This xBmt was completed by a member of The Brü Club in collaboration with Brülosophy as a part of The Brü Club xBmt Series. While members who choose to participate in this series generally take inspiration from Brülosophy, the bulk of design, writing, and editing is handled by members unless otherwise specified. Articles featured on Brulosophy.com are selected by The Brü Club leadership prior to being submitted for publication. Visit The Brü Club Facebook Group for more information on this series.

Authors: Mike Olivier & Josh Sharp

Advocates of pressure fermentation maintain that lager qualities can be accomplished by pressure-fermenting similar those of traditional fermenting. Acetates and other 30-plus esters created during the fermentation process can produce a fruity flavor profile, which is undesirable in many lagers. One of the purposes of traditional lagering is to suppress the formation of esters during fermentation and conditioning through cold temperatures. The assertion is that ester production is inhibited by pressure fermentation below that of traditional fermentation. Traditional lagering can take weeks and months to develop the desired flavor profile. A relatively new trend in lager home brewing (pressurized fermentation at ale temperatures) can significantly reduce the time from kettle to bottle by using pressure to inhibit ester formation.

A few commercial breweries have installed tall, slender fermenters (two-stories in height) to create hydrostatic head pressure (on the order of 15 psi) on the yeast at the bottom of lager fermenters. Every two feet of fermenter height creates 1 psi in hydrostatic pressure. On the home brew scale, creating this pressure to inhibit ester formation via hydrostatic pressure is unrealistic. There is a method for creating pressure in the fermenter on the home brew scale with the use of a spunding valve to control fermentation pressure.

A similar recent experiment in 2017 was conducted by Chris White (WhiteLabs) and John Blichmann (Blichmann Engineering) to perform quantitative and qualitative testing. They brewed a split batch of a Munich Helles. Fermented with WPL-833 high pressure yeast (4 packs per 5 gallons to match lager rates). The beers were sampled by the general public at a state fair. They were asked to comment on any taste differences. There was no formal triangle test.

| PURPOSE |

To evaluate the differences between a pale lager fermented under pressure at ale temperature and one fermented under no pressure at traditional lager temperature.

| METHODS |

For this xBmt, we chose a clean Czech Pilsner recipe using just Pilsner dry malt extract and Czech Saaz hops to keep things simple.

People On Streets

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5 gal | 75 min | 23.0 IBUs | 3.1 SRM | 1.048 | 1.012 | 4.8 % |

| Actuals | 1.048 | 1.007 | 5.4 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pilsner Dry Extract | 5.75 lbs | 100 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Saaz | 38 g | 75 min | Boil | Pellet | 4 |

| Saaz | 13 g | 10 min | Boil | Pellet | 4 |

| Saaz | 13 g | 0 min | Boil | Pellet | 4 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Bohemian Lager (2124) | Wyeast Labs | 71% | 48°F - 58°F |

Download

| Download this recipe's BeerXML file |

Given the point at which the variable of this xBmt occurs, we opted to brew a single 10 gallon batch of wort. Once the boil was complete, the wort was chilled and evenly split between two kegs of the same size before being dosed with pure oxygen at a rate of 1 liter per minute for 90 seconds to achieve 10-14 ppm. The traditional lager was chilled further to 55°F/13°C before the yeast was pitched, while the batch fermented under pressure was at 69°F/21°C; both received 4 packs of Wyeast 2124 Bohemian Lager yeast. The traditional lager was fermented in a chamber set to 45°F/7°F while the other was fitted with a spunding valve set at 15 psi and left in a room that averaged 68°F/20°C ambient temperature.

Following 8 days of active fermentation at the set temperature, the traditional lager was gently raised to 65°F/17°C for a 6 day diacetyl rest, after which the temperature was slowly reduced to 37°F/3°C where it was left to lager for 6 weeks.

