Author: Phil Rusher

Due to its deleterious effects on beer, cold-side oxidation has become a focus for many brewers, as it’s known to rapidly turn a good beer into a flabby, sweet, papery mess. As such, many strategies have been developed to reduce oxygen ingress during the packaging process including the use of chemical antioxidants, particularly sulfites.

One of the most common sources of sulfites when it comes to brewing is sodium metabisulfite (SMB), which comes in the form of Campden tablets and is also available as a powder. When added to beer, it readily dissolves, releasing the sulfite anion into solution to interact with any molecular oxygen that may be present. Whereas many of the techniques used to reduce cold-side oxidation are quite involved and may require specific equipment, adding just a small amount of SMB to a keg prior to packaging is said to accomplish the same result with much less effort.

In past xBmts on this topic, tasters have been able to reliably distinguish both a Kölsch and a NEIPA dosed with SMB at packaging from non-dosed versions of the same beers. Curious to see if this holds true for other styles, I decided to test it out for myself with an more traditional American IPA.

| PURPOSE |

To evaluate the differences between an American IPA dosed with SMB at packaging and one that was not dosed with SMB at packaging.

| METHODS |

Seeing as our last xBmt on this topic focused on the impact on hazy NEIPA, I went with a more classic American IPA for this go-round.

Evidence Is Clear

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.7 gal | 60 min | 83.9 IBUs | 6.1 SRM | 1.058 | 1.016 | 5.5 % |

| Actuals | 1.058 | 1.014 | 5.8 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pilsen Malt 2-Row (Briess) | 10 lbs | 76.74 |

| Mecca Grade Vanora: Vienna-style Barley Malt | 2 lbs | 15.35 |

| Mecca Grade Shaniko White Wheat Malt | 1 lbs | 7.67 |

| Roasted Barley (Thomas Fawcett) | 0.5 oz | 0.24 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Loral | 20 g | 60 min | Boil | Pellet | 10.2 |

| Enigma | 30 g | 20 min | Boil | Pellet | 17 |

| Enigma | 25 g | 10 min | Boil | Pellet | 16.7 |

| Mandarina Bavaria | 25 g | 10 min | Boil | Pellet | 8.5 |

| Enigma | 25 g | 1 min | Boil | Pellet | 16.7 |

| Mandarina Bavaria | 25 g | 1 min | Boil | Pellet | 8.5 |

| Mandarina Bavaria | 50 g | 5 days | Dry Hop | Pellet | 8.5 |

| Enigma | 25 g | 5 days | Dry Hop | Pellet | 16.7 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Independence (A15) | Imperial Yeast | 74% | 60°F - 72°F |

Notes

| Water Profile: Ca 59 | Mg 3 | Na 28 | SO4 110 | Cl 55 |

Download

| Download this recipe's BeerXML file |

I started this brew day by weighing out and milling two identical sets of grain.

I then adjusted the RO water for both batches to my desired profile before heating them to the same strike temperature, at which point I incorporated the grains and checked to make sure both hit the same mash temperature.

After setting each controller to maintain the same mash temperature, I weighed out the kettle hop additions.

When each 60 minute mash rest was complete, I removed the grain baskets and let them drip into their respective kettle while heating the wort.

With the full volume of sweet wort collected, I boiled each batch for 60 minutes, adding hops at the times stated in the recipe.

When the boils were finished, I ran each wort through a plate chiller on its way to a sanitized Brew Bucket.

