Author: Brian Hall

A few years ago, I came across a curious device that aromatizes hops such that one can get an idea of what specific varieties would contribute to beer. The fragrance this thing put out was delightfully pungent, similar in many ways to the delectable aroma I sense when purging the gas from a keg of IPA, which got my gears turning.

Over the following months, I conceptualized a method whereby hop-infused CO2 would be used to carbonate beer. To my mind, the fact gas purged from a keg of IPA smells so hoppy indicates CO2 carries aromatic compounds, and since carbonation is a function of CO2 dissolving in liquid, then using CO2 infused with hop aromatics ought to contribute an additional layer of hop character to beer.

While visiting Yakima, WA during a recent hop harvest, I shared my hypothesis with Nathan Cooper of Wandering Hop Brewery and he mentioned he’d been using “flavored gas” captured during fermentation to perform beer transfers, which he felt had a noticeable impact. We ended up discussing possible approaches to infusing CO2 with hop aromatics during the force carbonation process and agreed it would have to occur between the tank and the keg. It occurred to me I had a Blichmann HopRocket gathering dust at home that, given its airtight seal, seemed an ideal inline hop infusion device. Inspired by the prospect of discovering something new, I designed an xBmt to test it out for myself.

| PURPOSE |

To evaluate the differences between an IPA force carbonated with hop-infused CO2 and one carbonated with standard CO2.

| METHODS |

To test my hypothesis that carbonating with hop-infused CO2 improves hop aroma, I went with a simple recipe inspired by Tiny Bottom Pale Ale.

Big Bottom Pale Ale

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 35.4 IBUs | 8.8 SRM | 1.054 | 1.014 | 5.3 % |

| Actuals | 1.054 | 1.008 | 6.1 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Lamonta American-style Pale Malt (Mecca Grade) | 8.5 lbs | 77.27 |

| Caramel/Crystal Malt - 15L | 12 oz | 6.82 |

| Vanora Vienna-style Malt (Mecca Grade) | 12 oz | 6.82 |

| Victory Malt | 10 oz | 5.68 |

| Caramel/Crystal Malt - 60L | 6 oz | 3.41 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Magnum | 16 g | 60 min | Boil | Pellet | 11.6 |

| Perle | 14 g | 25 min | Boil | Pellet | 8.6 |

| Fuggles | 14 g | 10 min | Boil | Pellet | 4.4 |

| Fuggles | 15 g | 2 min | Boil | Pellet | 4.4 |

| Centennial (AromaCan) | 113 g | 0 min | Dry Hop | Pellet | 9 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Tartan (A31) | Imperial Yeast | 73% | 65°F - 70°F |

Notes

| Water Profile: Ca 126 | Mg 0 | Na 0 | SO4 118 | Cl 135 |

Download

| Download this recipe's BeerXML file |

After collecting the water and adjusting it to my desired profile, I lit the flame on my burner to get it heating up then moved on to milling the grain for this large batch.

Once the water was properly heated, I stirred in the grist then checked to make sure it hit my target mash temperature.

When the 60 minute mash rest was complete, I sparged to collect the expected pre-boil volume of sweet wort then brought it to a rolling boil.

