Author: Andy Carter

Water is the single largest ingredient in beer, and while adjusting it to a particular mineral profile is viewed as confounding by some, there’s heaps of evidence that indicate doing so has a very real impact. Lately, it seems the old adage, if it’s good enough to drink then it’s good enough to brew with, is losing popularity as more brewers opt to control the chemistry of their water.

Despite generally being pure enough to consume on its own without concern, municipal water can vary greatly in its mineral composition, making between-batch consistency difficult if not impossible. For this reason, many brewers rely on water that has gone through reverse osmosis (RO) filtration, which strips water of nearly all total dissolved solids including minerals, resulting in a blank slate that can then be built to one’s preference.

In addition to influencing perceptible aspects of beer, the presence of certain minerals in brewing water is said to affect things like enzymatic conversion during the mash, protein coagulation during the boil, and yeast health during fermentation as well. As such, using straight RO water to brew with is cautioned against. Indeed, tasters in a past xBmt were able to tell apart a Pilsner made with pure RO water from one where the water was adjusted with minerals, and the adjusted RO water beer was handily preferred. I was interested to see if these results would be the on a different beer style and put it to the test again.

| PURPOSE |

To evaluate the differences between a Blonde Ale made with straight RO water and one made with RO water adjusted with minerals.

| METHODS |

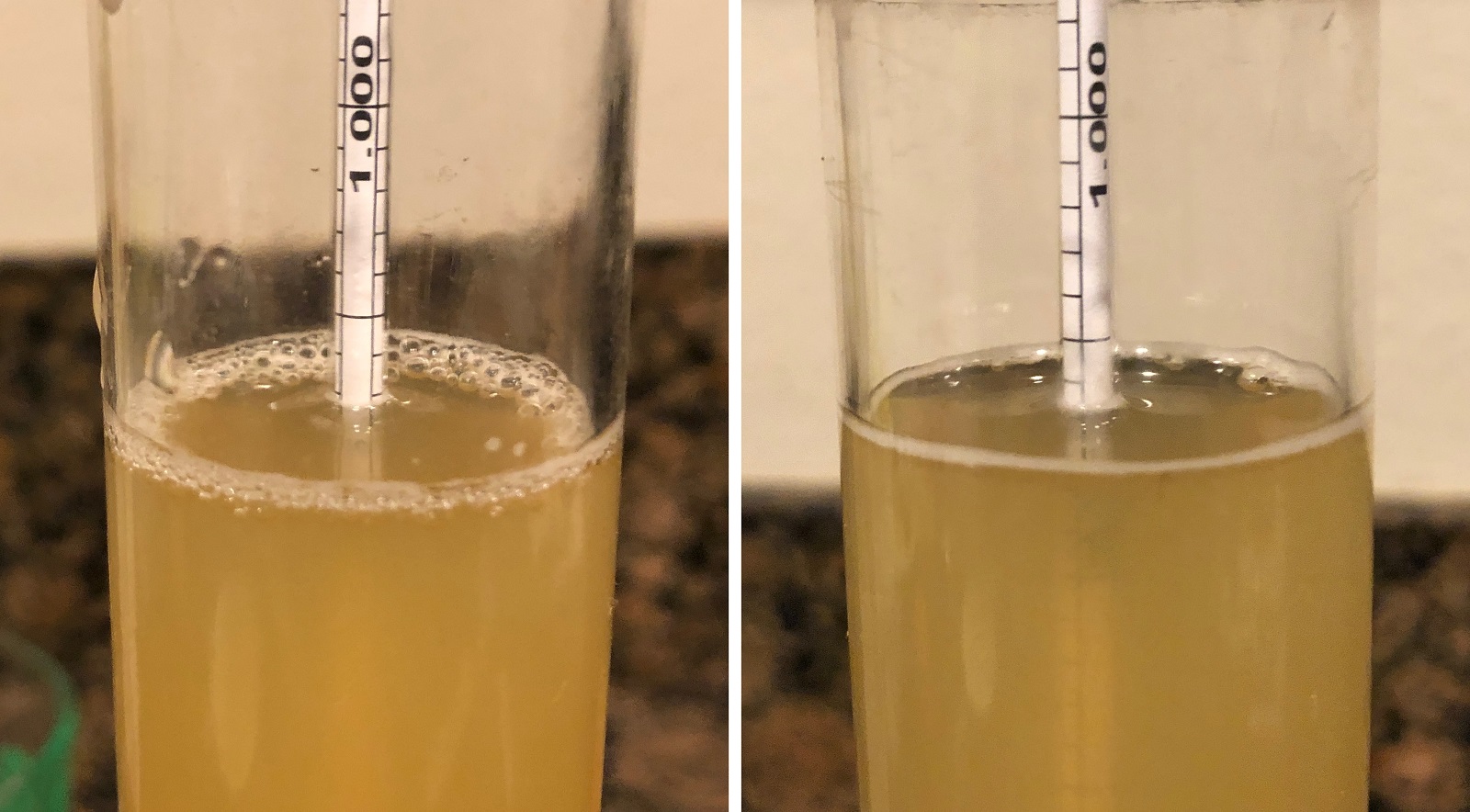

I designed a Blond Ale fermented with Imperial Yeast A44 Kveiking and hopped with fruitier varieties for this xBmt

Dry Heat

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 44.3 IBUs | 3.2 SRM | 1.046 | 1.009 | 4.8 % |

| Actuals | 1.046 | 1.007 | 5.1 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pilsner (2 Row) Ger | 7.562 lbs | 78.06 |

| Pale Malt (2 Row) US | 1.875 lbs | 19.35 |

| Wheat, Flaked | 4 oz | 2.58 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Cashmere | 14 g | 60 min | Boil | Pellet | 7.9 |

| Cashmere | 14 g | 30 min | Boil | Pellet | 7.9 |

| El Dorado | 27 g | 10 min | Boil | Pellet | 15.3 |

| Cashmere | 14 g | 10 min | Boil | Pellet | 7.9 |

Notes

| Water Profile (adjust batch): Ca 55 | Mg 5 | Na 0 | SO4 72 | Cl 59 |

Download

| Download this recipe's BeerXML file |

I made a single large starter of Imperial Yeast A44 Kveiking a day ahead of time.

The following day, I started out by getting two equal volumes of RO water heating up.

With the water heating up, I weighed out and added the minerals to achieve my desired profile to one batch while the other was left alone.

Next, I milled identical sets of grain for each batch.

Once each batch of water were adequately heated, I stirred the grains then checked to make sure both were at the same target mash temperature.

