Author: Cade Jobe

Wort aeration, either through dosing with pure oxygen or mechanical agitation, is commonly practiced by brewers as a means of ensuring healthy fermentation. While an arguably uncomplicated process, concerns have been expressed about the contact of oxygen with wort, in large part due fears of potential beer oxidation further down the line. As such, some brewers have sought alternative means of providing yeast with the resources they need to effectively ferment beer.

In 2005, graduate student Grady Hull performed an interesting study in which he hypothesized that adding, of all things, olive oil to yeast during storage could eliminate the need for standard aeration, as the yeast would theoretically take up the unsaturated fatty acids (UFAs) needed for cell wall development. Following a series of experimental trials in which a beer fermented with yeast dosed with olive oil was compared to one aerated with oxygen, Hull concluded olive oil could be used as an alternative to wort aeration and that any objectively measurable differences in esters were small enough as to not be perceptible by tasters.

While the olive oil in Hull’s study was added to yeast harvested from a prior batch during storage, people soon began talking about additions made just prior to yeast pitch. Despite new information contradicting Hull’s conclusion, I was curious about how a beer dosed with olive at yeast pitch would compare to one that was not aerated at all and decided to test it our for myself.

| PURPOSE |

To evaluate the differences between beers fermented with and without a small amount of olive oil added at yeast pitch.

| METHODS |

My goal being to accentuate any impact of the variable, I went with my clean Kölsch recipe for this xBmt.

Livvie Lou

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 18.0 IBUs | 2.6 SRM | 1.044 | 1.008 | 4.7 % |

| Actuals | 1.044 | 1.003 | 5.4 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pilsner (2 row) (Gambrinus) | 8 lbs | 94.12 |

| Wheat Malt (Gambrinus) | 8 oz | 5.88 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Hallertau Magnum | 10 g | 60 min | Boil | Pellet | 14 |

| Tettnang | 7 g | 5 min | Boil | Pellet | 4.5 |

Miscs

| Name | Amount | Time | Use | Type |

|---|---|---|---|---|

| Olive Oil | 8.00 ml | 0 min | Primary | Other |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Dieter (G03) | Imperial Yeast | 75% | 60°F - 69°F |

Notes

| Water Profile: Ca 194 | Mg 17 | Na 18 | SO4 389 | Cl 50 |

Download

| Download this recipe's BeerXML file |

I started off my brew day by collecting the proper volume of water for a 10 gallon/38 liter batch, adjusting it to my desired profile, then lighting the flame under the kettle.

While waiting on the water to heat up, I weighed out and milled the grain.

When the water was ready, I stirred in the grains then checked the mash temperature.

During the mash rest, I collected out the kettle hop additions.

When the 60 minute mash was complete, I sparged to collect the target pre-boil volume.

The wort was boiled for 60 minutes then quickly chilled with my IC.