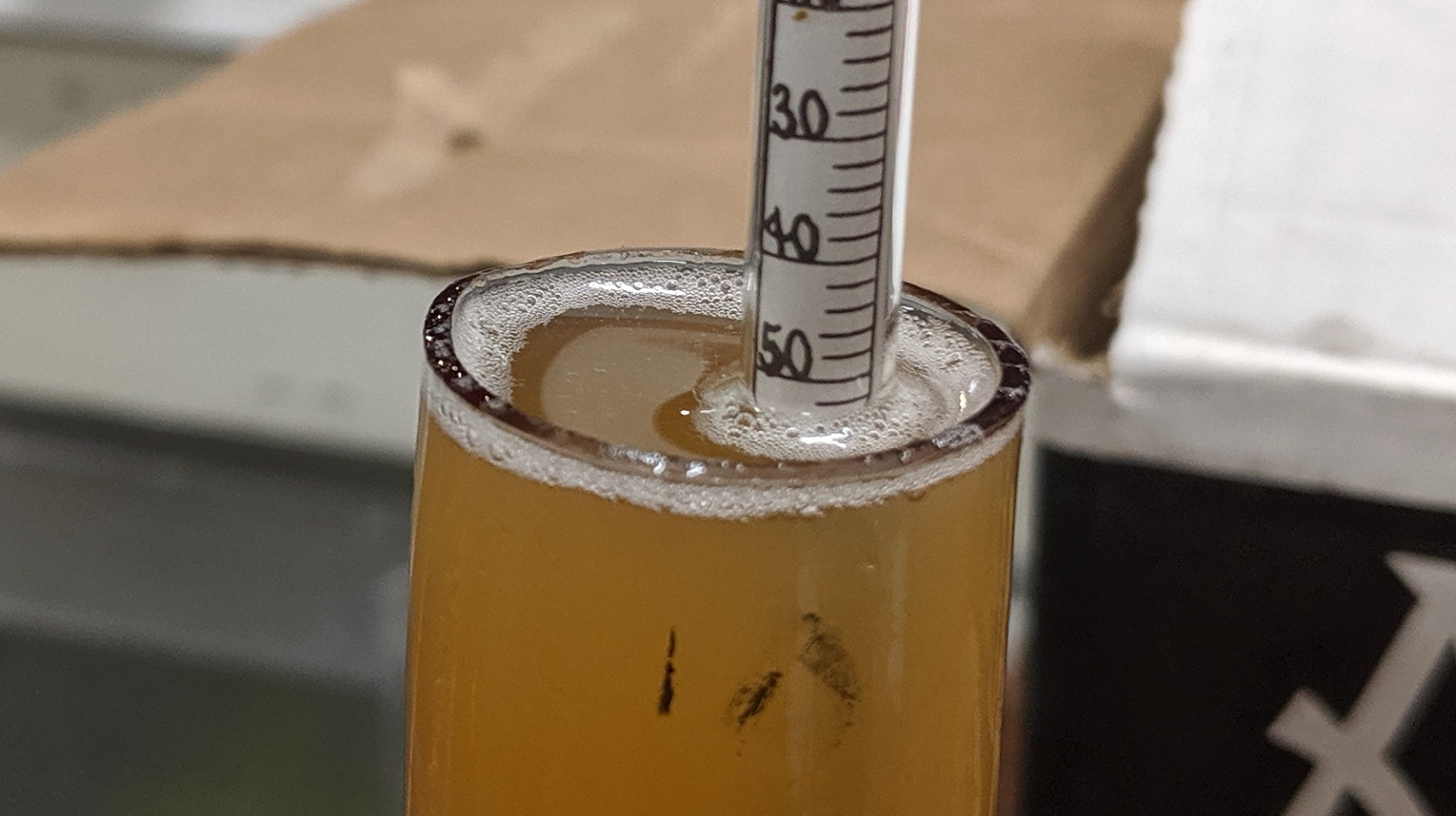

Following the 60 minute boil, I quickly chilled the wort before taking a hydrometer measurement showing it was at the target OG.

Identical volumes of wort were racked to separate sanitized Brew Buckets that were placed next to each other in my garage that maintains 64-66°F/18-19°C, at which point I pitched a single pouch of Imperial Yeast A31 Tartan into each batch.

