Author: Brian Hall

Regardless of the style of beer being made, fermentation temperature control is something all brewers focused on quality take seriously. On the homebrew scale, there are myriad options for regulating the temperature of fermenting beer, from simple ice baths to more elaborate systems that resemble commercial setups. What seems to be the most popular solution is storing fermenting beer in a chest freezer “chamber” that’s regulated by a temperature controller, which is what I’ve done for most of the time I’ve been brewing. Although simple and easy to maintain, the biggest drawbacks to this approach for me are that my chest freezer is quite large for only being able to hold 2 fermenters, and both beers in the chamber must be held at the same temperature, thus limiting my style options.

Having recently revamped my brewing space, I became interested in a solution that would allow me to independently control the fermentation temperatures of multiple beers while having a smaller footprint, and my focus quickly turned to glycol chillers. Possessing the quality of having a much lower freezing point than water, glycol can be chilled very cool and recirculated through or around fermenting beer to efficiently maintain a set temperature. Commonly used in commercial breweries, smaller options have become available to homebrewers that seemed to fit exactly what I was looking for.

Penguin Chillers is a reputable manufacturer of glycol chillers who recently began making smaller versions for homebrewers that are more affordable than other options. One reseller of these chillers, Delta Brewing Systems, offered to provide us with a Penguin glycol chiller in exchange for an honest review. I’ve since used it to the control the fermentation temperature of many batches over the last few months and am ready to share my thoughts.

The product reviewed for this article was provided by the manufacturer in exchange for an honest review; no other compensation was provided. The opinions expressed in the article are solely those of the author and a concerted effort was made to approach the review from an unbiased perspective.

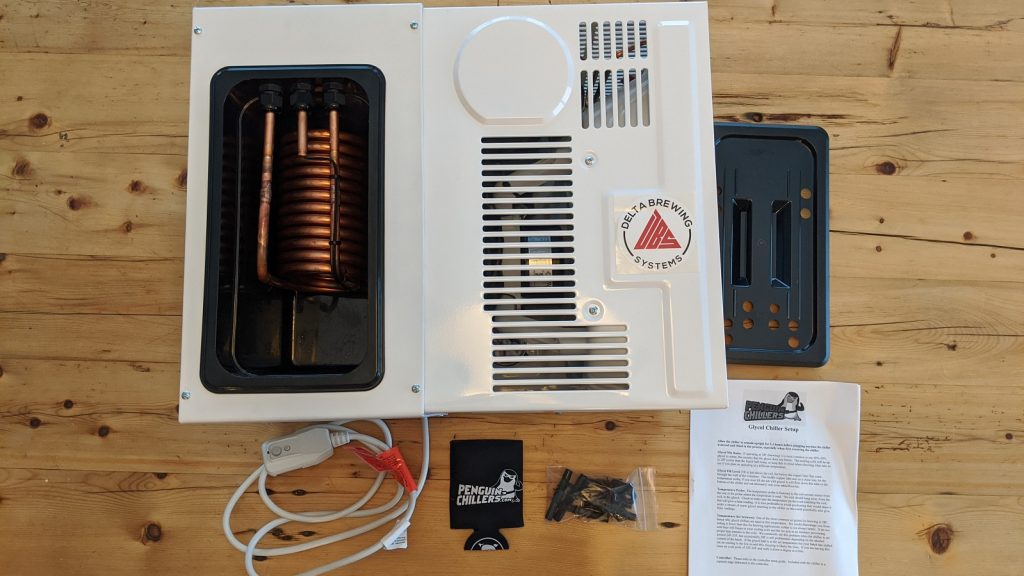

The Penguin glycol chiller I received is 1/3 horsepower and has the ability to connect to 4 different fermenters at the same time. Within a week of agreeing to the review, I received a well-packed box containing the glycol unit.

Once out of the box, I took inventory of all the pieces to ensure everything was there before proceeding with putting it all together.

It’s important to note this unit does not include pumps, tubing, temperature controllers, or fermenter-specific chilling coils.

Assembly & Use

Having never used a glycol chiller before, I wasn’t sure what to expect and was pleased with how little assembly was actually required. From the backside, the chiller looks similar to small air conditioner, and the manual says it provides 2200 BTU per hour when set to 28°F/-2°C.