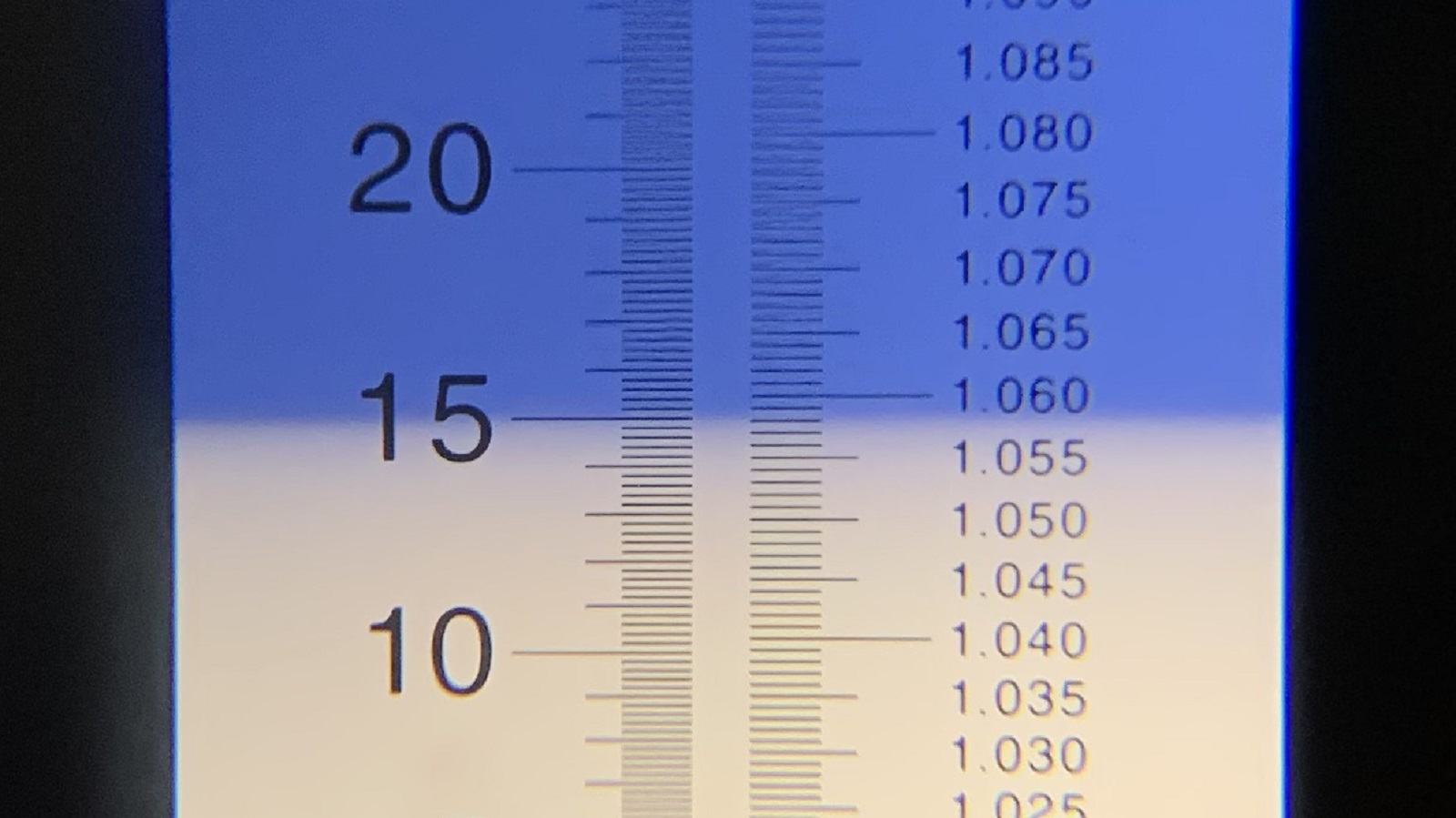

Refractometer readings showed the worts were at the same expected 1.058 OG.

Using some remnant wort, I made a vitality starter with 2 pouches of Imperial Yeast A15 Independence and let it spin for 4 hours before I evenly split it between the batches.

The beers were left to ferment in my 60°F/16°C basement for 10 days before I took hydrometer measurements showing both reached the same 1.014 FG, at which point I added the dry hops to each beer.