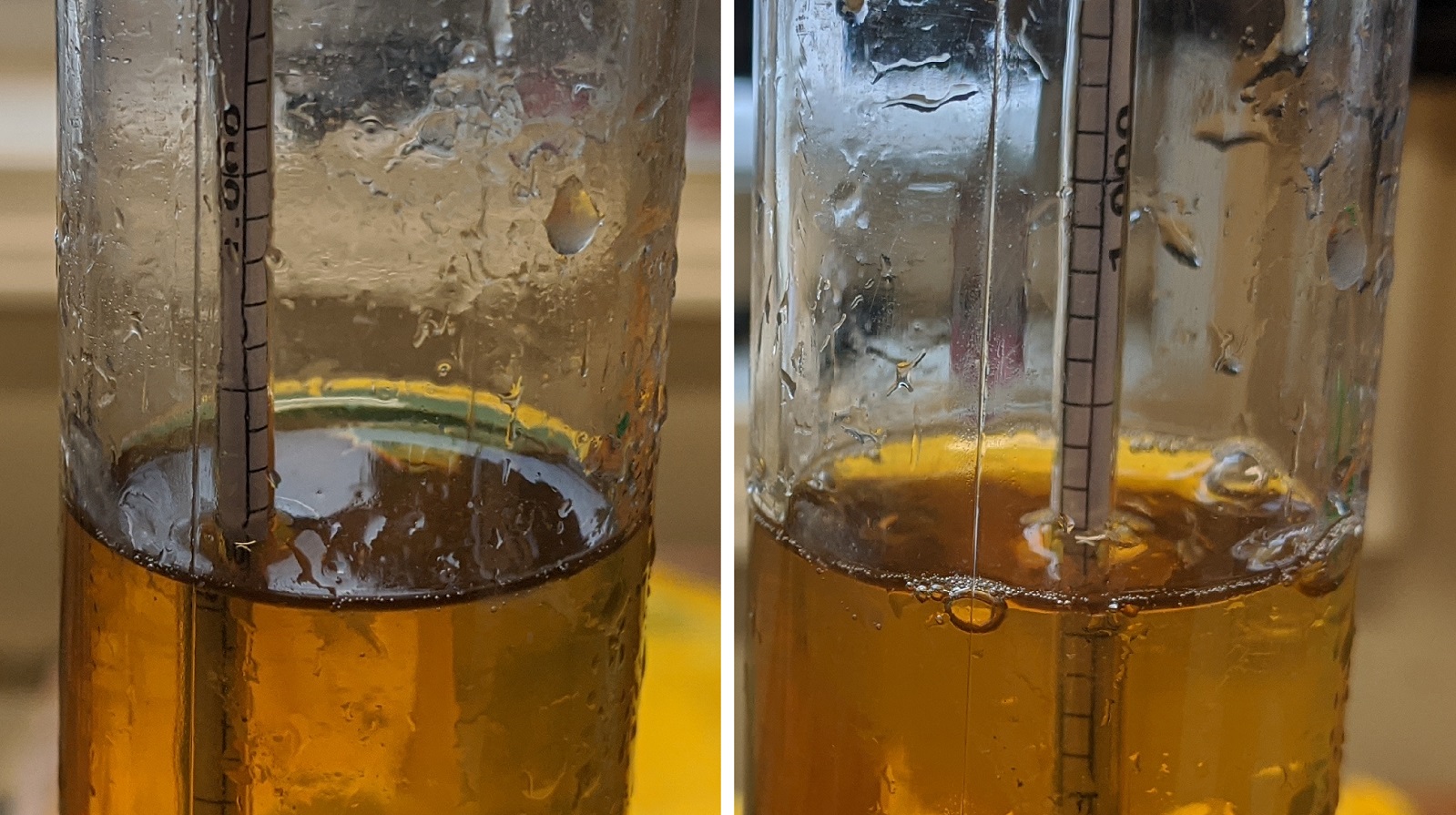

I left the beers alone for 4 weeks before taking hydrometer measurements showing both were at the same FG.

At this point, I racked one batch to a CO2 purged keg using my normal process, after which I prepared my Blichmann HopRocket by sterilizing it with heat.