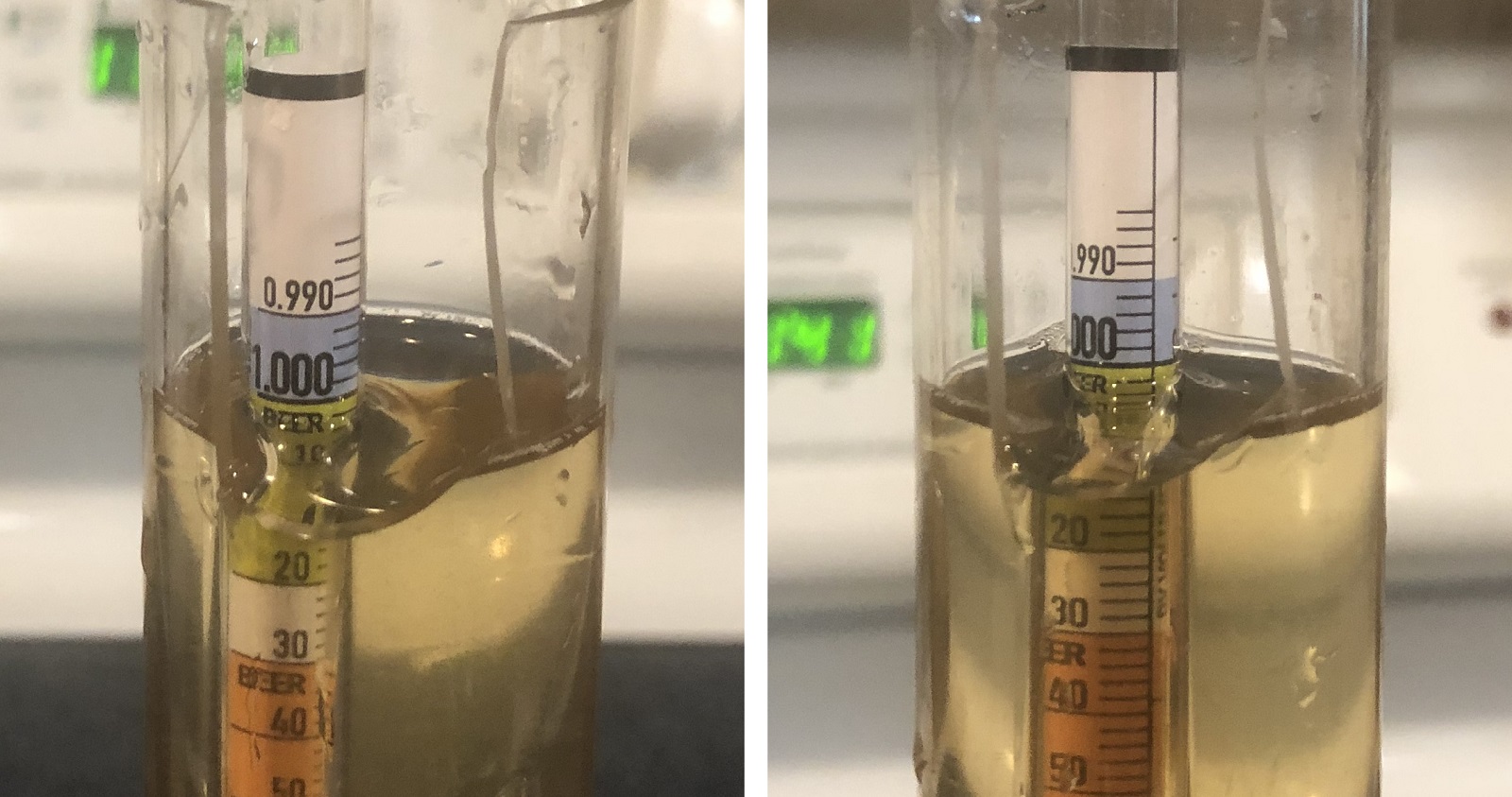

With a hydrometer measurement showing I’d hit my target 1.044 OG, I split the wort between two sanitized Brew Buckets and placed them next to each other in my fermentation chamber controlled to 54°F/12°C. At this point, I measured out 8 ml of olive oil to add to one batch, which is many times the 1 mg per 25 billion yeast cells recommended in the paper.

With the olive oil added to one batch, I pitched a single pouch of Imperial Yeast G03 Dieter into each.

The beer dosed with olive oil showed signs of fermentation activity a few hours sooner than the control batch then proceeded to ferment more vigorously (based on airlock activity) and ultimately finished 2 days before the batch fermented without olive oil. After 7 days, I raised the temperature to 68°F/20°C and left the beers alone for another 4 days before taking hydrometer measurements confirming both were at the same FG.

I reduced the temperature in the chamber to 34°F/1°C for an overnight cold crash then pressure transferred each beer to separate sanitized kegs.

