiled batch of wort was a conscious one, namely because this is what we did with the first xBmt and we wanted to maximize any potential differences in the current xBmt. Despite this fact, I was still not able to reliably distinguish these beers from one another.

My standard operating procedure is to get a decent rolling boil instead of something that can be compared to a volcanic eruption, and I see no reason to change that.

This is a very interesting exbeeriment – thank you! This is one variable I have a really hard time with. Boil strength feels like the most subjective measure in my process, and I’m convinced that when I “miss” my numbers, my amount of boil-off is the main culprit. I’d be interested to know your starting and final volumes for each if you kept them. I also brew with gas, so I’m envious that you can brew at a specific “setting” compared to my version: “that looks about right.”

Right, boil vigor can be tough to pin down when using gas setups (and to a lesser extent electric as well). The starting volumes were the same because the sweet wort was divided evenly between the two boil kettles, but the ending volumes were a bit different as expected. The volume of strongly boiled wort in the kettle was about 6 gallons or 22.7 liters while the weakly boiled wort was about 6.5 gallons or 24.6 liters.

Thank you for the reply! A half gallon is pretty significant!

I started reducing my boil vigor after reading 2-4 threads on HBT. You’re not helping your beer by over-boiling but can you taste a difference? Maybe not. I havent really tastes a difference that is obvious. My color may be a touch lighter now perhaps. I’m using less energy, sparging less and now i can mash a bit more and boil a bit more with a lower boil rate. There is also an interesting article in a somewhat recent Zymurgy by Brungard.

I wonder if the results would be significant if brewing with short & shoddy methods.

Maybe 60 mins of boil is still enough to drive off DMS precursors regardless of vigor, but 30 mins of boil time wouldn’t be.

Marshall did a 30 min boil vs 90 min boil a few years back. https://brulosophy.com/2015/09/14/boil-length-pt-2-pilsner-malt-exbeeriment-results/

I recently purchase a brewing system which can be used at either 110 or 220. I decided to try the lower power first. It was amazing. I did reduce the amount going into the boil to compensate for the reduction in boil off. Nailed the SG target. I had purchased everything to convert to 220 but I just love the flexibility of being able to brew anywhere. Thanks for the research – I’ll be less concerned about this decision.

Happy to oblige! I’ll just take a moment to point out that this post is not really research, but it’s a report on my experiences with these beers. It’s also another data point on a previous boil vigor xBmt we did.

Phil, I’m curious to know whether you (and perhaps your Brülosopher colleagues too) are coming around to the conclusion that DMS is more-or-less a myth? By which I mean, a boogie man story passed down by word-of-mouth from our elders and brewing forefathers, who spoke of it in terrified hushed tones with fear in their eyes, but which hasn’t actually been seen since about 1987. I’ve certainly never tasted it nor met anyone else who has.

One obvious explanation for this springs to mind: the improved quality of modern malt. (I’m not old enough to have any experience of ‘back-in-the-day’ malt, but I’ve certainly heard brewers talk about how malt has improved in the last decade or so.)

Maybe DMS has gone the way of the dodo?

Well, DMS is absolutely a real thing that’s a part of basically all malted barley, and it would be at least theoretically possible to produce a beer with perceptible concentrations of DMS so I’d be hesitant to call it a myth. But I think it’s very unlikely that brewers are perceiving DMS in most beers that are made with modern fully modified malt.

Yeah, perhaps “myth” is too strong – what I really meant was: “very, very unlikely to be a perceptable problem when brewing with modern malts”. Thanks!

According to Martin Brungard, DMS is a function of kilning, not modification. Which makes sense. Kilning drives the conversion of SMM to DMS. In very lightly kilned pale malts, e.g. pilsner malts, more SMM remains, and worts made from these malts need a longer boil for conversion. This aligns pretty well with my own experience. YMMV of course.

