Author: Brian Hall

Lagers are making a resurgence in the craft beer world, with professional and homebrewers alike brewing up styles like Pilsner, Munich Dunkel, and Schwarzbier, which offers drinkers a nice counterbalance to the adjunct-laden hazy hop bombs currently overwhelming the market.

While the term lager is presently a noun used to refer to a specific subset of beer, it started off as a verb that described the way certain beers were treated during and after fermentation. To put it simply, traditional lagers are fermented cool with lager yeast before being lagered, or allowed to mature at cool temperatures in the presence of yeast over an extended period of time. It’s this very process that’s credited by many as producing the quintessential crisp and clean characteristics associated with lager styles.

It’s often recommended to lager between 32°F/0°C and 40°F/4°C, which can be difficult for brewers who may not have the ability to precisely control the temperature of their beer. My typical approach, which is seemingly quite common, involves packaging the beer when it’s done fermenting then storing it in my keezer for a few weeks. However, this does take up precious space, leading some to resort to allowing their lager beers to mature at warmer temperatures. With warmer weather on the way, I was thirsting for some refreshing lager and decided to test this one out for myself.

| PURPOSE |

To evaluate the differences between a Czech Pilsner lagered at either 34°F/1°C or 60°F/16°C over 4 weeks.

| METHODS |

For this xBmt, I went with a simple Czech Pilsner recipe, as I felt it would be best exemplify any differences caused by the variable.

Sun Never Sets

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 34.8 IBUs | 3.5 SRM | 1.051 | 1.013 | 5.0 % |

| Actuals | 1.051 | 1.016 | 4.6 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pilsner (2 Row) Ger | 10 lbs | 95.24 |

| Acid Malt | 8 oz | 4.76 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Magnum | 14 g | 60 min | Boil | Pellet | 12.5 |

| Saaz | 28 g | 30 min | Boil | Pellet | 3 |

| Saaz | 28 g | 20 min | Boil | Pellet | 3 |

| Saaz | 28 g | 0 min | Boil | Pellet | 3 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Urkel (L28) | Imperial Yeast | 73% | 52°F - 58°F |

Notes

| Water Profile: Ca 65 | Mg 0 | Na 0 | SO4 45 | Cl 40 |

Download

| Download this recipe's BeerXML file |

A few hours prior to brewing, I collected the full volume of water, adjusted it to my desired profile, then used my HotRod heat stick to warm it up.