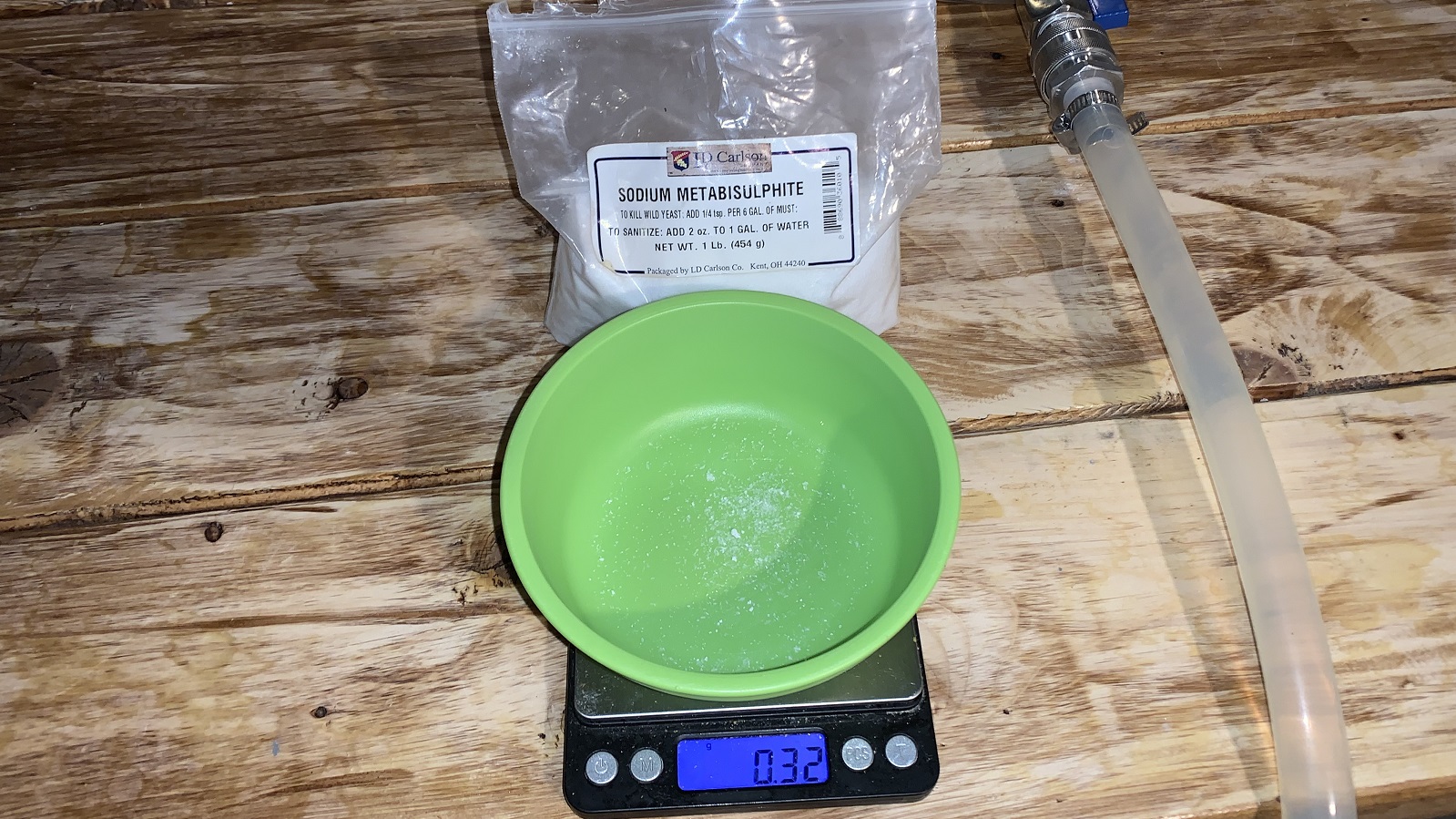

The dry hops mingled with the beers for 5 days before I proceeded with packaging, which is when the variable was introduced. Into one of the sanitized kegs, I added a 0.3 grams of SMB, the recommended amount to counteract oxygen ingress for 5 gallons/19 liters of beer.

