Author: Phil Rusher

Fermentation is the process whereby yeast produce carbon dioxide (CO2) and alcohol through the metabolization of sugar, which in the case of beer is largely maltose and maltotriose provided by malted barley. While the good majority of beers are brewed using all malt, some brewers rely on simple sugar additions for various reasons, the two most popular options being sucrose (table sugar) and dextrose (corn sugar).

One style of beer in which such sugar additions are routine is Double IPA, the goal being to boost the alcohol content while contributing minimally to aroma, flavor, or mouthfeel, which many feel improves drinkability. Due to concerns of imparting beer with cider-like flavors, dextrose is commonly recommended for such purposes, though there are some who report satisfactory results using sucrose.

I was admittedly skeptical of the concerns voiced by some about using sucrose in brewing, and my positive experience doing so was quite validating. However, results from a past xBmt showing tasters could tell apart Belgian Golden Strong Ales made with either sugar caused me to question this conviction enough to put it to the test again in a Double IPA.

| PURPOSE |

To evaluate the differences between a Double IPA made sucrose and one made with dextrose.

| METHODS |

Given the common usage of simple sugars in Double IPA, I thought it a good style for the repeat xBmt.

Novum Comum

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 106.7 IBUs | 5.6 SRM | 1.071 | 1.012 | 7.8 % |

| Actuals | 1.071 | 1.006 | 8.7 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| BEST Pilsen Malt (BESTMALZ) | 5 lbs | 35.24 |

| Lamonta American-style Pale Malt (Mecca Grade) | 5 lbs | 35.24 |

| Vanora Vienna-style Malt (Mecca Grade) | 2 lbs | 14.1 |

| Carapils (Briess) | 8 oz | 3.52 |

| Sucrose (or 2 lbs Dextrose) | 1.687 lbs | 11.89 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Loral | 20 g | 60 min | Boil | Pellet | 10.5 |

| Citra LupoMax 2019 | 40 g | 10 min | Boil | Pellet | 18.5 |

| Sabro LupoMax 2019 | 40 g | 10 min | Boil | Pellet | 19.5 |

| Citra LupoMax 2019 | 20 g | 10 min | Boil | Pellet | 18.5 |

| Sabro LupoMax 2019 | 20 g | 10 min | Boil | Pellet | 19.5 |

| Sabro LupoMax 2019 | 50 g | 5 days | Dry Hop | Pellet | 19.5 |

| Citra LupoMax 2019 | 35 g | 5 days | Dry Hop | Pellet | 18.5 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Pub (A09) | Imperial Yeast | 72% | 64°F - 70°F |

Notes

| Water Profile: Ca 60 | Mg 3 | Na 27 | SO4 125 | Cl 50 |

Download

| Download this recipe's BeerXML file |

I made two large yeast starters of Imperial Yeast A09 Pub a couple days ahead of time.

When brew day arrived, I weighed out and milled two identical sets of grain.

I then collected the water for both batches, adjusting each to my desired profile before heating them to the same strike temperature, at which point I incorporated the grains.