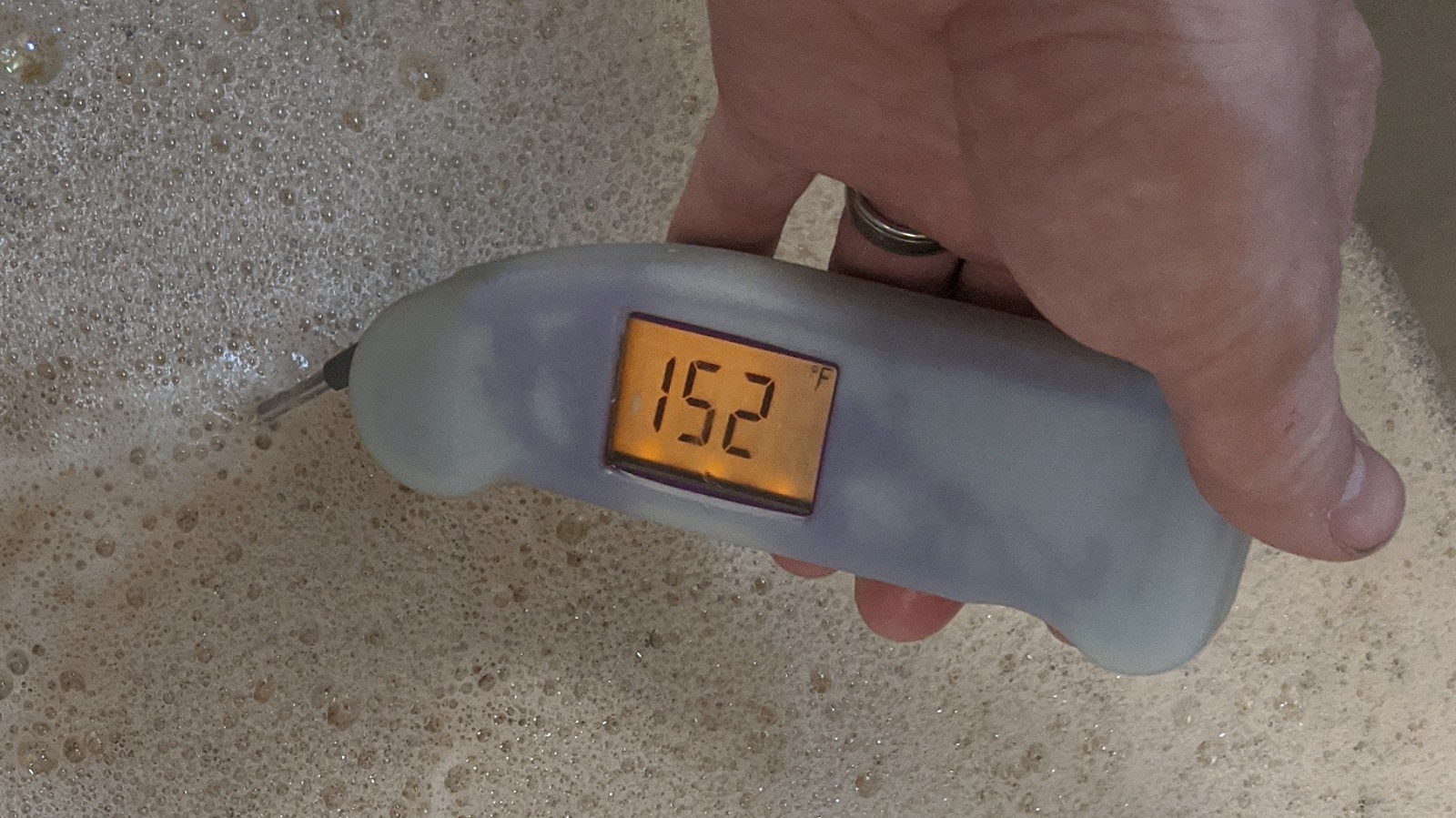

With the water adequately heated, I stirred in the milled grain then checked to make sure the mash was at my target temperature.

Following the 60 minute mash rest, I sparged to collect the expected pre-boil volume of sweet wort then brought it to a rolling boil.

Once the 60 minute boil was complete, I quickly chilled the wort.