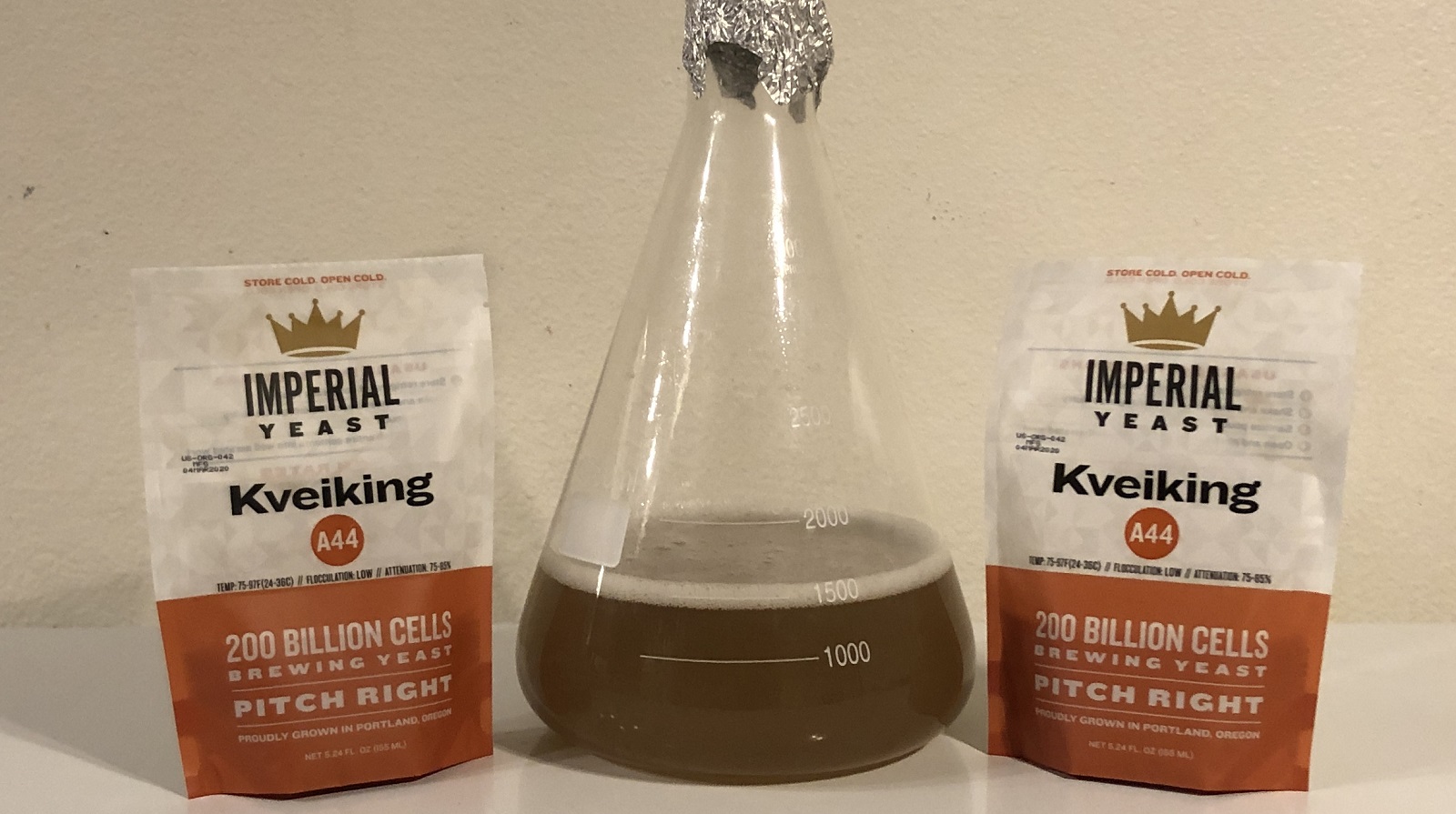

I took pH readings 15 minutes into each mash that showed barely any difference caused by the mineral additions.

Following each 60 minute mash rest, I removed the grains and sparged to achieve the target pre-boil volume.

While waiting on the wort to heat up, I weighed out the kettle hop additions.