So as to isolate and enhance any impacts of the the variable, I racked the beers into sanitized kegs that were not purged with CO2.

The filled kegs were placed in my keezer and burst carbonated overnight before I reduced the gas to serving pressure. Samples taken after just a week of conditioning revealed the beer dosed with SMB at packaging was noticeably lighter than the non-dosed beer.

I let the beers condition for another week before evaluating them and noticed a similarly stark color difference between them.

| RESULTS |

Due to social distancing practices as a result of the COVID-19 pandemic, data for this xBmt was unable to be collected in our typical manner. As such, temporary adaptations were made involving the author completing multiple semi-blind triangle tests in as unbiased a way as possible.

Utilizing 4 opaque cups of the same color where 2 were inconspicuously marked, one set was filled with the beer dosed with SMB at packaging while the other set was filled with the beer that was not dosed with SMB at packaging. For each triangle test, 3 of the 4 cups were indiscriminately selected, thus randomizing which beer was the unique sample for each trial. Following each attempt, I noted whether I was correct in identifying the unique sample. Out of the 10 semi-blind triangle tests I completed, I needed to identify the unique sample 7 times (p<0.02) in order to reach statistical significance. Ultimately, I correctly identified the unique sample in all 10 attempts (p=0.000), indicating my ability to reliably distinguish an American IPA that was dosed with SMB at packaging from the same beer that was not dosed with SMB at packaging.

I perceived both of these beers as having tangerine, black currant, and blueberry characteristics with a cracker and somewhat biscuity malt flavor. I felt the hop flavor and aroma were somewhat muted in both, though the one dosed with SMB was definitely more crisp and bright than the non-dosed beer. While I preferred the beer dosed with SMB at packaging, I still detected low levels of cardboard-like oxidation in it, which worsened over time.

| DISCUSSION |

There’s little question oxygen is the enemy of beer, and one of the biggest vectors for oxygen ingress is during the packaging process. Brewers have come up with a number of effective methods for reducing the risk cold-side oxidation, many involving the use of external CO2 and additional gear, though perhaps the simplest approach is to add a small amount of sulfites, usually in the form of SMB, to the beer at packaging. Confirming past xBmts on this topic, I was indeed able to reliably distinguish an American IPA dosed with SMB at packaging from one that was not dosed.

In addition to the perceptible impact adding SMB at packaging had on this American IPA, there was a rather drastic difference in appearance as well, the dosed sample maintaining a pale color while the non-dosed sample darkened rapidly over time. Considering this was also observed in a NEIPA though not a Kölsch, it seems plausible the culprit for such color change here was due to the fact that neither of the kegs were purged with CO2.

I do not enjoy oxidized beer and have been purging kegs as a means to reduce cold-side oxidation for years. It certainly works well, though requires quite a bit of CO2, which isn’t necessarily cheap. Given these results corroborate those of past xBmts, I feel even more confident that adding SMB at packaging can assist in reducing cold-side oxidation, though I’ll continue to purge kegs prior packaging just for the added assurance.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

56 thoughts on “exBEERiment | Cold-Side Oxidation: Impact Adding Sodium Metabisulfite (SMB) At Packaging Has On An American IPA”

I wonder how these cold-side oxidation experiments would play out with bottle conditioning. I bottle condition and would like to improve on the cold-side oxidation front.

I haven’t tried using SMB with bottle conditioning, mostly because I rarely bottle condition these days. I would wager that it would work fine, but I’d also be careful to not use too much, as it can be used to cause yeast to go dormant.