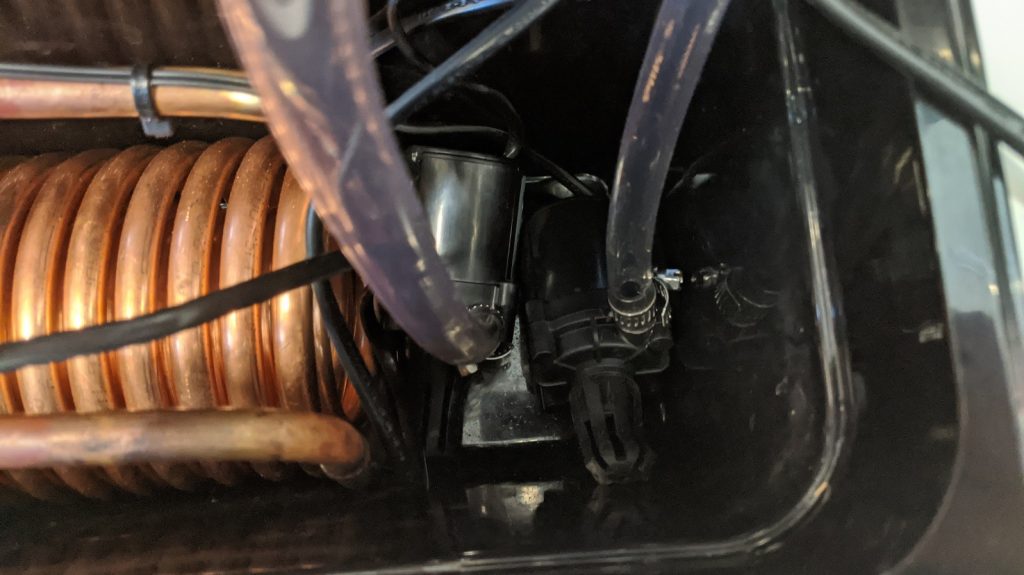

Looking down on the unit, one can see the copper coil attached to the wall of the 1.25 gallon/4.73 liter glycol reservoir.

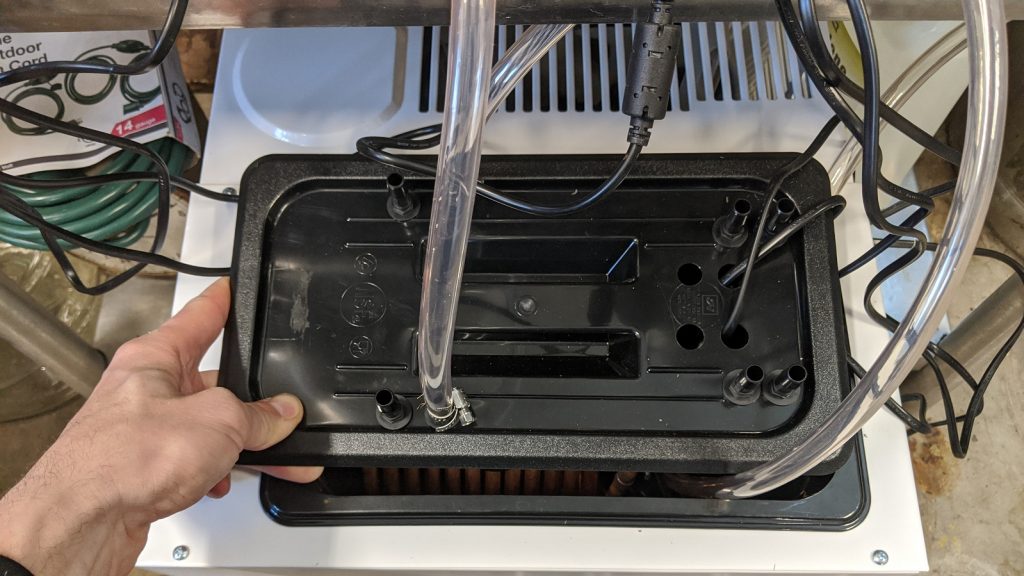

After attaching the barb fittings to the reservoir lid, I secured tubing onto the barbs as instructed.

I then attached the tubing to 2 submersible pumps and placed them in the glycol reservoir.

Next, I added a 50/50 mixture of polypropylene glycol and water to the reservoir.

Finally, I turned the unit on and set the controller to chill the glycol solution.

While the unit can get the glycol as cool as 5°F/-15°C, I left it at the factory setting of 28°F/-2°C. Once the glycol solution is properly chilled, it’s ready for use. After connecting each pump to separate temperature controllers and securing the probes to their respective fermenters, I set each one to my desired temperature and let the chiller do its thing. When the fermenting beer gets to 1°F/0.5°C over my set-point, the pump kicks on and recirculates cold glycol solution through the coils submerged in the beer until the temperature drops. Once fermentation is complete, I set the temperature controller to 34°F/1°C to cold crash and leave it for a day or two before packaging like normal.