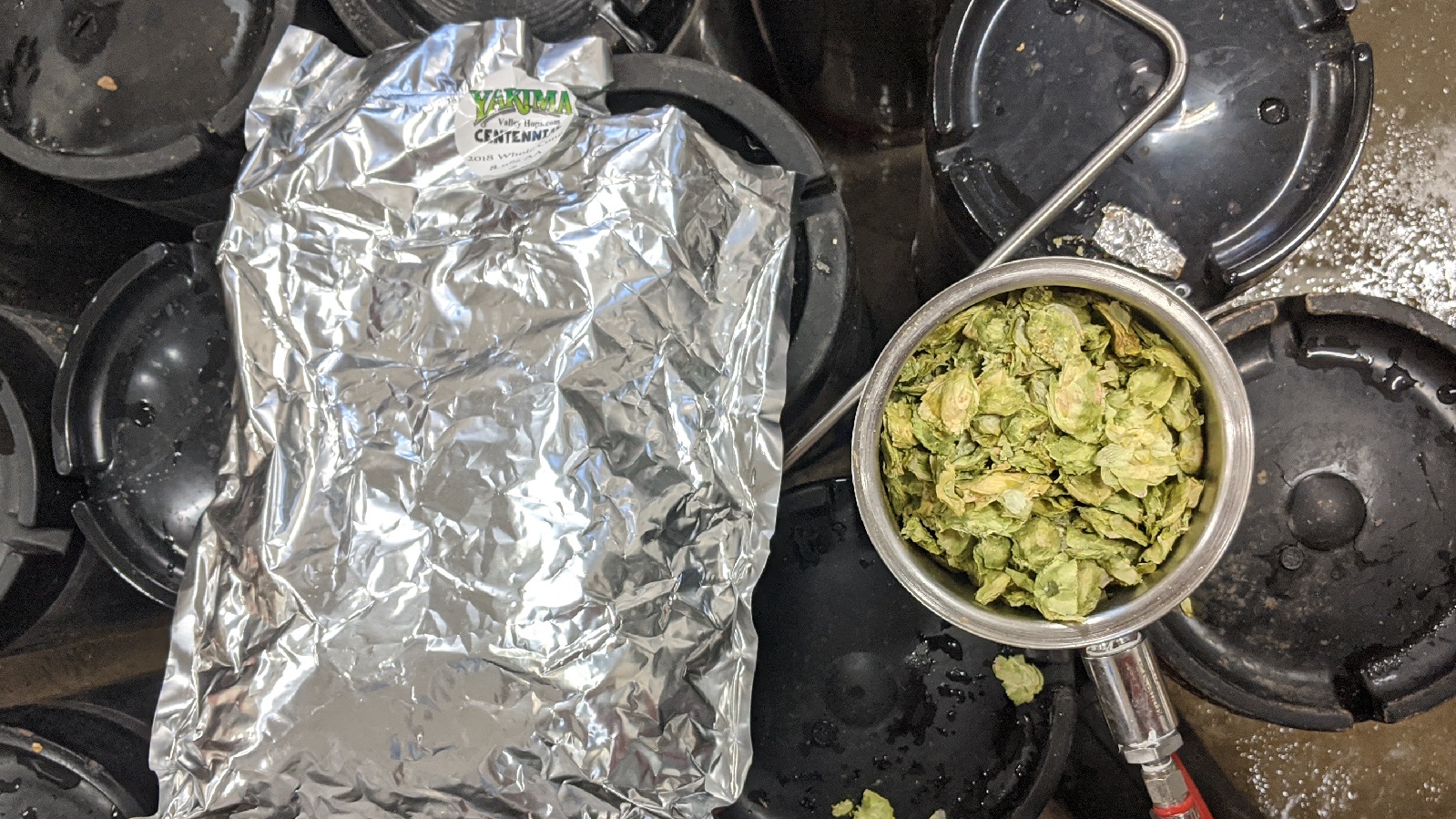

Next, I put 113 g/4 oz whole cone Centennial hops into the HopRocket, or what I came to call the AromaCan.

I then ran CO2 through the AromaCan for 30 seconds to purge it of as much oxygen as possible.

With the AromaCan free of oxygen, I used it to purge a sanitized keg with hop-infused CO2.

Finally, I racked the second beer into the purged keg. With the filled kegs in my cool keezer, I connected a CO2 line directly from my regulator to one while the other had the AromaCan inline, both set to 12 psi.

I used the set-it-and-forget-it carbonation method and left the beers on gas for 6 weeks before I began serving them to tasters.

| RESULTS |

A total of 24 people of varying levels of experience participated in this xBmt. Each participant was served 1 sample of the beer carbonated with hop-infused CO2 and 2 samples of the beer carbonated normally in different colored opaque cups then asked to identify the unique sample. While 13 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, only 10 (p=0.25) did, indicating participants in this xBmt were unable to reliably distinguish a Pale Ale carbonated with hop-infused CO2 from one carbonated normally.

My Impressions: When trying these beers side-by-side, I felt they were pretty easy to tell apart on aroma alone. I perceived the beer carbonated with hop-infused CO2 as having more pine and dankness than the one carbonated normally. Out of 5 triangle test attempts, I selected the unique sample 4 times, which is pretty consistent. The beer was good, nothing spectacular, just a nice easy-drinker.

| DISCUSSION |

For those brewers aiming to please the palates of the hoppiest of hop-heads, any method that increases hop character in beer is worthy of consideration. My love all things hoppy is what ultimately inspired me to develop the AromaCan, a device that gets placed inline between the CO2 tank and keg during carbonation, which I presumed would lead to increased hop character in the carbonated beer. Unfortunately, results from this xBmt indicate results from this xBmt indicate it didn’t have a dramatic effect in this instance, as tasters were unable to reliably distinguish a beer carbonated using normal methods from one carbonated with hop-infused CO2.

