Author: Matt Del Fiacco

One problem many home cider makers face is that fresh juice isn’t always accessible, so some rely on store-bought juice as a substitute. While this definitely works, certain practices are often recommended in order to compensate for some of the differences between store-bought and fresh-pressed juice.

Fresh-pressed apple juice contains a plethora of yeast, bacteria, tannins, acids, and nutrients, all of which play a role in the final product. On the other hand, in addition to primarily being made from apples with low tannin and high sugar content, store-bought juice goes through a centrifugal and heating process that strips much of the character as well as most of the nutritional content from the juice. This can be fine for regular drinking of the juice, but when it comes to fermentation, yeast purportedly require the nutritional content to perform effectively.

I love pressing my own apples every year for fresh cider, but seeing as this is a seasonal event, I’ve found myself relying on store-bought juice in the interim to keep the cider flowing. The absence of nutrients in store-bought juice is something of concern to some cider makers, but I’ve sampled many ciders that were made from such juice without nutrients added that turned out just fine. Interested to see just what impact nutrient additions have when fermenting store-bought juice, I tested it out for myself!

| PURPOSE |

To evaluate the differences between hard ciders made with store-bought juice with yeast nutrient either added or withheld.

| METHODS |

With a goal of emphasizing any impact of the yeast nutrient, I went with a very straight-forward recipe– no back-sweetening or acid additions, just juice, nutrients, and yeast.

Simmons’ Cider

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.2 gal | 60 min | 0.0 IBUs | 19.9 SRM | 1.049 | 0.998 | 6.8 % |

| Actuals | 1.049 | 1 | 6.5 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Apple Juice - Store Bought | 48.057 lbs | 100 |

Miscs

| Name | Amount | min | Type | |

|---|---|---|---|---|

| Fermaid O | 2.00 tsp | 7 days | Primary | Other |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Bubbles (A40) | Imperial Yeast | 93% | 62°F - 70°F |