My thought is that it is LESS of a problem with bottle conditioning as yeast tends to scavenge oxygen in solution. If you are cold crashing and bottle conditioning, I’d be cautious of adding SMB or KMETA as they not only remove oxygen, but kill wild yeasts. If your yeast population is already low from crashing and you add any of the aforementioned substances, you may kill your residual yeast and not successfully carbonate your beer. If you aren’t cold crashing, your chances are better, but I’d still let those bottles go ahead and condition a while longer before opening. When kegging, you’re adding CO2, so there’s no worry about dead yeast. Alternatively, I’ve begun using biotransformation (hopping during high krausen) for my dry hops, then kegging once I’m about 5 points from my expected FG to obtain a natural carbonation and limit O2 as the yeast is still active. A buddy of mine pasteurized about a liter of wort and cans it every brew day. After letting his beer finish entirely, he will keg and then add his saved wort to promote carbonation and O2 scrubbing. Just thoughts! Happy brewing!

I have used SMB with botttle conditioning. Dosage rate was as reccomended on package to reduce oxydation and there was no problem with recarbonation. I also dosed champange yeast (should tolerate sulfites better) to ensure carbonation.

I recently bottled a Hazy IPA and I will keep using K-Meta in all my hoppy beers for sure. This is the first time that I have really enjoyed a selfmade IPA after two weeks in the bottle. I ferment in kegs, but my procedure should apply to all types of fermentation vessels.

I use the CO2 from fermentation to purge a sanitized keg. I ferment under 0.5 bar of pressure to avoid oxygen ingress. After fermentation is done, I cold crash at 2° C for 48 h then transfer to the clean keg. I add 10 ppm of K-Meta together with the priming sugar solution (and dry hops if necessary). After 48 h dry hopping, I bottle from the keg which is fitted with a floating diptube. I use a standard bottling wand for now, maybe I’ll get a beergun at some point.

You could probably skip the transfer to a fresh keg and bottle directly from the fermentor, just be careful with the sediment.

My friend fills up around 6 bottles, turns his gas on at a low psi and ‘purges’ the neck of the bottle. Has done a couple of NEIPA’s and avoided oxidation so seems to work.

You’ll need a very accurate gram scale and a syringe that can accurately measure 13ml (if using 500ml bottles). Dissolve your carbing sugar and metabisulfites in 2 cups of water once boiled. Dose each bottle (~37 of them, if using 500ml bottles) with 13ml of your solution.

Exactly how much metabisulfites to use will be a tricky question though, and will require some trial and error. Estimates that I have seen say ~5ppm of metabisulfites are required to expire 1ppm of oxygen, but packaging, even crudely, doesn’t introduce oxygen on a scale of ppm but ppb.

But anyways, to determine your weighing amounts would be ppm = mg/l. 15 ppm of metabisulfites in 5 gallons (19L) would be 15mg x 19L = 285mg or ~ .3 grams of metabisulfites per 5 gallons.

10 ppm of metabisulfites = ~.2 grams per 5 gallons.

5 ppm of metabisulfites = ~.1 grams per 5 gallons.

This was assuming bottling from fermenter. Sorry for not mentioning that.

In a previous xbmt, it was reveled at 1 campden tablet in a 5 gallon keg provided 10ppm of SMB which was enough to remediate O. The 0.3 grams you used was obviously quite a bit less than 1 tablet. It looked like “a pinch.” Maybe a tablet has lots of filler?

My question is: What source of data are you using to the “ideal” amount of SMB? I also wonder how much of a tablet should be used?

There will probably be variable amounts of filler used for both the powdered or tablet forms depending on the manufacturer, and the tablets aren’t necessarily always exactly the same between themselves. For example, have you ever weighed whirlfloc tablets? They’re rarely uniform in weight in my experience (not that it particularly matters very much).

At any rate, I used Martin Brungard’s calculator included in the paid version of his Bru’n Water spreadsheet and I double checked this with the sulfite tool in BeerSmith 3.

Campden tablets are supposed to have 0.44g of SMB in each of them and that’s 29 litres at 10ppm. The ones I have weight exactly 0.5g, and that’s with testing 100 on a scale.