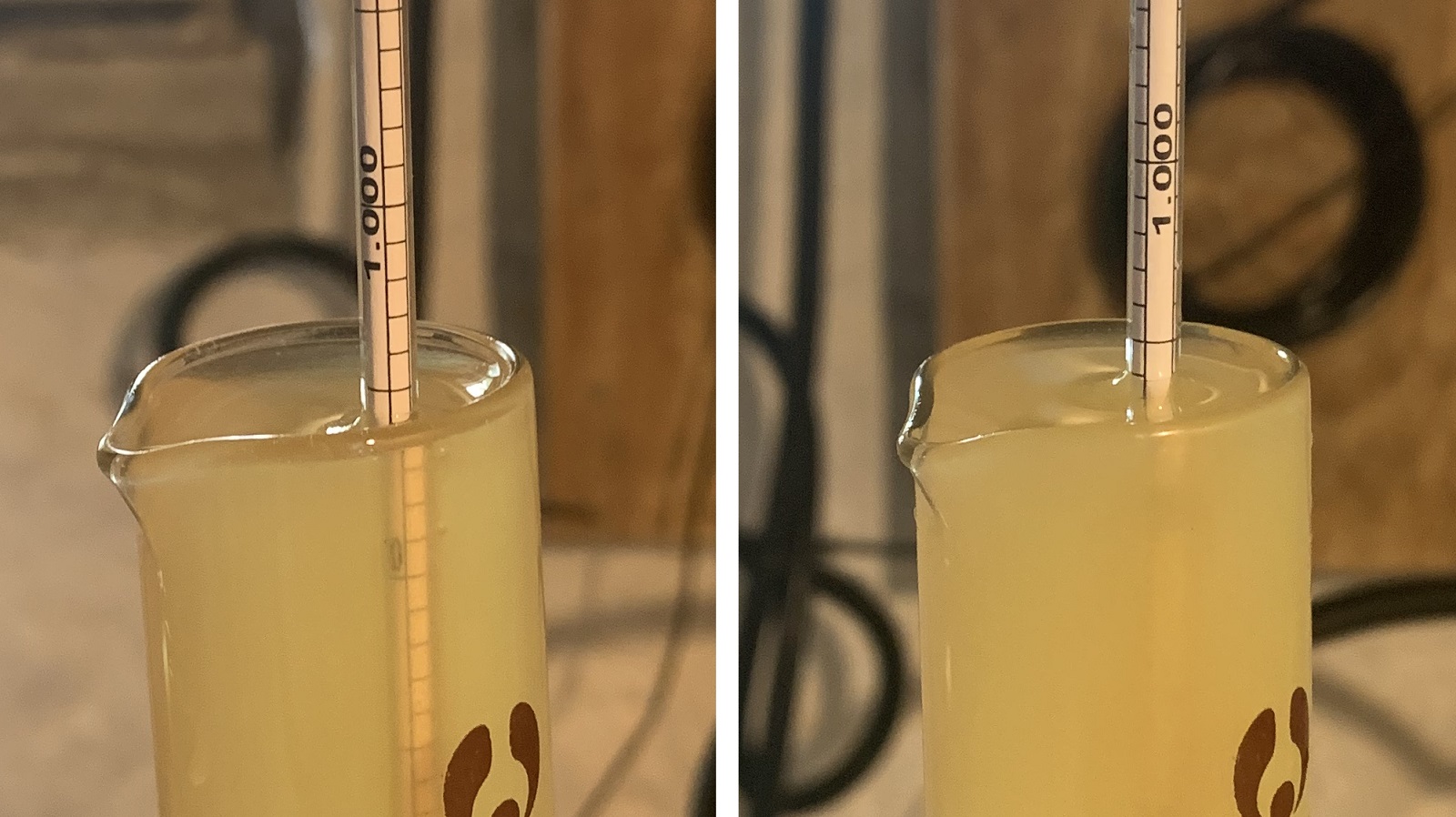

While the mash was resting, I measured out the sucrose and dextrose, the amounts of each adjusted to ensure both reach the same OG.

When each 60 minute mash rest was complete, I removed the grain baskets and let them drip into their respective kettles while heating the wort.

I then proceeded to measure out the kettle hop additions for both batches.

At 15 minutes into each boil, I added the sucrose to one batch and the dextrose to the other.

When the boils were finished, I chilled them with my CFC on their way to sanitized carboys.