Download

| Download this recipe's BeerXML file |

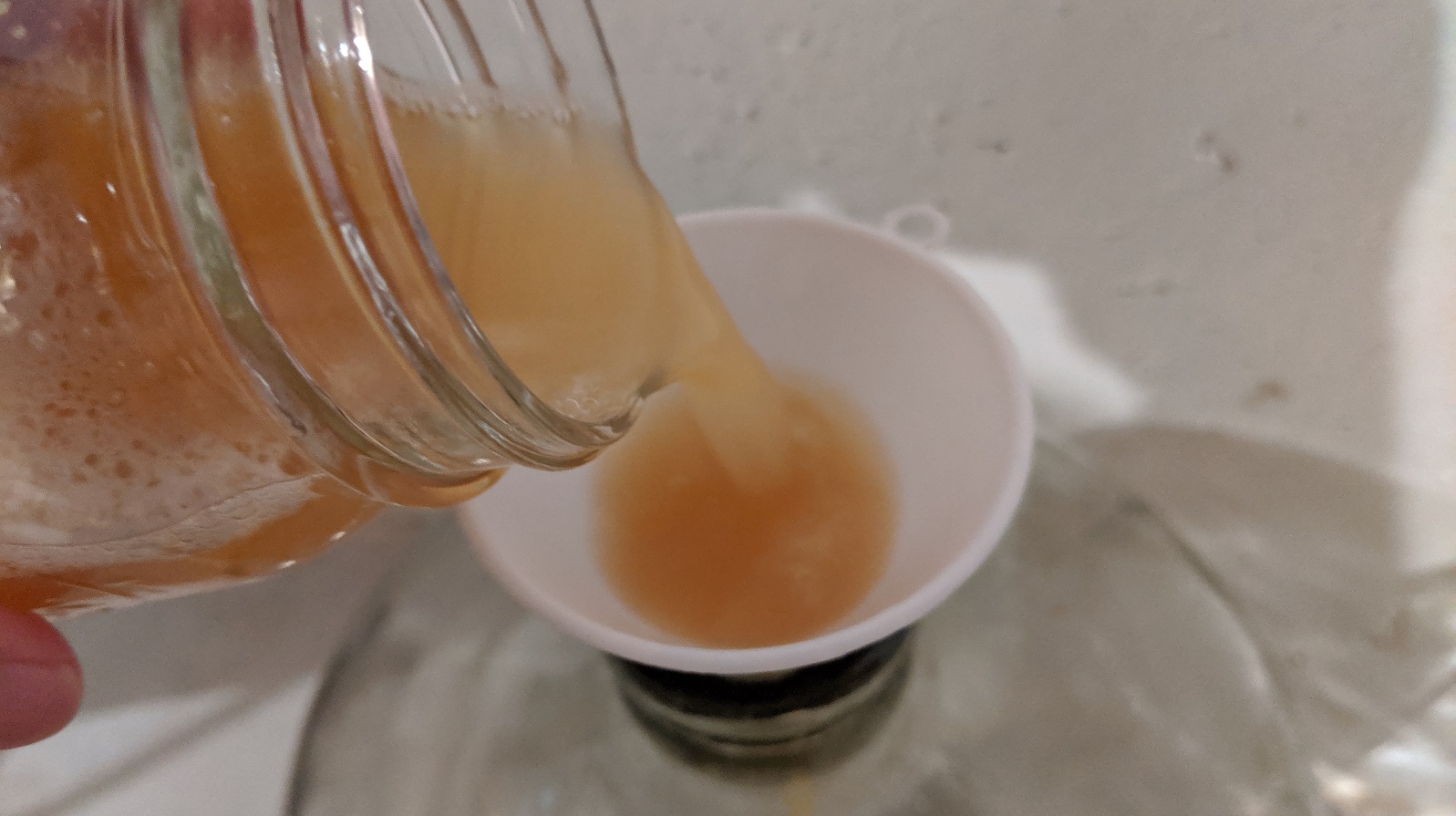

Preparation for this experiment consisted primarily of driving to the grocery store and picking up 10 gallons of generic juice that contains only a small amount of ascorbic acid. My first order of business on brew was dissolving my yeast nutrient of choice, Fermaid-O, in a small amount of juice.