In excel I have the equation = PPMRQD * LITRESOFBEER / (PPMPERCAMPDEN / CAMWEIGHTG)

Where PPMPERCAMPDEN = 291.7248 and the weight is 0.5

Damn, can’t edit, but that gives you the weight of campden tablet to use as I’ve got one of those fancy little scales.

I’ve found that with 10ppm I can taste and smell it, though. It’s a bit ‘farty’ if you know what I mean.

I hear you, and I can say that both me and Brian Hall have been able to detect SMB in beers as well, though I’d call it more matchstick sulfur than farty. Jake Houlihan would call you a liar for saying this, though!

I just tried a crushed up campden in my keg for the first time and I can smell it. I did one 0.5g tablet in a 5 gal keg. I really don’t want to end up smelling the sulfur in my beers, is there a specific safe dose, like 0.2 g per keg, that will still help with oxidation but ensure it won’t be detectable?

Yeah so any additional sulfites that do not scavenge oxygen are supposed to be tasteless. Jake did an xbmt where he tested 10 ppm vs 100 ppm and couldn’t tell the difference. I’d wager you’ll be fine.

https://brulosophy.com/2020/04/06/impact-higher-dosage-rates-of-sodium-metabisulfite-smb-have-on-beer-character-exbeeriment-results/

Keep your keg on CO2 and purge it several times a day over a few days. The sulfite bonds with free O2 to form SO2 gas. That’s what you smell. It won’t dissolve in solution readily. It will bubble up and come out over time. The more that’s in there, the longer it will take, but one campden tablet should purge out fairly quickly.

It looks like the color difference was already there in the FG picture – are you sure the difference was due to ocygen at packaging and not there all along?

Yeah, I see what you mean. The lighting in my basement can be weird (it’s 130 years old with few updates). They’re the same color at the time of gravity reading.

What I’ve been doing since I’ve had the ability to use a fermenter large enough that I don’t get any krausen in the blowoff, is to use the CO2 from fermentation to continuously purge the receiving keg. It’s free CO2, and I’ve noticed that the beer lasts longer in the keg.

Yeah, that’s a great way of using natural CO2 and preventing cold side oxidation. I think Marshall did a write-up about that, actually. Prost.

Uh Campden tablets are Potassium metabisulfate. No sulfur in them. Such a big mistake.

Sodium metabisulfite and potassium metabisulfite are very similar and both contain the same amount of sulfur atoms.

Campden tablets 100% contain sulfites, friend.

So you didn´t even purge the headspace after filling the kegs to isolate the variable even better?

Correct!

Awesome xBMT! Obviously most of us are concerned with cold side oxidation, and I can’t wait to try this method.

The one thing I’m curious about is what the most notable difference in flavor and aroma was. I know in the past oxidation has been described as an undesirable added sweetness, compared by Marshall to the flavor of “lifesavers” candy.

Did you take note of what you got perceptibly from the oxidized version vs the dosed beer?

Both of the beers seemed oxidized to some degree because the kegs were not purged prior to packaging, though the beer dosed SMB seemed to have fewer less desirable flavors. To me, the SMB beer had a more muted hop character than what I would have expected given the amount of hops I used.

I’m sure there is an easy answer for this but I can’t figure it out! I purge my keg by pushing sanitizer out with co2…. how do I get the campden in without filling the keg right back up with oxygen again??

Once you drop your campden tablet in, purge your keg in the same manner. Either pull pressure relief valve or open your liquid out with a picnic tap. No liquid will be coming out, but you will hear the gas flowing.

same question…and answer below doesn’t really answer it. I think I’ve seen people hook up syringes to ball lock connectors but would like to be walked through it.

Connect CO2 to gas in side and turn on gas. You will hear it filling the keg. As it fills, pull your pressure relief valve 5 to 10 times. Oxygen is lighter than CO2, so oxygen will be forced upward. After 5 to 10 pulls, you can be fairly sure you are purged of CO2. Do this after dropping the campden tablet in and resealing your keg of course. Hope this helps! I can’t add photos, but if you google “purge keg of O2” you’ll find it!

