Author: Phil Rusher

One of the most common methods for carbonating beer, particularly among newer homebrewers, is bottle conditioning whereby controlled refermentation occurs in the package. Typically, brewers blend a specific amount of priming sugar with the fermented beer, transfer it to bottles, then seal those bottles such that the CO2 produced during the conditioning process gets absorbed into the beer, thus carbonating it. A tight seal is also necessary to prevent oxygen from entering the vessel and potentially ruining the beer.

Brewers who rely on bottle conditioning have a few options when it comes to sealing their filled bottles, the most popular being crown caps, which get crimped over the lip of the bottle to form an airtight seal. As a one-and-done product, crown caps typically get

Brewers who rely on bottle conditioning have a few options when it comes to sealing their filled bottles, the most popular being crown caps, which get crimped over the lip of the bottle to form an airtight seal. As a one-and-done product, crown caps typically get tossed once removed from the bottle. An arguably more economical alternative is swing-top bottles, which are also referred to as Grolsch-style, flip-top, and keeper bottles. Instead of a cap being crimped in place, the seal on a swing top bottle is achieved with a rubber gasket affixed to a porcelain stopper that is held in place by hinged wires.

tossed once removed from the bottle. An arguably more economical alternative is swing-top bottles, which are also referred to as Grolsch-style, flip-top, and keeper bottles. Instead of a cap being crimped in place, the seal on a swing top bottle is achieved with a rubber gasket affixed to a porcelain stopper that is held in place by hinged wires.

Both crown caps and swing tops are successfully used by many brewers, though opinions abound as to which is better at retaining CO2 while resisting oxygen ingress. While I don’t tend to bottle condition much these days, I was curious whether either sealing method would lead to a noticeable difference and put it to the test.

| PURPOSE |

To evaluate the differences between bottle conditioned beers packaged in either crown cap or flip-top bottles.

| METHODS |

The recipe for this xBmt was somewhat inspired by the much beloved American classic, Sierra Nevada Pale Ale, which is famously bottle conditioned.

Pocono Pale Ale

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 52.2 IBUs | 6.0 SRM | 1.057 | 1.012 | 6.0 % |

| Actuals | 1.057 | 1.009 | 6.4 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Mecca Grade Lamonta: Pale American Barley Malt | 11 lbs | 89.8 |

| Mecca Grade Rimrock: Vienna-style Rye Malt | 1 lbs | 8.16 |

| Mecca Grade Opal 44: Toasted Toffee Barley Malt | 4 oz | 2.04 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Pahto HBC 682 | 5 g | 60 min | Boil | Pellet | 15 |

| Summit | 5 g | 60 min | Boil | Pellet | 15 |

| Centennial Hop Hash | 28 g | 10 min | Boil | Pellet | 32 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Flagship (A07) | Imperial Yeast | 75% | 60°F - 72°F |

Notes

| Water Profile: Ca 156 | Mg 0 | Na 25 | SO4 156 | Cl 63 |

Download

| Download this recipe's BeerXML file |

A day prior to brewing, I made a single large yeast starter of Imperial Yeast A07 Flagship.

Later that evening, I weighed out and milled the grain in preparation for the following morning.