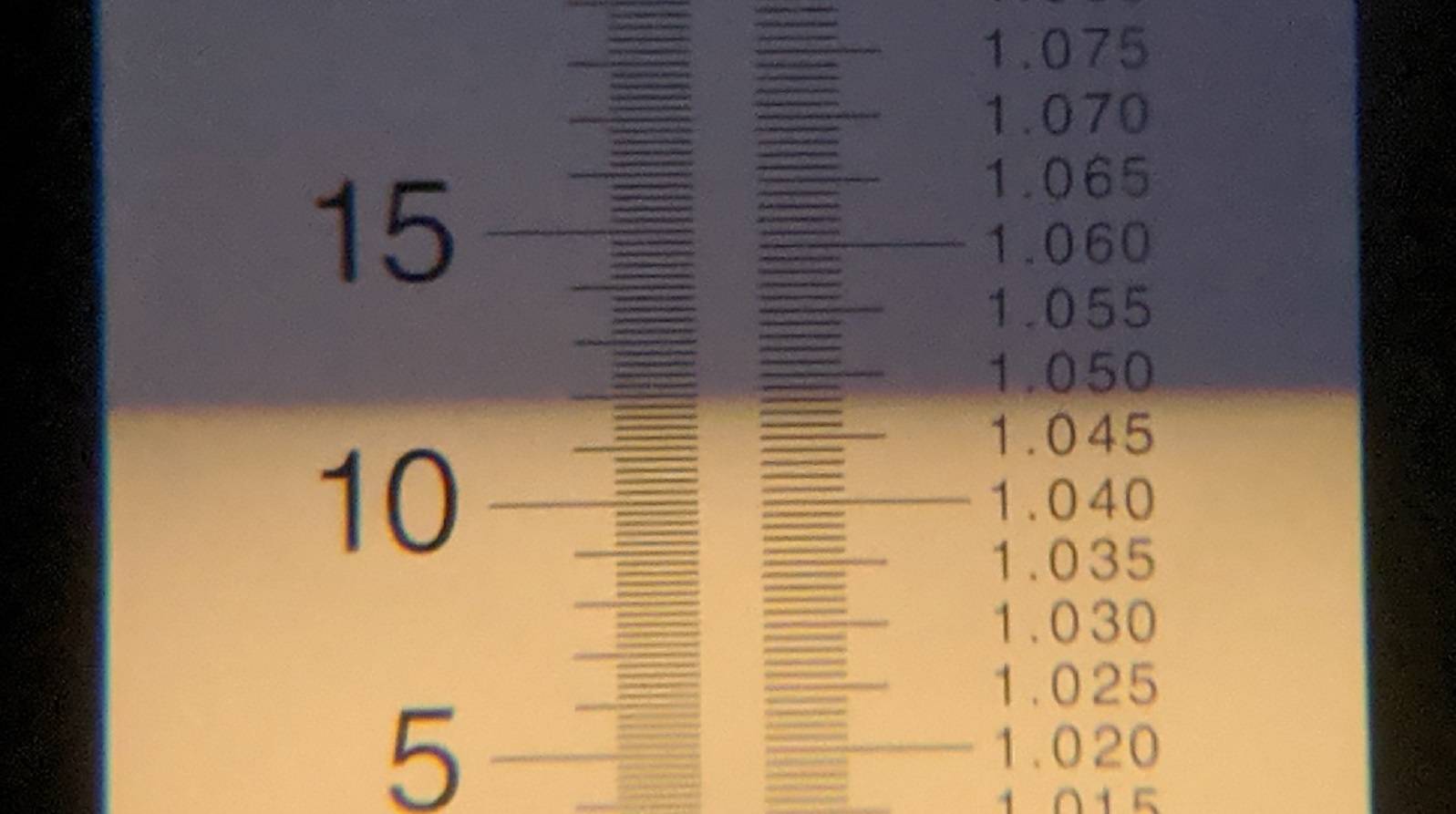

A refractometer reading showed the juice was at 1.049 OG, which is consistent with past batches I’ve made using store-bought juice.

Because I wanted to observe any differences in fermentation activity, I used glass carboys for this experiment, adding the dissolved nutrient solution to just one.

Next, I added 5.5 gallons/21 liters of juice to each fermentor.

I then pitched a pouch of Imperial Yeast A40 Bubbles into each batch.

The filled carboys were placed in an area in my basement that maintains a steady 64˚F/18˚C. Checking on the ciders 12 hours later, I noticed batch with nutrients added was showing visible signs of fermentation while the cider without nutrients was not.

It wasn’t until after another 12 hours, 24 in total since pitching the yeast, that the batch made without nutrients became active. By the 4th day, the nutrient dosed cider continued to ferment along while the one without nutrients appeared to have slowed down.