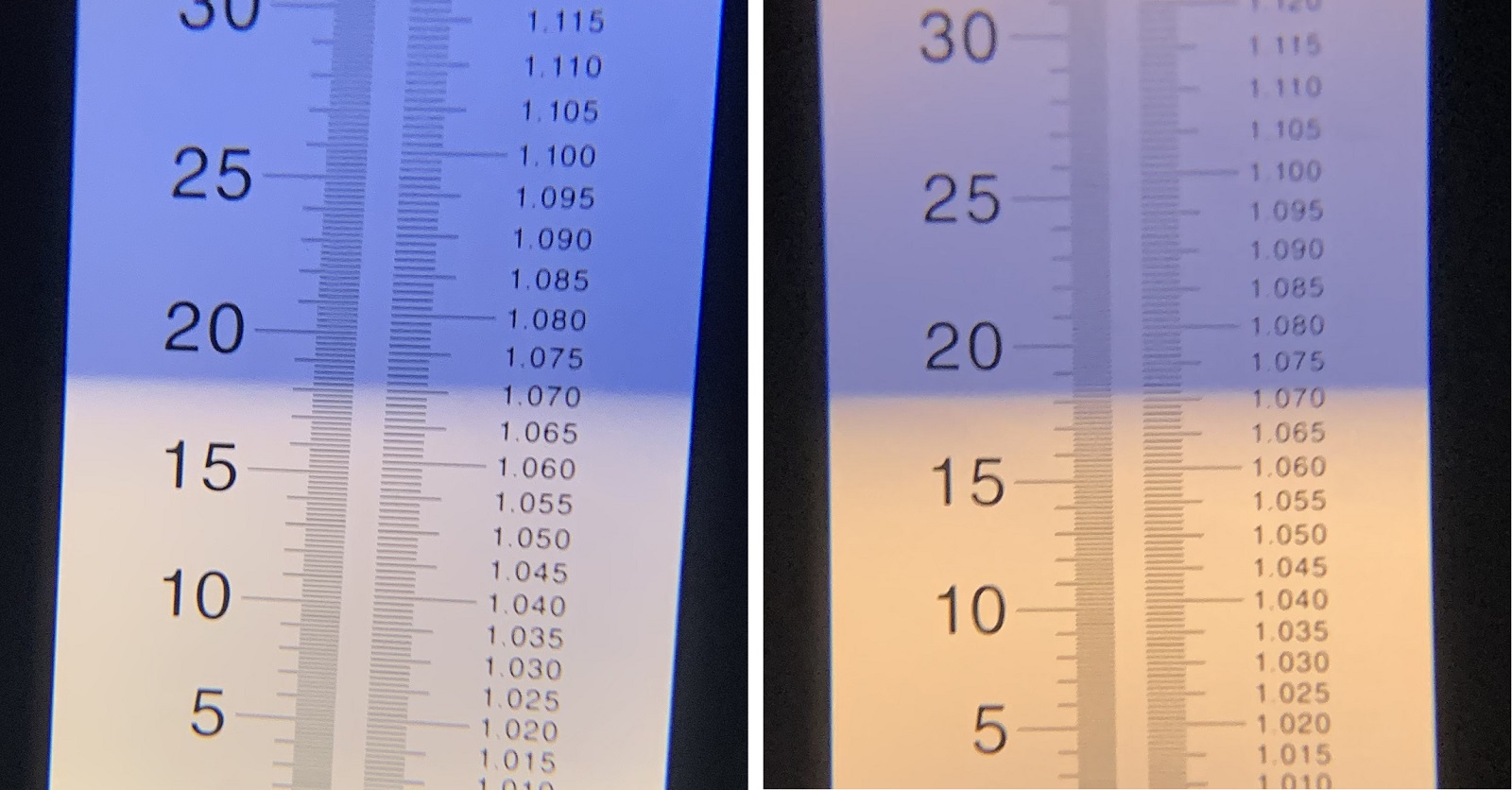

Refractometer readings showed the worts had indeed reached the same OG.

The filled fermenters were placed in my chamber controlled to my desired fermentation temperature of 65°F/18.4°C and pitched the yeast. Activity in both beers kicked off in a few hours and began to wind down 4 days later, which is when I added the dry hops.

I let the beers mingle with the dry hops for 6 days before taking hydrometer measurements showing both finished at the same FG.

The beers were then racked to sanitized and CO2 purged kegs.

The filled kegs were placed in my keezer, burst carbonated, and left to condition for a a few days before I began my evaluations.

| RESULTS |

Due to social distancing practices as a result of the COVID-19 pandemic, data for this xBmt was unable to be collected in our typical manner. As such, temporary adaptations were made involving the author completing multiple semi-blind triangle tests in as unbiased a way as possible.