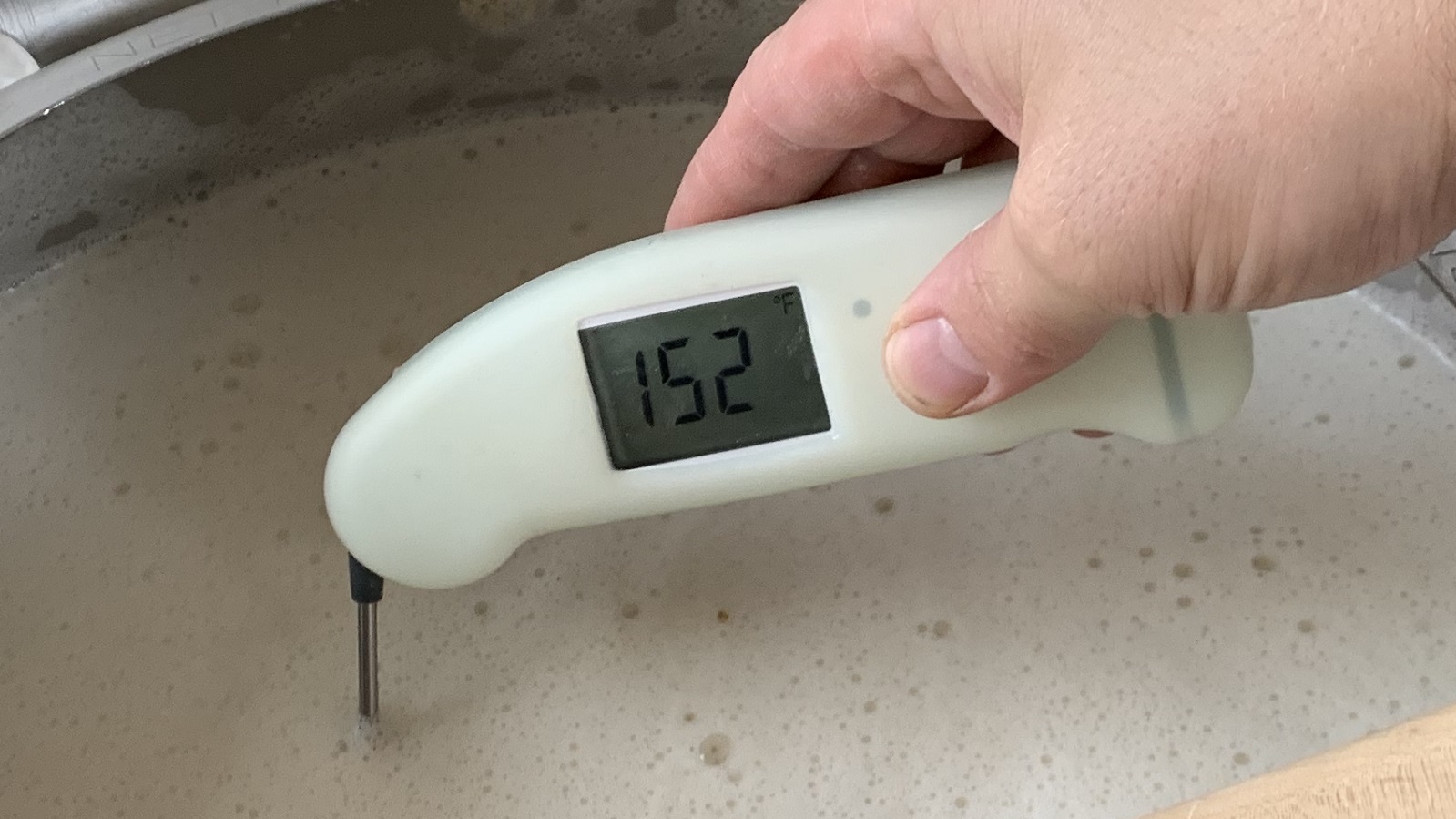

On brew day, I heated the previously collected RO water to my desired profile then mashed in to achieve my desired temperature.

While waiting on the mash, I prepped the kettle hop additions.

When the 60 minute mash rest was complete, I collected the sweet wort then proceeded with a 60 minute boil with hops added at the times stated in the recipe.