The beer fermented under pressure reached a high of 74°F/23°C 6 days into fermentation, after which the temperature gradually reduced back to ambient. Over the 2 week fermentation period, the pressure in the keg ranged from approximately 13 to 19 psi.

While the traditionally fermented lager took 10 days to reach the expected 1.007 FG, the batch fermented warm and under pressure was there after just 4 days.

Once both beers were finished fermenting, equal amounts were transferred under pressure to smaller CO2 purged kegs.

In total, the traditionally fermented lager was ready for consumption in 57 days while the batch fermented warm and under pressure was ready in just 16 days.

| RESULTS |

In all, 15 Dayton Region Amateur Fermentation Technologists (D.R.A.F.T.) club members of varying levels of experience participated in this xBmt. Each participant was served 1 sample of the beer fermented under pressure at ale temperature and 2 samples of the beer fermented under no pressure at traditional lager temperature then asked to identify the unique sample. While 11 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, 12 did (p=0.013), indicating participants in this xBmt were able to reliably distinguish a pale lager fermented under pressure at ale temperature from one fermented under no pressure at traditional lager temperature.

QUANTITATIVE DATA

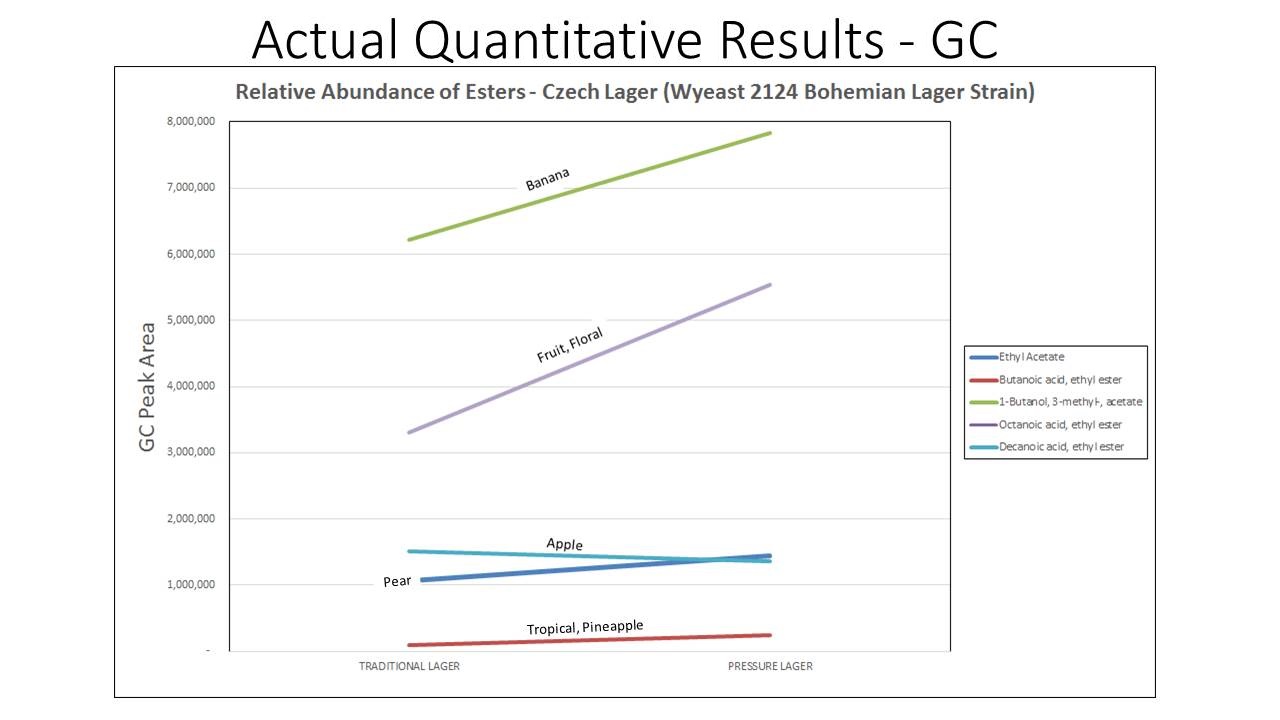

Samples of each beer were sent to the Bochman Lab at Indiana University Molecular and Cellular Biochemistry Department in Bloomington Indiana where they underwent gas chromatography (GC) to compare peak areas of certain ketones and esters.