The filled kegs were placed in my keezer, burst carbonated, then left to condition for a week before I began serving them to participants.

| RESULTS |

A total of 21 people of varying levels of experience participated in this xBmt. Each participant was served 2 samples of the beer fermented with olive oil and 1 sample of the beer fermented without olive oil in different colored opaque cups then asked to identify the unique sample. While 11 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, only 5 did (p=0.88), indicating participants in this xBmt were unable to reliably distinguish a Kölsch where a small amount of olive oil was added at yeast pitch in place of aeration from one fermented without olive oil or aeration.

My Impressions: Out of the 5 semi-blind triangle tests I attempted, I guessed the odd-beer-out just twice. To me, the beers looked, tasted, and smelled exactly the same– no differences esters or phenols, no signs of oxidation in either, and certainly no olive oil flavor.

| DISCUSSION |

Brewers are often willing to do some pretty peculiar things if it promises to improve the quality of their beer, for example, using olive oil in place of wort aeration. In a study comparing a beer pitched with yeast that had been stored with a small dose of olive oil to one that was aerated with oxygen, New Belgium’s Grady Hull demonstrated that, despite small measurable differences in certain compounds, people were unable to tell the beers apart. Interestingly, tasters in this xBmt were similarly unable to distinguish a beer dosed with olive oil at yeast pitch from one that received no aeration at all.

While the results of this xBmt showed that tasters we unable to perceive differences between the beers, the fact the one with olive oil added at yeast pitch not only had reduced lag but fermented with more vigor and finished earlier suggests the method may have had an impact. Whether this is enough to justify adding olive oil to one’s beer is up to each individual brewer to decide.

Prior to this xBmt, I presumed olive oil would have no impact on beer and was surprised with the observed difference in fermentation activity. However, since both beers tasted exactly the same to me, corroborating the xBmt results, I won’t be using olive oil in place of aeration in the future.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

57 thoughts on “exBEERiment | Impact Using Olive Oil As An Alternative To Wort Aeration Has On Kölsch”

You write “mg”……shouldent it be “ml”, e.g. 1 ml oil per 25 billion yeast cells? At least to me 1 mg (milli-gram) is not much?

I assume it is 8 ml to one potion of 200 billions cells from Imperial!

….or is the picture syringes with oil just a sample picture and not precise amount…………8 mg is like nofthing?

Yeah the Purpose section mentions zinc. Either they are seriously confused or they couldn’t be bothered to do even minimal proof reading. In the past they run about 50/50 for either of these.

Surely you don’t need to aerate when using dry yeast anyway. Wouldn’t it have been better to use liquid years in this experiment?

It was liquid yeast dude

Who knows…..half of this write up was typos dude

The yeast used here is a liquid yeast.

But now they are gonna have to do at least two more xbmts!

Olive oil plus liquid yeast – no aeration of non-olive oil batch (check)

Olive oil plus liquid yeast – with aeration of olive oil batch

Olive oil plus DRY yeast – no aeration

Interesting experiment. I’ve never heard of the use of olive oil before this. As a person without an oxygen stone I typically try to shake the wort. This would be worth a try for my own experiment. Thanks for the article! Sla’inte!

Let us know how it goes!

Why does the “Purpose” section state that the purpose of this experiment is to test differences between a wort which received zinc and one that did not?

Because they couldn’t be bothered to proofread (as usual)

Brendan, why all the attitude? You know this site is free, right? They don’t owe you or any of us anything. I appreciate these write-ups, even with the occasional error.

A) why not try to be better? B) the point of the site is that they are trying to be scientific. Science allows criticism in the effort to be better C) how can we discuss the experiment and the results if we don’t know if what is written is correct or a sloppy typo? D) someone on the site is getting advertising money and free equipment. In return I give them my eyeballs. E) They gain legitimacy and eyeballs and the stuff in D based on the idea that they are generating content that is more legitimate because of the perception of their scientific approach. As a scientist, I insist that if they are going to use science they should respect it. F) I’ve made gentler comments along this line in the past and they repeatedly still can’t be bothered to even do minimal proof reading let alone think about experimental design or proper control experiments so I’m happy to use attitude to act as an exclamation point.