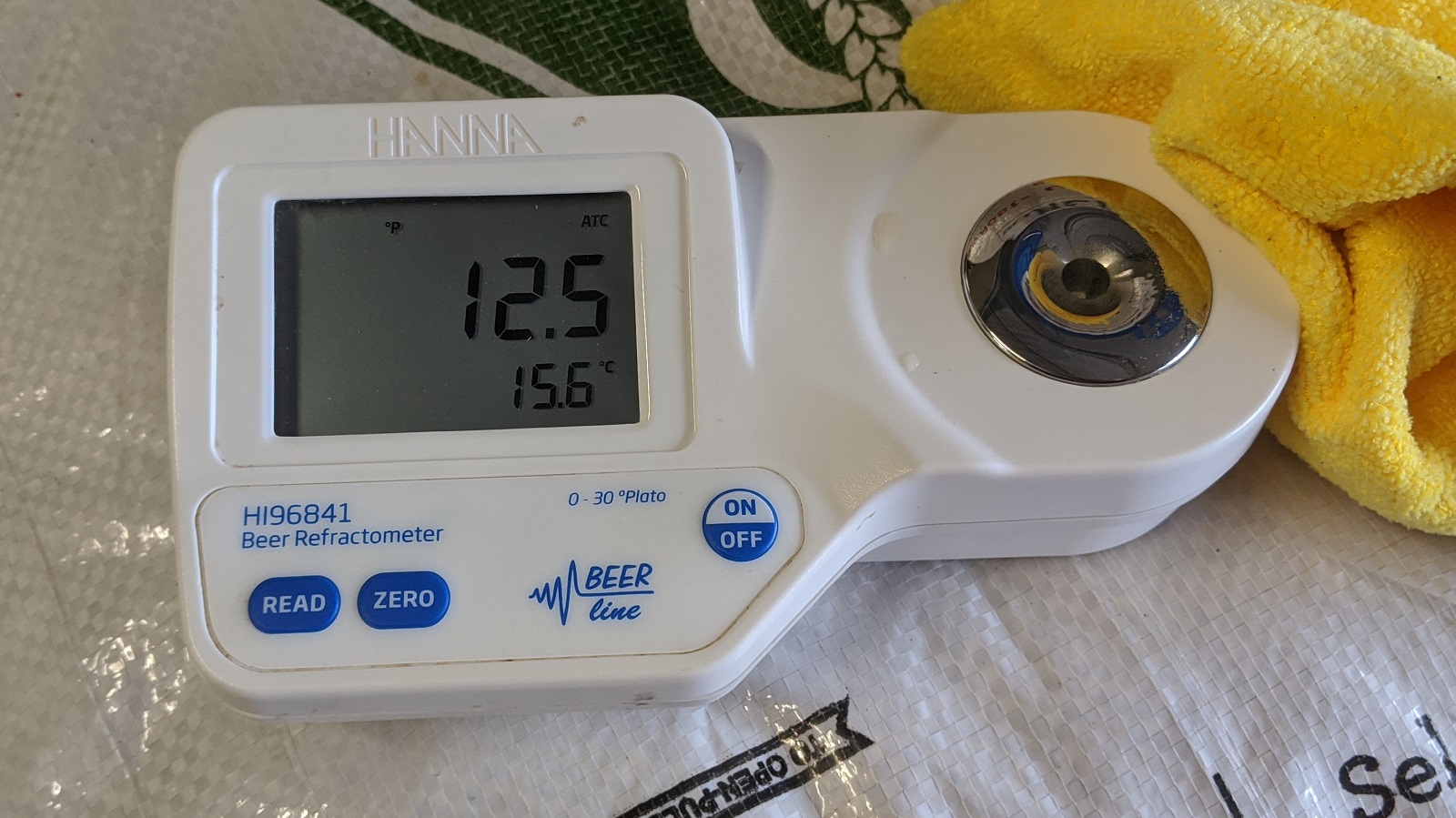

A refractometer reading showed the wort hit my target OG.