The lab data confirmed the beers were indeed different, showing that the batch fermented warm and under pressure possessed more esters than the traditionally fermented lager.

| DISCUSSION |

Published articles on fermentation under pressure consistently assert that ester levels are lower in lagers fermented under pressure at ale temperatures than those fermented at traditionally cool temperatures with no pressure. The results from this xBmt did not validate this claim, as not only were tasters able to reliably distinguish a traditionally fermented Czech Pilsner from one fermented warm and under pressure, but lab testing showed the latter possessed higher levels of esters.

While talk of the pros of pressure fermenting lagers warm is quite generalized, it’s possible the impact of such conditions are yeast dependent and that other strains would produced different results. It’d be interesting to conduct the same experiment using yeast strain known to produce a higher amount of sulfur, for example, as perhaps the combo of higher pressure and temperature would restrain that particular characteristic. I’m also curious how factors such as increased pressure and yeast pitch rate might impact things.

Interestingly, the majority of blind participants indicated they preferred the lager fermented warm and under pressure over the traditionally fermented version. Given the lab data showing less esters in the traditionally fermented lager, I’ll likely be sticking to that approach in my own brewing, though I wouldn’t hesitate to bump the temperature and pressure up if I was ever in a pinch.

Mike Olivier lives near Dayton, OH and is a member of the Dayton Region Amateur Fermentation Technologists (D.R.A.F.T.) brew club. He is a consultant Project Manager for the Oil & Gas Industry and holds a Mechanical Engineering degree. He also works part-time as a Brew-On-Premises Technician at a local brewery, interacting with and instructing customers in the art and technology of craft brewing. As an engineer, Mike draws on technical and process industry experience to collect, integrate, and present data through the use of open source microprocessors and IoT platforms with emphasis on repeatability and optimization of processes. He is interested in experimentation and sharing what he learns.

Mike Olivier lives near Dayton, OH and is a member of the Dayton Region Amateur Fermentation Technologists (D.R.A.F.T.) brew club. He is a consultant Project Manager for the Oil & Gas Industry and holds a Mechanical Engineering degree. He also works part-time as a Brew-On-Premises Technician at a local brewery, interacting with and instructing customers in the art and technology of craft brewing. As an engineer, Mike draws on technical and process industry experience to collect, integrate, and present data through the use of open source microprocessors and IoT platforms with emphasis on repeatability and optimization of processes. He is interested in experimentation and sharing what he learns.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

42 thoughts on “The Brü Club xBmt Series | Examining The Qualitative And Quantitative Impact Of Fermenting Pale Lager Under Pressure At Ale Temperature”

I appreciate your method and presentation. Well done. I hope more can follow your example. “keyones” not “ketones”… That dam autocorrect!

Lovley work!

Thanks for exposing this, we at WilliamsWarn in NZ have been brewing under pressure at high temperatures for years and really believe that is the reason our customers love their beer so much.

We did a test with Whitelabs a couple of years back and have the data if anyone is interested. FYI we typically ferment lagers around 25 Deg C but have fermented up to 33 Deg C without a problem and can have a lager crystal clear ready to drink in 7 days

I love my WilliamsWarn BrewKeg! Been pressure fermenting for about 3 years. So glad I did not go with those cheap plastic pressure fermentors that dent, crack and leak! Then need to be replaced often.

33c??? Wow.

What kind of yeast? Amazing!!

Really well done! Thanks for all of the work on this one!

Really nice work! It’s great to see some quantitative data along with the qualitative data. I wonder what the CG would relieve on warm vs cold fermented lagers without pressure?