Considering the amount of gas that dissolves into beer to produce adequate carbonation, I really felt use of the AromaCan would produce an obvious difference, which clearly wasn’t the case in this xBmt. One explanation is that, even if the gas did carryover some hop aromatics, the other beer characteristics were enough to overpower any perceptible impact. It’s possible using this method on a more nuanced style or perhaps packing more hops in the AromaCan would result in a more noticeable effect.

Even so, my original hypothesis was that using the AromaCan when carbonating would improve hop character in hoppier styles such as IPA, which these results do not support. However, I’m not ready to abandon the idea altogether and think it may have potential to add layers of hop character more traditional methods can’t accomplish.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

14 thoughts on “Impact Carbonating With Hop-Infused CO2 Has On American Pale Ale”

6 weeks?

That’s a little long for an IPA. However, with constant infusion of hop aromatics, good aroma should have been apparent in the results. That was the hypothesis, anyway. 😉

And that is in addition to the 4 weeks in the fermenter.

Wouldn’t the aromatic compounds need to be extracted in liquid, and THEN scrubbed and carried away with the CO2? You seemed to reliably distinguish it because you knew what to look for, just need to turn the dial to 11.

The Centennial (AromaCan) is listed as pellet, but I think you used cones?

Also, there’s a repeated “results from this xBmt indicate” in the DISCUSSION section.

Thanks for the xBmt, I would also have expected the beers to be more distinctive. I would be interested to know if using the CO2 generated from fermentation of heavily hopped styles would make a difference, as in that case the hop aromatics are disolved into the liquid and the generated CO2 might be able to extract them easier than from dry hops.

Please could you next time to do a dry hop experiment in one already carbonated beer?

So many thoughts on this one.

If you look at gas laws and diving science, we go to great lengths to protect our military divers from chemical exposure in diving chambers and diving air systems.

When you pressure a vessel, the gas gets into anything porous and when the pressure is reduced, someone breathes from it, it will leach out compounds that are health hazardous. Also a thing in submarine escape systems.

*Key thing about releasing compounds into gas is there pressure differential. When we prepare a new chamber for use it’s pressurized multiple times before talking air samples to verify any unacceptable compounds have been leached out and the chamber is safe for breathing.

So one thought could be setting the hops to saturate at a higher pressure… then release on intervals. In theory you’d be dosing with concentrated infused gas.

Another thought could be a cold brewed tea. If the hop rocket was oriented properly and not overfilled this could be another way to get the compounds moving out of the plant and into the gas.

The pressure holds, however, would still probably yield the best results.

This is a really cool xBmt. I’m thinking you could pre-extract some hops in an empty keg that is pressurized to 30 PSI or so, then use that keg to force carbonate. If that’s not enough pressure, then you could run your CO2 into the hop keg, then into the receiving keg.

Also, I can’t help but wonder if the blind sampling nature of this experiment could lead to the subjects not picking up on the differences because they’re focused on flavor rather than aroma.

What is going on in this image?

https://i1.wp.com/brulosophy.com/wp-content/uploads/2020/02/07_co2hopinfusion_sterilizehoprocket.jpg?resize=620%2C341

Hop aroma is more volatile at higher than room temperature. Wondering the effect if the AromaCan was heated during the process; if more aroma would be imparted to the carbonation.

Interesting that not may participants made the correct choice but you did. Like Eric J Branchaud said the focus on flavor from the participants could have changed with the suggestion of aroma.

I wonder if the design of the aroma can would have a part to play too? Something like the equivalent of the shower screen and perforated basket in an espresso machine, to ensure even extraction without channeling?

I wonder if the effect would be more pronounced with a cider instead of a beer?

You should redo and add 4 oz as a dry hop to the other beer. Meaning, if it did have an impact on aroma/flavor, was it a worthwhile use of the hop? Do you get more/different hop character out of the hops by flavoring co2?

Probably would have been useful to talk to some of the folks using supercritical CO2 to extract hop or marijuana compounds to learn more about the mechanisms involved.