Jeremiah,

the oxygen mixes perfectly with the carbon dioxide, so both gases are exiting the keg together, NOT the oxygen followed by the carbon dioxide.

You can never completely void your keg of oxygen using the method you describe.

It is a popular misconception among homebrewers that the gases in air become stratified according to their molecular weights. If that really happened, we’d all have trouble breathing the closer we were to the ground.

(The notion of a “carbon dioxide blanket” is a myth for the same reason)

@lee yes. Exactly this.

I agree Lee, this is why I suggest purging 5 to 10 pulls rather than one. The separation does happen slowly, but by purging multiple times, your concentration of CO2 will continue to rise. Yes… a small amount of O2 may persist, but that’s why I also mention above about using other carbonation methods like filling the keg a few points from FG, or using sanitized saved wort to promote natural carbonation rather than force carbing. This way you get a natural CO2 scrubbing effect. I like this better than adding sulfites to eliminate O2.

Jeremiah,

The methods you mention are good for conserving CO2 and for reducing O2 concentration in the keg’s headspace, but they do not completely eliminate the O2 from the headspace. The metabisulfite should prevent any remaining O2 from oxidizing the beer, however. If you are opposed to sulfites, then I suppose the technique of pushing sanitizer out with CO2 will be the best way to eliminate O2 from the headspace.

I agree with Mike, that there does not seem to be a way to add metabisulfite to the beer at packaging without introducing more O2. And as Will noted, if you are doing the full sanitizer purge with closed transfer, then you would not even need the metabisulfite.

I also agree with Bas: a single beer (not two different beers) should have been packaged with and without the SMB.

I don’t use Campden tablets or SMB but I do purge my kegs the same way as you (filling with sanitizer and then pushing it out with co2) is it possible you could dose the beer in the fermentor just before transferring to the keg (though I suppose you are still exposing the pre-transfer beer to oxygen)? Or you could do your normal sanitizer purge, rack in the beer and then pop the top to add the Campden and just flush the headspace after? That might be better than opening the keg post-purge but pre-rack? Or, if you’re taking the care to do a full sanitizer purge and a closed transfer to the keg … maybe there’s really no need for SMB?

Fabio, Good ideas, thank you!

@mike there’s no 100% anoxic way to do this. When I use SMB (which how I package beer 95% of the time) I will push sanitizer out with CO2 and then connect my liquid disconnect to the FV. After I start racking from FV to keg I will open the keg lid and drop in the SMB. In my experience, the addition of SMB here will be adequate for any oxygen introduced during the transfer.

There is always a way, if you care enough. You can attach a quick disconnect to a large syringe, dissolve the sulfite in water and squirt the solution with the syringe into the keg though one of the posts. Just make sure that the keg isn’t pressurized or your syringe piston will take off! You can use the same technique to add gelatin or priming sugar.

An alternative would be to use a plastic bottle with a carbonation cap, add your K-Meta solution, purge the bottle and connect it to a keg with some tubing. You could squeeze the solution into the keg by compressing the bottle.

I’m not saying that it’s worth the trouble (I just open the keg and add whatever I need to add), but it can be done.

Comment on your methodology… Why not just brew a single batch and split it into two kegs at rack time, one with sulfite and one without? Of course you’re getting double the enjoyment this way but my first thought was “what is one batch was subtly contaminated”

There’s always a remote chance that you’re introducing variability between the separate batches, it’s hard to guarantee 100% consistency and why run the risk at all if you could reduce it in this way?

The colour difference between the hydrometer readings indicate that this is exactly what happened.

I can see why you might think that. However, as was previously noted, any difference in color there is due to lighting.

It’s true that it would have been better to make a larger batch that was split evenly, but my 10 gallon kettles can’t handle a larger batch like that. What’s more is that I’m not keen on hauling around a 1/2 bbl fermenter than a 5 gallon one. Having brewed with my gear extensively and SMB, though, I’m reasonably confident that there weren’t any unintended variables introduced.