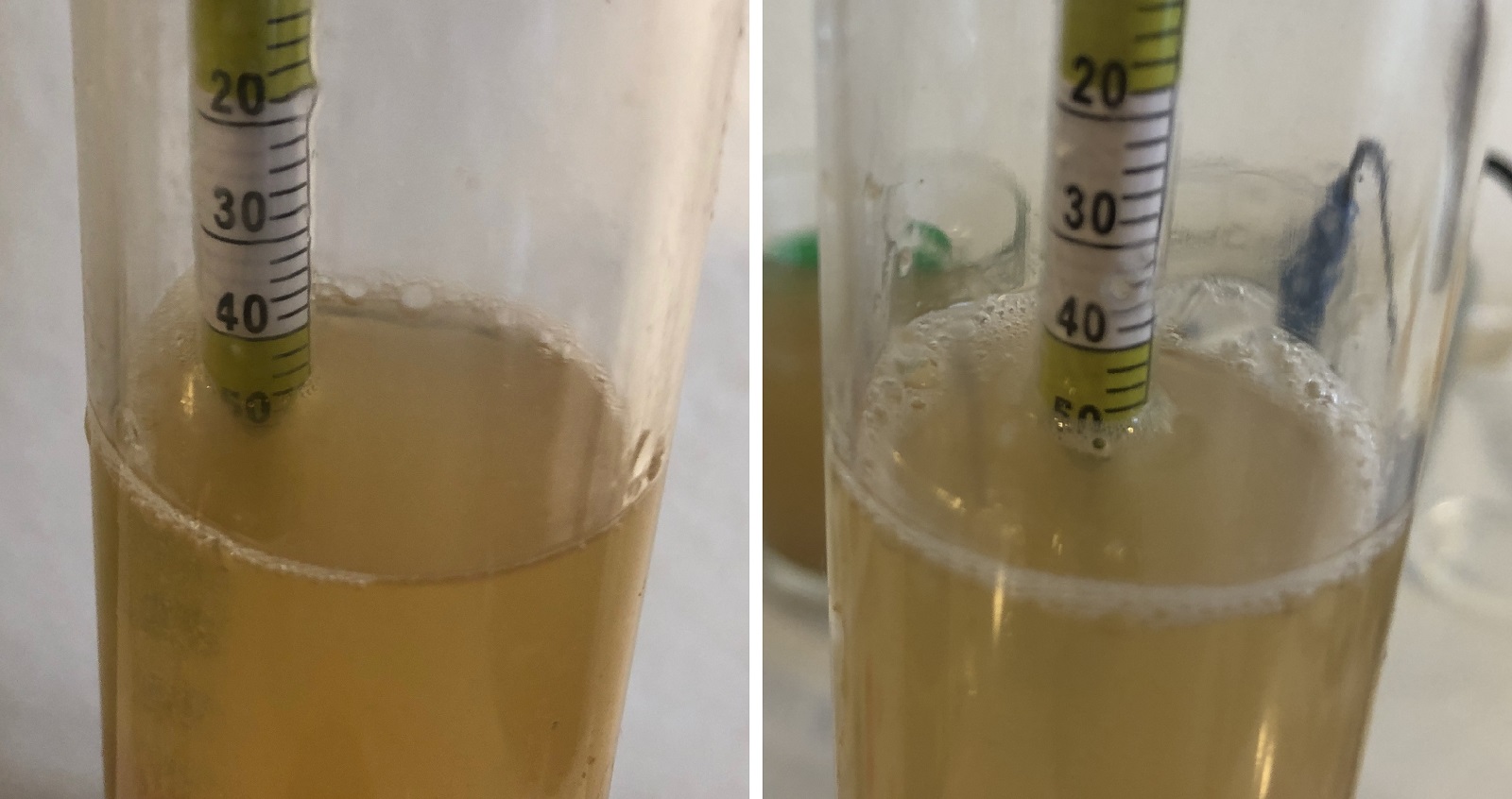

Once each 60 minute boil was complete, I chilled the wort then took hydrometer measurements showing both hit the same exact OG.

Equal amounts of wort were racked to sanitized 6 gallon/23 liter PET carboys that were placed in my fermentation chamber before I split the yeast starter evenly between them. After fermenting for a week at 85°F/29°C, I took hydrometer measurements showing the beer made with straight RO water finished about 0.001 SG point higher than the beer made with adjusted RO water.

I reduced the temperature in the chamber to 70˚F/21˚C and left the beers alone for another week before racking each to a sanitized keg.

The beers were then racked to sanitized and CO2 purged kegs.

The filled kegs were placed in my keezer, burst carbonated, and left to condition for 2 weeks before I began evaluating them.

| RESULTS |

Due to social distancing practices as a result of the COVID-19 pandemic, data for this xBmt was unable to be collected in our typical manner. As such, temporary adaptations were made involving the author completing multiple semi-blind triangle tests in as unbiased a way as possible.

Utilizing 4 opaque cups of the same color where 2 were inconspicuously marked, one set was filled with the beer made with straight RO water while the other set was filled with the beer made with adjusted RO water. For each triangle test, 3 of the 4 cups were indiscriminately selected, thus randomizing which beer was the unique sample for each trial. Following each attempt, I noted whether I was correct in identifying the unique sample. Out of the 10 semi-blind triangle tests I completed, I needed to identify the unique sample 7 times (p<0.02) in order to reach statistical significance. However, I correctly chose the unique sample only 4 times (p=0.44), indicating my inability to reliably distinguish a Blonde Ale made with straight RO water from one made with RO water adjusted to my desired mineral profile.