System Performance

In the time I’ve been using the Penguin glycol chiller, it’s done exactly what it’s intended to do—keep my fermenting beer at my desired temperature. Whether fermenting a lager at 50°F/10°C, an ale at 68°F/20°C, or both at the same time, this unit consistently keeps the beers within 1°F/0.5°C of my set temperature. Moreover, this glycol chiller allows me to cold crash in a matter of a few hours without fear of freezing the beer.

Due to this model being 1/3 horsepower model with a smaller reservoir, it does cycle quite often to keep the glycol solution properly chilled, particularly when fermenting beers at cooler temperatures or cold crashing. While a bit noisy, the unit does a great job of keeping the glycol cold.

Another convenient use for this glycol chiller is assisting in the initial wort chilling process prior to pitching yeast. Rather than continuing to run water through my immersion chiller to chill wort those last 10°F/6°C, I can transfer it to my fermenter and run the glycol chiller for about 10 minutes to get it down to my desired pitching temperature.

| The Verdict |

Overall, I’m very pleased with the Penguin glycol chiller and appreciate not only how it has afforded me independent control of multiple fermentations, but that it takes up significantly less space in my brewery. Simple, easy to use, and effective.

In considering potential cons of this particular product, I would like to see the plastic reservoir lid replaced with something more sturdy like stainless, which in addition to being more durable would better hold it in place. Also, the constant cycling of the unit is a bit noisy, though nothing some good brewing music can’t cover up.

The Penguin Chillers 1/3 horsepower glycol chiller is undeniably more expensive than a chest freezer fermentation chamber, especially considering the additional gear required to make it work properly, though compared to other similarly sized glycol options, the price is reasonable. This may not be for everyone, but in my opinion it’s an excellent option for those interested in independently controlling the fermentation temperatures of multiple batches of beer while taking up a minimal amount of space.

The Penguin Chillers Glycol Chiller is currently available at Delta Brewing Systems in various models. If you have any questions or thoughts about this product, please leave them in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

19 thoughts on “Product Review | Penguin Chillers Glycol Chiller”

I have a similar glycol chiller and I’m trying to dial in the set temp so as not to overshoot the cooling of the fermenting wort. I have the set temp at 30f and am experiencing overshooting, activating the heating pad. Do you have any general thoughts as to the optimum temp differential to maintain a more constant environment? I’m thinking of trying a 15-20f differential on my next ferment.

You probably need to slow your glycol flow down to the fermenter, usually with a ball valve. That will let your fermenter chill slow enough that it wont overshoot before the temperature probe picks up the change.

A cheaper option I’ve just set up is an aquarium chiller. They start at about £200 for a proper compressor version. I’ve got it set up cooling a picnic cooler full of water via a cheap aquarium pump, then have another pump controlled via inkbird which pumps the cooled water through a coil in my fermenter. The chiller can cool the water down to 3c so can do lagers with ease and it can get the fermenter down to 4c for cold crashing. Overall I’m happy with it and it’s much more affordable than glycol, but can be packed away which is handy as I don’t have room for a fermentation fridge.

Can you go into more detail? What unit did you end up settling on? Does it keep the water chilled enough for cold crashing?

I have an SS Brewtech ftss chiller that’s in a picnic cooler, but am getting tired of changing the ice :).

Buy a cheap chest freezer and inkbird temp controller. Set to 36 or 38 degrees F. Fill a trash can or corny keg with water and glycol, a cheap submersible aquarium pump and run a supply and return line outside the freezer. You can either install copper lines around your fermenter or make copper coils and put inside your fermenter. Let the pump run as long as you are fermenting and control the on off flow with a solenoid. You can use several T’s and solenoids for multiple fermenters. Pick the right size water container and still have plenty of room to store your beer. All for a few hundred dollars.

This sounds too good to be true…?

I don’t know of any videos doing exactly what I did with the freezer but there are many making DIY chillers and coils to use in your fermenters. If you are handy and like to tinker, check YouTube on DIY brewing.

I agree. I think the advantage of a real glycol unit is greater BTUs that aid in cold crashing. But if you don’t care about cold crashing and the bigger footprint of a full size freezer why go to the extra expense.