I just brewed a Munich helles with floor malted weyermann bohemian pils malt (under modified compared to their other pils varieties). 30 min boil on my 120v electric system. Zero dms. Tastes spectacular

DMS is definitely a thing. I’ve accidentally experienced it but almost always when a beer managed to not be able to be chilled fast enough…too much time in the 80-110F zone.

What’s interesting about this is the ability to get improved efficiency out of a batch. I just put together the Spike Brewing condensing lid and found i can reduce the energy input by at least 30% to get a similar boil vigor. No DMS that I can notice. Would be great to use less water to hit the same target FG.

I’ve been wondering something about the new method of triangle testing. Do you do all of the tastings one after the other in the same day, or do you do them across multiple days? I wonder about burning out your palette if doing them one after the other. Can tables of tasting results be included in the results section, and well as explanation of whether they were all done back-to-back, or across multiple sessions. I feel like that is a major difference between the single person vs. Large group tasting results. Not that I doubt these results, just want to have a better understanding of the methods used.

Palate fatigue can be a concern. The sensory industry tries to limit their tasters to something like 10 or so samples per session, but this can vary depending on the setting and what’s being tested. For me, I usually space out my tests over two days and have water/palate cleansers between samples.

I have learned a lot reading this exbeerment, but I always think about the pH of yours recipe, like this one 99% pilsen malt.. dont you worry about high pH of your wort? Do you use any acidification method to reach this saccharification?

I do adjust my recipes for mash pH. For this one I added enough lactic acid to get a pH of 5.47.

It’s hard to understand the data here. The final volumes were 22.7 and 24.6 litres and 13.0 and 14.5 plato. But I cant see any data for the pre-boil volumes or plato. The differences are 1.9 litres (8.4%) or 1.5 plato (11.5%) between the two trials. This is pretty good agreement between the two measurement methods of evaporation rate, say 10 % greater for the high boil trial.

We can assume that heat losses from the system will be the same in both cases. We have the same kettle, same boil temperature, same ambient temperature etc. we know that one boil ran at 40% heat and the other at 80%.

If we extrapolate back to a boil at 0% heat input (OK I know, thats not a boil) we would get 0% evaporation so our 40% boil must be 10%. The 80% setting must be delivering 20% evaporation per hour.

If my numbers are correct I’m not surprised you are not seeing a difference. Commercial breweries used to run at 15% per hour on a 90 min boil in the 60s but now run at 4%/hour for 60 min. If you play a few tricks you can run much lower.

The 40% boil/10% evaporation is way more than you need.

REGARDING DMS

Its real. what you get in your beer is a complex interplay of the degree of rootlet growth in the malting process (and the temperature at which this happens), the malt kilning profile, the temperature profile through the brew, kettle boil time and wort cooling time. And dont forget gas stripping of DMS in the fermenter.

DMS is produced from thermal degradation of SMM in the brewery and maltings. SMM is barley-growth related.

The conversion of SMM to DMS is slow but the evaporation of DMS is fast. So higher kilned malts will have less SMM (think ale malts). Longer brew cycles will reduce DMS

For a low DMS beer without spending a lot on boil energy I will run a 2-4% evap boil for 60 min to get as much SMM converted as possible. chill in <20 min to avoid any further SMM to DMS conversion and allow my fermenter to open vent and gas-strip volatiles for a day or two.

I can’t remember the starting volumes of the top of my head but your extrapolation seems reasonable!

With respect to DMS, yes it’s absolutely a real thing but I have only experienced it in sensory trainings and never in the wild, so to speak. This is one of the reasons I wanted to ferment these beers under pressure, just in case there was some encouragement to keep DMS from escaping the FV.

I would think the resulting wort volume after boil was different leading to the variance in OG. Less water left in the vigorous boil condition.

Thanks Phil – just getting ready to make a Helles, so perfect timing!

Sounds like a win-win-win (-win?)! You get 1/2 gallon more beer, slightly lower ABV (you can drink more at a sitting) use less power, and it tastes the same! What more could you ask for from an exbeeriment!

Well done.

I whole heartedly agree!