Fair enough! Was just wondering why you chose to do it this way..

Metabisulfite could also easily effect the colour of a beer, it should happily react with many colour forming compounds in there. The effect is way bigger than I would have expected for such small quantities though.

The only way that SMB should affect color is by preventing darkening through oxidation. The darker beer in this xbmt did not have any SMB.

When would I add smb to the beer to bottle condition?

So I personally wouldn’t if I were bottle conditioning. However, if you decide you want to, I’d add to bottling bucket, rack beer on top, then bottle as normal.

Could you try a exbeerimnet with smb v 3g of asorbic acid in the keg???

Sounds like a good future xbmt for when we get real-live participants!

Perfect timing for me as I am dry hopping an IPA today and kegging this weekend after a 24 hour cold crash. I don’t have a fancy-schmancy (LOL) closed transfer system. Just ye olde auto siphon and sanitized clothes on the keg opening and carboy. I purge keg of sanitizer with co2 before filling and purge after capping filled keg. I’m not a DIY kinda guy, but if there is a parts list and simply instructions to piece together a closed transfer system or a “MacGyver” way to do it without the disconnects etc … would like to see/hear about it.

Two similar things you can do… first, purchase a liquid out disconnect (black if you’re using ball lock), a gas swivel nut with barbed ending, and a hose clamp. Attach gas swivel nut to liquid out disconnect, then attach barbed swivel nut end to the end of your siphon tube with the hose clamp.

You’ve just created a siphon with a disconnect on the end. This is the best way to transfer while limiting O2 with an auto siphon. To use, first purge keg with CO2 to remove as much O2 as possible. Without pulling pressure relief, attach siphon tube. This will cause CO2 to back fill the siphon and remove oxygen from your line. Place your auto siphon into your beer, which may bubble a little bit due to CO2 coming through the auto siphon but that’s fine. Once the siphon is submerged, pull your pressure relief to relieve as much pressure from your keg as possible. Finally, give your siphon a good pump or 3 and watch your beer fill the keg with limited O2 uptake! You if the beer flow slows or stops, you need to pull the pressure relief on the keg and it will keep going.

Now, you can improve this one step further if you like. The only additional items you will need is a carboy cap with 2 openings and a standalone racking cane. Place the racking cane through the top opening, and connect CO2 line to the 2nd opening. Set gas to no greater than 3 psi. Attach siphon tube to racking cane and connect liquid out disconnect. Turn on gas and watch it do all the work for you! The keys… make sure your gas is set to 2 to 3 psi, and you give your pressure relief a pull every now and then. Don’t worry, your glass carboy will not break with the pressure. If your pressure is too high, the carboy cap will just come off. I’ve used both methods with great success. Good luck!

I am very intrigued by this but don’t have access to SMB but do have Campden tablets. These are potassium and not sodium based. Would it still work the same and would the dosage rate be the same?

Some campden tablets are sodium, be sure to check the packaging. But yes, potassium metabisulfite will scavenge oxygen just like soidum metabisulfite because the active ingredient that helps prevent oxidation is the metabisulfite component. You can use the same dosage of 0.3g for 5 gallons of beer.

I would like to see a test with Kräusen vs spundig or force carbonation or something like that. Active fermenting yeast ought to be the best yeast scavenger? Or?

I use Campden/SMB to rid my water of chloramine/chlorine before brewing; I’m curious how much residual SMB might be in the wort post boil and should I consider this if planning to add more at bottling? Thanks!

That depends on the mass of SMB and volume of water you are using. For example, Bru’n Water tells me that if I use 0.29 grams of SMB in 7.5 gallons of strike water, that’ll give me 10 ppm. The amount of water may be slightly different, I’m just going off memory. Regardless, your mileage will vary depending on your volume of water/wort and the amount of sulfites you use.