Utilizing 4 opaque cups of the same color where 2 were inconspicuously marked, one set was filled with the beer made with sucrose while the other set was filled with the beer made with dextrose. For each triangle test, 3 of the 4 cups were indiscriminately selected, thus randomizing which beer was the unique sample for each trial. Following each attempt, I noted whether I was correct in identifying the unique sample. Out of the 10 semi-blind triangle tests I completed, I needed to identify the unique sample 7 times (p<0.05) in order to reach statistical significance, which is exactly how many times I did (p=0.02), indicating my ability to reliably distinguish a Double IPA made with 12% sucrose from one made with 14% dextrose.

I felt both of these beers were solid examples of Double IPA and enjoyed drinking them immensely. To my palate, the one made with sucrose had a slightly sharper bitterness that worked well for the style, though the softer bitterness of the dextrose version was also rather pleasant.

| DISCUSSION |

Using simple sugars like sucrose and dextrose as a means of upping alcohol content while contributing little else to beer has been occurring for a long time, and two of the more common types of sugar used in brewing are sucrose and dextrose. It’s been claimed sucrose can impart beer with certain flavors some find undesirable, and hence the common recommendation to use dextrose, though others believe any differences are small enough to be unnoticeable. My ability to consistently distinguish a Double IPA made with a portion of sucrose from one made with dextrose supports the notion these two sugars do produce unique characteristics.

Unlike a previous xBmt on this same topic, I opted to adjust the amounts of each type of sugar used so that both beers would achieve the same OG, which resulted in the dextrose batch receiving 5 oz/142 g more sugar by weight than the sucrose batch. While it’s possible this was the reason for the perceived difference, the fact the results corroborate those of said past xBmt indicates it may actually be a function of the type of sugar used.

I don’t brew with simple sugar too often and had’t put much thought into whether to go with sucrose or dextrose, but my experience with these beers has certainly influenced my thinking. I found it interesting that contributor Matt Del Fiacco described his Belgian Golden Strong Ale made with sucrose as having a “harsh” character not present in the dextrose version, as it sounds similar to what I perceived as a sharper bitterness in the Double IPA I made with sucrose. However, while Matt preferred the dextrose BGSA, I preferred the sucrose DIPA. Perhaps rather than writing one type of sugar off completely, the best approach involves choosing the one that best suits the style being brewed, just as we do with all other ingredients.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

39 thoughts on “exBEERiment | Sugar Additions: Sucrose Vs. Dextrose In Double IPA”

In these days of DUIs and liver failure, I am not sure why anyone wants to increase alcohol levels in a good beer. As you said, you were not trying to change flavor or mouth feel.

Oh please. Enjoying a nice 9% ABV beer is as dangerous as enjoying a glass of 12% ABV wine, or a good martini, or a 2,000 calories slice of cake. We’re adults. We don’t need lecturing.

If the original intent was only to increase alcohol and not change anything else, why do it ? Just drink a bottle of 151 instead.

That’s a false equivalence if I’ve ever seen one!

Want to explain why?

Would you care to explain how drinking a bottle of 75% alcohol is equivalent to increasing the ABV of a beer by something like 1.5% by using simple sugars?

If you make a good beer and only want to increase the alcohol, I would think it is because you want to feel high or drunk. Not because it makes the beer better. So 151.

Ignoring all of the assumptions and judgements you’re making, it’s impossible to equate 75% alcohol to a moderate strength beer.

Sorry if I offended everyone. I just love beer and not high alcohol content. That way I can enjoy more of the best beverage on earth.

We can still be friends!

So a comparison to honey next?

I like it!

Based on the molar mass of sucrose and glucose (dextrose) you would have expected to add different amounts of each. So your 1.687 lbs of sucrose, is equivalent to 1.900 pounds of sucrose.

I know you adjusted for gravity, but this means your Mash gravities were not identical. Ideally, you would have done one mash/sparge and split that – then added sugars.