Says the guy who spelled his own name wrong in the above comment! Now I am only poking fun, but you gotta admit it’s a wee bit ironically funny… For real though, it’s a free site that does a bunch of interesting beer related experimentation in the interest of expanding our collective homebrewing knowledge… I personally value their efforts as well as appreciate the time, money and energy they all put in, despite some grammatical imperfections… But that’s just my opinion ‘eh, cheers to all!

Or maybe I did it on purpose because I appreciate irony too. But seriously the issues weren’t minor grammatical mistakes, they were major problems that affected the ability of the reader to understand what is going on (see the confusion expressed in the other comments for example) but could have been fixed with even basic proofreading. Moreover does it really cost them much money or time? They would be making beer anyway and they get free stuff.

Was this a holdover from a copy and paste? “To evaluate the differences between beers fermented with and without a zinc addition.”

Just curious if 93% attenuation is normal for you with this strain?

Same here. Imperial lists the attenuation range at 73-77% for Dieter. I can only assume a measurement error or contamination. The later might be dominating flavor differences.

No, 93% is not normal attenuation for that recipe, but I’m happy with the results.

Why not actually quantify the observed difference in fermentation lag? It would be easy. And not that I don’t trust you but this write up has been especially sloppy….

The olive oils started a few hour before non-OO and finished 2 days quicker. What do you want, exact start and stop times? Why the hell does that even matter? Gosh.

Gosh. There are many reasons why the hell that matters. It was one of the only observable differences so it is essential to determine if it significant before any conclusions can be made. Having a nice time curve with multiple data points could be a step in that direction. Moreover, thinking about different assessment techniques could expand the site beyond simple taste tests and open up the experiments in new directions. The major questions tackled by this experiment were about how conditions affected yeast viability. What is the best and easiest way to test this? Do taste tests directly answer questions about yeast viability?

Given the goal was less cold side O2, I’d be very interested in long term shelf stability.

So far (4 weeks after kegging), both beers still look and taste the same to me. I’ll keep and eye on them and post if anything changes.

Very interesting. It would be even more relevant to see the difference in how these two beers compare over time in holding up against oxidation and preserving their character.

How was the head retention? I would think any oil would make it quickly diminish. The head looks smaller in the olive oil beer in the pic.

I haven’t noticed a difference. The beer with olive oil was poured earlier then the other.

I’d be curious if this was repeated with a higher gravity beer, as higher OG beers need more yeast, therefore more oxygen. The differences could be more staggering. A single packet here should easily ferment a beer with an OG below 1.050.

The amount of sterols and unsaturated fatty acids required by the yeast is more likely to be on the order of the amount of oil that you can pick up on the head of a pin vs. 4 mL. The negative impact upon head retention is likely a product of gross overkill with the olive oil.

I don’t see that as negative head retention. If you put a drop of oil in a fermenter you’ll see everything drop. That’s as much about how long it’s been in the class, cleanliness of glass, and how long it took to take a good picture as “head retention”. I’ve been brewing for 25+ years and the etherial “Belgian lace” is few and far between.

I am curious as to why you won’t use this method in the future?

I am also curious. Was the final sentence a typo or are you actually not going to use olive oil ? Why not use both ?

From the article: “At this point, I measured out 4 ml of olive oil to add to one batch, which is many times the 1 mL per 25 billion yeast cells recommended in the paper.”

1) Any chance we could get a link to the paper? I’ve heard about it many times, but never seen it myself.

2) If the recommendation (see Q 4 below) is 1 ml per 25 billion cells, and you used 4 ml (see Q 3 below) with an entire packet (200 billion cells) of yeast, then you are using at half the recommended dose, not “many times” the recommended dose. You sure these numbers are correct?

3) You say 4 ml, but your picture shows what looks like 2 syringes, each with 4 ml (8 ml total). Could you verify how much was added?