What was your preference reg or pressure? And why?

Great job!

Used 15 psi as the regulating pressure. The previous experiment by Chris White and John Blichmann indicated that 15 psi is the “sweet” spot for pressure fermentation. Higher pressures tended to produce results that drifted too far away from lager characteristics.

Preferences data from the tasters?

Would be interested see how 3470 performs as ferment is has published some great data as well indicating temperature matters little.

Also would be interested to see a more moderate temper under pressure, 58-60f at 15psi, compared to 45F.

Excellent high quality work here! Way to go!

They said “Interestingly, the majority of blind participants indicated they preferred the lager fermented warm and under pressure over the traditionally fermented version. “

Hey Dan, yes it was interesting that most tasters liked the warm pressure fermented one, another thing we found is that women like the beer more from pressure ferments but I suspect that is something to do with less oxidization which we can manage

I say interesting because there were some BJCP-certified judges in the group that I assumed would have preferred the traditional lager beer. I was surprised.

Individual score sheets were filled out by the participants with preference comments.

Yep, pressure fermentation was conducted at basement temperature beginning at about 69°F and naturally rising to about 74°F. This also confirmed the notion that fermentation temperature rises during active fermentation. In our case, it rose about 5°F.

Another interesting one!

I wonder how much of the effect was due to the lagering phase of the traditional beer? I have noticed that my ales start to taste more lager-like after 6 weeks in the keg, and young lagers taste more ale-like until some lagering time passes

.

Were both beers 57 days old at the time of tasting/testing? How was the warm pressure beer stored for the extra 41 days?

Or did you send the warm sample to the lab after 16 days and sent the traditional sample to the lab after 57 days?

Sensory sampling was done at the same time for both beers. Both samples were sent to the lab at the same time after F.G. was reached on the traditional lager.

This is incredibly well done. I personally appreciate the detail of equipment and process that makes it much easier to reproduce. My lager process generally revolves around brewing 15 gallons at a time and letting it lager while I pull off pints for a few weeks! Eventually it’s lagered long enough.

I’m just curious why you used 4 packs of yeast for each 5 gallons. That seems like an excessive over-pitch of yeast for a lower ABV beer. I’m probably missing something, so please enlighten me.

Pitch rate for lagers it’s typically twice that of an ale.

Any idea how look the pressurized fermentation took to reach 15 psi? I’m not sure how it’s done in a professional setting, but I wonder how much ester formation took place before the keg actually got up to pressure.

I would estimate about 3-4 days. Its amazing how much CO2 is produced in fermentation. I use the CO2 to naturally purge my serving keg while primary fermentation is underway.

I heard that fermentation produces approximately 40x the volume of beer being fermented.

Evan, I misunderstood your question. Once the Adaptation Phase completed and active fermentation began it was within a 7 to 10-hour period (estimated from the pressure/temp graph) that the pressure reached 15 psi and it would have been higher if allowed. Active fermentation took about 4 days.

Regarding the time it took to reach 15 psi – It is tempting to apply 15 psi right at the start after pitching to control esters. However, pressure lowers yeast growth therefore it’s recommended to allow pressure to build as fermentation progresses without fully pressurizing the keg with CO2 from the start.

We have done tests on pressure fermentation to see the effect on esters and have some graphs from Whitelabs which show that most esters are significantly reduced by pressure fermentation.

If you are really concerned about it you can pressurize the vessel with Oxygen from the start instead of CO2.

I don;t know exactly how long it will take to get to 15psi as it will depend on the yeast and head space in the vessel but I have had 20psi in a BrewKeg10 after around 6.5 hrs and the head space was 20% of the liquid volume.

Tests were done at both high ferment temperatures and cooler and we find the higher temperatures to be faster and more complete. If you want the graphs please send me your email. Cheers Sam

Beautiful figures, great experiment. Of course I would have loved to see quant dat from a third condition with ale temps and normal atmospheric pressure. Cheers

these infographics are awesome!!!!