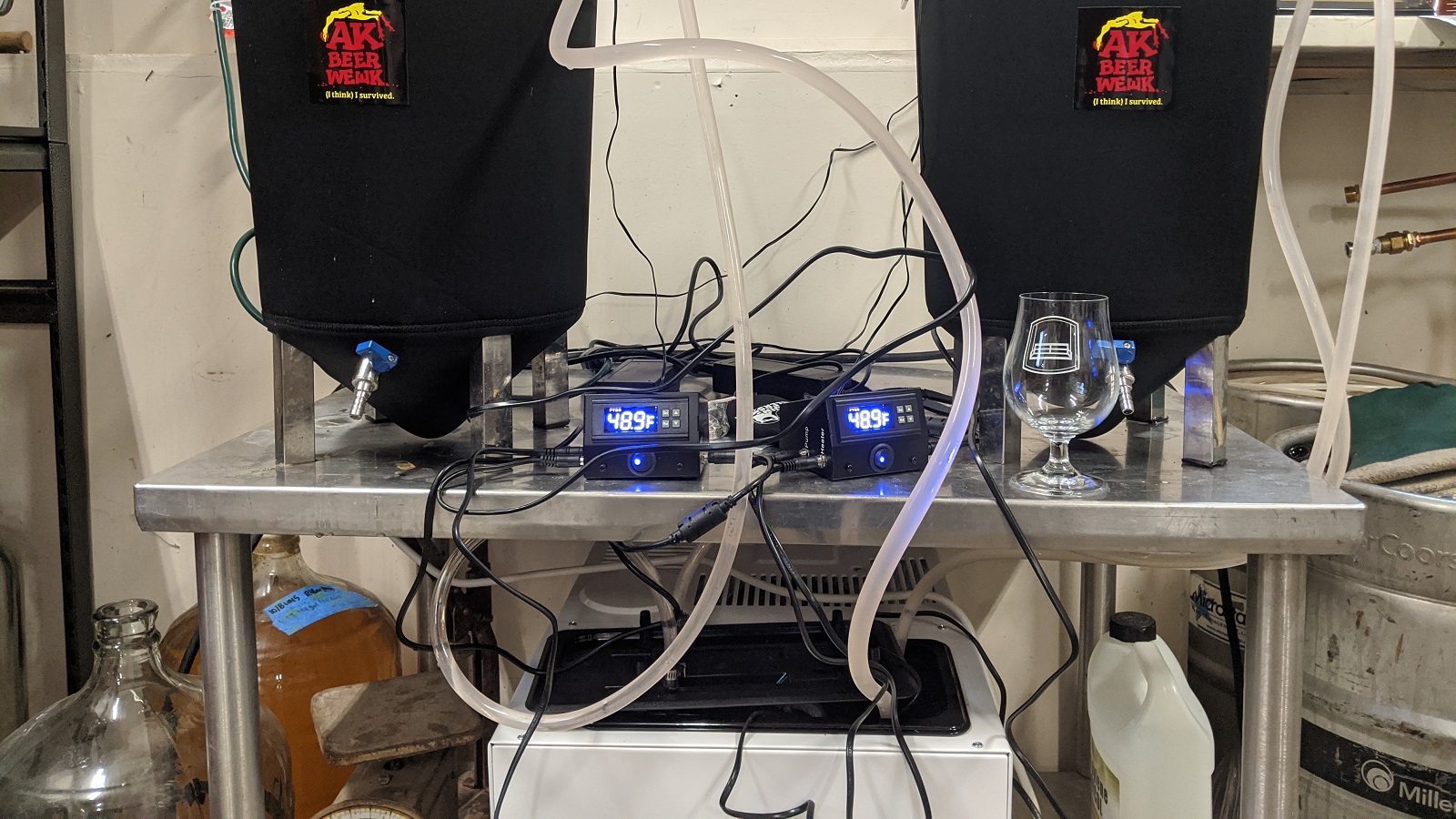

The wort was evenly split between two sanitized Brew Buckets that were connected to my glycol unit set to maintain a temperature of 49°F/9°C.

I used remnant wort to make separate vitality starters of Imperial Yeast L28 Urkel, which I let spin for 4 hours before pitching one into each wort.

The beers were left to ferment for 3 weeks before I raised the temperature to 60°F/16°C for a diacetyl rest. After 2 days, I took hydrometer measurements showing both beers were at the same FG.

At this point, I cold crashed both beers to 34°F/1°C and left them for 3 days before pressure transferring to purged kegs. After hitting both kegs with enough gas to seat the lids, I put one in my 34°F/1°C keezer while the other was placed in an area in my garage that maintains an average temperature of 60°F/16°C. After 4 weeks of conditioning, I gently moved the warm lagered beer to my keezer, attached gas to both kegs, then let them carbonate over 2 weeks before I began my evaluation. I noticed the beer lagered cold was quite a bit clearer than the one stored warm.

| RESULTS |

Due to social distancing practices as a result of the COVID-19 pandemic, data for this xBmt was unable to be collected in our typical manner. As such, temporary adaptations were made involving the author completing multiple semi-blind triangle tests in as unbiased a way as possible.