4) Like I said, I haven’t seen the paper, but anytime I’ve heard about this, it’s always been described as adding a minuscule amount of olive oil for a 5-gal batch. I’ve heard of people dosing by using a pin dipped in the oil. That is considerably less than 1 ml per 25 billion cells. Are you sure your numbers are correct?

Found a downloadable PDF here: https://pdfslide.net/download/link/hull-olive-oil-thesis

Previous exbeeriments on wort aeration have failed to achieve statistical significance even with high OG beers. You should have chosen better the style for this study. Maybe a big beer or a lager?

In my opinion the only conclusion you can take from this one is that olive oil is not deleterious to head retention nor leaves residual taste.

Thanks for this. I’d be curious to see the experiment repeated with a much bigger beer, where the yeast is put under a lot more stress. Would be interesting to see whether the differences in lag and total fermentation time are further exacerbated. At 1.044, that pouch of yeast isn’t going to have any trouble one way or another.

I have been using a single drop of olive oil in my yeast propagation starters for some time. Based on the prior published data, I have felt this adds sterols for the yeast so they can be their best and yet I don’t have to worry about O2 issues in the propagators. Don’t have any objective data, but sure do seem to have happy starters. Standard starter for me is a 2L batch with 200g or light DME and a pinch of yeast nutrient, a drop of olive oil and a drop or two of antifoam. Boil for 6-7minutes and then chill. Store in fridge until need to prop another round of yeast.

I would be interested in seeing whether there is a difference in shelf life.

Me, too. I feel confident that my processes are good to go it’s just my beers seem to fade after 6 to 8 weeks.

Is that water profile correct? Seems a bit heavy handed for a Kölsch?

Is it just me or is the second picture a photo of your milling the grain or a photo of an empty sack of Gambrinus malt perfectly stretched and framed? 😛 I suspect someone instructed you a bit on the content of that photo! ( it’s not the only one but this one seems a little too deliberate…).

All digs and joking aside, I’ve read the now famous experiment where a brewery compared aerated vs non-aerated with olive oil. In it they concluded they ‘preferred’ the non-aerated+olive oil beer but never did a non-aerated beer with no additions to rule out the possibility that they just don’t like beer made with aerated wort.

But given Greg Foster of Brulosophy demonstrated a non-significant result comparing a Barley wine fermented with pure O2 or nothing at all, it would seem strange that you would be able to detect a difference here with a much weaker beer. I’m sure there is some difference on a chemical level but the average cohort of beer tasters would never be able to conclude a perceivable difference.

A few contributors have frequently mentioned about combining non significant variables in one experiment to see if it tips the scales, but so far it’s been a bit dry on that front. Maybe a non-aerated underpitched with no added zinc nutrient semi-cold fermented malt liquor / Barley wine vs an O2 aerated overpitched +zinc experiment? Not only could this show a difference but it probably typifies the two extreme conditions seen between a novice homebrewer and a professional brewery.

8ml is about 7.3 grams = 7300 mg which is about 1000 times more than the paper suggests…

I always thought 8ml = 8g = 8000mg

It is with water. Oil is lighter.

Thanks for sharing this experiment! I was always curious about this “olive oil fad”.

A constructive criticism: This type of question is hard to answer with only 2 experimental conditions.

With your question in mind, I think the first step would be to create a protocol/ recipe in which you can show that Aerated vs. Non-aerated causes a perceptible difference to tasters (the method of aeration would to be defined and consistent). Once you establish this, you can use that protocol/recipe to test if tasters can perceive difference between the 3 experimental groups (Aerated, Non-aerated, Non-aerated + Olive oil).

Keep up the good work.

Thanks heaps for doing this exbeeriment! I remember seeing a writeup about this use of olive oil in brewing a fair while back. I thought about trying it in a batch of beer but choked and erred on the side of caution.

That’s the beauty of this site youse test out all these crazy brewing practices and triangle test them side by side or any differences. I was sure the olive oil bree would impact head retention for sure but your side by side these looks pretty similar to me.