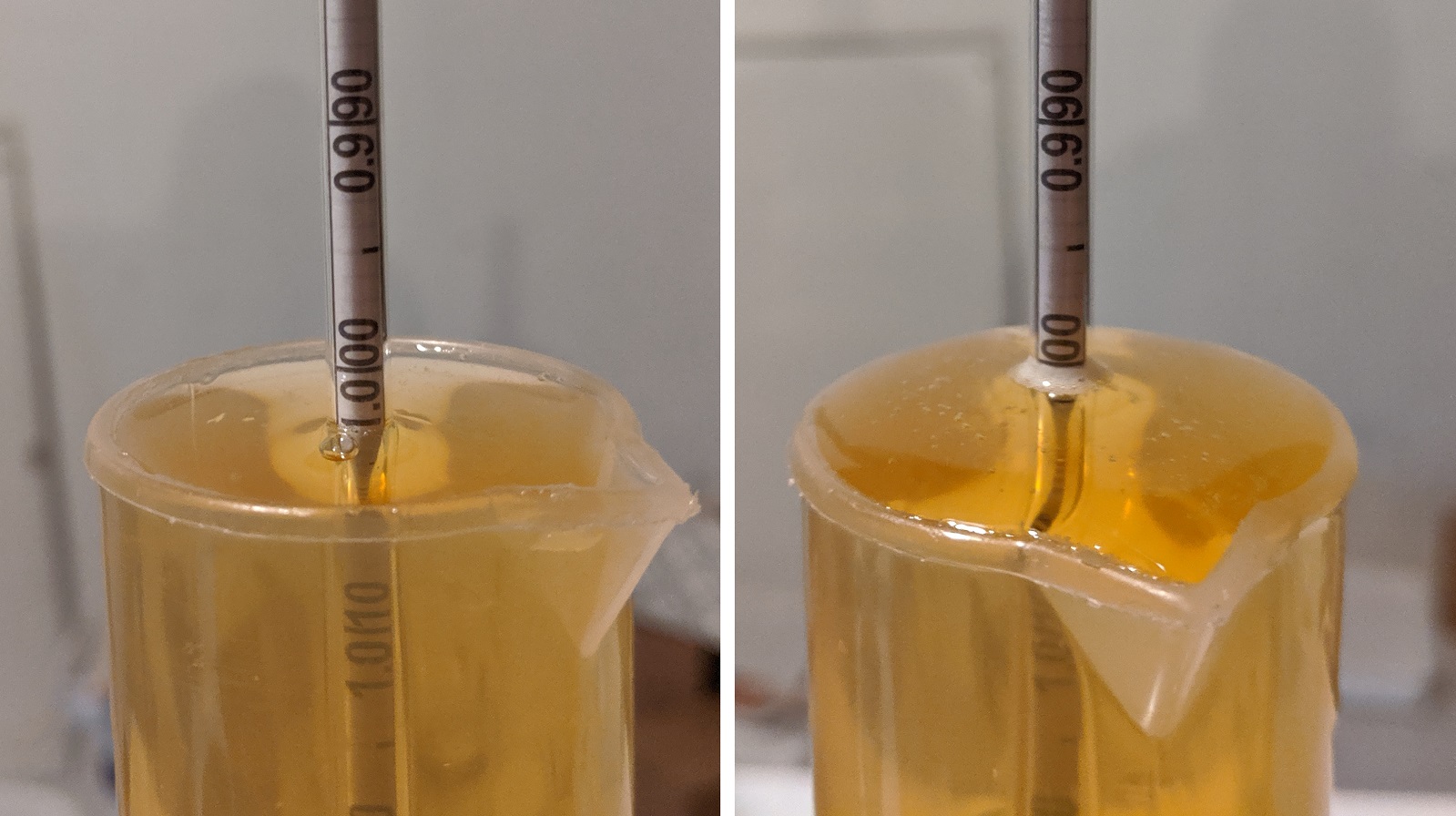

I let the ciders ferment for a total of 2 weeks before taking hydrometer measurements that indicated the batch with nutrients finished slightly lower than the one made without nutrients.

At this point, I racked the ciders to sanitized serving kegs.

In samples taken while kegging, I noticed the cider fermented with nutrients was dramatically clearer than the one fermented without nutrients.

The filled kegs were placed in my keezer, burst carbonated, and left to cold condition for 3 weeks before I began serving them to participants. At this point, the ciders seemed equally clear.

| RESULTS |

A total of 21 people of varying levels of experience participated in this experiment. Each participant was served 2 samples of the cider made without yeast nutrient and 1 sample of the cider made with yeast nutrient in different colored opaque cups then asked to identify the unique sample. At this sample size, 12 tasters (p<0.05) would have had to identify the unique sample in order to reach statistical significance, though only 9 (p=0.24) made the accurate selection. These results indicate participants in this experiment were unable to reliably distinguish ciders made of store-bought apple juice either with or without yeast nutrients.