The conclusion here could be that you are tasting the difference in the mash efficiency or a combination of sugar and mash efficiency or as you were hoping to test just the sugar.

One hypothesis about why sucrose is not as good is because the yeast has to breakdown the sugar with the enzyme invertase, so the yeast has work harder and in a bigger beer where yeast is stressed more that this can make a difference in flavor,

A good followup would be to use sugar to make invert syrup and then compare that to an equivalent amount of sugar.

You’re neglecting to account for things like anti-caking agents. The gravity contribution from each of these sugars as well as the mash conversion was the same.

You are right that I didn’t think about anti-caking reagents. As a chemist, I don’t usually have to worry about those! Any idea what the percentages would be? I know for salt it’s generally very low 0.2-0.7% and powdered sugar is between 2 and 5%.

Sucrose is more crystalline, so I would think significantly less anti-caking than say dextrose/glucose. The numbers you used would indicate that the amount of anti-caking stuff is at least 5% more in the dextrose, which seems really high to me. (And something to think about in the future)

How close were the pre-boil gravities?

The invert sugar vs sucrose experiment I suggested might help get at the cause of the difference.

I don’t know how much filler/anti-caking is used for either of these without googling! But I know that they’re used in the production of both sucrose and dextrose. Pre boil gravities were again identical.

It is easy to match predicted gravity contributions from different sugars when using recipe builders like Beersmith because all one needs to do is input all of the grain before adding the amount of sugar needed. For me, I had 2 lbs of dextrose I wanted to use up and that was my starting point for sugar additions. Without including sugar in the recipe, the expected OG was 1.058, but with 2 lbs of dextrose it jumped up to 1.071. After substituting sucrose for dextrose I simply dialed back the quantity of sucrose in the recipe until I arrived at the same targeted OG of 1.071.

As I recall, dextrose is sold as a monohydrate and sucrose is anhydrous, so make sure to keep that in mind when doing your calculations. I’d wager that would make a much bigger difference than accounting for any trace anticaking agents.

I’ve missed something here. Chris says the mash gravities are not identical. But weren’t the grain bills the same for both batches? And the sugar was added to the boil, correct? If this is the case, the mash gravity (and thus pre-boil gravity) would have to have been the same since sugar gravity contribution and OG were both the same for both batches.

Right, Chris was assuming the mash gravities were not identical, when in fact they were the same.

Dextrose typically has 5% moisture according to all the info on brewing sites.

I’ve been looking for info on the flavour threshold for invertase for ages. The only time I heard mention of it was on a podcast (can’t remember which one) but the brewer didn’t expand on it.

I did an experiment called “Not a kit and a kilo” doing a full grain vs a sugar replacement (4.3kg of base malt vs 1.6kg + a kilo of sugar) and the sugar beer was unnervingly good and very a typical British pub pint. Later someone asked me when I put the sugar in and if it was at the start of the boil could it have been inverted during the boil. I honestly didn’t note it down so the experiment needs repeating.

Also on a podcast a brewer was saying they need to adjust for bitterness when using invert sugar because of it’s different sweetness to sucrose.

But keep that in mind that he put the sugar at the beginning of boil so the acidic environment and long boil time might have broken those chain in two parts hence changing chemical structure.

This talk of corn vs table sugar lately has made me want to use up some corn sugar I have lying around. Not for experiments but just for drying out a beer. Maybe a Bitter??? Nice work!

Just a note from the typo division of the internet police: the 10 min hop additions might be off.

There’s always at least one member of the internet public editors 🙂

Right, that is a typo that’s derived from the Beersmith xml file. The 40g hop additions were added at 194F/94C for 10 minutes.

Great exBEERiment!

Any noticeable difference in taste using the Lupomax as compared to normal hop pellets?