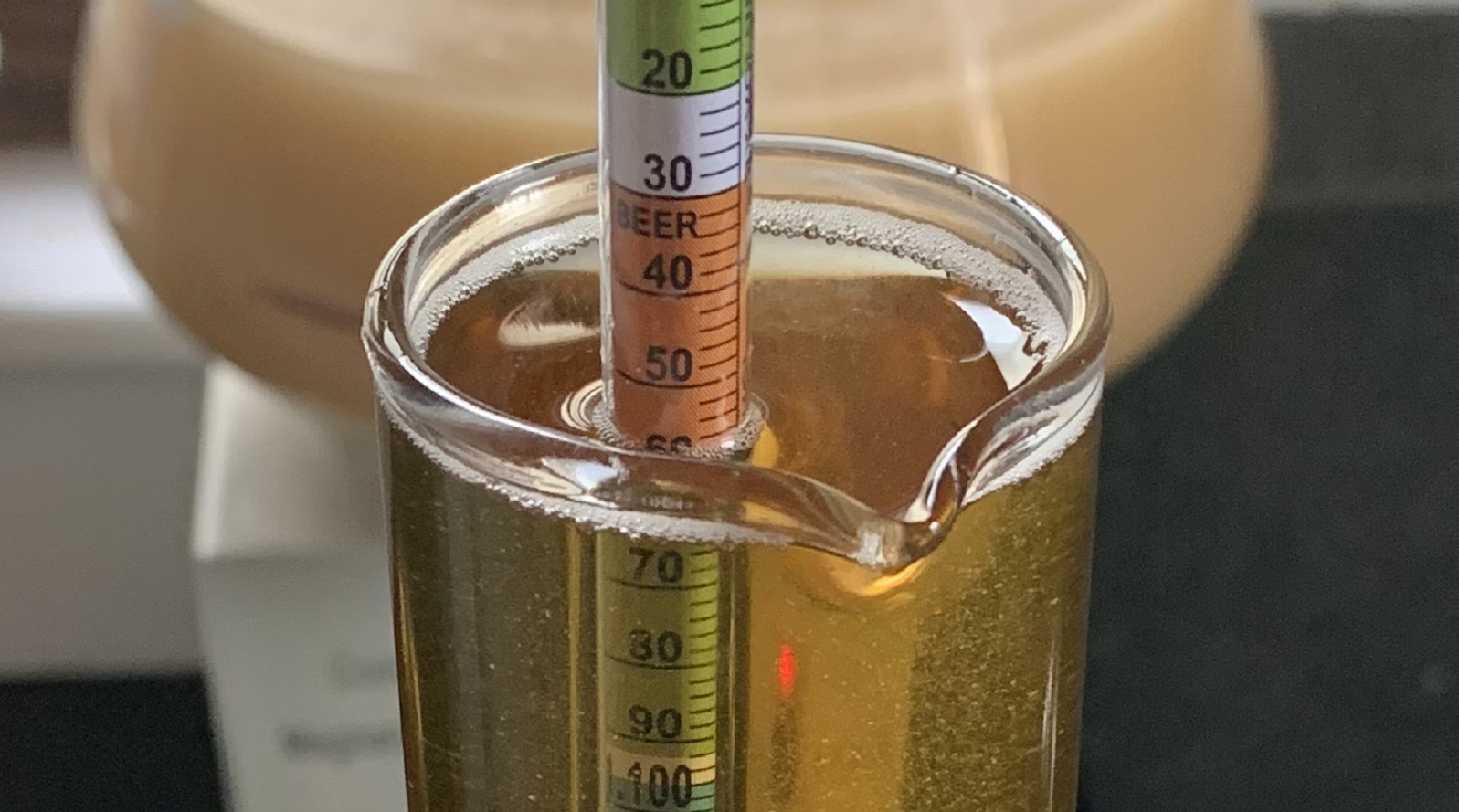

When the boil was finished, I quickly chilled the wort with my IC then took a hydrometer measurement confirming it was at my intended OG.

The wort was then racked to a 60 liter/16 gallon Speidel fermenter.

The filled fermenter was placed in my chamber and left alone for a couple hours to allow the wort to finish chilling to my desired 66°F/19°C fermentation temperature. Once there, I pitched the entire yeast starter.

After 9 days, no signs of activity were present so I took a hydrometer measurement confirming FG had been reached.

At this point, I proceeded with packaging by first adding 4 conditioning tablets to each of the 12 oz amber bottles. In order to reduce potential extraneous variables, I then racked the beer directly from the fermenter into each bottle, alternating between crown cap and swing-top just to be sure.

The filled bottles were placed on a shelf in my dining room that maintains a consistent 68°F/20°C. After 3 weeks of conditioning, I moved the bottles to my fridge for a 3 week chilling and clearing period before serving them to tasters.

| RESULTS |

A total of 21 people of varying levels of experience participated in this xBmt. Each participant was served 2 samples of beer from a crown cap bottle and 1 sample of beer from a swing-top bottle in different colored opaque cups then asked to identify the unique sample. While 12 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, only 7 did (p=0.58), indicating participants in this xBmt were unable to reliably distinguish an American Pale Ale conditioned in a crown cap bottle from one conditioned in a swing-top bottle.

My Impressions: Out of the 10 triangle tests I attempted, I ended up picking the odd-beer-out 8 times, which is arguably quite consistent. While the beers smelled and tasted identical, I noticed the one from the swing-top bottle was ever so slightly less fizzy than the beer packaged in a crown cap bottle. The difference wasn’t drastic at all, and there’s no doubt my performance was biased by my awareness of the variable.

| DISCUSSION |

Bottle conditioning is often the first carbonation method utilized by new homebrewers because it requires less equipment and has a lower associated cost. Some commercial breweries also choose to bottle condition, with some claiming it contributes higher quality carbonation and foam to beer. While crown cap bottles are most popular, swing-top bottles also get used fairly regularly, and some have developed a belief one is better than the other. The fact tasters in this xBmt were unable to tell apart a Pale Ale conditioned in either a crown cap or swing-top bottle suggests the type of seal did not have a noticeable impact.