Utilizing 4 opaque cups of the same color where 2 were inconspicuously marked, one set was filled with the beer lagered cool while the other set was filled with the beer lagered warm. For each triangle test, 3 of the 4 cups were indiscriminately selected, thus randomizing which beer was the unique sample for each trial. Following each attempt, I noted whether I was correct in identifying the unique sample. Out of the 10 semi-blind triangle tests I completed, I needed to identify the unique sample 7 times (p<0.05) in order to reach statistical significance, which is exactly the number of times I did (p=0.02), indicating my ability to reliably distinguish a Czech Pilsner lagered at 34°F/1°C from one stored at 60°F/16°C for the same amount of time.

While these beers were rather similar, I perceived the one lagered cold as being more crisp and clean while the warm lagered version had a peculiar flavor that I associated with buttered corn. Since diacetyl is known to dissipate in warmer environments, I’m not certain that’s what I was tasting, all I know is the beers different enough for me to tell them apart fairly consistently. I had a fairly strong preference for the cold lagered Pilsner, though the one stored warm wasn’t terrible.

| DISCUSSION |

A proper lagering process is ardently believed by many to play a very important role in the flavor development of classic lager styles, hence much emphasis is placed on ensuring such beers spend an adequate time at cool temperatures. The fact I was able to reliably distinguish a Czech Pilsner lagered at 34°F/1°C from one stored at 60°F/16°C for 4 weeks supports the notion that lagering temperature has a noticeable impact.

It’s a widely accepted fact that chemical reactions occur more rapidly in warmer environments, which may help to explain the importance brewers place on storage temperature, as the staling process is slowed down at cooler temperatures. Considering these results corroborate those of two past xBmts, it can be said with a touch more confidence that storage temperature seems to have a perceptible impact.

Lagering beer at cooler temperatures isn’t something I struggle with, as I’ve the means to rather easily do so without affecting my regular brewing behavior. As such, and seeing as I preferred the cold lagered beer in this xBmt, I won’t be making any changes to my methods. The difference between the beer stored cold and the one stored warm wasn’t terribly drastic, but enough to convince me I prefer lagers lagered at traditional lager temperatures. For the person who may not have the ability to lager cold over time, storing warm would likely be a sufficient alternative.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

5 thoughts on “exBEERiment | Impact Storage Temperature Has On Czech Pilsner”

I assume it’s just a case of sedimentation of trub and yeast that any beer can benefit. I have the feeling that czech lagers taste “cleaner” if undergo to lagering. Czech classics like Budvar proclaim that they perform longer maturation, 90 days at 2ºc, or even longer in case of stronglagers. I prefer to perform the secondary fermentation usually at 6ºc that you’ll still got some yeast activity with few strains. 16ºC seems a tolerable temperature for secundary, but I’m afraid of effects of oxidation too. Did you get any oxidation or esters? I feel also i could have a downside if you carry trub and hops to the secundary.

Great post, thanks! I wonder how the two beers would match up after another month of lagering in the keg.

After listening to your podcasts for a bit, I got curious and started brewing lagers at ale temps. They have all been fantastic. So, thanks for that. Here is what I’ve learned: if a lager beer isn’t completely clear, it tastes bad. Once it fully clears, well that’s the ticket to flavor town. When they start to really sparkle is when they really taste great. If I move a keg and stir up sediment, they taste bad until it settles. I don’t know of lager yeast has some kind of flavor I don’t like or what, but it’s consistent for me. I fine with gelatin.

I’d think your buttery taste could still be diacetyl. The beer could have the favorless precursor acetolactate. The warm lagered beer could have had the acetolactate convert to diacetyl and since there is no active yeast after the cold crash, there is nothing to clean up the diacetyl. Since the other sample was kept cold, the conversion of acetolactate to diacetyl never happened. Would be interesting to bottle a sample of the cold lagered beer, store it warm, and see if it develops the same buttery character.

It looks like with the wicking of the beer up the side of the hydrometer, the reading should actually be 1.020? (I recognize the photo angle might be misleading, too…)

(and interesting post — I agree with PZ that it’d be cool to know what happens if you age it out another month)