Based on my experience with water chemistry and the results of the last xBmt on this topic, I was confident I’d be able to tell these beers apart, but I couldn’t, they tasted exactly the same to me. Seeing as they were fermented with Kveik, I expected pungent fruit notes and was surprised by how clean they turned out. While the beers were quite good, I’d be inclined to bump up the late hopping in future versions.

| DISCUSSION |

Viewed by many a new brewer as too convoluted to care about, adjusting the mineral composition of brewing water is something brewers of extraordinary beers tend to take very seriously. In order to have the most control over these adjustments as possible, it’s common to start with RO water and add specific minerals to achieve one’s desired profile. While using non-adjusted RO water is believed to negatively impact beer quality, I was unable to consistently distinguish a Blonde Ale made with straight RO water from one made with adjusted RO water.

In considering explanations for these results, a few possibilities came to mind. First, it didn’t take much to achieve my preferred profile, and perhaps greater amounts of the various minerals used would have had a more noticeable effect. However, seeing as my profile closely approximated that of the beer in the past xBmt on this variable, I thought the Kveik yeast or fruitier hop varieties may have reduced the perceptible impact of the mineral additions. It’s also possible my palate was to blame and others would have tasted a difference– thanks COVID.

These results swayed my opinion that water chemistry is an important aspect to crafting great beer, I’ll continue adjusting my RO water for every batch, even if I couldn’t tell these particular beers about. As my first run with Kveik, I was pleased with the outcome and look forward to using more in the future at different temperatures in various beer styles!

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

22 thoughts on “exBEERiment | Water Chemistry: Straight vs. Adjusted RO Water In A Blonde Ale”

Depending on the beer style, Bel Air Brewing uses either 100% RO, or a blend of RO with filtered city tap water. For some beer styles 100% filtered tap water is used. No adjustments are made. Never.

And how do the beers turn out? Very, very good. In fact, the beers are so good that we often wonder why so many brewers waste time/effort in fooling with chemistry.

However, we are blessed with water that is in the “ballpark” for most beer styles.

Can we know your water chemistry profile? I sometimes use regular water with no additions and turns very well. It depends, I think, more in whats hops, what yeast and what malts your using. And of course a right temperature. Recipe is esential in my opinion. Cheers!

Our water:

Ca – 38

Mg – 3.7

Total Hardness – 110

pH – 8

Total Alkalinity – 90

Potassium – 5

Sulphate – 33

Sodium – 20

I liked this xBmt. Thanks for doing it.

Your pH was interesting. I would’ve assumed it would’ve been different by more than a couple hundredths.

I brewed a hefe a few years ago with 100% distilled. The beer came out very neutral (blah would be a better word). It was well carbonated but, even bottle conditioned to 4.0 vol, it had almost no head retention. I noticed in the side-by-side photo; the adjusted RO seemed to have a more “pillowy” head. Was this a factor of the pour or were they all like this?

the water didn’t have much, if anything, to do with head retention. check your grain bill and adjust as needed.

I am attributing the head retention to the kveik yeast, given similar grains bills of others beers without this level of retention.

Many Kveik strains work best when underpitched compared to normal yeasts, like 10% of a normal pitching rate. Lars recommends, “1 billion cells/liter”. http://www.garshol.priv.no/blog/393.html

When I see numbers for mineral content, what are the units? ppm by mass? micromolar?

Good question! Its in ppm.

What was your source for RO water? Did you run TDS tests on both sets of water to see that there was actually a detectable difference?

Agreed. I didn’t see a mineral breakdown of the RO water. There’s still some minerals left behind. My TDS is 53ppm, then Ca 2 | Mg <1 | Na 13 | SO4 <1 | Cl 16 | Alk 6.0

If you were to perform this experiment with RO, you should have the breakdown so you have a technical comparison point. The idea behind RO and salt additions is that you don't add salts that precipitate unwanted mineral concentrations and you simply add what you need for a desired profile.

I get the water from a machine RO source at the grocery store, and all the water was purchased at the same time to control from source variation. It is a fair point to be checking TDS of the water, and plan on getting a meter to have that control.