My Impressions: Out of the 5 triangle tests I attempted, I chose the unique sample just once. Nothing about these ciders stood out to me as different, which is a bit startling given the obvious clarity difference at kegging. Likely because I didn’t adjust these ciders in any way post-fermentation, I felt they were a bit flat, though very clean and refreshing. The A40 Bubbles yeast left behind a bit more apple character compared to other yeasts I’ve used, which was very pleasant.

| DISCUSSION |

In order to ferment effectively, yeasts need nutrients, and while many of these nutrients are present in the apples used to make hard cider, they tend to be stripped out during processessing of store-bought juice. An easy way to make up for this is to add exogenous nutrients to the juice prior to fermentation. Interestingly, participants in this experiment were unable to reliably distinguish between ciders made of store-bought juice that were fermented either with or without a yeast nutrient addition.

Despite the apparent lack of a perceptual difference between these ciders, there were some objectively observable differences. First off, the cider made with yeast nutrients not only showed signs of activity earlier than the batch made without nutrients, but also fermented a bit longer. It’s possible this was an indication of yeast health, which may also help to explain the fact the yeast nutrient cider had a lower FG than the batch made without nutrients.

These results are validation enough to keep me using yeast nutrients when making cider from store-bought apple juice, regardless of non-significant sensory results, as I prefer quicker clarification and better attenuation. Plus, yeast nutrients are relatively cheap and super easy to use, adding little additional time to my already brief cider brew days. Then again, I certainly wouldn’t worry about fermenting a cider without nutrients or recommend people start doing it themselves if they’re not interested. After all, neither tasters nor I could tell these experiment ciders apart, and I thoroughly enjoyed both.

If you have any thoughts about this cider experiment, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brülosophy, please check out the Support page for details on how you can very easily do so. Thanks!

15 thoughts on “exBEERiment | Hard Cider: Impact Adding Yeast Nutrient Has When Using Store-Bought Juice”

Was there any noticeable sulphur smell coming out of the airlock of either?

I actually didn’t notice a sulphur character from either, but this is also my first time trying out Imperial Yeast’s Bubbles, so I can’t really speak to its general sulphur production unfortunately.

When using store brand juice, do you sulfate (i.e.; campden tablets)?

You dont need to use metabisulfite on store bought shelf juice. Personally, I don’t even use it on fresh pressed unpasteurized juice.

can you say what commercial juice you used?

For some reason I had thought I added that in the article, my apologies! It was the generic juice from Aldi, which I’ve had good experience with compared to the generic juice from Walmart and not too different than Musseleman’s post fermentation (IME).

I wonder how it would turn out with a staggered yeast nutrient addition and daily de-gassing, like Michael Fairbrother’s standard mead-making process. Take your yeast nutrient addition and divide it up 4 ways. Add a quarter each day starting with the first pitch. Once or twice a day use a de-gasser (mine attaches to my drill) to get (almost) all the co2 out of solution. After the last staggered yeast nutrient addition (3 days into primary) just let it roll like normal. I made a gold-medal mead with this method. And I think the same principles would apply with store bought apple juice (which I have a lot of experience with). It basically speeds up the processes normally required with age (1 year+).

Thats a really interesting though! I’m pretty familiar with TONSA from mead making, I could definitely try that out. I also want to try TONSA with and without degassing, for fun.

Just started my very first batch of cider. 2.5 gal. of organic cider without preservatives. Used

3 cups brown sugar, some pectin enzyme, and yeast nutrients. Used campden tablets in the cider 36 hrs. before pitching the yeast. In 68 deg. room temp the fermentation has started after 3 hrs.