These findings seem to indicate crown caps and swing-tops can be used to achieve the same ends with neither being any better or worse than the other. With respect to my own triangle tests, I can’t help but wonder the extent to which time in the bottle may have contributed to my performance, as I did my trials over a week after tasters. It seems plausible that some gas may have escaped the swing-top seal in that time, thus reducing the perceptible fizz just enough for my biased tongue to notice. Or perhaps the explanation has to do with one complaint I’ve heard about swing tops– the rubber gaskets aren’t always uniform between bottles, which can lead to poor seals. Regardless, the difference was slight, which the fact exactly 1/3 of tasters picked the unique sample supports, and neither showed signs of oxidation.

As I imagine is the case for most homebrewers, I started off bottle conditioning in crown cap bottles because that’s what came with my kit. The few times I used swing-top bottles worked out just fine, I didn’t perceive it as having any noticeable impact. I keg the large majority of my beer these days, but if I was going to bottle, I wouldn’t shy away from swing-tops for standard beers, as they provide an element of convenience. For beers I plan to age for awhile, I might go with crown caps to eliminate the concern of rubber gaskets drying out or not being seated properly.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

27 thoughts on “exBEERiment | Bottle Conditioning: Crown Cap Vs. Swing-Top In An American Pale Ale”

Having bottle conditioned since my first brew in 2015, I would be more impressed if you had taken a brew and conditioned it much longer. I currently have a whole lot that are already one year old in swing top bottles, and even some of the same brew (imperial stout) in both swing top AND crown cap bottles. I still get a good head (depending upon style, Belgians have more CO2 than e.g. bock or English style beers) out of them.

However, this experience has shown me that swing top bottles from commercial breweries seem to be sometimes a bit more problematic. Probably wear and tear of being used more. So I am now dumping these caps and replacing them with newer ones, with replaceable gaskets. Not all commercial bottles have these: some are glued to the cap itself.

Also “rubber gaskets drying out or not being seated properly”, never had a problem with that. How old would rubber need to be before it starts drying out? For rubbers of preserving jars, the advice is: never put your rubber in the oven for sterilising, boil in hot water. So, I presume that no one will sterilise his rubber gaskets in the oven. Spritzing them with some Star San is enough, and it moisturises them.

The gaskets being dry in these bottles is more or less impossible because they were all brand new (purchased for this xbmt). I think what may be more likely is that there was some variability between the bottles with respect to the placement of the gaskets and hinges.

I have been brewing for several decades and I have always bottled. Originally I used standard 750 ml brown commercial beer bottles with crown caps; then I changed to the same sized brown PET bottles with screw caps.

For the past several years I have been using flip top Grolsh bottles, and I would never go back! I have about 180 of these bottles now, and each has been refilled multiple times. I have only needed to replace about 10 gaskets so far – with silicon equivalents.

As far as carbonation performance goes there is no problem at all, the spring clips on these bottles are strong enough to maintain more than enough pressure for optimum carbonation. In fact I recently had one bottle explode due to accidentally double priming it.

For me the advantages of flip top bottles are:

Reduced bottling time as each cap can be clipped on while the next bottle is filling.

Ease of sanitation. I clean each bottle immediately after emptying then put in a squirt of sodium metabisulphite solution and just rest the top back on for storage. On bottling day it is just a matter of rinse – prime – fill – clip.

The pleasure of hearing that loud pop when the bottle is opened!

I bottle condition my hefe’s in 16 oz flip tops. 3 – 4 times per year. In 5 years time, I’m on my third set of replacement gaskets.

3 weeks??? Brown bottles??? Grolsch comes in a green bottle. How about you do it again with a realistic timeline, say 3 to 4 months, and add in some green bottles, now THAT would be worthy of this site. How many people drink 19ltrs (5 gal) of the same brew in 3 to 4 weeks? Grolsch (green) bottles are the most commonly available swing tops in most parts of the world and the “light struck” skunk which is part of the Grolsch appeal may be very different in a pale ale. I brew a lot of RIS’s, barley wines and quads and use champagne bottles which are invariably green (pressure on the quads) and after many years have stopped using swing tops (available on evil bay as a retrofit) due to oxidation, and (please don’t laugh) I dip them in black acrylic house paint then put them where the sun don’t shine (under the house) yes it’s extreme but I have 6+ yrs bottles that are a delight. I know you can’t do 6 yrs but I feel 3 or 4 weeks isn’t indicative of how most home brewers consume their beers. cheers G

Three to four months is more realistic? Generally, the only time I have beer on hand for longer than a few weeks to a month or whatever is when it’s a sour or funky beer. Fresh beer is best beer!! (most of the time)

That’s a wild account of aging your bottles! I’m into it, though I’d never go to the trouble haha.