I have to admit, I was kind of looking for this info too. I’m guessing it was bottled RO water, in which case it’s likely proprietary

Thank you for this comparison. I started homebrewing last year and have always used R/O water with good results. I’m starting to get into water chemistry to hopefully improve my beers but at least I know I wasn’t too far off.

I hoping there will be more in this series looking at water chemistry. I like the idea of trying to approach it in a relatable way through perception. Most of the info out there is pretty technical. Although, I would encourage folks to look into the technical side. There are some people doing good work on this beyond Palmer’s RA calculation.

I’d like to see this done with a little more water data, and a better established yeast strain. To me, blowing through a fermentation with Kviek yeast at 85F is a potential confound. The experiment just makes me think Kviek is some kind of beast that will churn through anything.

I’d also really like to see this done in the reverse of the normal protocols. Normally, the experiments start simple and then get more extreme as time goes on. For me, I’d rather see an extreme example that shows a perceptible difference where you would expect one (like a beer that is supposed to taste bitter or minerally), and then dial it back until you can’t tell a difference, as opposed to a bunch of null results.

I’m glad you guys are taking this on. I know when I started brewing it was Palmer’s RA calculation and maybe a little bit of work that was just starting to be done by people DeLange and Troester that you had to dig to find, and you needed a strong knowledge of mash chemistry to fully understand.

Try it ONE more time with a hoppier beer. IPA champions claim you cannot get a proper isomerization and aroma-cling without the mineral contribution. Something in the 45-50 IBU should work well with a 60 minute addition and the rest in the last 15 minutes, no dry hopping. I’d be curious about the results but believe the minerals are essential with regard to hop utilization.

I love this experiment! When trying to troubleshoot off-flavors, it’s nice to know you can essentially eliminate the main ingredient by using R.O.

The pH seemed high to me. Having such high pH may have made these beers taste so similar. Try acidifying the mash a bit. Also that Kveik yeast had a fair amount of strain dependent flavor,I would think. A more neutral US yeast might have exhibited more of a difference.

Good experiment. Interesting results.

I am no longer surprised when Brulosophy experiments reveal little to no discernable difference in their final taste tests. Even when the taster is fully aware that the beers were made differently. That he perhaps should be able to distinguish it. In fact, i rather find it amusingly gratifying.

My local water is essentially mineral free, low in alkalinity etc. I dont do any additions. Never have. I am told my water might be better suited to lighter to amber beers. Thats generally all i make. That heavier, darker beers demand more control over water makeup. Perhaps something to consider in the experiment.

In reality, is water chemistry not something mass brewers would need to control in order to maintain consistency across a product line, perhaps brewed in different locations, rather than homebrewers producing decent beer? Does unadjusted RO water make inferior stouts, ambers, or lagers? I suggest possibly not.

Thanks for the exbeeriment.

I would like to see another water chemistry exbeeriment made where the variable is the water source. Hard Tap Water (with necesarry mineral adjustments to meet the beer style) vs RO Water (with necessary mineral adjustments to meet the beer style).

Would people be able to tell the difference if both are adjusted towards the same water profile?

Or does a RO water starting point yield better results?

Brewers are getting way too deep in the weeds here…

Again, we never adjust our water. Not one time. And we were awarded two gold and one bronze medal at this year’s Bluebonnet Brewoff. About 1400 brewers and 4000 entries.

City tap water is all we use, filtered. Either RO or a simple counter top filter.

The results don’t surprise me. Many people are of the assumption that ALL of the minerals in the fianl beer come from the source water. In fact the majority comes from the grain and beer and NOT the source water. There are only two studies that I know of that determined how much of the resultant minerals came from the grain and hops, but it seems to be in the order of 75-80%!!! Thus the influence of the source water is quite negligible. It varies by the type of mineral. For example, about 99.8% of the fianl Phosphorus comes from the grains/hops and about 95.7% of the Potaasium comes from the grain/hops. However, only about 18.1% of the chloride comes from the grain/hops, and about 56.4% of the sodium comes from the grains/hops. Thus the water adjustment is important for the chlorides and Sodium and perhaps even the Sulfates, but is not at all needed fro the Magnesium, Phosphrius and Potassium adjustments. This could help explain the result of your exBEERiment.