It was interesting that the olive oil batch fermented with more vigour might be worth trying in a stuck fermentation scenario or in High Gravity worts to kick start fermentation

Cheers

Perhaps Brendan has gotten to the point where his frustration makes him come off as rude. But, I have to agree with him in principal. Many of these write-ups are full of errors — most of which seem to come from using a previous post as a template, and accidentally leaving a bunch of garbage in the new post. I have really enjoyed Brülosophy. But, relying on your readers to proofread is a bit annoying.

Do you have any idea why the batch with olive oil fermented faster? In the original experiment done by Grady Hull (see table 3 in this link: https://www.kotmf.com/articles/oliveoil.pdf) the result was the opposite (see page 26): ” The rate of attenuation in all trials was slower than the control samples but the fermentations were complete and all final gravities were similar to controls. “

Given this contradictory result (faster ferment) and the 93% attenuation doesn’t it seem likely that olive oil batch was infected? Maybe even by the olive oil? Wonder what it will taste like in a month or two? Let us know Cade.

Yeah I was thinking of something similar, but when the author said, “No, 93% is not normal attenuation for that recipe, but I’m happy with the results” I was reminded of undergrads who’d proudly report 110% isolated yield in their lab reports and argue for a higher grade. I tried to say this earlier, but it evidently was censored.

Thanks for posting this experiment. I’d be interested to see you guys run this again but this time, compare a beer that receives no aeration AND the olive oil dose to a beer that receives pure O2 aeration with no olive oil. Perhaps even make it an extended experiment. Perform the usual initial taste testing, but bottle a couple of them from each batch and store them for 6 months and re-run the taste test then to see if there’s any effect on shelf stability.

To me, the study published by Grady Hull is comparing what I listed above. They were using olive oil to replace aeration so I would think you might see some interesting results if you compare the use of the olive oil to the use of aeration, instead of NO aeration. Just my 2 cents.

What aeration method was used? previous exbeeriments only showed statistical significance at nothing vs pure O2. Huge fan of your site btw, makes some sense of all the brewing claims that are made over the years. Keep up the good work!

As far as I can tell, the only thing you have demonstrated is that you don’t need to add anything (including additional oxygen) to the wort to get a normal fermentation. Olive oil did not improve the fermentation because there was already enough oxygen in the wort after it was transferred to the fermentor This is precisely what I published when Hull published his experiment and long before White labs repeated Hull’s experiment. Thanks for confirming that olive oil was not effective in providing anything that the yeast in these experiments needed because whatever the yeast needed for a healthy fermentation was already in the wort.

Thank you for an interesting exbeeriment

You conclude: “Prior to this xBmt, I presumed olive oil would have no impact on beer and was surprised with the observed difference in fermentation activity. However, since both beers tasted exactly the same to me, corroborating the xBmt results, I won’t be using olive oil in place of aeration in the future.”

Why not use olive oil? To me it seems like it is easier to simply add a drop of olive oil rather than messing around with a lot of oxygenation equipment that need to be maintained.

The short answer is olive oil didn’t make a big enough difference for me to change my brewing practices. 1) I direct pitch from pouches (no oxygenation equipment), 2) using olive oil didn’t impact the flavor of the finished beer in this xBmt, and 3) when homebrewing, I don’t necessarily need the beer to finish as fast as possible. The extra 2 days don’t really matter much to me.

It’s all dependent on what is important to you as the brewer. While there were differences in fermentation activity, it wasn’t sufficient for me to start adding olive to my brews.

Thank you for your quick answer. I guess I didn’t read the exbeeriment well enough. I thought one fermenter got oxygen or air, while the other got olive oil. My bad.

Like 3 years too late on this string but added a small amount of olive oil (roughly 0.5ml/L) while growing (scaling up)a large scale starter for a 1-2 bbl gluten-free beer using sorghum extract. Oil added during boil and served dual purpose of keeping down foam and (maybe) nutrient. Subjectively gave a better yeast yield than previous time. Both times had aeration from aquarium pump and yeast nutrient.

Alas no quantitation, only anecdotal.