This was my first time using Sabro and you can count the times that I’ve used Citra on one hand because I don’t really care for it (blasphemy, I know!), not to mention the fact that I hardly ever make IPA, so I may not be providing the best insight here. However, I will say that the LUPOMAX versions of these varieties were quite interesting. It was as though all of their inherent characteristics were magnified to the MAX (see what I did there?). And when using what can be easily described as an excessive amount of hops for a DIPA, being able to cut back on 30% or more of the plant material is dope.

A timely experiment. I just brewed up an IPA (Centennial and “Experimental Grapefruit” that YVH was selling a while back) and added about a half pound of table sugar. Took the first pint out after a week. I liked it but my wife said “it’s kinda sharp”, referring to the bitterness.

The plural of anecdote is not data but it still can be interesting.

Indeed, plurality =/= causality. Irrespective of simple sugars used, though, the bitterness and sharpness that we perceive (among other things) are relative to IBU, water profile, and malt as well. If you tweak the ingredients and water the right way, it is totally possible to make a 100+ IBU IPA that does not have any overly sharp or bitter-beer-face characters.

Hey Phil!

Great Exbeeriment! I have a random question about your closed transfer from fermenter to keg. I have the same Fermonsters and I’m wondering if you are racking with pressure and if you are using a something specific in the bung to make that happen? Any help would be great as I’ve been struggling how to closed transfer with my equipment.

Thanks!

Thanks, man. It was a fun one to do. To be clear, my transfer to kegs is anything but closed. In fact, it is very much open; you can’t see it but the tops of the FVs simply have a sanitized paper towel over the bungs. Eventually I’ll be looking to get a different setup that doesn’t rely on gravity, but for now, this is where we’re at!

That said, I don’t know if I’d trust the Fermonsters to hold any pressure for closed transfers. Sorry this probably wasn’t the answer you wanted to hear!

No that’s perfect. To know that you are doing it with just gravity is a better step than my current siphon set up. Thanks for the reply!

I use Fermonsters too and found a simple solution for minimizing O2 during transfer. I cut a piece of a plastic bottling wand and stuck it in some tubing, connected the tubing to my CO2 line so I can stick the wand into the hole on the #10 stopper on the carboy as soon as I pull the airlock. It’s a good fit and just a little bit of pressure allows me to push the beer to the keg with almost no O2. You just have to keep a close eye on the pressure so you don’t go too much or too little (the Fermonster will start collapsing on itself if too little, too much will blow the stopper off). My process is to turn on the gas, insert the wand, quickly attach carboy line out to the keg liquid post so it fills from the bottom. Beforehand I purge my keg and on the gas side I connect a pin lock with a very short tube that has a vodka filled airlock attached to release the pressure as the keg fills.

It’s a clunky description but the process works great for me (easy and cheap!) and since moving to this method I have seen a significant increase in hop aroma and flavor that lasts through the life of the keg (especially with traditional carb times, the burst carbing process seems to blow off some of that hoppy aroma.)

Thanks for all you guys are doing! Long time fan of Brülosophy!

This is great, Dan. Thanks so much!

I just liked that it was Wegmans sugar.

My man!

An good Exbeeriment!

I would be interested in whether or not the significance found was due to yeast struggling to metabolise a disaccharide (Sucrose) vs dextrose (Glucose) a monosaccharide.

I’d love to see whether or not two monosaccharides, glucose and fructose, could return a similar result. This would narrow down the variable to see if yeast stresses when breaking down more complex sugars as opposed to the simple sugars themselves parting different characteristics.

Can I add dextrose to make a dipa, without boiling it, and still achieve my intended higher og? Thanks

I’m assuming you mean that you want to add sugar directly to your fermentation vessel? You can do it this way, but you risk contamination issues as well as sugar not being fully utilized because it’s not in solution. I’d recommend a quick boil and cooling it down before adding it to the FV.

My intention was to attempt a no boil brew session so I’m essentially asking if the dextrose will fully incorporate properly at whirlpool temps. It’s purely being used to up my fermentable sugars without adding grain.

Oh, I see. Yes, you can use sugar at whirlpool temps. Again, for contamination concerns I’d do something around 180F in this case. You may also want to double check that the sugar fully dissolves.