I mean absolutely no disrespect to Matt as I know he is an accomplished cider maker, BUT:

There are so many unknown variables here that are not being accounted for.

First, and one of the most important IMO, is that we have no idea what the YAN content of the juice is before adding nutrients. It could very well be high enough that no, or very little nutrients were needed for a healthy fermentation. Every single juice is going to be different. It’s even possible that the same brand of juice in different batches could have differing YAN contents. Different brands will even have different amounts of YAN, yet the brand was not mentioned until the comments section. There is a big reason why professional wine and cider makers test YAN levels prior to fermentation.

What are the nitrogen needs of the yeast in question? Low? High? Somewhere in between? Is it an aggressive fermenter? Is it a yeast that performs better in highly clarified must (i.e. filtered shelf stable juice)? Or does it prefer turbidity? Is it a high h2s producer, or low?

What were the actual fermentation temperatures in the two fermenters? Did the one with Fermaid O reach a higher temperature? Or were only the ambient temperatures of the room recorded?

If the nutrients were added at yeast pitch, you may have encountered an entirely different scenario than if you had added them 24 hours post pitch or at the 1/3 sugar break as most winemakers would add them.

Of the 21 people who tasted the samples, how many of them had actual cider judging experience, winemaking experience or had cider industry experience? How many of them were hardcore cider enthusiasts? How many were primarily beer drinkers or brewers? How do we know whether or not the 9 who chose the correct sample were more knowledgable when it comes to cider than the 12 who incorrectly chose? How were the ciders tasted? Were palettes cleansed between samples?

If I were to look at this completely without bias, as someone who had never made cider and only made beer, my take away from only reading the experiment and not the comments would be “Using nutrients in cider is for suckers, this experiment proves it” without ever acknowledging that there are far more variables involved than what was actually tested.

From roughly August straight through spring, there are a constant flood of posts on home brewing groups and forums asking “Why does my cider taste so dry, hot and alcoholic with no apple flavor, I’m so disappointed.”

I would be willing to wager that the majority of these brewers looking to make cider probably didn’t use nutrient (if they did it was likely a generic yeast energizer), probably didn’t try to control temperature and fermented too warm, likely used a cheap champagne yeast because the internet told them to (or on the flip side used an ale yeast based on its average attenuation in wort and expected it to come out sweet), or they had totally unrealistic expectations of making something similar to AO but only have the ability to bottle condition.

As I know most of those involved in Brulosophy are members of many of the same groups I frequent on social media, they have inevitably seen links to xBmt’s posted as scientific fact instead of what it usually is: an inconclusive experiment that may garner different results than someone else who tries it. Inevitably, this xBmt will end up being linked to as “fact” that you don’t need nutrients for a healthy fermentation if you are using a shelf stable juice anytime someone mentions needing nutrients for cider making.

Overall, I am glad to see cider making become more mainstream and Brulosophy having an interest in experimenting with cider. Unfortunately, IMO, too many people try to just through yeast at a bottle of juice and expect cider making to be simple and easy and come out exactly like the many ciders on the market. Inevitably, many of these folks will be disappointed when they can’t get it right and just give up on it.

>First, and one of the most important IMO, is that we have no idea what the YAN content of the juice is before adding nutrients.

Great critique, I’ll explore this further in the future on cider experiments and include this information.

>What are the nitrogen needs of the yeast in question?

Also an excellent point, and I reached out to Imperial yesterday to get some details. Will update when I can! All of your questions in that paragraph are good points, I’ll add them to my list as I’m thinking about the next round.

>Or were only the ambient temperatures of the room recorded?

This, which is something we could improve but it would be tricky given the current set up. It would be interesting information actually, most of my exbeeriments are only ambient of one keg in the fermentation chamber.

>If the nutrients were added at yeast pitch, you may have encountered an entirely different scenario than if you had added them 24 hours post pitch or at the 1/3 sugar break as most winemakers would add them.