Checking DO after 2 weeks and 3 months would be a good experiment.

I think you mean TPO, but yes, measuring at this point would be interesting. Here’s a quick reference distinguishing the differences between DO and TPO.

https://tapintohach.com/2012/06/20/total-package-oxygen-101-the-difference-between-dissolved-oxygen-and-tpo/

You need to brew more 😉 As you say it depends on what beer you brew, a barley wine/RIS/strong ale at 3 weeks is undrinkable, a cask conditioned best bitter is approaching end of life at the same time, my “fresh” beers I keg, the whole bottling palava for something that is going to be drunk immediately seems a waste of time and effort although I understand not everyone is into kegging, especially as a beginner, I still think a follow up after 3 months would be a useful addition to this exbeeriment. Cheers Grahame

If I brewed any more frequently I’d have a second full time job! And more beer that I’m able to consume before it’s no longer fresh.

Right, the extended aging is another test that we could potentially do. This was a good starting point for that series of experiments.

Updated URL for DO vs. TPO

https://tapintohach.wordpress.com/2012/06/20/total-package-oxygen-101-the-difference-between-dissolved-oxygen-and-tpo/

The variable they were testing wasn’t the colour of the bottle, it was the type of cap. Testing caps AND bottle colour would create a confounding variable. If a difference was found, there would be no way to tell what was causing what. Since this result was insignificant, it would be interesting now to go further and see if there is a significant difference between green and brown flip top bottles.

Not really, the crown cap brown bottle v swing top brown bottle would still be valid for this experiment, then as an aside a comparison between swing top brown and swing top green could be done, admittedly it could also constitute another experiment but I was thinking “kill two birds with one stone”, especially as Grolsh bottles are mentioned, and would be even more interesting if another test was done after 3 or 4 months. A further consideration would also be storage of said brown/green bottles with total darkness, on a bench with indirect light, and full light being the variables. mmm, make that 3 birds, looks like Phil is going to be busy Cheers G

Using green Grolsch bottles vs amber crown cap bottles is definitely a multi variable xbmt.

Grolsch made brown bottles too:

https://i.etsystatic.com/5791958/r/il/ff3865/1063073037/il_794xN.1063073037_8bll.jpg

Well that’s a new one, I’ve only ever seen the green ones here (Australia) Are the brown bottles used for a different beer? And if not how the heck do they get that light struck skunky flavour with a brown bottle? Or is the whole sunlight through green bottle v brown bottle thing a myth? As previously mentioned I use champagne bottles which are invariably green and dip them in black paint after perceiving what I thought were light struck flavours after extended aging, have I been kidding myself all these years? I’ve seen the light strike experiment on fermentation using clear glass carboys but this is a whole new ball game. One thing is for sure though, swing tops definitely result in more oxidisation in beers kept for more than 12 months, I’ve bottled a few beers using a mix of swing and crown and after aging the difference is obvious, I only use crown seals now. Sorry for getting off track a bit here Phil.

It is most definitely not a myth. Basically every brewery that has used green bottles for a particular brand has tried to convert it to the darker amber or brown bottles in order to avoid the beers developing a light struck character. The brands that still exist in green bottles today tended to not sell very well in brown bottles so the brewery would more often than not sell the thing that sells.

That said, there are hop products one can use with clear vessels and not develop light struck character.

I have a set of brown Grolsh bottles, but they are from the early 90s, and I think they moved to green after that for some reason, so I stopped using them. I find the returnable 500ml brown German lager flip tops better, and I get a ready supply as returns to my local beer shop, which I buy for the deposit value (about 20p) if I don’t buy them full. Being smooth sided and built for long re-use, they are ideal for homebrew and labels.

I always bottle a mix of caps and flip-tops, so I have some I can give away and not get back. I’ve never noticed any difference, nor (assuming the rubber is in good condition) any loss of carbonation even after several years for some strong dark beers.