Great article! I routinely ferment my lagers using WLP830 under 15 psi at approx. 64 deg F. Now that you’ve published this you’re making me want to do a side-by-side to see for myself.

Does fermenting under pressure cause less or more krausen (foamy head during fermentation)? Quick google search says yes. In your experience does it to the effect that I could fill my corny keg rather than filling with 4 gallons? This alone would be a good reason to ferment under pressure. More beer= better. I think this might be a valid reason for the pros to do this also.

The more pressure you set the VPRV, the less krausen yes. There should be nobody that disagrees with this. They did 15psi and that will make krausen less. I ferment at 22psi and it is even less krausen. I don’t use a soda keg or corny keg. I have a purpose built WilliamsWarn BrewKeg that is a metal, conical pressure fermentor with sediment dump. It has a viewing port on top so you can see krausen activity.

Since the height of the Krausen is determined by the size of the bubbles you get ‘less’ krausen under pressure because your bubbles smaller. The gas is compressed and more gas remains in solution. I would suspect though that the solids in the krausen would be around the same

SInce fermentation was conducted in corny kegs, I couldn’t tell if more krausen developed under pressure. However, there was no blow-off of excess krausen. In subsequent pressure fermentations in kegs on other brews, there was no blow-off (and my keg was filled to about 4.5 gallons). One interesting observation on trub though – after I opened the de-pressurized keg after transfer, I waited 10 seconds and the yeast at the bottom bubbled violently – perhaps the release of pressure affected the cell walls much like an undersea diver experiences the “bends” when he ascends too quickly…

All the data presentations are really cool!

My takeaway from this is experiment is that shows that a lager fermented warm will contain more esters than a lager fermented cold, which is something we knew already, didn’t we?

I’m curious why you didn’t control for temperature in this experiment if the goal was to test the effect of pressure on fermentation.

Yep we already knew that a lager fermented warm will produce more esters – what we didn’t know was the effect of ester development under pressure. It was theorized that ester development would be inhibited by pressure. In our case, we could not verify this with the yeast we used. The idea was to determine the effects of ester development under pressure at ale fermentation temperatures. The fermentation temperature was allowed to float naturally (excluding the effect of pressure). A follow-up experiment could be set up to control the fermentation temp to say, 74°F throughout the entire primary phase under pressure.

Awesome, thanks for clarifying!

I agree this must be strain dependent. I tried this with lager strains other than w34/70 and didn’t like the result

Interesting. I’ve only tried w34/70 under pressure at 20psi and 75*f and results were awesome

Would be interesting to see next another quanitiative analysis of Pressure fermentation at ale temp vs Non-pressure at ale temp

What a good article!! I’d appreciate the graphs and sheets. We can learn such more with “small” details like this. Thanks for the effort.

One thing that I’m curious about is what concentration is the flavor threshold for the esters in question. Even though there was a measured increase in the warm-fermented beer, was it enough where a typical person would be expected to taste the difference?

I had good results when I tried WLP925 (High Pressure Lager Yeast), but I haven’t tried with other strains yet. I might have to give 34/70 a try under pressure now, since it is the dry equivalent of 2124.

Excellent observation! One limitation (due to time) is that we could not obtain concentrations from the CG analysis – only peaks areas. So we knew the relative abundances but not absolute abundances. It is quite possible that the actual abundances (in ppm) of the esters were below sensory threshold levels in both beers.

Nicely done and I love the addition of the gas cromatography data to verify that the warm+pressure fermented beer had more esters than the traditional lager.

Regarding the preference data, I think it just goes to show that the tasters prefer an estery ale-like beer to a traditional lager.

One wonders how much of the increased esters in the pressure batch were produced during the beginning of fermentation, before the CO2 built up to create pressure. IOW, would there have been a different result had the wort been cooled further and only allowed to rise once pressure in the fermenter had reached 15 psi?