Agree entirely, I’d especially be curious on that impact compared tot he same practice in a higher gravity juice. Performance in a 1.040 juice vs a 1.080 concentrated juice.

>Samples and testing

Unfortunately, I don’t know how many had cider experience, judging or otherwise. This is a frequent criticism of Brulosophy in general, and it has its place if the argument was to (as you mention later) make a definitive argument about something. It’s definitely not, all of the experiments are specific to “can this sample reliably detect the impact introduced by this variable in this context”. Could another sample, say all pro cider makers, reliably detect it? Potentially! Totally open to that.

>“Using nutrients in cider is for suckers, this experiment proves it”

Hopefully that’s not the takeaway, though as you noted later I have seen some people take a single experiment as fact. We (Bru) try to be vocal about that as a bad practice. Honestly, if anything, I hope people walk away seeing that the nutrient batch fermented lower and cleared faster. That said, as you mentioned in the beginning of your comment, we can’t make an argument about the reasons for these results because we don’t have the measurements or yeast requirements.

>Overall, I am glad to see cider making become more mainstream and Brulosophy having an interest in experimenting with cider.

Me too dude! And I want to point out that I really appreciate your comments here, because it will help me make sure I am including relevant information for people moving forward.

>Inevitably, many of these folks will be disappointed when they can’t get it right and just give up on it.

This is probably the only point I disagree with, and it isn’t so much a “disagree” as it is “my perspective is different”. I think what you’re proposing there could happen, I’ve seen it as well. Unfortunately, I’ve also seen people who don’t have access to a nearby orchard, or fresh juice with preservatives, not even attempt making cider. One of the things I want to be more thoughtful about in these experiments is “Hey, if you just want to dip your toe in, what are the things you could do to make a difference in your product?”. So the use of store bought juice is pretty intentional there. I would be interested in your thoughts on that as well!

Cheers dude, I really do appreciate the thoughtful comment and I’m looking forward working on cider more for the site.

> This is probably the only point I disagree with, and it isn’t so much a “disagree” as it is “my perspective is different”. I think what you’re proposing there could happen, I’ve seen it as well. Unfortunately, I’ve also seen people who don’t have access to a nearby orchard, or fresh juice with preservatives, not even attempt making cider. One of the things I want to be more thoughtful about in these experiments is “Hey, if you just want to dip your toe in, what are the things you could do to make a difference in your product?”. So the use of store bought juice is pretty intentional there. I would be interested in your thoughts on that as well!

I definitely understand what you mean there. To be totally honest, even though I work for a cider mill, I actually make cider from store bought shelf stable juice year round. I’ve found that if you want to make a more modern American style cider (for example: a more fresh, fruit forward off dry to sweet cider, or a non traditional fruited/hopped/spiced cider) that shelf stable juice, using the right yeasts, is the way to go. If I want a more traditional cider, I’ll use fresh pressed. And I’ll rarely use the same yeasts for a dry, traditional cider that I would use for a more modern, fruit forward cider.

This fresh cider season, i opted to do an experiment on more traditional, dry cider. I have 15 gallons of a Northern Spy heavy blend, all wild fermented. 5 gallons will be aged on the lees without sulfites, 5 gallons is getting racked with no sulfite additions and will have L. plantarum added in secondary to encourage MLF, and 5 gallons will get my usual sulfite treatments. Instead of my normal turn around time, I plan on letting these age in glass until spring.

Just curious about choice of yeasts for your ciders. I have had good results with S-04 and Belle Saison. The Saison yeast gave pleasant dry crisp notes and a bit of spice and help up well for two years in the keg. Blending this cider with a canned fruit extract was amazing.

Nice experiment.

I make a batch of cider every year. So easy to do. And great shelf life (in bottles).

One thing I do with my batches that you guys might also consider, adding a can of Frozen Apple Juice Concentrate to jack up the ABV and apple flavor.

Regards!

Doug

What would be the best water profile for making hard cider when workig with appel concentrate?