I’m interested in what you say about oxidation; I’ve never noticed it but have not compared an aged flip vs cap of the same beer. However, Unless there is gas physics that I am not aware of, I can’t see how you can get oxidation (oxygen ingress) when the beer is still under good CO2 pressure; the oxygen simply would not be able to get in against the higher pressure, even if somehow the rubber seal was permeable to it. The high pressure CO2 would leak out long before if the seal was gas permeable.

As others have said, testing brown vs green bottles for light strike is a different and completely separate variable and experiment; there is no point confusing the two variables in one experiment.

The degree can vary but there’s always oxygen ingress with bottled beers no matter what type of cap is used. This is one of the reasons why beers that are aged in bottles change over time. Here’s a link to an MBAA page I found after a quick google. It’s a good, albeit old, abstract that talks about ingress of oxygen with crown caps.

https://www.mbaa.com/publications/tq/tqPastIssues/1990/Abstracts/tq90ab25.htm

And another interesting study about wine and oxygen.

https://www.ncbi.nlm.nih.gov/pubmed/16939334

Hi Jurgen, see my comment, I completely agree with you, and the rubber drying out is a nonsense, I replaced all my swings with silicon gaskets when I used them, as for swing tops I now use crown seals on my champagne bottles, They are really good for the extra pressure of Belgians, you need a different bell on your capper and different caps, they are called “tirage” caps. I looked at corks and cages but here in Australia it would cost over $1.00 per bottle so caps it was. Sorry if this is old news to you. Cheers G

Hello, Graham. I actually started out with swing top bottles because it was the simplest and cheapest option: no capper and crown caps needed. I was lucky two summers ago, someone I knew gave me a whole kit for free, and so I got a capper. Now I can also cap 37.5 and 75 cl bottles. The idea with the black acrylic house paint is nice. I might do that in the future.

G’day from Sydney Australia.

No surprises here I recon. They wouldn’t make swing top bottles if they didn’t work. Aye?

My mate and I are about to get back into homebrewing and wanted to can our beer. But then everyone in the forums shitcanned it. So we decided to use swing top for convenience. But after talking with some semi pro brewers and seeing a few successful videos and the low cost of canners these days I think we’re going to get back in the can. If done correctly cans offer a better seal, no light in & taste better in many peoples opinion. Plus your not throwing out glass. Aluminium is one of the most recyclable substances on earth.

We would of course love to have kegs in our houses but cause we will be splitting the brew and convincing our wives to lets us get home brew was hard enough. Especially for me as the gear will live in our house.

Cheers guys and keep up the great work. Love the podcast!

P.S. Get some good fresh East/West Coast Australian or NZ IPA’s in ya. They are good. you just keep getting shitty old beer.

P.P.S. Stop shitcanning East Coast IPAs (NEIPA’s). There is a reason they are so popular. A bit like the swing tops. They are being made and people do buy them so…

@exceptionalgrogs

Nice to see this,

Uk homebrewer here supported by a really helpful home brew club and local bottle shops/bars.

Both hosting venues save their empty wheat and lager (hacker pschorr and flensburger For example) swing bottles and offer them for free at the home brew club

Brown glass good quality seals been very popular indeed.

Thanks for this.

Regarding the difference in fizz; did you control measure the volume in each of the two types of bottles? You write they had the same stated volume but I guess the numbers could be off?

A larger volume with the same amount of priming (one tablet) would give less fizz of course.

I hear what you mean and it’s a sound thought process. However, the volume of beer was consistent in each of the bottles. Further, even if there was some small variability it would have been minute and could not have been enough to cause a meaningful difference at this volume.

So you used the Brewers Best conditioning tablets? I’ve used the Coopers can drops in the past and the beers didn’t carbonate well at all. Switching to either table sugar right into the bottles or a sugar solution in a bottling bucket worked fine, so the carb drops had to have been the issue. But if the Brewers Best ones seem to work well I’d love to give them a try to avoid the hassle of a bottling bucket or the mess of table sugar.

I’d be curious to see an experiment 2.0 with the following 4 scenarios to evaluate permiability via caps over extended aging of 4+ months.

1) crown cap with oxygen barrier

2) crown cap regular

3) flip top with silicone seal

4) flip top with old school rubber seal

#1 & #4 should perform the best in theory because the material of the seal is less out permiable. Silicone is highly permiable

Bottles should be capped on foam to minimize oxygen in headspace.

Who’s up for the challenge?