You are right. But, you can still cold crash down to the temperature of the freezer. It just takes longer to get there. Previously, I did the YouTube thing converting a window ac and a plastic cooler into a glycol chiller and it worked pretty well since I left the whole thing outside. (I didn’t want the ac condenser exhaust heating up my house) I just ran the glycol lines thru the wall to the fermenters. I live in Florida so I shaded the AC and added spray foam inside the cooler lid. After a couple of years I tried the freezer with a wood collar to raise the lid. (Youtube). I wanted to keep more kegs cool and chill my fermenters at the same time. It is not perfect, but it works for me. And a lot cheaper than a Penguin Glycol Chiller. YouTube is your friend !

You mention that this is a cheaper option compared to alternatives. What’s the MSRP? Surprised that this purpose specific device, doesn’t include pump, tubing, or coils. How much to actually turn it into something useful?

Also, how do I use this? You mentioned that you attached it to a coil and put it in your fermenter. Any pics of that process? Or how you would use it to chill to pitch temps? How long did it take to chill to pitching temps?

I appreciate what you are doing, but this review seems a little thin.

Peace and Love,

Ben

A 7 cu ft freezer at Best Buy is just over $200 and a 10 cu ft is just over $300. There are no accessories, just like there are NO accessories with the $1000 glycol cooler. Not even the $30 – $50 glycol.You can buy a roll of 1/4″ copper for around $40 which you can roll into 3 copper coils to install inside or outside 3 fermenters. Add a blanket if outside coils. An aquarium pump at 270 gph is less than $20 and plastic tubing is also about $20. Throw in a few plastic valves and misc plastic fittings $20. A few solenoids $30. A trash can to hold 3 to 5 gallons of water $15, And now you can cool 3 fermenters and still have room for a few 5 gallon kegs. Since you are probably partially cooling your beer before going into your fermenter, an extra hour won’t make any difference cooling from 90 degrees to 65 degrees. Total cost is most likely $375 to $475 which includes everything. Unlike a $1000 chiller.

Some pics of how this attaches to the fermenters would be helpful. Having never used glycol before, this review left more questions than answers.

I think the price should be included in reviews. “…more affordable than other options…” means something different to each of us.

This unit is $879.00. It is a simple statement and there is no reasonable cause to exclude it from the review.

https://www.deltabrewingsystems.com/collections/chiller/products/1-3-hp-glycol-chiller

And that is with only 1 year warranty. How many refrigeration compressors have less than 5 years. Also. that price is only the unit. Nothing else. Not even their $41 glycol.

I have the 1/2 hp version and couldn’t be happier! People are complaining that it doesn’t include pumps, etc, however all that comes with the SSB unitank or Spike conical when you get the right package. They sell it too if you want to go that route. Also, their quick disconnects are the best! Friends have used several competitors versions and are always complaining but Penguin’s have been perfect. Also, it’s American made and their customer service has been great. I’ve seen a lot of Facebook posts complaining about SSB versions leaking and/or quickly failing because of Chinese manufacturing but I’ve seen nothing bad about Penguin AND it’s less money than the SSB versions of similar hp.

I honestly think when comparing products to homebrewers you should compare to cost of a refurbed beer line chiller, considering how similar they are. I purchased a nearly new Vision V15 beer line chiller for £300 with a 30L reservoir. It cycles only 2 times in 24hrs when maintaining fermentation temps.

All you do is remove any beer line coils and fit a cheap diaphragm pump and reinforced silicone tubing on the outside, hardly any more work than setting up one of these.

I think like for like they’re also built to a higher spec (stainless steel instead of plastic cooling coils, larger resevoirs) for less $$$ (simply because refurbed units are much more abundant). Pair this up with a Brewpi temp controller and your running like a pro.

All of this put together cost half the price of a new equivalent SS Brewtech or Penguin chiller and frankly does a better job than any temp controller bundled (or not) with chillers targeted for homebrewers.

I realise that second hand VS new may be an unfair comparison, but even new, small beer line chillers may offer better value given the selection, spec and warranty

I understand companies have to make money. But, I think making something DIY that works as well as a commercial device is much more rewarding, can be shared and talked about with friends and can save you a good deal of money (so you can buy more beer supplies)

We appreciate the comments regarding our Penguin Chillers products. You can view our entire product line on our website at http://www.penguinchillers.com. You can also read product reviews and discussions from actual customers by looking us up on our social media accounts. You’ll find us on Facebook, Instagram, twitter, Youtube and more.